Operating Steps and Safety Practices

Vermeer BC1000XL Brush Chipper

Visit Vermeer at www.vermeer.com to locate your local Vermeer Tree Care dealer.

04/2012 Your machine may have product improvements and features not yet contained in this guide. Part Number 105400SFo Edition 1_00

Vermeer Corporation reserves the right to make changes at any time without notice or obligation.

© 2012 Vermeer Corporation. All Rights Reserved.

1210 Vermeer Rd. East, Pella, IA 50219 USA

Your rental associate or technician will explain each of the following operating steps and safety practices before you use this brush

chipper. WARNING: Do not use or attempt to operate the machine until you understand proper operation and safety of

this brush chipper. Read the operator’s manual. Read safety signs attached to the machine. In addition, a

Vermeer Brush Chipper Operation and Safety Video is available for viewing at your rental center. If you are

unsure of content or meaning of the safety messages or information regarding machine operation, ask your rental

associate or technician for more details.

INTENDED USE: Vermeer BC1000XL Brush Chippers are designed solely for use in chipping organic material such as wood, bark, limbs, brush,

and undergrowth.

OPERATING STEPS

1. Brush Chipper Transport:

a. Vehicle must have towing capacity of 4860 lb (2204 kg), safety chain and highway light connections and equipped with a brake controller.

b. Fold and latch feed table. Rotate and lock discharge chute facing tow vehicle. Stow tongue jack.

2. Brush Chipper Setup:

a. Set up machine in area free of obstacles. NEVER setup under a tree being pruned or removed.

b. Always keep machine attached to tow vehicle and feed table set a minimum of 24” (61 cm) off the ground.

c. Rotate and lock discharge chute to direct chips away from work area.

d. Wear appropriate personal protective equipment.

e. If working along the road use all necessary signs, cones, and flag persons needed for the work situation.

3. Brush Chipper Start:

a. Place “Cutter Engage/Throttle Lever” in DISENGAGED/LOW RPM.

b. Place “Upper Feed Control Bar” in top “STOP” position.

c. Turn ignition key clockwise to ON/Preheat position to turn on the electrical system (allow wait to start lamp to go out on 49 hp 36.5 kW).

d. Start engine and let it warm up for 3-5 minutes before engaging the cutter drum.

e. Grip “Cutter Engage/Throttle Lever” firmly and move it slowly to the ENGAGED/HIGH RPM position.

f. Pull “Upper Feed Control Bar” into “FORWARD” feed position and push the green “Hold-to-Run” button on either side of machine. Feed

roller will start rotating in “FORWARD” to pull material into brush chipper.

NOTE: When engine speed drops below selected RPM because of heavy chipping, SmartFeed will momentarily reverse and stop the

feed roller. The feed roller will resume once engine speed RPM recovers.

4. Brush Chipper Feeding Tips:

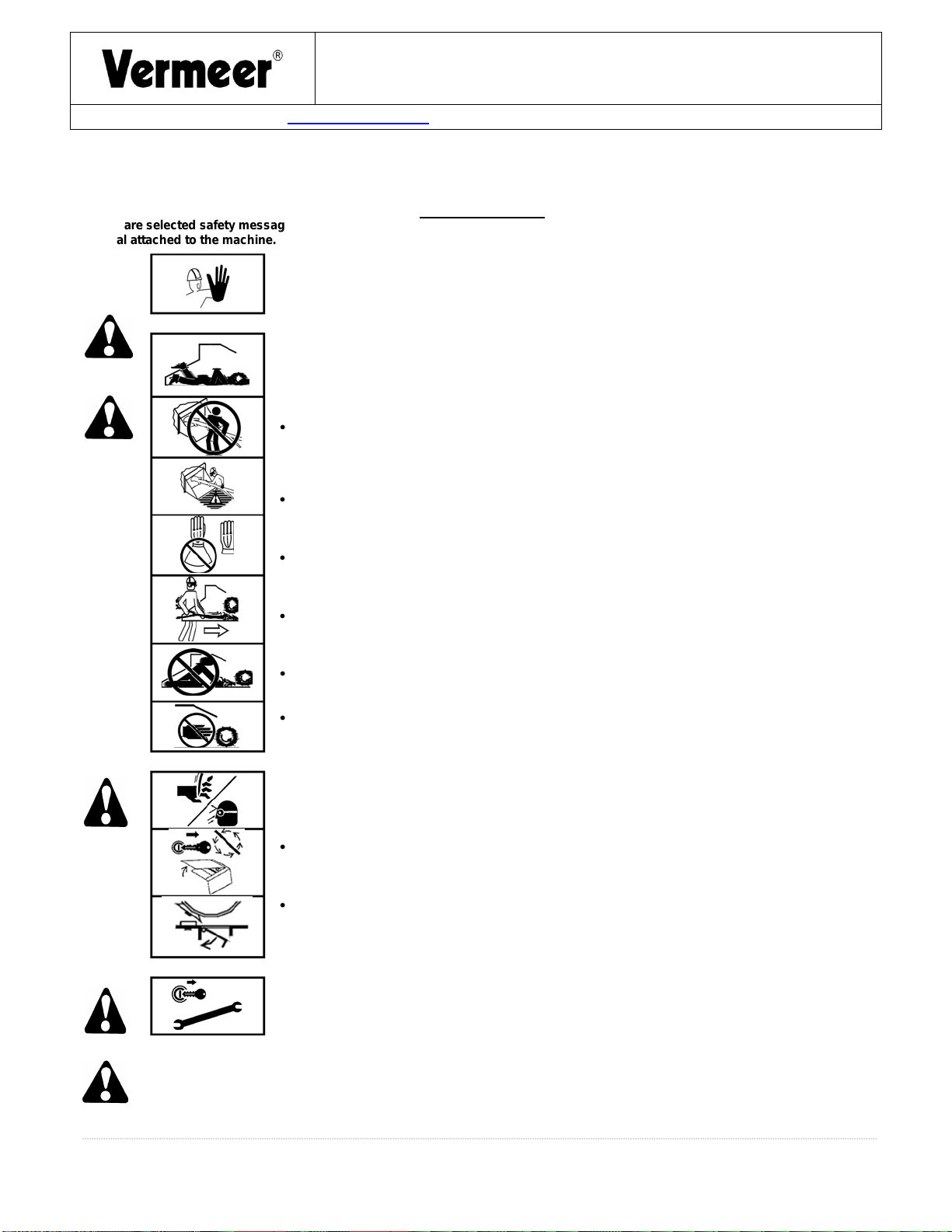

a. To reduce risk of being pulled into machine:

•Feed from side of feed table, NEVER directly behind it.

•Feed large end of log or branch into chipper first.

•If wearing gloves, they must have narrow tight-fitting cuffs. NEVER wear gauntlet-style cuffed gloves.

•Keep away from rotating feed roller. NEVER climb onto feed table.

•Use wood object to push twigs or small short material into feed roller. NEVER push material with hands, feet, rake, shovel or other

non-wood objects.

b. To reduce risk of being struck by material, release limb immediately after it begins feeding, then turn away.

5. Stopping Brush Chipper Feeding:

a. Push “Upper Feed Control Bar” toward front of machine to center “STOP” position or,

Pull “Upper Feed Control Bar” toward rear of machine to “E-Stop” position or,

Push “Lower Feed Stop Bar” toward front of machine.

6. Removing Plugged Material:

a. If feed roller plugs or stalls, push “Upper Feed Control Bar” to “REVERSE” feed position. Reposition or trim oversize material and re-feed

into chipper.

b. If reversing the feed roller does not dislodge the plug, follow “Shutdown Procedure” outlined in attached operator’s manual. Then follow

instructions to unplug the machine.

c. If cutter drum or discharge chute plugs, follow “Shutdown Procedure” outlined in attached operator’s manual. Then follow instructions for

unplugging.

7. Restarting Stalled Machine:

a. Place “Upper Feed Control Bar” in center “STOP” position.

b. Place “Cutter Engage/Throttle Lever” in DISENGAGED/LOW RPM position and restart engine.

c. Place “Cutter Engage/Throttle Lever” in DISENGAGED/HIGH RPM position, use “Upper Feed Control Bar” to reverse material out of feed

roller.

d. Place “Cutter Engage/Throttle Lever” in ENGAGED/HIGH RPM position, pull “Upper Feed Control Bar” to forward position, push green

“Hold-to-run” button and resume operation.

8. Shutdown Procedure:

a. Place “Upper Control Bar” in center “STOP” position.

b. Place “Cutter Engage/Throttle Lever” in the DISENGAGED/LOW RPM position and turn engine off and remove key.

c. Wait for cutter drum to stop. Check left cutter drum bearing to ensure rotation has stopped.

IMPORTANT: Cutter drum will continue to rotate for a short time after engine has stopped.

Operator’s

manual

and

rent

al

center

guide

are

available

in

other

languages.

Contact

products

[email protected].

Se

dispone

de

l manual del operador

y

de

la

guía

de

centros

de

alquiler

en

otros

idiomas.

Póngase

en

contacto

con

products[email protected].

See other side for Safety Practices