DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

TB-7588 Page 3 of 7 © 2017 DESCO INDUSTRIES, INC.

Employee Owned

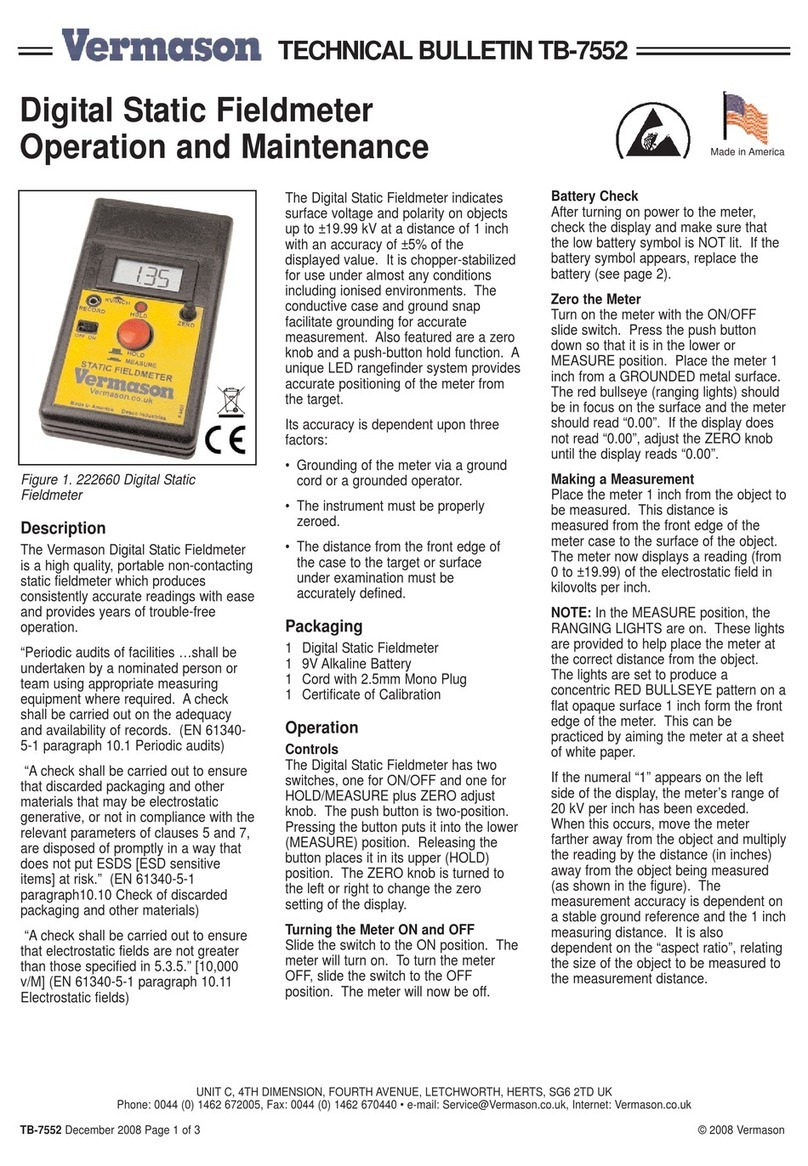

A. Test Jacks: The shielded test leads connect here. The

black test lead’s 3.5mm plug connects into the stereo jack,

and the white test lead’s banana plug connects into the

banana jack.

B. Liquid Crystal Display: Temperature, Relative Humidity

and Resistance Mantissa values appear on this display.

When the test button is depressed and the meter is set to

FULL test mode, the following information will display in

sequence:

• Temperature in degrees Fahrenheit (±10%)

• Temperature in degrees Celsius (±10%)

• Relative Humidity as a percentage (±10 integers)

• Surface Resistance Mantissa (with exponent displayed

via LED, measurement in ohms)

Surface resistance ohm values are expressed with a

mantissa and exponent (power) of the number. For example,

if the #8 exponent LED illuminates and the meter displays

“7.14”, the measurement is 7.14 x 108ohms or 714,000,000

ohms.

If the measured surface resistance is over 1012 ohms, “1___”

will appear on the liquid crystal display.

C. Exponent Light Emitting Diodes (LED): These LEDs

indicate the surface resistance exponent value. They are

colour coded for quick checks.

Exponent Colour

<3, 3 Red

4, 5 Green

6, 7, 8 Blue

9, 10 Green

11, 12, >12 Yellow

Quick Checks

The surface resistance exponent number illuminates

immediately (i.e. 8 = 1 x 108ohms to less than 1 x 109ohms

or 100,000,000 to less than 1,000,000,000 ohms).

D. Function LEDs: These LEDs indicate the measurement

type displayed. The surface resistance mantissa is displayed

when either the “10V” or “100V” LED is illuminated.

The Function LEDs will flash when the battery voltage drops

to approximately 2 volts. Replace the batteries when this

occurs.

E. Test Voltage Button: When set to AUTO, the meter will

automatically switch to the appropriate test voltage for the

measured resistance range. The Function LEDs will indicate

the applied test voltage. Material that is 9 x 105ohms or

less should be measured at 10 volts. Material that is 1 x

106ohms or greater should be tested at 100 volts. (Ref: IEC

61340-2-3) When the switch is set to 10V HOLD, the test

voltage will be fixed at 10 volts regardless of the measured

resistance value.

F. Quick Check Button: When set to FULL, the meter will

cycle through the approximate 15 second electrification

period that displays the temperature and relative humidity

before the surface resistance mantissa is displayed. When

set to QUICK, the meter will skip the 15 second period

and immediately display the measured surface resistance

mantissa.

G. Test Button: Push and hold this red button to make a

measurement with the meter. Testing in accordance with

IEC 61340-2-3 requires 15 seconds of electrification. These

15 seconds are included when the meter is set to FULL test

mode. The surface resistance mantissa will display on the

meter after temperature and relative humidity measurements

are displayed.

The surface resistance exponent number illuminates

immediately, and the meter first displays the temperature

and relative humidity during a 15 second electrification

period. The mantissa is then displayed at the end of the test

sequence. For example, if the #8 exponent LED illuminates

and the meter displays “7.14”, the measurement is 7.14 x 108

ohms or 714,000,000 ohms.

H. Battery Compartment: Open this compartment to install

the two AA alkaline batteries needed to power the meter.

Replace the batteries once the Function LEDs begin flash.

Operation

Per IEC User Guide Testing of Installed ESD Control

Items

“Once the ESD ground reference has been verified it is

important to ensure that each of the ESD control items used

is connected to the ground reference. First ensure that each

ESD control item is connected to the ground reference. Next,

using the test method or standard and limits for each ESD

control item given in Tables 2 and 3 of IEC 61340-5-1,verify

that the resistance to ground (or to the common connection

point) meets the required limit”. (CLC/TR 61340-5-2 User

guide Grounding/bonding systems clause 4.4.5 Verification of

proper installation of ESD control items)

General Guidelines

• Use both 2 kg electrodes for Rp-p measurements.

• Use one 2 kg electrode and connect the black sensing

test lead to ground for Rg measurements.

• Ensure that the item being measured is electrically

isolated (placed on an insulative surface). The meter will

measure the lowest resistance path.

• Ensure that the test leads are separated and uncrossed

as a best practice.

• When using 2 kg electrodes:

• Place them no closer than 5 cm from the edge of

the surface being measured

• Place them no closer than 8 cm to any groundable

point

• Place them about 25 cm apart from each other for

Rp-p measurements of a worksurface

• Place them about 1 m apart from each other for

Rp-p measurement of a floor