To ensure the constant improvement of its products, VERLINDE reserves the right to change the equipment as

described below and, in this case, to supply products which differ from the illustrations in this instruction manual.

All rights reserved

Summary

1 - Contents.................................................................................................................................................. 2

2 - What not to do......................................................................................................................................... 3

3 - Compulsory regulatory inspections by the user...................................................................................... 3

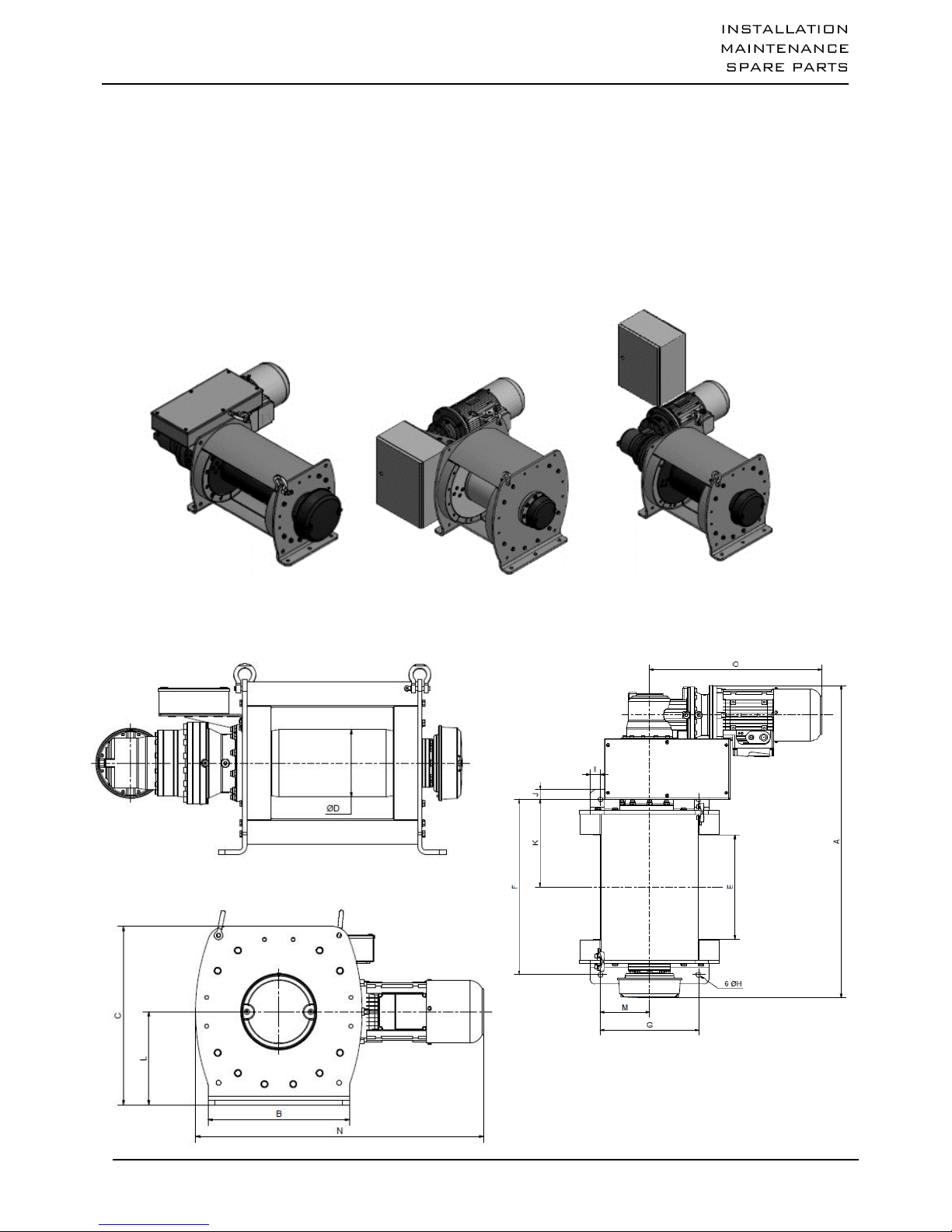

4 - Introduction to the machines................................................................................................................... 4

5 - Handling - Storage.................................................................................................................................. 7

6 - Installation and start-up........................................................................................................................... 7

7 - Servicing and maintenance..................................................................................................................... 14

8 - Decommissioning.................................................................................................................................... 15

9 - Spare parts.............................................................................................................................................. 15

10 - Troubleshooting....................................................................................................................................... 16

11 - Declaration of conformity......................................................................................................................... 17

12 - Appendixes.............................................................................................................................................. 18

1 –Contents

All users are asked to read the start-up instructions carefully before using the winch for the first time. These

instructions will help the user to become familiar with the winch and to use it to the best of its capabilities. The

start-up instructions contain important information on how to use the winch in a safe and correct manner.

Observing these instructions can help prevent risks, minimize repair costs, reduce down time and increase the

reliability and useful life of the winch. The instruction manual must always be available at the winch operation

location. In addition to the start-up instructions and the regulations relating to accident prevention, it is important

to consider current rules in terms of TVIl safety and professional standards in force in each country.

This machine is covered by European regulations and, more specifically, machinery directive

2006/42/CE, EMC directive 2004/108/EC and low-voltage directive 2006/95/EC, as well as standard EN

14492/1.

The TVI Series winches can be used to perform lifting and pulling operations.

When used for lifting, European regulations require the use of certain equipment, including a limit stop and a

load limiter (above 1000 kg).

The user must make sure that this equipment is in place (optionally available from the manufacturer) before

undertaking any lifting operation.

Please ensure that the operator is qualified to operate the winch under the conditions laid down in this

manual. This is to respect the safety of workers and the environment.

The capacity indicated on the winch corresponds to the maximum operational capacity (M.O.C.), which may

not be exceeded in any case.

This winch may not be used to lift personnel under any circumstances.

Do not lift or carry loads while personnel remains in the danger zone.

Do not authorize personnel to walk under a hanging load.

Never leave a load hanging or under tension without supervision.

Never begin to handle a load without fixing it correctly and making sure that all personnel has left the danger

zone.

Before each use, the operator must check that the machine, its ropes, its hook, its markings and its restraints

are in good condition.