Network Interface Unit

October 2000 GFK-1551D

4

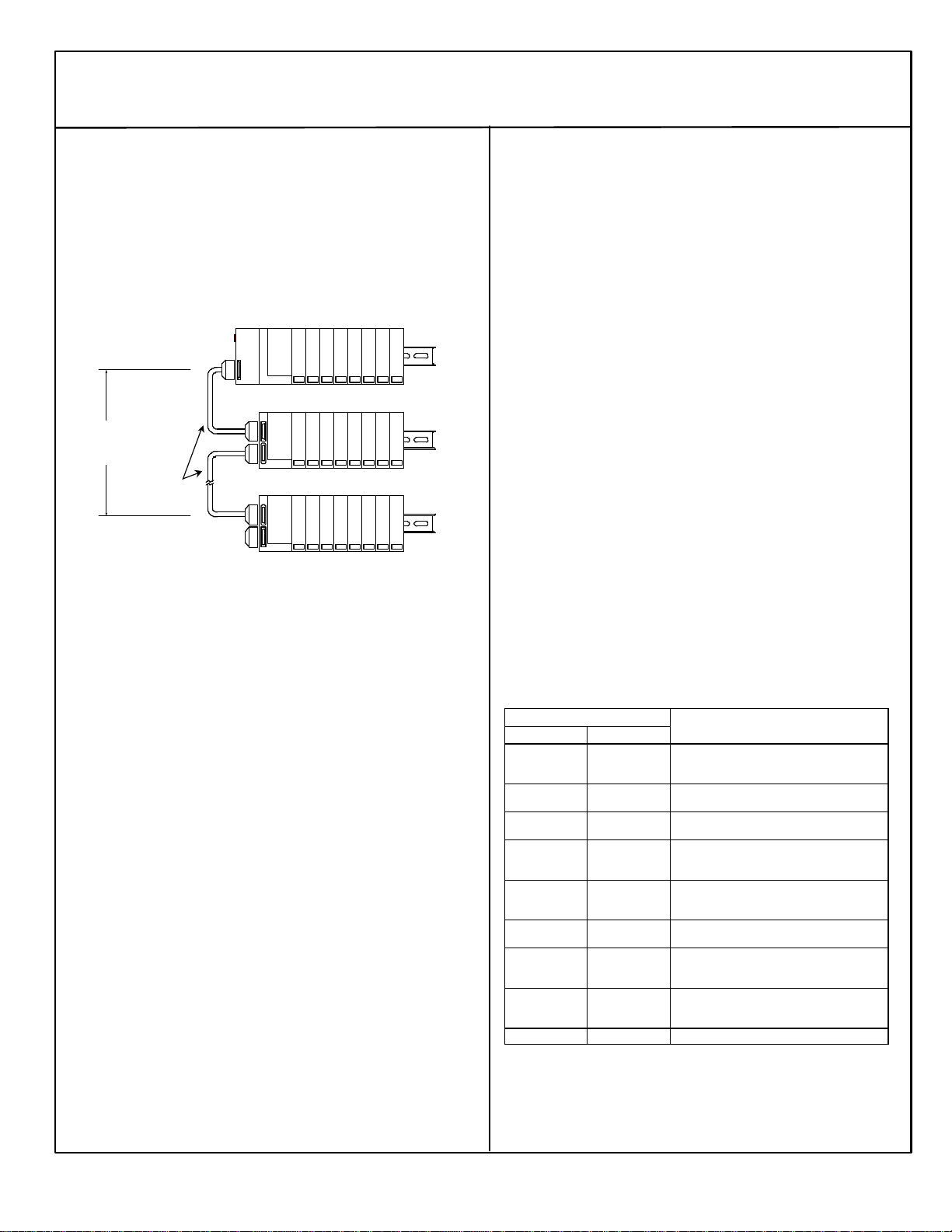

RS-485 Differential Expansion System

A multi-rack expansion system requires an Expansion Transmitter

Module in the NIU I/O Station. Up to seven expansion racks can be

included in the system. With any non-isolated Expansion Receiver

Module in the system, the total overall length of the expansion cable

can be up to 15 meters.

With all Isolated Receiver Modules, the total overall length of the

expansion cable can be up to 750 meters.

The expansion bus must be terminated with terminator plug *ACC201

(included with the Expansion Transmitter).

ExpansionRack 1

Terminator

15M with any

750M with all

I/O Station Main Rack (0)

ExpansionRack 7ICBL601,

Communications in an Expansion System

The NIU in the main rack communicates with the expansion racks

through a high-speed serial interface. The frequency used depends on

the types of expansion receivers in the expansion rack(s).

§In a Two-Rack Local system, the communications frequency is

3MHz.

§In Differential system, the NIU communications frequency is 3MHz

unless at least one isolated expansion receiver is installed.

Modules for an Expansion System

Expansion racks are built from the same carrier bases and I/O

modules that are allowed in main rack applications. Note the special

revisions required for some analog modules mentioned above.

Configuration and Installation Notes for Expansion Systems

§The NIU must have its rack dial set to rack 1 or it will not auto-

configure. The Expansion Receiver modules also have Rack ID

selection dials. Each must be set correctly as described in the

Expansion Module datasheets.

§In a multiple-rack expansion system, any available rack number

can be used for a new expansion rack but they must all be

unique (no duplicate rack numbers). It is best to assign

expansion racks numbers from lowest (1) to highest (7) as they

are installed. That is most compatible with the NIU auto-

configuration feature. Auto-configuration automatically assigns

reference addresses to I/O points and channels as it configures

them. Autoconfiguration starts in the main rack and proceeds

through the slots and additional racks in order, assigning

references from lowest to highest.

§To force auto configuration for expansion racks, first power down

the NIU. Remove the transmitter module from the NIU or remove

the expansion cable at the transmitter. Power up the NIU and let

it autoconfigure. Power the NIU down again, reattach the

transmitter or cable and power up the NIU again.

§In an local system, the NIU rack and the expansion rack may be on

different power supplies if desired. If so, on a single-ended or

differential system, disconnecting the cable between the

NIU/transmitter and receivers may cause disruptions on the bus.

§In a multiple-rack expansion system, if a new expansion rack is added

in the future, it should be assigned a rack address that is higher than

the racks that are already installed. If a new expansion rack with a

lower rack number than those previously auto-configured is installed

and the system is auto-configured, the racks numbered higher than

the new rack number have their I/O reference addresses shifted in the

reference tables. Any existing program logic that uses those

references must then be adjusted to use the new references.

§To add a new expansion rack to the system, the system must be

powered down. After adding the module, according to the

instructions in the Expansion Module datasheet, power up the

system. It will then autoconfigure.

Fault Handling for an Expansion System

This version of the NIU can detect extra, lost, and added expansion racks

as a result of a power cycle.

§When a complete rack is lost, only a “Loss of Rack” fault is generated.

Individual “Loss of Module” faults are suppressed.

§When a rack is added only an “Addition of Rack” fault and any I/O

module mismatch or loss conditions are reported. Individual I/O

module additions are suppressed.

§An “Extra rack” fault is generated when an expansion rack is present

but has not been configured. The Scan LED on the Expansion

Receiver Module is green instead of yellow whenever the Expansion

Receiver is properly configured and is working.

§Hot swapping of Expansion Transmitter Modules is not supported. The

NIU detects the loss and addition of the Expansion Transmitter

Module and generates the appropriate faults.

§If the run-time expansion frequency changes, an “Expansion bus

speed change” fault is generated.

The table below summarizes programmer faults in an expansion system:

Programmer Fault Text

VP/C90 LM90 Fault Description

Expansion Bus

Speed Change Reset of, Addition

of, or extra option

module Expansion bus operating frequency has changed from

250kHz to 3MHz or vice versa.

Addition of rack Addition of, or

extra rack Occurs when a receiver is first configured and when it

returns after being lost.

Loss of, or missing

rack Loss of, or missing

rack Occurs when a properly configured receiver is not

physically present at power up or lost at run-time.

System

Configuration

Mismatch

System

Configuration

Mismatch The configuration stored for a receiver does not match

the physical receiver present.

Extra Rack Addition of, or

extra rack Generated when a receiver is present that is not

currently configured. Also indicates improperly-

numbered rack ID.

Loss of, or missing

option module Loss of, or missing

option module Generated when a properly configured transmitter

module in a differential rack system is not present.

Reset of module Reset of, Addition

of, or extra option

module

Generated when a transmitter in a differential rack

system is either configured for the first time or is now

present after being lost.

Extra module

present but not

configured

Reset of, Addition

of, or extra option

module Generated when a system is configured for single-

ended operation and a transmitter module is present.

Extra Transmitter Expansion Transmitter installed in 2-rack local system