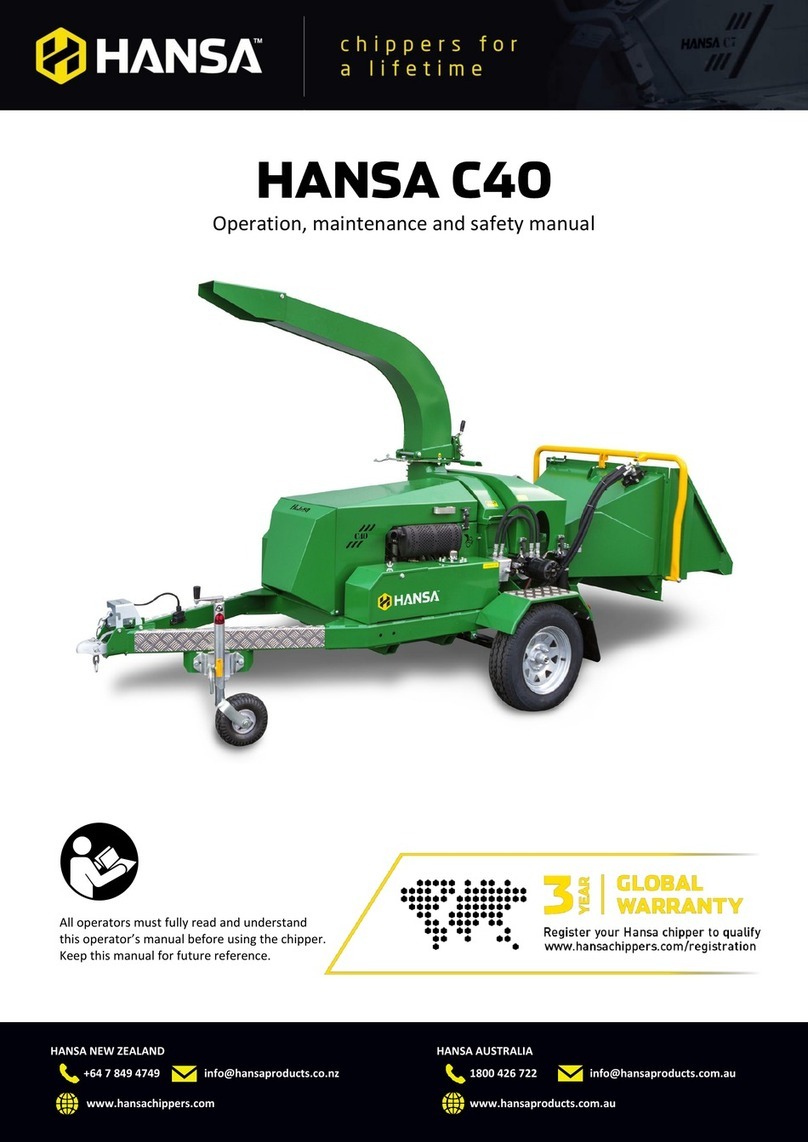

Hansa C3e User guide

HANSA NEW ZEALAND

+64 7 849 4749 info@hansaproducts.co.nz

www.hansaproducts.co.nz

HANSA AUSTRALIA

1800 426 722 info@hansaproducts.com.au

www.hansaproducts.com.au

Operation, maintenance and safety manual

All operators must fully read and understand

this operator’s manual before using the chipper.

Keep this manual for future reference.

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

TABLE OF CONTENTS

SAFETY .........................................................................................................................................................................................1

OPERATOR COMPETENCY.........................................................................................................................................................................1

AMBIENT CONDITIONS............................................................................................................................................................................ 1

WORK AREA SAFETY ...............................................................................................................................................................................1

ELECTRICAL SAFETY.................................................................................................................................................................................1

PERSONAL SAFETY..................................................................................................................................................................................1

MACHINE USE AND CARE.........................................................................................................................................................................2

SERVICE ...............................................................................................................................................................................................2

IDENTIFYING HAZARDS AND RISKS ..............................................................................................................................................................2

WHAT CAN MY HANSA CHIPPER PROCESS?..................................................................................................................................3

INTENDED USES OF THE CHIPPER ...............................................................................................................................................................3

RECEIVING YOUR HANSA CHIPPER ...............................................................................................................................................4

CHIPPER COMPONENTS...........................................................................................................................................................................4

ASSEMBLING YOUR CHIPPER........................................................................................................................................................5

ATTACH THE WHEELS ..............................................................................................................................................................................6

FIT THE INLET CHUTE............................................................................................................................................................................... 7

ATTACH THE (OPTIONAL)CHIP CATCHER BAG ...............................................................................................................................................8

OPERATION..................................................................................................................................................................................8

SAFE SETUP PROCEDURE..........................................................................................................................................................................9

SAFE OPERATING PROCEDURE...................................................................................................................................................................9

POWER SUPPLY ...................................................................................................................................................................................10

START/STOP.......................................................................................................................................................................................11

TRANSPORTATION ..................................................................................................................................................................... 12

STORAGE.................................................................................................................................................................................... 12

TROUBLESHOOTING................................................................................................................................................................... 12

WHAT TO DO IF:.................................................................................................................................................................................. 12

MAINTENANCE........................................................................................................................................................................... 13

KNIFE RE-SHARPENING AND KNIFE REPLACEMENT .......................................................................................................................................13

REMOVE THE KNIFE FOR SHARPENING ......................................................................................................................................................14

SHARPEN THE KNIVES............................................................................................................................................................................ 15

REINSTALL THE KNIVES .......................................................................................................................................................................... 15

BOLT TORQUE .....................................................................................................................................................................................18

SPECIFICATIONS ......................................................................................................................................................................... 18

DECALS....................................................................................................................................................................................... 19

HANSA CHIPPER INDUSTRIAL LIMITED WARRANTY.................................................................................................................... 20

COMMISSIONING CHECKLIST AND REGISTRATION ..................................................................................................................... 20

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

1

Safety

Preventing accidents is the responsibility of every equipment operator. The operator is responsible for any accidents or hazards

occurring to people or their property. Ensure every operator is familiar with the safe operation procedures and controls of the

machine, how to identify hazards, and the steps required to avoid injury while handling and operating the chipper. Relevant

information is contained in this manual.

Do NOT modify the design of the chipper.

Operator competency

Ensure that every person operating the chipper understands and follows the safe operating and maintenance procedures

as detailed in this manual.

Do NOT allow persons below the age of 18 to operate the chipper. Additionally, local regulations may restrict the age of

the operator.

Do NOT allow persons with reduced physical, sensory or mental capabilities, or lack of experience and knowledge to

operate the machine.

Ambient Conditions

Only use the C3e in an environment that is between -5°C and 40°C. Do not use the C3e in the rain or in wet environments.

Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate machines in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Machines

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a machine. Distractions can cause you to lose control.

Electrical safety

a) Machine plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded)

machines. Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or grounded.

c) Do not expose machines to rain or wet conditions. Water entering a machine will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the machine. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a machine outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a machine in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a machine. Do not use a machine while you are

tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating machines may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety

shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack,

picking up or carrying the machine. Carrying machines with your finger on the switch or energising machines that have the switch

on invites accidents.

d) Remove any adjusting key or wrench before turning the machine on. A wrench or a key left attached to a rotating part of the

machine may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the machine in unexpected

situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts. Loose clothes,

jewelry or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-related hazards.

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

2

h) Do not let familiarity gained from frequent use of machines allow you to become complacent and ignore machine safety

principles. A careless action can cause severe injury within a fraction of a second.

Machine use and care

a) Do not force the machine. Use the correct machine for your application. The correct machine will do the job better and safer at

the rate for which it was designed.

b) Do not use the machine if the switch does not turn it on and off. Any machine that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the machine before making

any adjustments, changing accessories, or storing machines. Such preventive safety measures reduce the risk of starting the

machine accidentally.

d) Store idle machines out of the reach of children and do not allow persons unfamiliar with the machine or these instructions

to operate the machine. Machines are dangerous in the hands of untrained users.

e) Maintain machines and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other

condition that may affect the machine’s operation. If damaged, have the machine repaired before use. Many accidents are

caused by poorly maintained machines.

f) Keep cutting machines sharp and clean. Properly maintained cutting machines with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the machine, accessories and machine bits etc. in accordance with these instructions, taking into account the working

conditions and the work to be performed. Use of the machine for operations different from those intended could result in a

hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow

for safe handling and control of the machine in unexpected situations.

Service

a) Have your machine serviced by a qualified repair person using only genuine replacement parts and accessories. This will ensure

that the safety of the machine is maintained.

Identifying hazards and risks

Identify hazards and risks, and take preventative steps to avoid accidents and minimise risk. Possible hazards include, but are not

limited to, moving parts, thrown objects, weight of chipper and components, and the operating environment.

Below is a list of hazards and actions required to prevent injury.

Hazard

Risk

Corrective action

Dust

Injury or irritation of the

eyes

Respiratory irritation

Wear safety glasses

Process freshly cut materials and/or wear a dust mask

Electric cable

Electric shock

Ensure you use a residual current device (RCD). Ensure power

supply cords are in good condition

Cutting rotor and knives

Pinching, crushing,

cutting, severing

Keep your face and body out of the inlet chute

Do not extend hands/arms past the rubber flap

Use a stick to push materials into the inlet chute

Do NOT push the stick beyond the rubber flap

Sound

Damage to hearing

Always wear hearing protection when operating the machinery

Discharge material

Eye injury, minor cuts

Always wear safety glasses when operating the machinery

Do NOT put body parts in front of the outlet chute

Do NOT put the machinery in a place where the outlet

chute is directed on a hard surface

Feeding material

Cuts and scrapes

Wear safety gloves

Wear tight fitting long sleeves and pants to cover bare skin when

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

3

operating the machinery

Weight of the chipper

Straining, crushing

Place the machinery on firm level ground

What can my Hansa chipper process?

Intended uses of the chipper

The Hansa C3e chipper is built to process organic material including wooden branches not exceeding 40 mm in diameter. It is

designed for intermittent use by the suburban gardener. Do NOT use the chipper for any other purpose.

Organic wastes include:

Prunings, stalks, roots, vegetable matter, hay, grass, bark

Dry manure

Branches

Palm fronds

Dead and hard timbers (Note: these will dull the knives faster)

Paper or cardboard

Do NOT process:

Bones

Soil, root balls, sand, grit, stones, metal

If you have any questions, contact your authorised dealer.

Do NOT exceed 40 mm branch diameter

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

4

Receiving your Hansa chipper

You may receive your chipper assembled from your dealer or it may be packaged in two boxes. Assembly takes approximately 30

minutes, two people working together will make the assembly easier.

Chipper components

Note: Your Hansa C3e may not come with the chip catcher bag. The chip catcher bag must be purchased separately.

Tools required for assembly (not supplied)

•A knife to cut open the box

•Two 13 mm spanners - to tighten the inlet chute and wheels

•18 mm spanner to attach the wheels

Box 1 contains:

✓The chipper body

✓Two wheels

✓A cardboard block for support of the chipper body for wheel attachment

CAUTION: The chipper body weighs 42 kg; it is recommended to cut the box open rather than lifting the body out.

Box 1

Box 2

All the C3e parts in two separate boxes

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

5

Box 2 contains:

✓The inlet chute

✓A fastener pack containing parts required for assembly

✓Documentation (Hansa operations manual, warranty card and Honda motor manual)

Item no.

Fastener pack contents (in box 2)

1

Two bolts to attach the inlet chute.

2

Two heavy washers to attach the inlet chute.

3

Two spring washers to attach the inlet chute.

4

Two nuts to attach the inlet chute.

Wheels and cardboard block

Chipper body

Contents in box 2

Inlet chute

Documentation

Fastener pack

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

6

Assembly

Attach the wheels

It is recommended but not required to place a cardboard block (or suitable alternative) underneath the chipper

body - this makes it easier to attach the wheels.

Insert the axle shaft through the wheel, then slide the

washer on.

Slide the axle shaft through the holes in the base of

the chipper body.

Screw the nyloc nut onto the end of the axle shaft.

Tighten the axle shaft using an 18 mm and 13 mm

spanner.

111

2

3

4

Axle shaft

Washer

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

7

Fit the inlet chute

Fix the inlet chute –Slide the tab at the base

of the inlet chute over the tab at the top of

the rotor housing. Adjust the inlet chute

until the holes at the back of the rotor

housing line up with the holes on the back of

the inlet chute.

Line up the holes and insert the bolts (item no. 1),

heavy washers (item no. 2), spring washers (item no.

3), and nuts (item no. 4). Ensure that the heavy

washer is touching the chipper body (top) and the

spring washer is touching the nut (bottom).

5

6

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

8

Attach the (optional) chip catcher bag

Hook the lower bar of the chip catcher bag into the

slot underneath the outlet chute.

Slide the top bar of the chip catcher bag up and over

the hooks on the top of the outlet chute.

This is how it should look when properly attached. To

remove the chip catcher bag, repeat steps 7 and 8 in

reverse order.

Operation

The chipper is self-feeding and has a large inlet opening. It can process:

•Prunings, stalks, vines, leaves, roots and vegetable matter, paper and cardboard

•Freshly cut material is better to process than dry material

•Maximum capacity is 40 mm diameter branches

It is helpful (but not required) to keep a wooden stick handy, approx. 50 mm diameter x 600 mm long for:

•Pushing in short, brushy and very leafy materials

•Keeping the inlet chute clear

7

8

9

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

9

Safe setup procedure

Before you start:

Ensure the chipper is positioned in an open area and on firm level ground.

Ensure the outlet chute is discharged onto soft ground (e.g. grass)

Do NOT allow the outlet chute to discharge chip onto hard surfaces (such as paved or gravel surfaces)

Ejected material can rebound and cause injury

Keep children, pets, and spectators clear of the work area at all times

Do NOT operate the chipper where there is a hazard to onlookers

Do NOT allow any person under the age of 18 to operate the chipper

Check:

That all screws, nuts, bolts, and other fasteners are properly secured

That the power source has an RCD

That the supply and extension cord are in good condition with no nicks or abrasions

That the inlet chute and housing are clear of any leftover material

That all chipper components are in place and in good condition

If any parts are worn or damaged, contact Hansa for replacements

That all labels are in good condition and easily legible

Replace damaged or unreadable warning labels

View photos of labels in the ‘Decals’ section

Safe operating procedure

Wear safety equipment: Safety glasses and hearing protection must be

worn at all times

Wear work gloves: Wearing work gloves is optional but highly

recommended - ensure that the gloves fit tightly

Tie long hair up

Long hair could be pulled into the chipper

Wear clothes that sit tightly

Avoid wearing scarves or any item that can get caught in the chipper

Wear substantial footwear and long trousers while operating the machine

Do NOT operate the machine when barefoot or wearing open footwear

Keep your face and body away from the inlet chute

Stand clear of the discharge zone, even when no material is being fed into the machine

Keep proper balance and footing at all times and stand at the same level as the chipper

Do NOT overreach

Do NOT run near the machine

Feed only freshly cut material into the chipper

Do NOT feed in materials covered in gravel, stones and dirt as this can rebound, injure the operator and damage

the machinery

Prune to a size that suits the chipper’s capabilities

Pre-cut side branches

Branches will ‘self-feed’ more efficiently

Keep the motor clean of debris and other accumulations

Doing so reduces the risk of fire and prevents damage to the motor

Feed limbs and branches through butt end first, leaving the foliage on

This helps guide the limb down the inlet chute

It reduces spinning and the occurrence of ejection of small pieces back up the inlet chute

Hold larger branches back and feed the chipper with care until you are familiar with its capacity

The motor will slow down or stall if the branch is too large

Feed longer pieces together with short stubby pieces

Feed soft materials intermittently with branches

The wood chips tend to clean out any soft residue left in the chipper

The chipper can clog up with soft, wet or fibrous materials

Keep the outlet free of blockage

DO:

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

10

If a blockage occurs, turn the motor off, disconnect the power supply and wait for rotor to stop spinning. Attempt

to free any blocked material via the outlet opening

Be mindful of the sharp knife inside the housing while doing so

As the discharge material piles up

Move the chipper to direct the outlet chute away from the pile, or move the processed material

to avoid blocking. Ensure the chipper is turned off before moving

Turn the motor off and disconnect the power supply before removing/attaching the optional bag attachment

Turn the motor off and disconnect the power supply whenever you leave the work area

Operate the chipper wearing loose clothing and untied long hair

Operate the chipper with the motor electrical enclosure open

Stand at a higher level than the base of the chipper when feeding material into it

Use the chipper in wet weather conditions

Process old materials such as dried wooden branches

They get very hard and springy when dried out

They are more awkward to handle

The knives dull much quicker

Feed short, stubby pieces of wood into the chipper

They bounce and spin in the inlet chute

Feed short stubby pieces together with longer pieces

Put soil, sand, grit, stones, glass, pieces of metal or other foreign objects into the chipper

This will damage the sharp edge of the cutting knives and can rebound and injure the operator

Put root balls and dead wood into the chipper

This dulls the knives quickly

Overload the chipper by feeding too much material

The motor operates optimally at high RPM. Overloading the chipper can result in damage to the motor. Never

overload the chipper

If you can hear the motor starting to slow down, wait for the motor speed to recover and feed the material in

slower

If the speed of the motor is dropping more so than usual when feeding material, check if there are any blockages

in the housing, and check the condition of the blade.

Allow processed material to build up in the discharge area as this can:

Prevent proper discharge

Result in kickback of material through the feed opening

Transport the chipper while the motor is running

Remove the catcher bag while the motor is running

Operate the chipper with blunt knives

This causes excessive vibration which may result in damage to the chipper

Move or tilt the chipper while it is running

Touch any guards or stick hands between guards while the machine is on or connected to a power supply

Put hands or any other part of the body or clothing:

Inside the feed chute past the rubber flap

Inside or near the opening of the discharge chute

Leave the chipper on while it is unattended

Power supply

The C3e requires a 220-240V AC 50Hz earthed power connection. The C3e is rated at 8.4 A. It is recommended that the C3e is only

connected to a power socket which is protected by a circuit-breaker that would activate with a residual current not more than 30

mA. It is also recommended that the C3e is always used with an RCD (residual current device) having a rated residual current of 30

mA or less. Always check and test your RCD every time you use it.

DO NOT:

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

11

If extension cords are used, they must meet these requirements:

Rated at 10 A minimum

Minimum conductor cross section is 1.0 mm2

Maximum length of all cords connected must be less than 40 m

Comply with H05VV-F or H07VV-F

Be in good condition

Used away from sharp edges and water

Ensure the power supply cable is kept away from moving hazardous parts

Ensure the power supply cable is kept away from any sources of water

If the power supply cable becomes damaged, do NOT attempt to operate the chipper

If the power supply cable becomes damaged, do NOT touch the damaged cable unless it has been disconnected from its

power source

Do NOT attempt to repair any damaged cables unless you are competent to do so

Start/Stop

Before proceeding, ensure the ‘safe setup procedure’ has been followed on page 7 of this manual.

Plug the power supply cable into a suitable power socket and press the green power button to start the chipper. To stop the

chipper, press the red stop button. Note that the cutting rotor will take approximately to 30 seconds to fully stop.

Be sure to stop the machine, remove the plug from the socket, and check that all moving parts have come to a complete stop:

-Whenever you leave the machine

-Before clearing blockages or unclogging the chute

-Before checking, cleaning or working on the machine

Processing fibrous material

The C3e can process palm fronds, flax, cabbage tree leaves and other similar fibrous material. The machines cutting disk is

cantilevered (supported on the engine side with two bearings), therefore there is no risk of anything fibrous wrapping around the

shaft and working its way into the bearings. The resulting output is not as consistent as that of branch material due to the fibrous

nature. When processing fibrous material, take note of the following points:

Blades must be sharp to process fibrous material

Fibrous material is best introduced to the machine as a bundle

Fibrous material should be introduced slowly into the machine. Tease the material in and out while feeding it into the

cutting mechanism, ensuring it is not drawn through the machine without being cut properly

Do NOT extend hands past the rubber flap while doing so

Fibrous material is processed more effectively when it is green rather than when dried

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

12

Transportation

The C3e is designed to be moved by one person using both handles at the top of the inlet

chute to lean the chipper backwards and transfer its weight onto the wheels. The chipper

can then be wheeled to and from the work location. The chip catcher bag should be

removed from the chipper when transporting or moving to avoid damage to the bag.

Take care when moving the C3e up and down stairs or kerbs

The wheels can be damaged by the shock loading caused by uncontrolled

ascent/descent

The chipper is heavy and the operator can lose control of the machine

Do NOT move the chipper while it is running

Storage

Always allow the chipper to cool before storing

Store the chipper out of the reach of children

Store the chipper out of the rain

Water can rust the steel body of the chipper

Troubleshooting

What to do if:

The chipper won’t start

•The power source might be switched off

Check that the power supply cable is plugged in and switched on

Check that the power supply cable is undamaged

Do NOT attempt to use the chipper if the cable is damaged.

The chipper slows down and stalls

•The chipper is clogged up

Turn the motor off, disconnect the power supply, ensure that the cutting rotor has completely stopped,

then remove debris/empty chip catcher bag

Discharge slows down

•The chipper is clogged up

Turn the motor off, disconnect the power supply, ensure that the cutting rotor has completely stopped,

then remove debris/empty chip catcher bag

The chipper is slowing down

•The chipper can’t process the amount of material fed into it

Feed the material in slower

Reduce material volume

The chipper will not self-feed

The knife and/or anvil might be blunt

Inspect and sharpen or replace the knife and/or anvil as required. Ensure correct clearances between

the knife and anvil

The material is ejected in long strips

•The knife and/or anvil might be blunt

Inspect and sharpen or replace the knife and/or anvil as required. Ensure correct clearances between

the knife and anvil

The chipper is clogged

Turn the motor off, disconnect the power supply, ensure rotor has completely stopped and remove

debris. You may need to disassemble the housing in order to remove the debris. See step 10 of ‘Remove

Handles

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

13

the knife for sharpening’ on page 15 for more details on this process

The chipper starts making unusual noise, the cutting rotor strikes a foreign object or the chipper starts to vibrate

Turn the motor off, disconnect the power supply, ensure that the cutting rotor has completely stopped,

then inspect for damage

Replace or repair any damaged parts

Check for and tighten any loose parts

Do NOT attempt to repair the chipper unless you are competent to do so

Maintenance

Maintain the chipper with care and keep it clean at all times.

To service or inspect the equipment, or to change an accessory, you must:

✓Switch the motor off and unplug the power supply cable

✓Allow the chipper to cool before any inspections or adjustments are made

✓Wait until the cutting rotor and motor are at a complete standstill before opening the cutting rotor housing

Initially after 2 working hours:

✓Check for any loose nuts and bolts

Every 20 working hours:

✓Check for any loose nuts and bolts

✓Check the sharpness of the knife

Knife re-sharpening and knife replacement

How do I know that the knives need re-sharpening?

Chipper loses its self-feeding action with blunt knives

Material has to be pushed in

Material comes out in long strips

How to re-sharpen the knives:

If you don’t have a surface grinder or are unsure how to re-sharpen the knives, contact a professional saw doctor or Hansa to

arrange re-sharpening.

Tools and materials required for re-sharpening (approx. 40 mins):

•2 x 13 mm spanners

•2 x 16 mm spanners

•6 mm hexagonal Allen key

•Nylon hammer (recommended)

•Surface grinder

•Coolant

WARNING! Do NOT operate your chipper with blunt knives.

Blunt knives will cause excessive vibration

Blunt knives result in damage to the chipper

WARNING! Be careful when working around the sharp knives. Be aware that even though the power source is

unplugged, the cutting means can still move.

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

14

Remove the knife for sharpening

Remove the inlet chute - use two 13 mm spanners to

remove the nuts and bolts holding the inlet chute on.

Tilt the chipper body so that the motor is resting on the

floor. Using a 13 mm spanner, remove the two smaller

bolts which hold the base onto the chipper body.

Open the cutting rotor housing by removing the four

housing bolts using two 16 mm spanners.

Using a nylon hammer (or suitable alternative), gently

dislodge the housing from its grooves and remove it.

1

2

3

4

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

15

Use a 13 mm spanner to remove the knives from the

rotor. There are three nuts you must remove to do so.

If the bolt head turns, hold it with a 6 mm

hexagonal Allen key

Note: Do NOT try to loosen the bolt with the

hexagonal Allen key

Measure the width of the knife and check that it will be

at least 35 mm after sharpening.

If the knife will be shorter than 35 mm, then the knife

should be replaced. Please contact your nearest Hansa

dealer.

Sharpen the knives

Sharpen the knives on a surface grinder. A cutting

angle of 40° is critical for the performance of the

chipper. Make sure plenty of coolant is used when

grinding to avoid softening of the steel knives.

Reinstall the knives

Clean all mounting surfaces and remount the knife in the reverse procedure. Tighten all three nuts as tight as

possible by hand using a 13 mm spanner and 6 mm hexagonal Allen key. Do NOT tighten the bolts with the

hexagonal Allen key.

Note: When the knives are sharpened, material is removed from the knives, affecting the distribution of weight in

the rotor. The rotor must be balanced appropriately after knife sharpening, as per the method outlined below:

5

6

MIN 35 mm

7

8

40 °

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

16

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

17

Adjust the anvil at this stage as the

location of knife edge will change after

sharpening or replacement.

The anvil is reversible. Normally the edge

will last for over 200 operating hours.

When the edge is dull, it can be reversed.

When both edges are worn, the anvil

should be replaced (contact Hansa for a

replacement).

The clearance between the knife and

anvil should be approx. 1 mm on the

inside closest to the bearing and 3 mm on

the outside closest to the edge of the

rotor (refer to diagram for more detail).

Ensure you are using the outer blade for

calibrating these distances.

The gap between the knives and the anvil

is tapered out slightly to allow for a small

amount of movement in the rotor as it

bites into the wood.

The anvil position can be adjusted by

loosening the anvil mounting bolts. Once

adjusted correctly, tighten the anvil

mounting nuts using a torque wrench to

22 Nm.

If there is not enough clearance, the knife

edge may touch the anvil through

deflection when cutting heavy branches

and damage the sharp edge. Too much

clearance will allow small twigs and

fibrous materials to be dragged through

without being cut.

Turn the cutting rotor by hand to check

that it turns freely.

Reassemble the housing and inlet chute

by repeating steps 1-3 in reverse.

Note: When reassembling the housing,

first align the hooks on the curved wall

with the tabs near the outlet on the

housing front. Once these are aligned

use a nylon hammer (or other suitable

alternative) to hammer the back of the

housing to locate the remaining four

tabs. Do not attempt to do up the

housing bolts until these tabs have been

aligned.

WARNING! Every time the knife clamping bolts are torqued up to 22 Nm and loosened off again, the life of the bolts is

reduced. The knife clamping bolts must be replaced at most after every six sharpens. Contact Hansa for replacement

bolts (m8x25 countersunk bolts of grade 12.9 or higher). Use only genuine Hansa bolts.

9

Bearing

Edge of

rotor

Anvil

Cutting

rotor

Knife

1 mm

clearance

3 mm

clearance

10

Align the

‘hooks’ on

the housing

wall with the

tabs in the

housing back

Align the four

remaining tabs

Hansa C3e O&M Manual - OM-004 Revision H 09/07/2019

© Hansa Chippers 2019

18

Bolt torque

Relative Strength Bolt Marking

4.6

8.8

Recommended Tightening Torque

Recommended Tightening Torque

Bolt size

Spanner size

lb ft

Nm

lb ft

Nm

M8

13 mm

6

8.5

16

22

M10

16 mm

12.5

17

32

44

M12

18 mm

22

30

57

77

M16

24 mm

54

73

140

190

M20

30 mm

105

143

274

372

Specifications

C3e

General

Length

1040 mm

Width

520 mm

Height

1040 mm

Weight

55 kg

Motor

Type

Electric 2.2kW

Power source

Single phase 230-240V AC

50-60 Hz

8.4 A (S1)

Cutting System

Disc speed

2820 RPM

Disc dimensions

260 x 6 mm

Shaft diameter

24 mm

Knives

1

Feed System

Chipping capacity

40 mm

Feed type

Gravity fed, self-feeding

Inlet chute opening

100 x 130 mm

Discharge System

Discharge height

450 mm

Outlet chute type

Fixed

Table of contents

Other Hansa Chipper manuals

Popular Chipper manuals by other brands

TMG

TMG TMG-WC62S product manual

Northern Tool and Equipment

Northern Tool and Equipment Powerhorse 63388 owner's manual

GXi Outdoor Power

GXi Outdoor Power Brush Master owner's manual

Timberwolf

Timberwolf TW 150VTR manual

TruYard

TruYard CM90 Series Safety, operation & maintenance instructions

EarthQuake

EarthQuake 14267 Operator's manual