Crommelins GTS1300 Administrator Guide

Hire and Rental Industry Association Ltd

Product Safety Assessment Sheet

PLANT INFORMATION

PSA Ref #: 00366

Model No: GTS1300SH & GTS1300S

Plant Name: Crommelins 13.5hp Wood Chippper GTS1300SH

Manufacturer: Crommelins Machinery WA

Manufacturer's Website: www.crommelins.com.au

Web Link for Plant: www.crommelins.com.au

Potential noise level in dB: 85 to less than 90

Required hearing protection class: 1

Mandatory Personal Protective Equipment:

Dust Mask Face Foot Hand Head, Protective

Protection Protection Protection Hearing Clothing

and Eye Protection

RISK ASSESSMENT INFORMATION

Operator Competency: Plant Licence Not Required

Potential Hazard(s) Risk Level Control Measure(s)

Protective Equipment High • Face, Eye and Ear protection must be worn

while chipper is in operation

Explosion or fire from fuel

vapours. Medium • Stop the engine before refuelling. Do not

refuel while hot. Avoid spillage of fuel when

refuelling. Ensure the fuel cap is properly

secured after refuelling. Carry out visual

checks for fuel leaks and repair before

operation. Keep flammables away from the

engine. Warning label on engine. Do not

smoke while operating, servicing or refuelling

this machine.

Exposure to ultraviolet radiation

if working outdoors. Medium • Wear sunscreen, hat, long sleeves and long

trousers.

Coming into contact with hot

parts of the engine. Medium/Low • The muffler is fitted with a heat shield. Let

the engine cool down before attempting any

maintenance. Avoid contact with hot

components. Warning label on engine.

Issue #: 2 • Issued 14-5-2018 • Printed 14-5-2018 • Copyright ©2018 HRIA Ltd. Page 1 of 3

Inhaling exhaust or fuel fumes. Medium/Low • Only operate in a well ventilated area. Do not

operate in a confined space. Avoid breathing

petrol fumes. Avoid skin contact with petrol.

Coming into contact with moving

parts. Low • Belt guard fitted to plant. Do not remove

guards or covers.

• Protective footwear must be worn at all

times.

Hearing damage from excessive

noise. Low • Hearing protection with a rating of 15db must

be worn.

Coming into contact with the

cutter blade. Low • Keep hands and feet well clear of the cutting

blade. Ensure that the engine is turned off

before attempting any adjustments or

maintenance.

• Protective footwear must be worn at all

times.

• Keep all people and animals away from

discharge tube at all times.

Injury or ill health due to

exposure to excessive vibration. Low • The operator needs to take regular breaks to

provide postural relief for safe work

practises.

Do not use on inclines of more

than 20 degrees • Ensure the equipment is operated on a

stable, level surface. If equipment is

operated on a slope, engine seizure may

occur due to improper lubrication, even with

max. oil level and functioning oil protection

system. Fuel spillage may also occur.

•

Manual Handling Hazard • Use correct lifting techniques, weight 166kg.

The GTS1300SH is provided with lifting hook

for use with mechanical lift.

Customer Identified Hazard(s)

Issue # 2 • Issued 14-5-2018 • Printed 14-5-2018 • Copyright ©2018 HRIA Ltd. Page 2 of 3

Key Operating Instructions

The hardness of the wood depends on the wood type, the time between pruning and chipping and how dry

the branches are. The machine performs best if the branches are chipped right after pruning. The

GTS1300SH & GTS1300S is made only for chipping newly cut wood having a maximum diameter of 75mm.

It is prohibited to feed in any other materials into the machine ie metal, stones, plastics, paper, processed

timber or any other materials.

Before starting the machine, check that the input tube is empty, if not clean input tube with a stick or long

handled implement.

Ensure that machine is placed in a clear area and is on level and stable ground. Mark up an area at least 3

metres wide and 12 metres long on the discharge side. While chipping, the user must take care that no one

can get hurt with flying chips. Use red/white safety tape to define this area.

Do not allow people or animals to enter into this area while the chipper is in operation.

Setup a clear area for the discharge of the chippings to accumulate in one pile. Set the deflector plate on the

discharge tube to roughly work out the deflection angle, adjust as necessary after test chipping.

TO START THE ENGINE - Turn on the fuel, ensure the engine switch is in the ON position, the two

Emergency Stop buttons are in the ON (open) position : check by twisting the red knob clockwise, the input

hopper and discharge chutes are bolted down and the micro switches are activated. Set the engine throttle

lever to half speed ( you may need to use the choke lever for a few seconds for a cold start),pull the starter

cord in a medium fluid manner to start the engine.

OPERATING THE CHIPPER - With the engine speed set at full throttle, start to feed, one at a time, the

narrow end of the pruned materials into the input tube, when these are pulled in let them go, the chipper will

automatically draw the materials further into the input tube. Cut side branches thicker than 3cm off and feed

them in separately. Large branches will have to be pruned down to manageable size. Do not force or over

feed the input tube with materials. Do not feed in loose leaves .Long branches could lash into your face,

keep a safe distance and always wear face protection.

In case of an emergency during operation - Activate the Emergency Stop Button to shut the machine off.

TO STOP - Allow a few minutes for the last of any chippings to exit before stopping the engine. Reduce the

throttle speed to low and activate the Emergency Stop button by foot, turn the engine switch to OFF, turn the

engine fuel tap to OFF.

Please refer to the User Guide and Operator's Manual for Operating Instructions

The Safety Information on this assessment has been developed for the Hire and Rental Industry to assist in

the safe operation of this equipment.

This information contains general information only and should not be relied upon as a substitute for

professional advice, which the user should seek before operating.

Once printed this is an uncontrolled copy.

Issue #: 2 • Issued 14-5-2018 • Printed 14-5-2018 • Copyright ©2018 HRIA Ltd. Page 3 of 3

CROMMELINS™ CHIPPER GTS1300

Thank you for your selection of a CROMMELINS™ Chipper GTS1300. This

Operation Manual explains its use, installation, checking and maintenance. We

highly recommend that you retain this manual for ready reference regarding

proper handling of the CROMMELINS™ Chipper GTS1300.

Spare Parts & Service

Phone: 1300 554 524

Freecall Fax: 1800 636 281

[email protected]om.au

www.crommelins.com.au

WA Metro 9350 5588

WA Regional 1800 655 588

East Coast 1300 650 659

OPERATION & INSTRUCTION MANUAL

2

Thank you very much for purchasing a CROMMELINS™ CHIPPER GTS1300. This manual

covers operation and maintenance of the CROMMELINS™ CHIPPER GTS1300. This

CROMMELINS™ CHIPPER GTS1300 can be used by arbor industries, landscaping, councils,

hire industries and general use.

Please take a moment to familiarise yourself with the proper operation and maintenance

procedures in order to maximise the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at anytime.

Due to constant efforts to improve our products, certain procedures and specifications

are subject to change without notice.

When ordering spare parts please have handy your products model number and serial

number. Record these numbers in the boxes below for future reference.

Please fill in the following blanks after checking the production number and serial

number on your product. (The location of these numbers, vary depending on product).

SERIAL NO.

MODEL NO.

3

CONTENTS

1. General

1.1 Safety & Environment 4

1.2 Personal Safety 4

1.3 Explanation of the warning signs 5

2. Using the chipper

2.1 Safety and Technical remarks 6

2.2 Starting the chipper 6

2.3 Using the chipper 7-8

2.4 Transporting 8

3. Maintenance of the chipper and checks

3.1 Removing the input tube 9

3.2 Replacing and adjusting the belts 9

3.3 Changing the engine oil 10

4. Problems, causes and solutions 10

5. Technical specifications 11

6. Parts Diagram 11

7. Spare Parts List 12

8. Spare Parts List Continued 13

9. Warranty 14

4

1. GENERAL

1.1 Safety & Environment

The chipper should be used only by an adult who fully understands the users manual and

the way the machine works.

See that the machine stands horizontal and check the tyre pressure regularly (minimum

22psi, maximum 28psi).

Mark off an area at least 3 meters wide and 12 meters long on the output side. While

chipping, the users must take care that no-one can get hurt by chips flying out. Use

re/white ribbons for mark the danger zone.

See that no-one and no animals are within a zone of 12 meter around the machine.

Remove the key from the ignition switch when:

The chipper is left unattended.

The chipper is being maintained or worked on.

Covers and/or input/output tubes are being removed.

Maintain the chipper regularly (see chapter “Maintenance of the chipper and checks”)

1.2 Personal Safety

Wear personal safety devices at all times when using the chipper. In use, the machine

makes more than 90 dBA and therefore it is compulsory to wear ear protection.

There is risk of hearing damage otherwise!

Do not wear any loose clothes, or clothes with strings or ties.

Use the chipper only in the open air.

The GTS1300 is made only for chipping newly cut wood having a maximum diameter of

75mm. It is prohibited to feed any other material into the machine (e.g. metal, stones,

plastics or any other material). If you wish to chip roots, clean the roots from sand,

earth, stones or other debris.

Every use different from that described above discharges the manufacturer from any

responsibility.

Fill the fuel tank in the open air only. Use a jerry-can with a flexible hose. Use only unleaded

petrol.

5

Every time you want to use the machine, check beforehand that machine is working

properly and replace any faulty or worn parts immediately.

Check the following before every use:

Loose bolts and nuts

Damaged rubber flaps in the input tube –change them if they are damaged or

worn

Oil level in the engine

Cracks in the plating and/or failed welding

Cracked or damaged wiring

Be sure the chipper has been maintained properly. Damage or harm caused using faulty,

worn or not original parts are not within the manufacturer’s responsibility.

Keep your face and body as far as possible from the input tube. While feeding the

machine do not stand higher than the bottom of the wheels.

Never service the machine before having switched off the ignition and remove spark

plug cap.

Never tilt the machine while the engine is still running.

Replace warning signs if damaged or not sufficiently legible.

1.3 Explanation of the warning signs

Sticker 1: Watch out: danger! –read the users’ manual carefully – Danger of flying

chips –Keep a sufficient distance (12 meters) away –Risk of severe cuts

and wound –Risk of getting stuck.

Sticker 2: Danger of flying chips –Keep a sufficient distance away from the machine

(12 meters).

Sticker 3: Risk of severe cuts and wounds –Risk of getting crushed.

Sticker 4: Read the users’ manual carefully – Wear safety goggles, ear protection

and safety gloves.

Sticker 5: CE –sticker

Sticker 6: Hot surface –Risk of burns

6

2. USING THE CHIPPER

2.1 Safety and Technical remarks

The machine must be prepared and operated according to the following instructions:

When fitting the blades, the bolts must be tightened by a torque wrench (70Nm for

the cutting blades (nr. 19 on the spare parts drawing) and 40 NM for the counter

blade (nr. 15 on the spare parts drawing) and locked with Loctite 243! Check the

tension on the bolts once again after one hours work.

Before starting the engine, check that the input tube is empty. If not, clean the input

tube with a stick or a long handled implement.

Keep hands, limbs or clothes away from the input tube, the output tube or moving

parts.

See that you keep a good balance and stand firm at all times. Do not lean over the

machine.

Keep away from the output zone while working with the machine.

If the blades hit a foreign object (anything except wood) or if the machine starts

making unusual noises and/or shaking unusually, you must switch off the machine at

once to stop the blades rotating. Switch off the engine and take the machine to the

recommended dealer.

If the machine gets jammed, you must switch off the machine and wait until the

blades stop rotating.

It is obligatory to wear safety gloves, ear protection and safety goggles (fig 4).

This machine is solely intended for use in the open air. Also avoid working

in open spaces where exhaust fumes might collect.

The machine should be used by one, preferably the same, person only.

Never put your hands into the input tube, until the switch has been turned

off, the blades have come to a stand-still.

Pieces of wood lying crosswise in the input tube should only be removed when the

blades have stopped. In case the rotor is blocked by a piece of wood: remove the

ignition key, dismount the cover on the bearing housing of the rotor shaft and turn

the rotor is blocked by a piece of wood: remove the ignition key, dismount the cover

on the bearing housing of the rotor shaft and turn the rotor a few degrees by means

of the specially made spanner for this purpose. Then remove the cross-lying piece of

wood with another stick or implement DO NOT PUT YOUR HANDS IN THE ROTOR.

(fig. 6, 7 and 8).

7

Never leave the machine running unattended.

Stop the engine and remove the key from the ignition switch before replacing the

blades or the counter blade.

Check after one hour’s work that all bolts, nuts and screws are tight. If not, tighten

them or consult your dealer.

Always use original spare parts otherwise your warranty will be voided.

The machine should be repaired only by a service agent/dealer authorised by the

manufacturer.

2.2 Starting the chipper

Before starting the machine, always respect the instructions on Safety & Environment

(see chapter 1.2)

2.3 Using the chipper

Start the engine and let it warm up at 1/3 throttle for 1 minute. Then put the engine at full

throttle. Consult the engine manual on how to switch on the engine properly and the

correct use of the engine in the separate engine manual (fig. 9 and 10)

Put the branches into the input tube and when these are pulled in let go the branches. The

branches will be pulled in automatically. Feed thick branches in see that the engine revs are

maintained. Cut side branches thicker than 3cm off from the main branch and feed them

into the machine separately. Long branches could lash into your face, so keep at a distance

and always wear face protection.

PAY ATTENTION TO THE FOLLOWING REMARKS:

Do not hesitate to use the emergency switch (fig. 11) in case of emergency. For switching

off the machine normally, the engine should be allowed to idle first and then the key switch

should be put in the “0” or “Off” position.

The output tube must be tightly bolted on the machine at all times, so chips cannot be

slung away and nobody can get harmed.

TIPS WHILE CHIPPING

The hardness of the wood depends on the wood type, the time between pruning and chipping and

how dry the branches are. The machine performs best if the branches are chipped right after pruning.

8

Always check that the two bolts at the bottom of the input tube are securely tightened (fig.

12 & 13), if you wish to stop chipping allow the machine to run for several minutes to chip

and eject all debris which otherwise can jam the rotor when you next want to start the

machine.

2.4 Transporting

Before you move the machine, shut off the engine, remove the key from the switch and

remove the cap from the spark plug.

3. MAINTENANCE OF THE CHIPPER AND CHECKS

Before checking and servicing the machine, switch of the engine, remove the key from the

switch and remove the cap from the spark plug.

When cleaning the machine with a high pressure cleaner, never spray on the bearings. It

could damage the bearings and the machine, thereby void the warranty.

Grease/oil bearings, blades and rotor against corrosion before storing the machine.

Block the rotor with the special spanner on the axle of the rotor before servicing/working

on the rotor. Do test the emergency switch regularly.

Check the tire pressure and keep it at the right pressure (minimum 22psi, maximum 28psi).

Engine maintenance: please consult the engine manual (Subaru EX40DU) of the engine

manufacturer.

The chipper has parts weighing more than 20kg. Handling these parts should always be

done by two people to avoid risk of injury.

Parts heavier than 20kg:

Rotor housing +/- 27kg

Input tube +/- 29kg

Engine +/- 32kg

Rotor +/- 24kg

9

3.1 Removing the input tub

First remove the output tube by un-tightening the 2 Allen-screws (picture 1.1 & 1.2).

Then remove the Allen-screws from the input tube (picture 1.3). Tilt the input tube

backwards carefully (picture 1.4). Be aware that the machine could lose its balance –if

need be support the frame at the bumper (picture 1.5). If the input tube is tilted

backwards, it can be removed from the machine sideways (picture 1.6). Mount the input

tube by following the same steps in reverse order.

3.2 Replacing and Adjusting the belts

Remove the key from the switch before changing the belts.

Remove the cover from the belt housing. Loosen slightly the bolt that fixes the belt

housing to the rotor housing (picture 2.1).

Unscrew the bolts fixed horizontally to the engine (picture 2.2) Loosen slightly the bolts

that fix the engine on the chassis (picture 2.3).

Move the engine block to the back. Check that the belt housing is moving in the same

direction. Now it is simple to remove the old belts and to fit the new ones. Note that

once the belts are removed, it is easy to check the distance between blades and counter-

blades, because the rotor can turn freely.

Only use belts with the correct power transmission rating!

Tension the belts by moving the engine block forwards and, once the correct belt

tension is found, block the engine position by screwing tight the 4 bolts to the chassis.

Once you have got the right tension, check that the pulleys are in-line. You can see this

by holding a bar against the pulleys (picture 2.4 above). You have reached the right

tension when the belt can be pulled down +/- 6cm (2.5 inches).

When new belts are fitted the distance between pulley spindles should be +/- 730mm.

Check after tensioning the belts that the pulleys are in-line again. Check that all bolts are

tightened properly, especially the bolt holding the belt housing to the rotor housing. Put

the cover for the belt housing back in place and mount the input and output tubes.

After changing the belts, let the machine run for 5 minutes without load. While running

without load, check the machine for loose bolts, unusual noises or vibrations. Now the

machine is ready for use.

10

3.3 Changing the engine oil.

Change the engine oil at the recommended interval see engine user manual for

instructions. Fill the engine with SAE30 engine oil. Use funnel to avoid spillage.

4. PROBLEMS, CAUSES & SOLUTIONS

PROBLEM

CAUSE

SOLUTION

The shredder does

not perform

properly: the

wood is not pulled

in by the rotor

itself

The chips do not

have the same

size

- The blades are worn too much

- The diameter of the branches

inserted into the machine is too

large

- There is too big a gap between

the fixed blade and the counter

blade: correct gap is 0.5mm (half a

millimetre)

Reverse, sharpen or change the blades.

Remove branches thicker than 75mm.

Adjust the gap between fixed blade: and

counter blade: the correct gap is 0.5mm.

The engine does

not start/ the

engine shut off by

itself

- Electrical problem with engine

- No fuel

- No or not enough oil in the

engine (the oil should be level with

the threads of the filler hole).

Check that the start-switch on the engine is

on “on” or “I”.

Check if the emergency switch is de-activated

Check oil and fuel levels

Contact your dealer

The machine jams

during use

The engine will

not start/turn

because the rotor

is jammed

- the diameter of the branch is too

big

- there are unacceptable materials

such as stones or metal in the

input tube

Shut off the engine and remove the key from

the start switch. Remove the cap from the

rotor-axle. Turn the rotor a few degrees

counter-clock-wise by means of the special

spanner. Block the rotor by blocking the

special spanner on the rotor axle behind the

wheel axle. Remove material from the input

tube by means of a stick or tool and start the

machine again. If need be, change the

blades.

NEVER PUT YOUR HAND INTO THE INPUT

TUBE OR ROTOR

The machine does

not throw out

chips any more.

The output tube is

jammed

Too much wet material (leaves,

grass, rotten material) has been

fed into the machine

Shut off the engine, remove the spark plug

cap. Block the rotor-axle by blocking the

special spanner behind the wheel axle.

Dismount/remove the output tube.

Do not touch the blades, even if you are

wearing gloves! There is a high risk of cutting

your hands badly. Remove debris with a stick

or tool. Mount the output tube again, tighten

the screws firmly. Remove the special

spanner from the axle.

Fit the cap on the rotor axle. Start the engine

again.

11

6. PARTS DIAGRAM

5. TECHNICAL SPECIFICATIONS

GTS1300 Powered by a SUBARU EX40 14hp engine

Maximum RPM 3600

Dimensions –150L x 75W x 152H cm

Weight –165kg

Chipping system: 2 blades on rotor and 1 counter blade on chassis

12

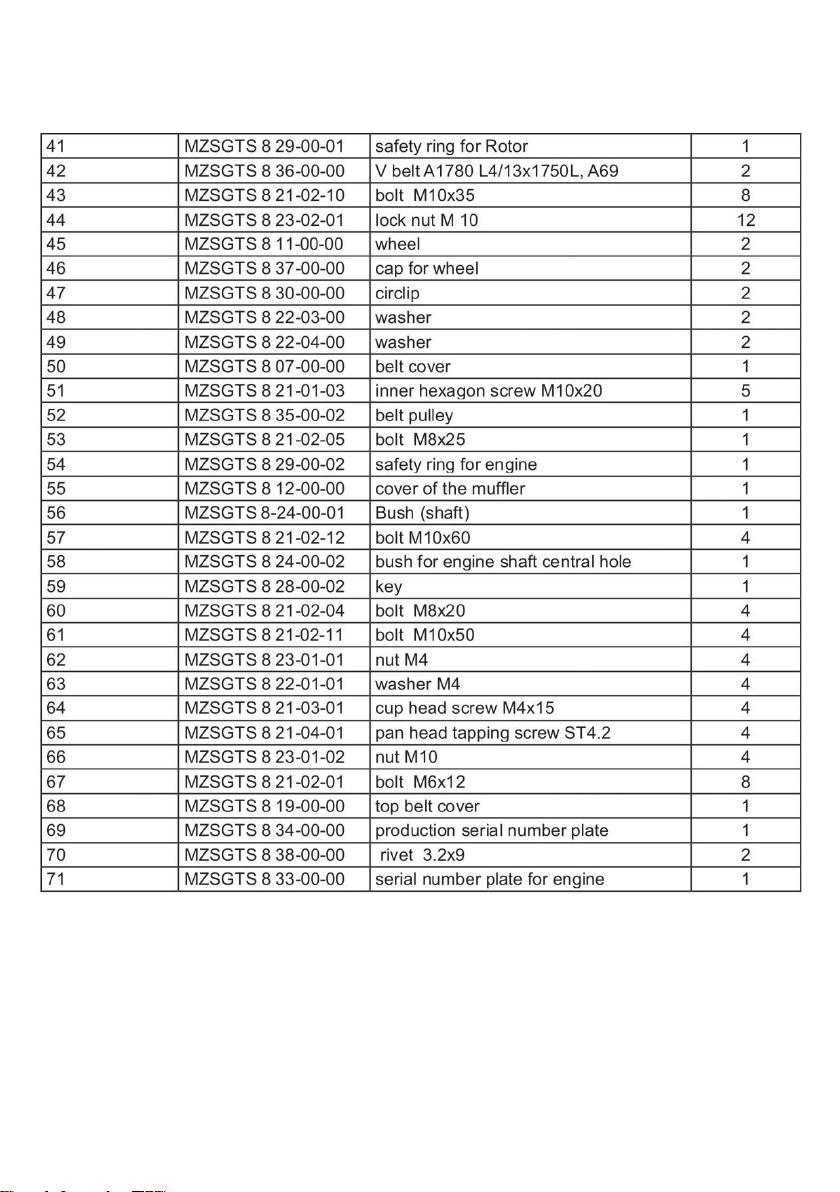

7. SPARE PARTS LIST

13

8. SPARE PARTS LIST

14

9. WARRANTY

Consult the CROMMELINS Machinery warranty leaflet (supplied with your new product)

for full details and a list of service dealers for this product, also available online at

www.crommelins.com.au.

15

NOTES

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

.................................................................................................................................................

16

Table of contents

Popular Chipper manuals by other brands

TruYard

TruYard C150 Safety, operation & maintenance instructions

hillvert

hillvert HT-HECTOR 212 user manual

Briggs & Stratton

Briggs & Stratton CH8993H owner's manual

DK2 Power

DK2 Power OPT118 Assembly guide

AGRI EASE

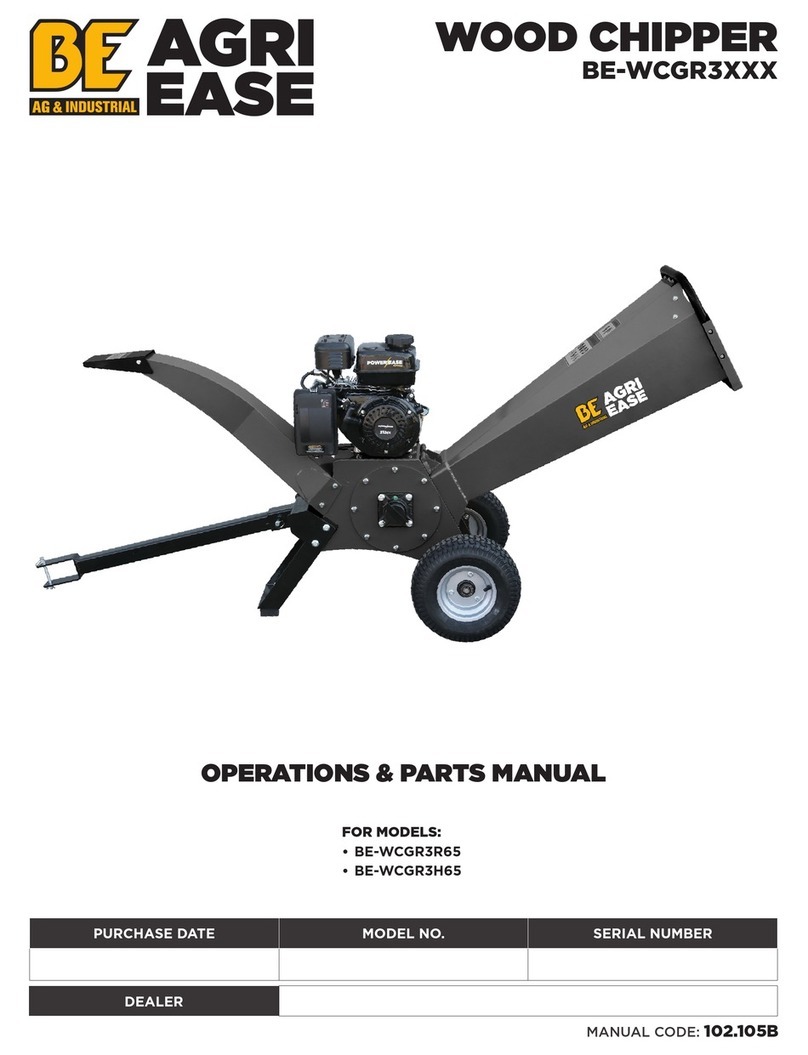

AGRI EASE BE-WCGR3 Series Operations & parts manual

hillvert

hillvert HT-HECTOR 420T user manual

DR

DR 18 HP Safety & Operating Instructions

Hansa

Hansa C65RX Operation, maintenance and safety manual

Electrolux Professional

Electrolux Professional CF4 instruction manual

Farmi Forest Corporation

Farmi Forest Corporation 100F OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Sioux Tools

Sioux Tools 5264 instructions

hillvert

hillvert HT-HECTOR-6600 user manual