Page 2of 38

Index

1Data producer and specific machine: ............................................................................................. 4

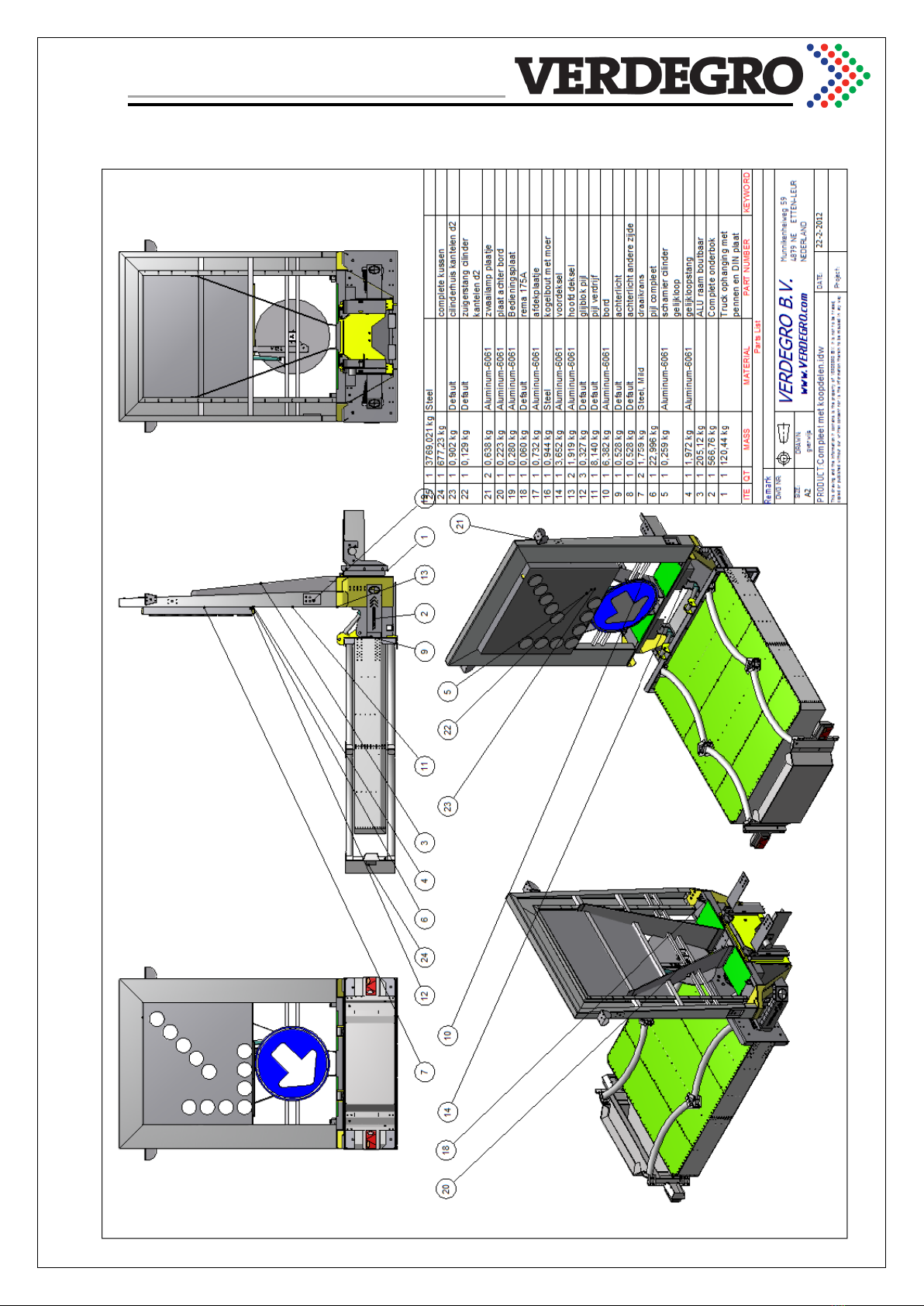

2Introduction:................................................................................................................................... 5

3Recognition and dimensions .......................................................................................................... 6

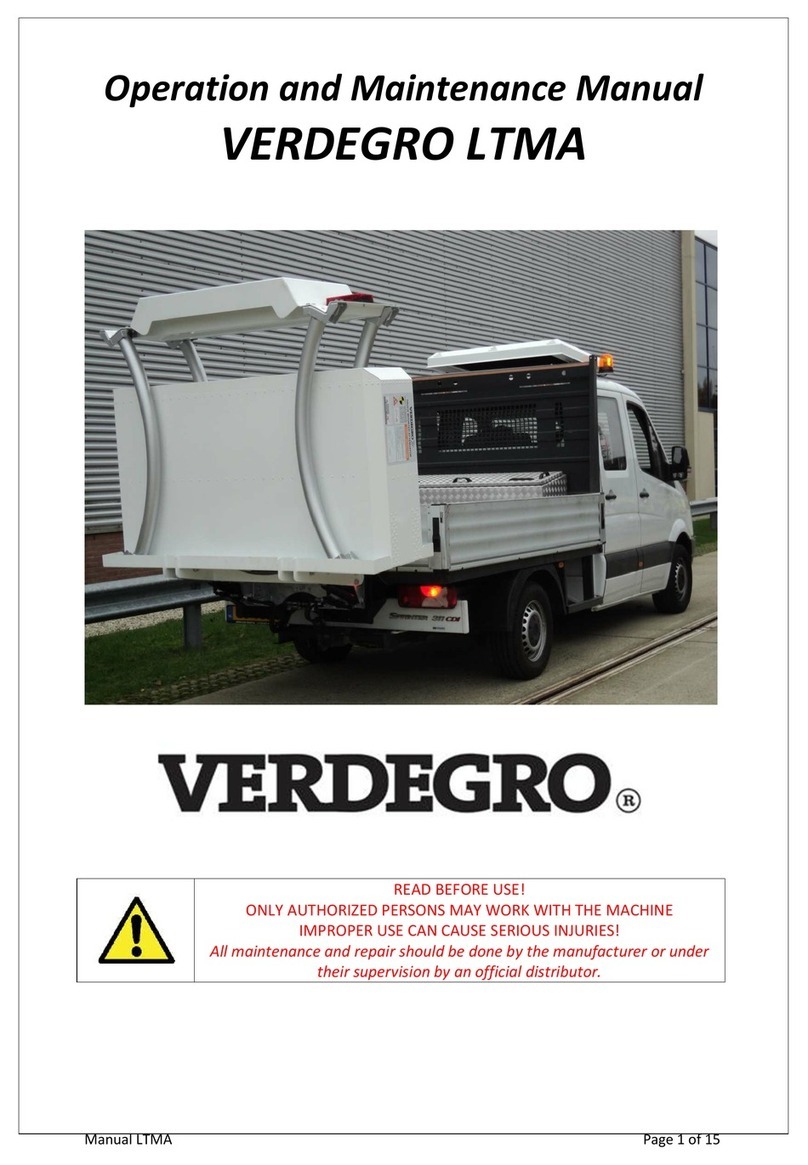

3.1 Photos of a typical TMA-US 100K............................................................................................ 6

3.2 Cushion dimensions and details.............................................................................................. 7

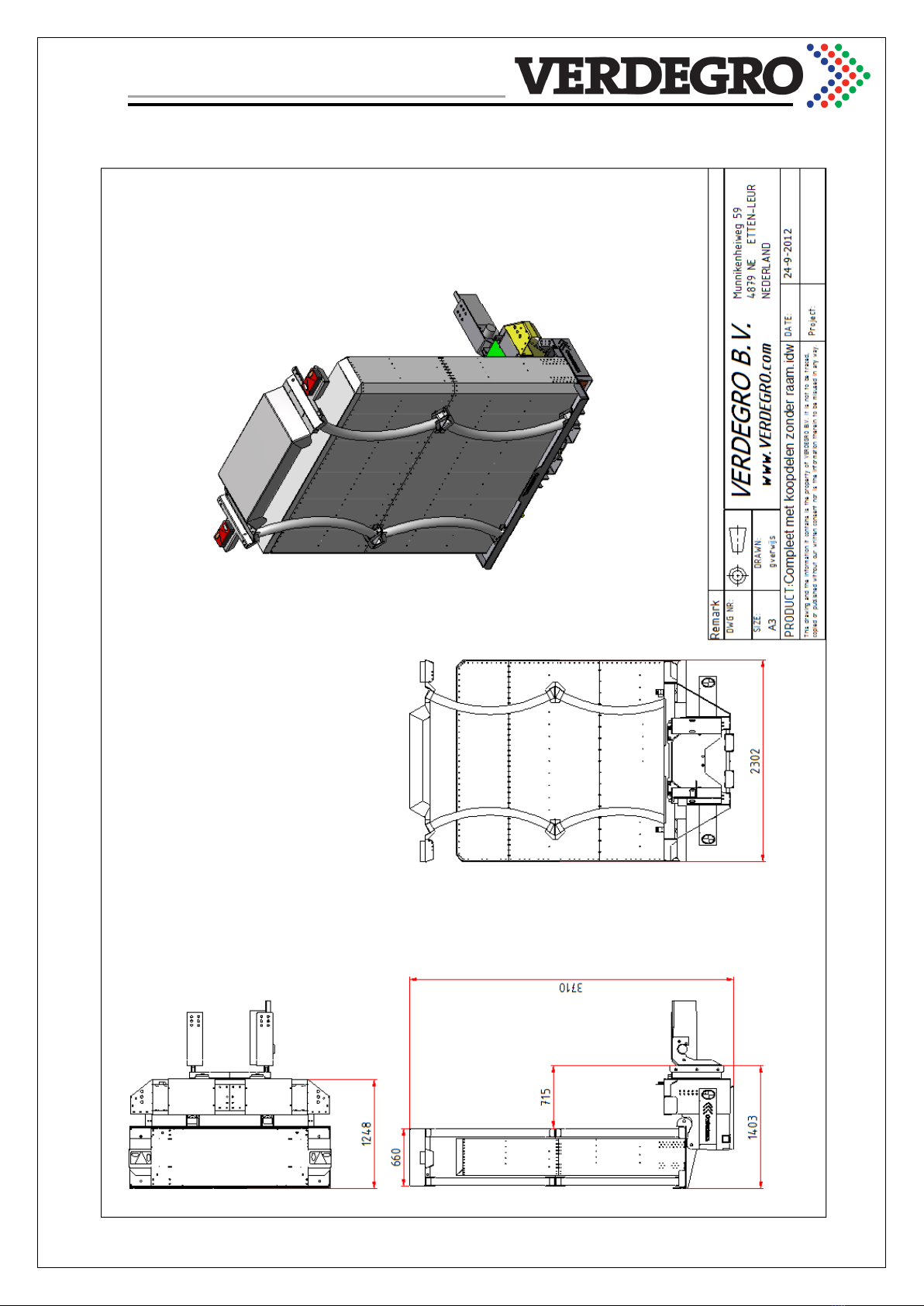

3.3 Drawing TMA with optional frame for rotatable arrow:......................................................... 8

3.4 Drawing TMA with optional frame for LED display or arrow panel: ....................................... 9

3.5 Transport dimensions............................................................................................................ 10

3.6 Operational dimensions ........................................................................................................ 11

3.7 Rotating mechanism.............................................................................................................. 12

4Technical data............................................................................................................................... 13

4.1 Table ...................................................................................................................................... 13

4.2 Hydraulic schedule with optional cylinder for rotatable arrow............................................ 14

5General specifications and instructions ....................................................................................... 15

5.1.1 Description of system.................................................................................................... 15

5.1.2 Performance criteria ..................................................................................................... 17

6Safety ............................................................................................................................................ 18

7Operation...................................................................................................................................... 20

8Supporting vehicle and adjustment.............................................................................................. 21

8.1 Specifications for mounting .................................................................................................. 22

8.1.1 DIN mounting system.................................................................................................... 22

8.1.2 Six pin mounting system................................................................................................ 23

9Inspection ..................................................................................................................................... 25

9.1 Inspection table..................................................................................................................... 25

9.2 Control position Crash Cushion............................................................................................. 26

9.3 Use of the machine in cold.................................................................................................... 26

9.4 High voltage........................................................................................................................... 26

10 Maintenance................................................................................................................................. 27

10.1 Check hydraulic oil................................................................................................................. 27

10.2 Torque index Tension............................................................................................................ 28

11 General control points of TMA..................................................................................................... 29

12 Repairs (by manufacturer or official distributor) ......................................................................... 30

12.1 Welding ................................................................................................................................. 30