VMB20XXXXXXXXXXXX-rev1122 VMB20XXXXXXXXXXXX-rev1122

Service & Repair Kits

Parts underlined are only available for sale in kits

Item Part Number Description Qty

1 ** 031.140.000 Air Valve Assembly (Integral Muer) 1

031.141.000 Air Valve Assembly (No Muer) 1

2 095.110.558 Pilot Valve Assembly 1

3 114.024.551 Intermediate Assembly 1

4 115.174.115 Bracket, Foot 2

5 115.177.115 Bracket, Hanging 2

6 132.035.357 Bumper 2

7 135.034.506 Bushing, Plunger 2

8 165.118.551 Cap, Air Inlet 1

9 165.171.551 Cap, Clean Out 2

10 170.018.115 Capscrew, Hex-Hd, 3/8-16 x 1 1/4 4

11 170.069.115 Capscrew, Hex-Hd, 5/16-18 x 1 3/4 4

12 170.129.115 Capscew, Hex-Hd, 3/8-16 x 2 3/4 8

13 170.130.115 Capscrew, Hex-Hd, 3/8-16 x 3 24

14 171.015.115 Capscrew, Flat-Hd, 3/8-16 x 7/8 8

15 171.053.115 Capscrew, Socket-Hd, 3/8-16 x 2 1/2 4

16 171.102.110 CAPSCREW, Socket Hd, 5/16 -18 x .63 16

17 196.217.551 Chamber, Inner 2

18 196.218.552 Chamber, Outer 2

19 286.007.360 Diaphragm, Buna-N 2

286.007.363 Diaphragm, Fluorocarbon FKM 2

286.007.364 Diaphragm, EPDM 2

286.007.365 Diaphragm, Neoprene 2

286.007.354 Diaphragm, Santoprene 2

286.007.356 Diaphragm, Hytrel 2

20 338.016.110 Flap Valve 4

21 360.093.360 Gasket, Main Air Valve 1

22 360.103.360 Gasket, Pilot Valve 1

23 360.104.360 Gasket, Air Inlet Cap 1

24 360.105.360 Gasket, Inner Chamber 2

25 405.013.551 Handle 2

26 518.222.552 Manifold 2

27 535.102.000 Plate, Name 2

28 545.005.115 Nut, Hex 24

29 547.002.110 Nut, Stop 8

30 560.001.360 O-ring 2

31 560.213.360 O-ring, Buna-N 2

560.213.363 O-ring, Fluorocarbon FKM 2

560.213.364 O-ring, EPDM 2

560.213.365 O-ring, Neoprene 2

32 570.009.360 Pad, Wear, Buna-N 2

570.009.363 Pad, Wear, Fluorocarbon FKM 2

570.009.364 Pad, Wear, EPDM 2

570.009.365 Pad, Wear, Neoprene 2

33 570.021.360 Hinge Pad, Buna-N 4

570.021.363 Hinge Pad, Fluorocarbon FKM 4

570.021.364 Hinge Pad, EPDM 4

570.021.365 Hinge Pad, Neoprene 4

35 612.225.552 Plate, Outer Diaphragm (with stud) 2

36 620.007.114 Pin, Plunger 2

37 670.005.110 Retainer, Flap Hinge Pad 4

38 675.059.110 Retainer, Flap Valve 4

39 675.042.115 Ring, Retaining 2

40 675.073.360 Ring Sealing, Buna-N 4

675.073.363 Ring Sealing, Fluorocarbon FKM 4

675.073.364 Ring Sealing, EPDM 4

675.073.365 Ring Sealing, Neoprene 4

Item Part Number Description Qty

Composite Repair Parts List

LEGEND:

= Items contained within Air End Kits

= Items contianed within Wet End Kits

Note: Kits contain components specic to the material codes.

**Air End Kit does not include entire air valves assembly. It includes

replacement sleeve and spool set, plus o-rings.

41 685.059.120 Rod, Diaphragm 1

42 710.021.115 Screw, Pan Head 4

43 720.004.360 Seal, U-cup 2

44 720.076.360 Seal, Clean Out Cap, Buna-N 2

720.076.363

Seal, Clean Out Cap, Fluorocarbon FKM

2

720.076.364 Seal, Clean Out Cap, EPDM 2

720.076.365 Seal, Clean Out Cap, Neoprene 2

45 720.077.360 Seal, Seat, Buna-N 2

720.077.363 Seal, Seat, Fluorocarbon FKM 2

720.077.364 Seal, Seat, EPDM 2

720.077.365 Seal, Seat, Neoprene 2

46 722.137.110 Seat, Flap Valve, Suction 2

(Includes 2X 807.018.110 Studs)

47 722.138.110 Seat, Flap Valve, Discharge 2

(Includes 2X 807.018.110 Studs)

48 807.018.110 Stud 8

49 900.004.110 Washer, Lock 5/16 16

50 901.038.115 Washer, Flat 5/16 4

51 901.048.115 Washer, Flat 3/8 4

52 901.052.115 Washer, Flat 3/8 48

ANSI/DIN Flange Manifold Option

12 170.129.115 Capscrew, Hex-Hd, 3/8-16 x 2 3/4 4

13 170.130.115 Capscrew, Hex-Hd, 3/8-16 x 3 16

53 115.174.552 Bracket, Mounting 2

(Replaces Item #4)

54 170.083.115 Capscrew, Hex-Hd, 3/8-16 x 3 3/4 12

(Replaces Item #12 (4X), & #13 (8X) )

55 518.225.552 Manifold, Flanged 2

(Replaces Item #28)

476.V353.000 Air End Kit

Seals, O-rings, Gaskets, Retainer Rings, Aluminum Sleeve and spool set, pilot valve assembly

476.V353.162 Air End Kit

Seals, O-rings, Gaskets, Retainer Rings, Brass/Stainless Sleeve and spool set, pilot valve assembly

476.V396.360 Wetted End Kit

For Model For Model VMB20FPPB0SS0xxxRA

Buna-N Diaphragms, Hinge Pads, Seals, Wear Pads and Sealing Rings

476.V396.363 Wetted End Kit

For Model VMB20FPPV0SS0xxxRA

FKM (Viton) Diaphragms, Hinge Pads, Seals, Wear Pads and Sealing Rings

476.V396.364 Wetted End Kit

For Model VMB20FPPE0SS0xxxRA

EPDM Diaphragms, Hinge Pads, Seals, Wear Pads and Sealing Rings

476.V396.365 Wetted End Kit

For Model VMB20FPPN0SS0xxxRA

Neoprene Diaphragms, Hinge Pads, Seals, Wear Pads and Sealing Rings

476.V396.677 Wetted End Kit

For Model VMB20FPPR0SS0xxxRA

Santoprene Diaphragms, Hinge Pads, Seals,Wear Pads and Seals

MODEL SPECIFIC

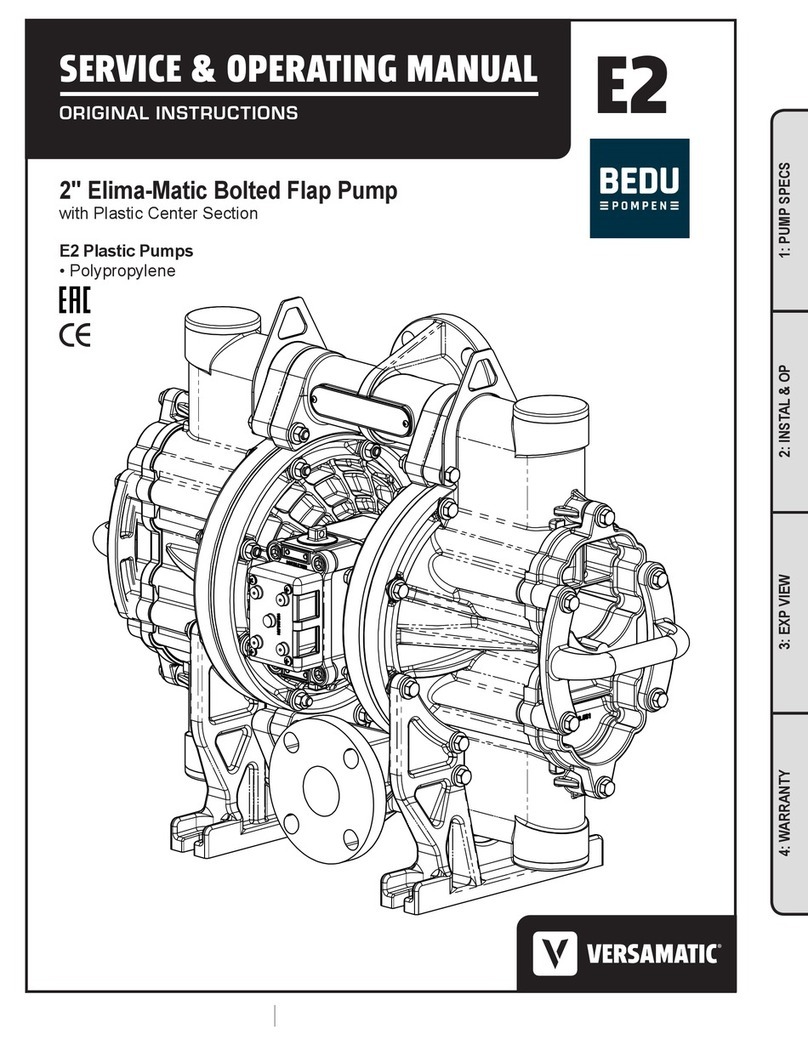

Model VMB20 Bolted Plastic Flap • 12

11 • Model VMB20 Bolted Plastic Flap www.versamatic.com www.versamatic.com

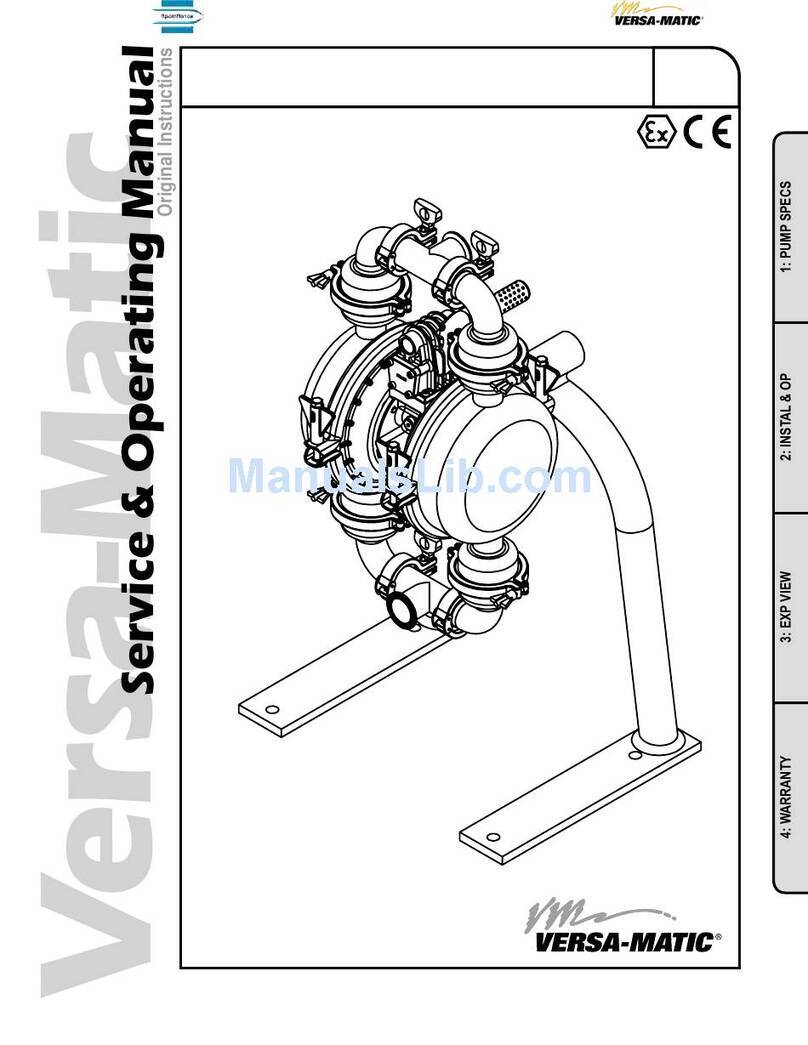

3: EXP VIEW

3: EXP VIEW