Limited Warranty

Vermason expressly warrants that for a

period of one (1) year from the date of

purchase, Vermason Digital Static

Fieldmeters will be free of defects in

material (parts) and workmanship

(labour). Within the warranty period, a unit

will be tested, repaired or replaced at

Vermason’s option, free of charge. Call

Customer Service at

0044 (0) 1462

672005

for a Return Material

Authorisation (RMA) and for proper

shipping instructions and address. Any

unit under warranty should be shipped

prepaid to the Vermason factory. You

should include a copy of your original

packing slip, invoice, or other proof of

purchase date. Warranty repairs will take

approximately two weeks.

If your unit is out of warranty, Vermason

will quote repair charges necessary to

bring your unit to factory standards. Call

Customer Service at

0044 (0) 1462

672005

for a Return Material

Authorisation (RMA) and proper shipping

instructions and address.

Warranty Exclusions

THE FOREGOING EXPRESS

WARRANTY IS MADE IN LIEU OF ALL

OTHER PRODUCT WARRANTIES,

EXPRESSED AND IMPLIED, INCLUDING

MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE WHICH ARE

SPECIFICALLY DISCLAIMED. The

express warranty will not apply to defects

or damage due to accidents, neglect,

misuse, alterations, operator error, or

failure to properly maintain, clean or repair

products.

Limit of Liability

In no event will Vermason or any seller be

responsible or liable for any injury, loss or

damage, direct or consequential, arising

out of the use of or the inability to use the

product. Before using, users shall

determine the suitability of the product for

their intended use, and users assume all

risk and liability whatsoever in connection

therewith.

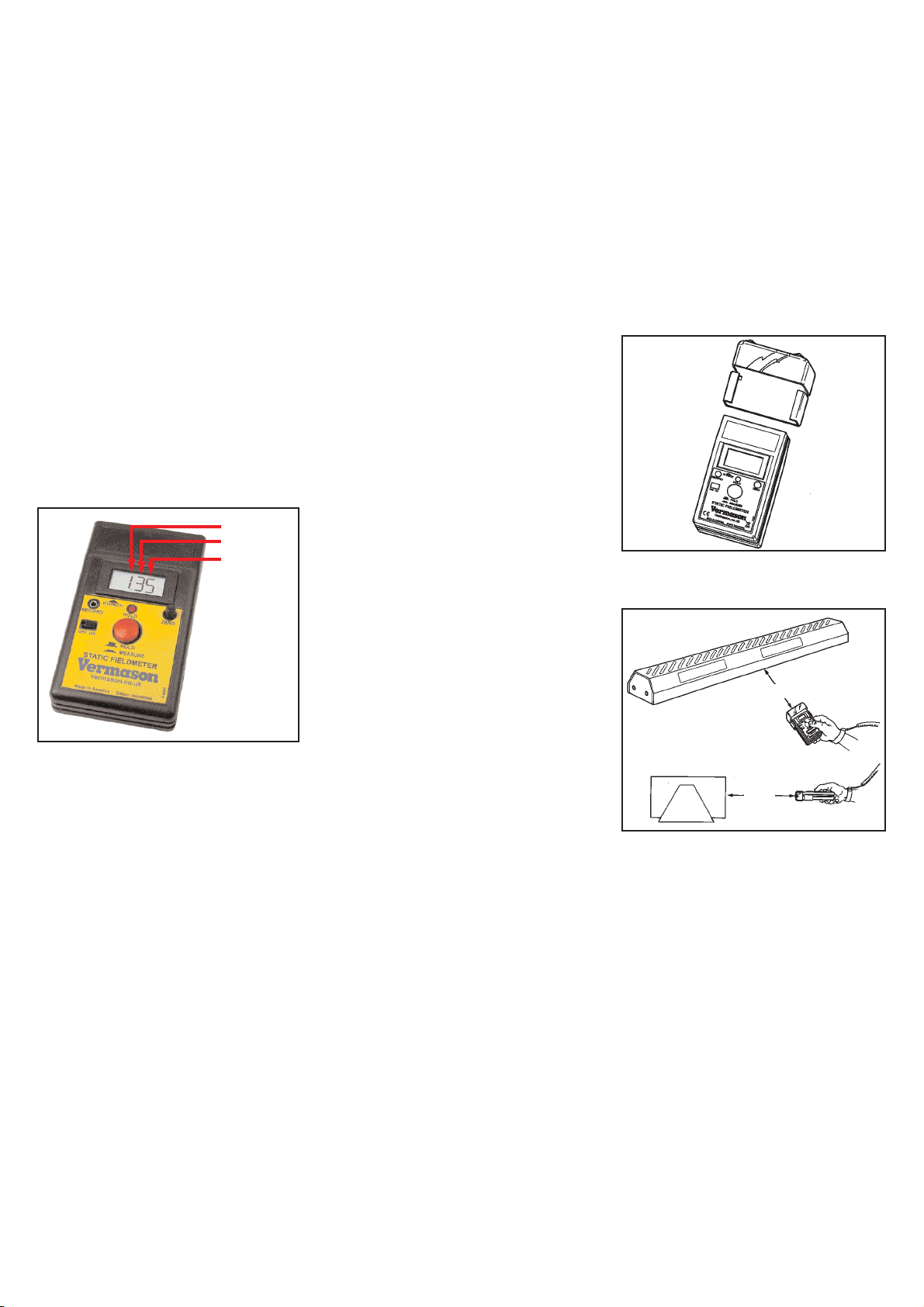

Figure 6. Using the Personal HBM Test

Fixture to measure charges on the body

UNIT C, 4TH DIMENSION, FOURTH AVENUE, LETCHWORTH, HERTS, SG6 2TD UK

Phone: 0044 (0) 1462 672005, Fax: 0044 (0) 1462 670440 • e-mail: Service@Vermason.co.uk, Internet: Vermason.co.uk

TB-7552 Page 3 of 3 © 2008 Vermason

static charges produced by walking

across substrates such as carpeting,

vinyl floor tile, and sealed concrete. It

can also be used to detect charge

generation on surfaces such as

conductive or dissipative floor tiles and

carpeting. An ESD technician may also

use this tool to verify proper grounding

between a conductive or dissipative floor

surface and a person wearing personal

grounding devices such as foot

grounders. The amount (or size) of the

charge generated will vary from one

human body to another. Other factors

such as humidity, contamination

between the foot and flooring surface, as

well as human body capacitance will

also affect the amount of charge

generated.

Installation and Removal

If the fixture needs to be removed to

allow use of the Field Meter alone, see

Figure 5.

To obtain the desired result, a ground

cord must be installed onto the Field

Meter and attached to a utility or

common ground point.

Method of Operation

In order to obtain the desired test

results, the meter must be properly

grounded as stated in the Installation

and Removal section. Once installed on

the Fieldmeter, the Test Fixture itself is

isolated from the meter case and ground

and should remain that way.

Cradle the Test Fixture in the palm of

your hand. Once the meter is grounded

and you are standing on the substrate to

be tested, simply walk around, shuffle

your feet or raise a foot, to determine if

the combination of footwear and

substrate produces an electrical charge.

If an electrical charge is generated and

induced onto the human body, the Test

Fixture will transfer that charge onto the

Fieldmeter, and the amount of the

charge will be registered. If it is

necessary to record the amount of

charge, you can save the result by

simply pressing the Hold button on the

front of the Fieldmeter, and pressing the

button with an insulated object. This test

can be done regardless of the type of

footwear or substrate combination.

Other items in your ESD Control

Program may also be tested such as

conductive or dissipative chairs. Simply

sit in the chair on the desired substrate

and move the chair back and forth to

determine if the chair and human body

combination produces and electrical

charge.

Figure 5. Installing the 222662 Personal

HBM Test Fixture on the Digital Static

Fieldmeter with Charging Plate

A: Slide the Digital Static Fieldmeter

down into the Personal HBM Test

Fixture. NOTE: The Charging Plate

is required to use the Personal HBM

Test Fixture.

B: Insert the screw from the back of the

Personal HBM Test Fixture.

A

B