Allied Systems W6G User manual

P/N 599002W-CAT Printed in U.S.A. 08/14/2020

Towing Winch

for Caterpillar Dozers

This manual must be with the vehicle

on which this winch is installed.

Please check the Allied Systems website

regularly for updates to this manual.

www.alliedsystems.com

A Product of

Sherwood, OR USA

Operating Manual

W6G

Applicable to winches with serial numbers:

• AW6GE6*2057C***

• AW6GE6*2059C*** and later

08/14/2020

Printed in U.S.A.

A Product of Allied Systems Company

Sherwood, Oregon

U.S.A.

Winch Model W6G

Date Delivered

Serial Number

Date Installed

Special Equipment or Attachments

Foreword

The safe and efficient operation of a winch requires skill

and alertness on the part of the operator. To develop the

skills required, the operator must:

• Receive training in the proper operation of the winch

and the machine on which it is mounted.

• Understand the capabilities and limitations of the winch

and the machine on which it is mounted.

• Become familiar with the winch and the machine on

which it is mounted and see that they are maintained

in good condition.

• Read and understand the SAFETY SUMMARY

and OPERATING PROCEDURES contained in this

Operating Manual.

In addition, a qualified person experienced in the operation

of the winch must guide a new operator through several

load handling applications before the new operator

attempts to operate the equipment alone. It is the

employer’s responsibility to make sure that the operator

can see, hear, and has the physical and mental ability to

operate the equipment safely.

This Operating Manual contains basic information

necessary for the operation and maintenance of a winch.

Optional equipment is sometimes installed that can

change the characteristics described in this manual.

Make sure the necessary instructions are available and

understood before operating the winch.

Some of the components described in this Operating

Manual will NOT be installed on your winch. If you have

questions about any item on your winch or described in

this Operating Manual, contact your local winch dealer,

or contact Allied Systems Company:

Allied Systems Company

21433 SW Oregon Street

Sherwood, OR 97140

U.S.A.

Phone: 503-625-2560

Fax: 503-625-7269

E-Mail: [email protected]

Also visit our website, www.alliedsystems.com, where

the most current copy of this manual is always available.

Foreword

i

ii

Note: For repairs and overhaul, contact

your Allied winch dealer. If you maintain

your own equipment, a service manual is

available for your specific winch.

Note: This publication may be translated

to different languages for sole purpose of

easy reference in non-English speaking

locations. Should there be differences in

interpretations to the text, please refer to

the English language edition published

by Allied Systems Company as the

controlling document.

iii

Contents

Foreword ..................................................................i

Contents................................................................. iii

Safety Summary .....................................................v

General

Introduction...............................................................1

How The Winch Operates.........................................1

Nameplate ................................................................2

Wire Rope Selection.................................................3

Recommended Oil List & Oil Capacity .....................4

W6G Winch Description ...........................................5

Optional Equipment..................................................6

Serial Number Codes ...............................................7

Dozer Identification and Gear Ratios........................8

Operation

Checks Before Operation .........................................9

Checks During Operation .........................................9

Operating Procedures ............................................10

Operation................................................................13

Inching....................................................................14

Freespool Operation...............................................15

Freespool Drag Adjustment ....................................15

Troubleshooting Chart ............................................17

Maintenance

Maintenance...........................................................21

Maintenance Points ..........................................21

Maintenance Schedule.....................................22

Contents

(continued on next page)

iv

Operating Techniques

Dozer or Skidder Operation....................................23

How To Move A Disabled Vehicle............................26

Working on A Steep Slope .....................................28

Tractor Is Down The Slope ...............................28

Other Equipment Is Down The Slope...............29

Operational Differences, Optional Equipment

Integral Arch ...........................................................31

Fairlead...................................................................31

Drawbar ..................................................................32

Optional Gear Ratios..............................................32

Contents (continued)

v

Safety Summary

Safety Summary

General Safety Notices

The following pages contain general safety warnings

which supplement specific warnings and cautions

appearing elsewhere in this manual. All electrical and

hydraulic equipment is dangerous. You must thoroughly

review and understand the Safety Summary before

attempting to operate, troubleshoot or service this winch.

The following symbols/terms are used to emphasize safety

precautions and notices in this manual:

DANGER

The “DANGER” symbol indicates a

hazardous situation which, if not avoided,

will result in death or serious injury.

Carefully read the message that follows

to prevent serious injury or death.

WARNING

The “WARNING” symbol appears

wherever incorrect operating procedures

or practices could cause serious injury

or death. Carefully read the message that

follows to prevent serious injury or death.

CAUTION

The “CAUTION” symbol appears where a

hazardous situation which, if not avoided,

could result in minor to moderate injury

and equipment damage.

vi

NOTICE

This signal word alerts to a situation that

is not related to personal injury but may

cause equipment damage.

NOTE: …

The term “NOTE” highlights operating

procedures or practices that may improve

equipment reliability and/or personnel

performance.

Safety Regulations

Each country has its own safety legislation. It is in the

operator’s own interest to be conversant with these

regulations and to comply with them in full. This also

applies to local bylaws and regulations in force on a

particular worksite.

Should the recommendations in this manual deviate from

those in the user’s country, the national regulations should

be followed.

NOTE: All possible safety hazards cannot

be foreseen so as to be included in this

manual. Therefore, you must always

be alert to potential hazards that could

endanger personnel and/or damage the

equipment.

Operation, Inspection, and Maintenance Warnings

WARNING

The winch shall not be used for hoisting.

WARNING

Use hearing protection when operating

winches.

vii

Safety Summary

»Do not work with a damaged or worn wire rope.

»Do not use a winch that needs repairs.

»If the wire rope and ferrule must be removed from

the drum, make sure the end of the wire rope and

ferrule are controlled when the ferrule is released.

The end of the wire rope can suddenly move from

the drum like a compressed spring when the

ferrule is released and cause an injury.

• Stay in the operator’s seat when operating the winch.

• Do not stand on the vehicle when operating the

winch.

• Avoid winch operation near people or other machines.

• Never stand nor permit others to stand in the bight

(loop) of a wire rope.

• Do not stand nor permit others to be near the winch

or wire rope when there is tension on the wire rope.

• Observe jobsite rules.

• Be in complete control at all times.

• Do not use the control levers as hangers for clothes,

water bags, grease guns, lunch pails, etc.

Obey the following cautions and

warnings before using your winch to

avoid equipment damage, personal

injury or death.

• Do not operate the winch unless you are authorized

and trained to do so.

• Do not operate the winch unless the vehicle is

equipped with a screen to protect the operator if the

wire rope breaks.

• Read, understand, and follow the operating,

inspection, and maintenance instructions in this

Operating Manual.

• Do not use the control levers for hand holds when

entering or leaving the vehicle.

• Do not permit other people near the control area

when you inspect or repair a machine.

• Never inspect, repair, or perform maintenance on a

machine that is in motion.

• Inspect the winch before each use:

»Make sure that the controls and instruments

operate correctly.

»Report the need for repairs immediately.

viii

• Do not leave the vehicle when the winch wire rope

is under tension.

• Do not permit riders on the vehicle or load.

• Do not use the winch as an anchor for a double or

two-part line.

• Do not pull the hook through the throat or over the

drum, which will cause damage.

• When the winch is not in use, make sure the control

lever is in BRAKE-ON position and the winch brake

is applied.

• Do not use winch as a hoist. Tractor and skidder

mounted winches are designed for towing.

• Always inspect wire rope, tail chain and other rigging

components for wear, damage, broken strands or

abuse before use.

• Never use wire rope, tail chain or other rigging that

is worn-out, damaged or abused.

• Never overload wire rope, tail chain or rigging.

• Wire rope and tail chain will fail if worn-out, overloaded,

misused, damaged, improperly maintained or

abused. Wire rope or tail chain failure may cause

serious injury or death!

• Do not terminate wire rope to tail chain by the use

of a knot.

KG

KG

ix

Safety Summary

• Do not handle wire rope if the hook end is not free. A

load could break away, suddenly tensioning the wire

rope, resulting in serious injury or death.

• Stay clear of wire rope entry areas (fairlead or arch

rollers, winch drum etc).

• Make sure ground personnel are in plain view of the

operator, and at a distance of at least 1½ times the

working length of the wire rope.

• Make sure that any hand signals used by ground

personnel are clearly defined and understood by

everyone involved.

• Do not attempt to “jerk” or “shock” a load free. Doing

so can cause loads in excess of the rated capacity of

the wire rope, winch, or mounting hardware.

• Replace any parts only with genuine Allied

Winch parts. Refer to W6G Parts Manual (P/N

599003W-CAT).

• Maintain a minimum of three (3) complete wraps

of wire rope on the drum for normal operation. It

may help to paint the last five wraps of wire rope a

contrasting color, to serve as a visual indicator.

• Do not handle wire rope with bare hands. Wear

leather gloves at all times.

• Align the tractor with the load to prevent side loading

the winch, and to maintain even spooling of the wire

rope.

• If applying tension to the wire rope manually during

spooling:

»ensure that the operator is winching in slowly,

»keep your hands and clothing well clear of any

rollers or the winch drum,

»do not maintain tension by letting the wire rope

to slip through your hands,

»use a hand-over-hand technique to maintain

tension.

• Be aware of the ground conditions, and make sure

the ground and tractor are stable enough to pull

the intended load.

• Do not attempt to pull loads in excess of the rated

capacity of the winch.

• Keep yourself informed of any applicable codes,

regulations and standards for the job.

• Your winch may have temperature shut-off system

for protection of tractor and winch. Manual override

of high temperature shut-off will cause damage to

tractor and winch.

x

• This winch is neither intended, designed, nor rated

for any application involved in the lifting or moving

of personnel.

• Use only the lubricants listed in the Recommended

Oil List. See Page 5.

• Do not weld on any part of the winch. Contact Allied

Systems if weld repairs are needed.

• The hydraulic system must be kept clean and free

of contamination at all times.

• Be aware of the hazards of pressurized hydraulics:

»Wear personal protective equipment, such as

gloves and safety glasses, whenever servicing

or checking a hydraulic system.

»Assume that all hydraulic hoses and components

are pressurized. Relieve all hydraulic pressure

before disconnecting any hydraulic line.

»Never try to stop or check for a hydraulic leak with

any part of your body; use a piece of cardboard

to check for hydraulic leaks.

»Small hydraulic hose leaks are extremely

dangerous, and can inject hydraulic oil under the

skin, even through gloves.

»Infection and gangrene are possible when

hydraulic oil penetrates the skin. See a doctor

immediately to prevent loss of limb or death.

1

General

Introduction

This Operating Manual contains basic information

necessary for the operation and maintenance of the W6G

winch.

How the Winch Operates

A winch is normally installed on a skidder or dozer:

• to increase the pulling power of the skidder or dozer.

• to reach into an area where a skidder or dozer cannot

go.

• to make lift functions available when special attachments

are installed.

The winch has hydraulic clutches that are similar to a

hydraulic (powershift) transmission. The dozer or skidder

has a power take-off (PTO) that is used to connect the

power from the engine to the winch. The SCH (Self

Contained Hydraulics) on the winch label indicates that

the hydraulic system for control of the winch is inside of

the winch case. When the PTO is operating, a hydraulic

pump in the winch case takes hydraulic oil from the

winch sump and sends it to the hydraulic control valve.

The hydraulic valve controls the operation of the winch.

Removable covers on the winch case allow access for

repairs and adjustments.

When PTO is rotating, the hydraulic pump shaft is also

rotating. Oil from the hydraulic pump is used to cool

and lubricate the winch components. The pressure is

connected via gears to an oil clutch for the LINE-IN (power

forward) operation and another oil clutch for the LINE-OUT

(power reverse) direction.

The power through the winch to the drum for the wire rope

is controlled by a LINE-IN and a LINE-OUT clutch. When

the LINE-IN clutch is applied, the drum rotates to pull the

wire rope into the winch. When the LINE-OUT clutch is

applied, the drum rotates to reel the wire rope from the

winch at the speed controlled by the engine rpm.

When the control lever is in the BRAKE-ON position, the

oil brake is automatically applied by a spring to hold the

drum in its position. If the control lever is moved to apply

one of the clutches, the brake is released by the same oil

pressure that applies the clutch. In the event that hydraulic

power is lost, the brake remains applied and the winch

will not turn.

General

2

Figure 1 - Nameplate

The winch has an intermediate gear assembly that

provides a gear reduction and increases the available

torque at the winch drum. For winches equipped with

the FREESPOOL option, a sliding sleeve with splines

engages the drum pinion gear and the intermediate gear.

When the control lever is in the FREESPOOL position,

the sliding sleeve disengages the drum pinion gear from

the intermediate gear. The gear train is disengaged from

the clutch and brake shaft so that the wire rope can be

pulled from the drum by hand. Only the drum and drum

pinion gear rotate when the wire rope is pulled from the

drum during a FREESPOOL operation.

CAUTION

Shifting to FREESPOOL with a suspended

load on the wire rope will cause the load

to fall uncontrollably.

The W6G winch has a maximum line pull capacity of

266,880 N (60,000 lbf) when there is one layer or less of

wire rope on the drum.

Nameplate

Each winch is shipped from the factory with a nameplate

as shown in Figure 1. The nameplate is stamped with:

• winch model

• winch serial number

• maximum bare drum line pull

• maximum wire rope diameter

DO NOT operate the winch with larger diameter wire rope.

If the nameplate is missing, DO NOT operate the winch

until its capacity is known.

The serial number for the winch is also stamped into the

frame next to the nameplate.

3

General

Wire Rope Selection

Each winch model can have a variety of wire rope sizes

installed by the user.The maximum wire rope size is shown

on the nameplate. See Figure 2 for approved wire rope

sizes and drum capacities. When a larger diameter wire

rope is used, the length of wire rope installed on the drum

will be shorter. In some situations, the winch can create a

tension in the wire rope that is greater than the strength

of the wire rope.The user must be careful to select a wire

rope that has enough strength and length for the job.

WARNING

Load loss hazard.

A wire rope that breaks under high tension

can suddenly whip back towards the

winch, causing injury or product damage.

Be sure the operator knows the capacity

of the wire rope and the winch.

WARNING

Load loss hazard.

A loaded wire rope with fewer than

three complete wraps on the drum

could disengage from the ferrule pocket,

causing load loss and possible injury.

Paint the last five wraps of wire rope a

contrasting color to alert the operator that

end of the wire rope has been reached.

Figure 2 - Wire Rope Size and Capacities

Wire Rope Diameter Capacity for 12 in (305 mm)

Drum Diameter

3/4 in (19 mm) 376 ft (115 m)

7/8 in (22 mm) 271 ft (83 m)

1 in (25 mm) 210 ft (64 m)

NOTE:

1. Loosely or unevenly spooled line will reduce capacities.

2. Use flexible wire rope with independent wire rope center.

3. Ferule size: 2 inches diameter, 2 1/4 inches long.

4

Recommended Oil List and Oil Capacity

The type of oil used in Allied winches affects the line

control. Use the following oils in the W6G winch:

Figure 3 - Recommended Oil List

°F °C

ExxonMobil Mobil Fluid 424 (Factory fill) -13 to 104 -25 to 40

05ot52-221ot31-™draG-yHereeDnhoJ

04ot52-401ot31-FHT0001norvehC

Caterpillar Multipurpose Tractor Oil (MTO) -13 to 104 -25 to 40

05ot92-221ot02-artlU

narT-yHesaC

°F °C

03ot04-68ot04-TLdiulFliboMliboMnoxxE

John Deere Low Viscosity Hy-Gard -40 to 86 -40 to 30

03ot04-68ot04-WFHTnorvehC

* Note: Use of non-recommended oils may void warranty.

Recommended Oils* - General Conditions

Ambient Temperature Range

Recommended Oils* - Low Temperature Conditions

Ambient Temperature Range

Manufacturer Oil Type

Manufacturer Oil Type

Winch Model Oil Capacity

W6G 19.5 Gallons (73.8 Liters)

Figure 4 - Oil Capacity

5

General

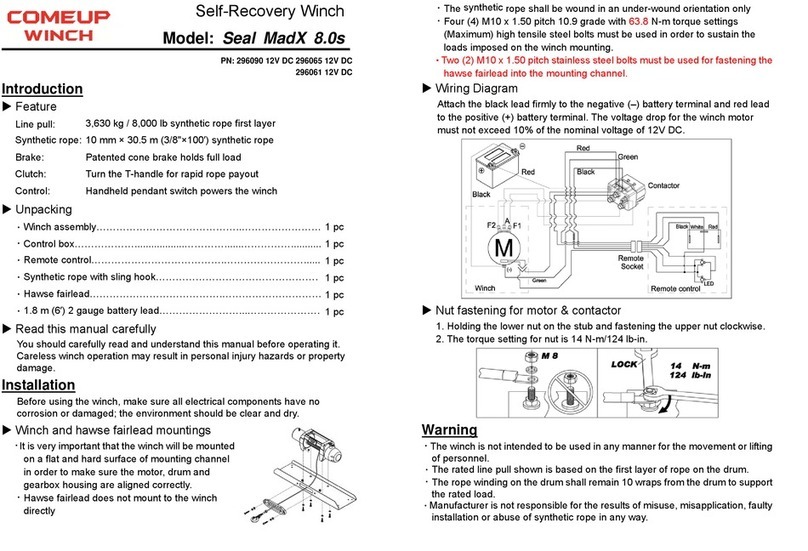

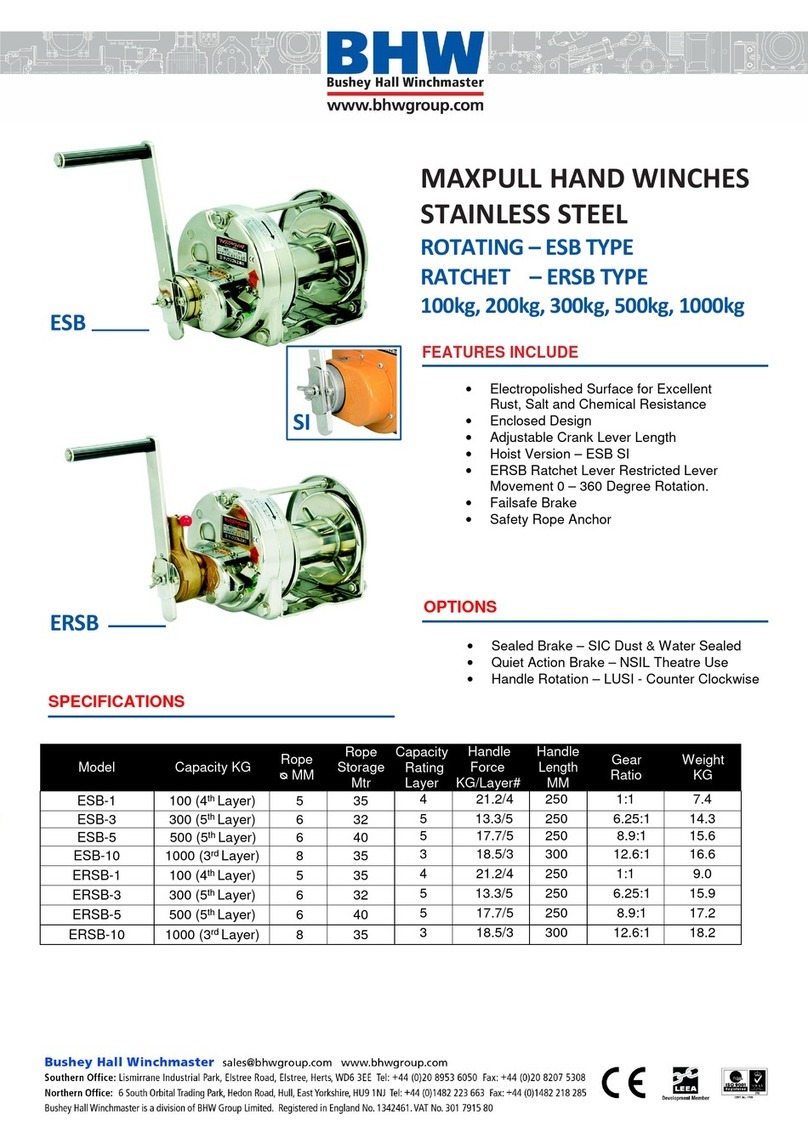

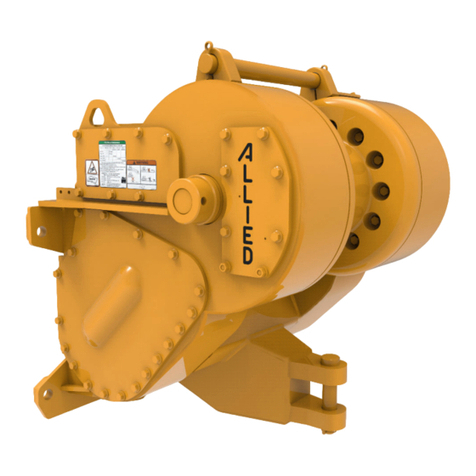

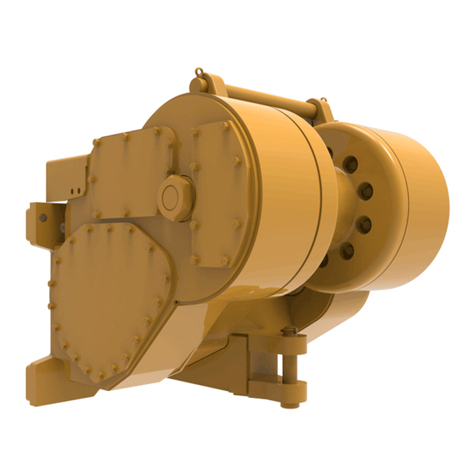

Figure 5 - W6G Winch

W6G Winch Description

1. Drum

2. Access Cover for Filter

3. Access Cover to Hydraulic Valve

4. Access Cover to Hydraulic System

5. Plug to Check Oil Level

6. Plug to Drain Oil

7. Tie Rod

8. Fill Plug

9. Cover for Oil Brake

10. Intermediate Shaft Bearing Retainer

11. Drum Shaft Bearing Retainer

12. Drawbar

13. Breather

14. Nameplate

15. Drawbar Pin

16. Clutch Shaft Retainer

17. Idler Shaft Retainer

1.

D

r

u

m

7

.

Tie

R

1

3.

B

r

ea

t

her

1

23

4,9

5

6

7

8

13

10

11

15

12

14

16

17

6

Optional Equipment (See also Page 31 for details)

The W6G winch may be equipped with the following

options:

• Integral Arch - To raise the load slightly to reduce drag

due to ground contact;

• Fairlead Assembly - To protect wire rope and frame

from damage at odd pull angles;

• Heavy Duty Extended Drawbar

NOTE: Not all optional equipment listed is available

for each model of dozer.

Figure 6 - Optional Equipment

Integral

Arch Assembly

Fairlead

Assembly

Heavy-Duty

Extended

Drawbar

7

Serial Number Codes

The nameplate with the serial number code is found on

the left front corner of the winch case. A serial number

indicates the following information:

General

A W6G E 6 N 1555 C712 N

Manufactured By

Vehicle Code

Sequence Number

Internal Option

Winch Model

Type Drive

Gear Ratio

A = Allied Systems Company

E = Electronic Controls

See Figure 7

In Addition to the serial number plate,

the serial number is stamped on to

the left hand side of the frame.

Notes: 1.

W6G = Standard

K6G = Special Design (Contact Factory)

Code = Forward Ratio/Reverse Ratio

6 = 103:1

N = Non-Freespool

F = Freespool

Branding

Blank = Allied Branded

N = Unbranded

8

Figure 7 - Dozer Identification and Gear Ratios

Vehicle Code Caterpillar Model and Serial Number Prefix, Where Applicable

C71 D6T

D6R II

C712 D6 Build 20A

C713 D6 Build 18A, 19A

C810 D5 Build 17a

D6N Tractor Tier 4i; 4f (s/n prefix PER, PBA, GB6, SGG, NJN, MG5)

Other manuals for W6G

2

Table of contents

Other Allied Systems Winch manuals

Allied Systems

Allied Systems W8L User manual

Allied Systems

Allied Systems Allied H6G Series User manual

Allied Systems

Allied Systems W8L User manual

Allied Systems

Allied Systems H12E User manual

Allied Systems

Allied Systems W3C User manual

Allied Systems

Allied Systems H6H User manual

Allied Systems

Allied Systems W8L User manual

Allied Systems

Allied Systems H5C Series User manual

Allied Systems

Allied Systems H6H User manual

Allied Systems

Allied Systems W6G User manual