Page 7 of 16

5General specifications and instructions

A. Always make sure the system is delivered with the right certificates, stickers and

documentation!. Do not remove the sticker(s)!!

B. Never remove safety instructions of the LTMA!

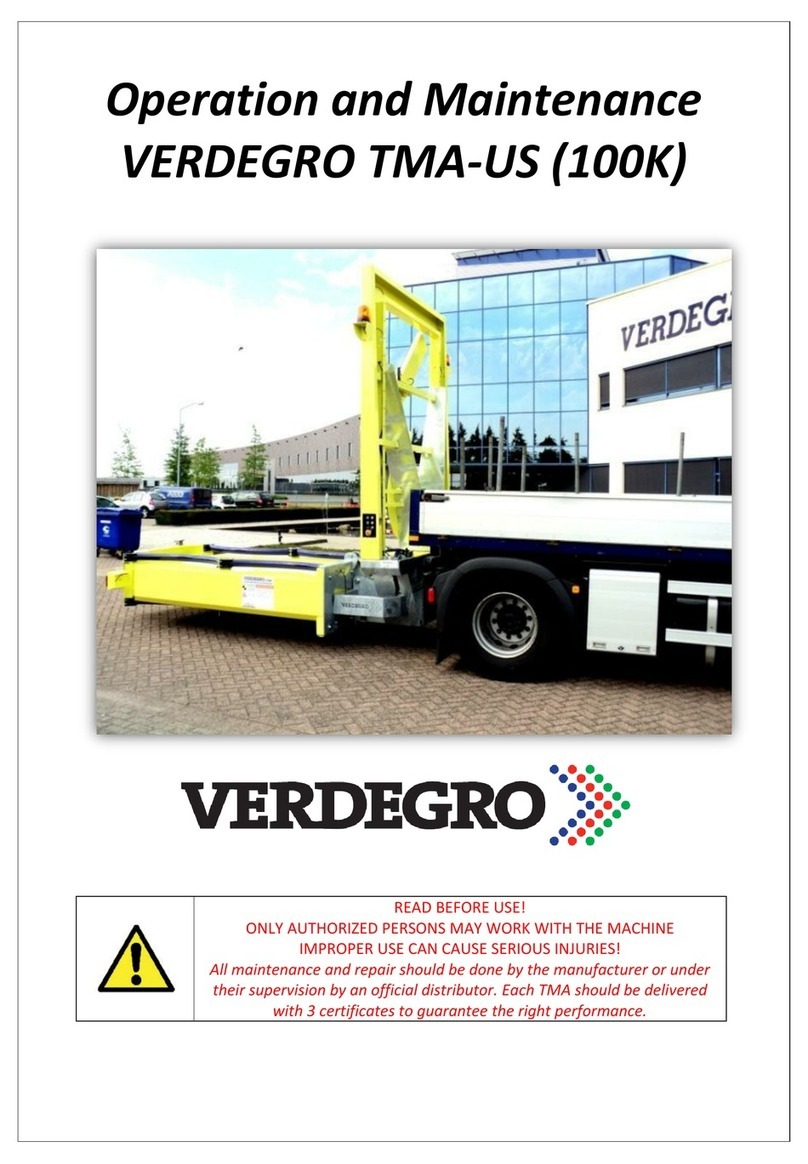

C. All Verdegro Truck Mounted Attenuators (Verdegro LTMA) shall be designed and

manufactured by the Verdegro Group, in accordance with the specifications.

D. The Verdegro LTMA is an attenuator system designed for installation at the back of trucks

with gross vehicle weight (GVW) ranges between 3500 kg and 12 000 kg (Contact your

country for other specifications!).

Note: Any added ballast must be adequately anchored to the truck so that it will not move

during impacts. Because the back end of the truck supports the weight of the rearward

protruding LTMA, care must be taken not to exceed the manufacturer's published maximum

axle loads. To ensure that the driving characteristics of the vehicle are maintained, the

manufacturer's recommended center-of-gravity zone should also be adhered to.

5.1 Description of system

A. The Verdegro LTMA shall consist of the following basic components: An aluminum foldex box

with 2 aluminum Cartridges, a steel Support Structure and a Support Frame with 2 mounting

options for attaching the system to the truck.

A hydraulic system shall also be included in the system to raise the structure and cartridges

to a vertical position. When the system is in a horizontal position, the frame assembly shall

be capable of collapsing when impacted by an errant vehicle. No portion of the system shall

protrude forward under the truck during an impact. The complete Verdegro LTMA is

designed to make attachment or detachment from the truck simple and fast.

B. The Verdegro LTMA shall have a standard trailer lighting system. This system shall include

brake lights, taillights and turn signals. The wiring for the rear lights shall be routed and

secured on the articulating frame. This system also has additional lights on the cartridge so

that the lighting system meets the standards, whether the system is in its horizontal or

vertical orientation.

C. Under the support frame are two tubes to lift the complete system with a forklift, for

example to mount on the truck.

D. All welding is done by, or under the direction of, a certified welder. Metal work shall be made

at the Verdegro Group.

E. All exposed steel surfaces on the LTMA shall be primed and painted and or galvanized.

F. The LTMA shall be assembled with Commercial Quality bolts, nuts, and washers conforming

to European Standards.

G. The hydraulic system shall consist of a pump with a 12 or 24 (standard) volt DC motor,

cylinders, hoses, switches, wiring, and necessary subcomponents to tilt the frame assembly

to a 90° position from horizontal. The complete hydraulic system, including the pump and

hoses, shall be factory assembled and mounted to the LTMA by the Verdegro Group.