VersaMax* PROFIBUS Network Interface Unit

December 2016 GFK-1552L

2

Fixed for Version 2.21

•PROFIBUS NIU incorrectly reported “Loss of IO module

fault” after auto configuration. When the PROFIBUS NIU was

auto-configured and power-cycled, its fault LED came ON and it

reported a “Loss of I/O module” fault although the module was

connected. This occurred with module IC200MDD841 and all

other intelligent modules.

•Uncorrected Loss of module and Loss of Rack faults were not re-

reported after Clearing All NIU Faults. The PROFIBUS NIU did

not re-report standing Loss of Module and Loss of Rack faults

after clearing all faults by setting bit 7of PNIU control byte either

through application logic or through reference memory in

Machine Edition.

•PROFIBUS NIU Produced Repeated System Configuration

Mismatch Faults When Analog Current Input Module had

Incorrect Jumper Setting. If the jumper-selected input range on

an Analog Current Input Module did not match the hardware

configuration, the NIU produced System Configuration Mismatch

faults every 2 to 5 seconds. With NIU firmware version 2.22, the

NIU does not log this fault repeatedly.

•PROFIBUS NIU always held the input values of a mismatched

module in their last state regardless of the module’s

configuration. For PROFIBUS NIU firmware version 2.22, the

mismatched module’s inputs are correctly set to either hold last

state or default, according to the module’s “Default/Hold Last

State” configuration parameter.

•VersaMax PROFIBUS NIU does not report loss of module for a

module that fails after jumper mismatch is detected. If an I/O

module that has a mis-matched jumper configuration fails or is

removed from the PROFIBUS NIU station after the NIU detects

the mismatch, the NIU will not report the loss of module fault to

its Masters. If the attempt is made to clear all PROFIBUS NIU

faults (by setting 7th bit of PNIU control byte) while this condition

exists, the NIU would not report any fault for this module. In

PROFIBUS NIU firmware version 2.22, the NIU reports the loss

of module fault and lights its Fault LED.

Preinstallation Check

Carefully inspect all shipping containers for damage. If any equipment

is damaged, notify the delivery service immediately. Save the

damaged shipping container for inspection by the delivery service.

After unpacking the equipment, record all serial numbers. Save the

shipping containers and packing material in case it is necessary to

transport or ship any part of the system.

Quick Start Guide

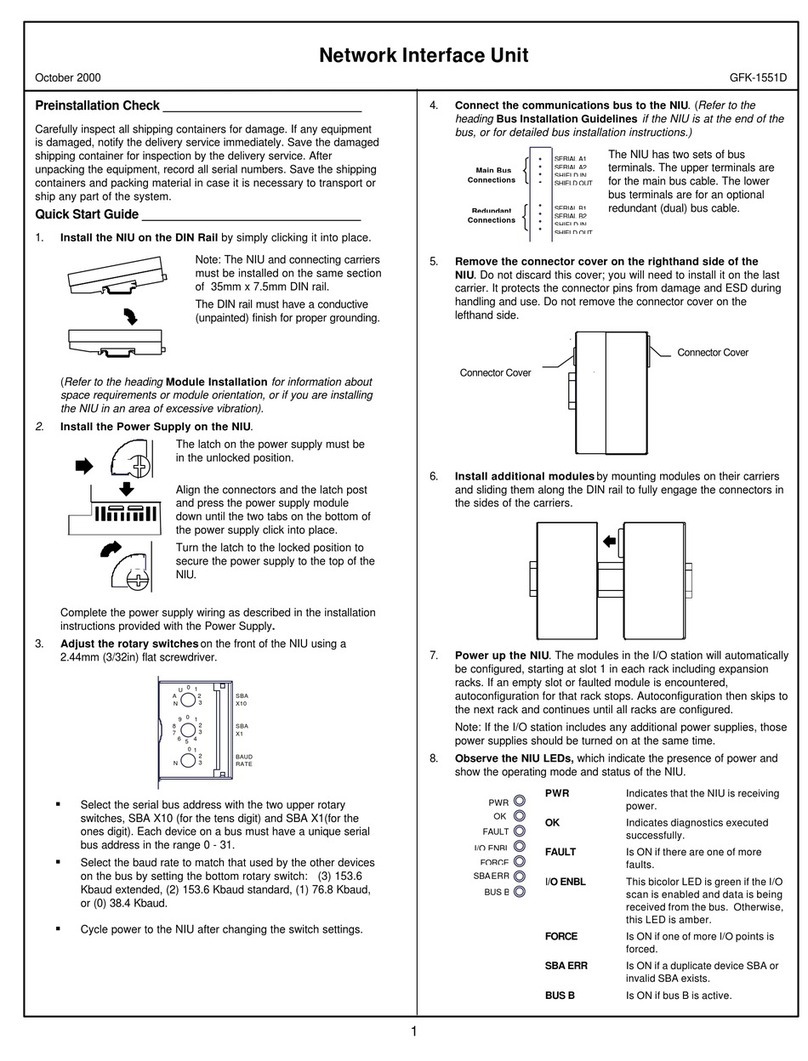

1. Install the NIU on the DIN Rail by simply clicking it into place.

Complete the power supply wiring as described in the installation

instructions provided with the Power Supply.

3. Adjust the rotary switches on the front of the NIU using a

2.44mm (3/32in) flat screwdriver. These switches, marked Node

Address X100, X10 and X1 select the hundreds, tens and units

digits of the network address. Select any valid address in the

range 1-125. Always cycle power to the NIU after changing the

switch settings.

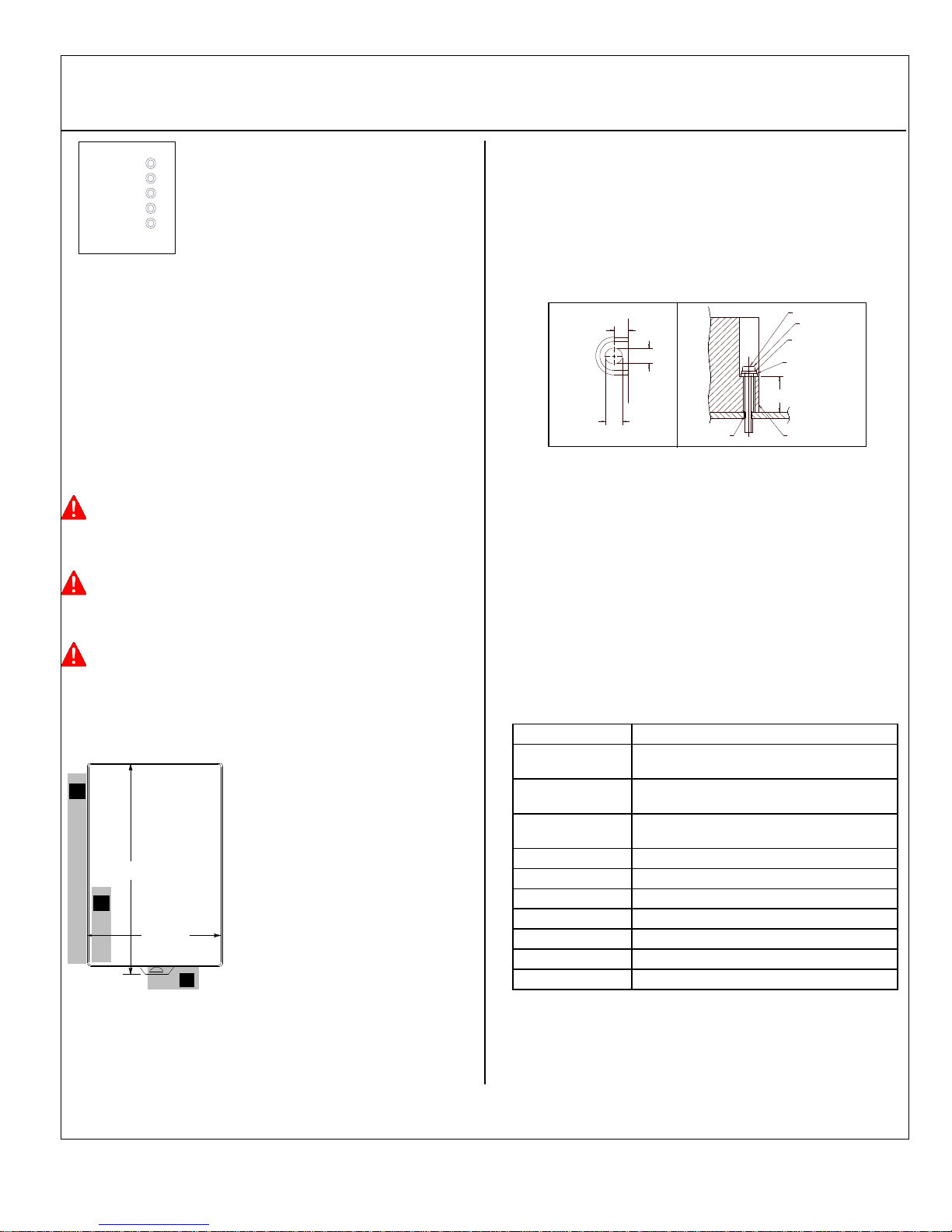

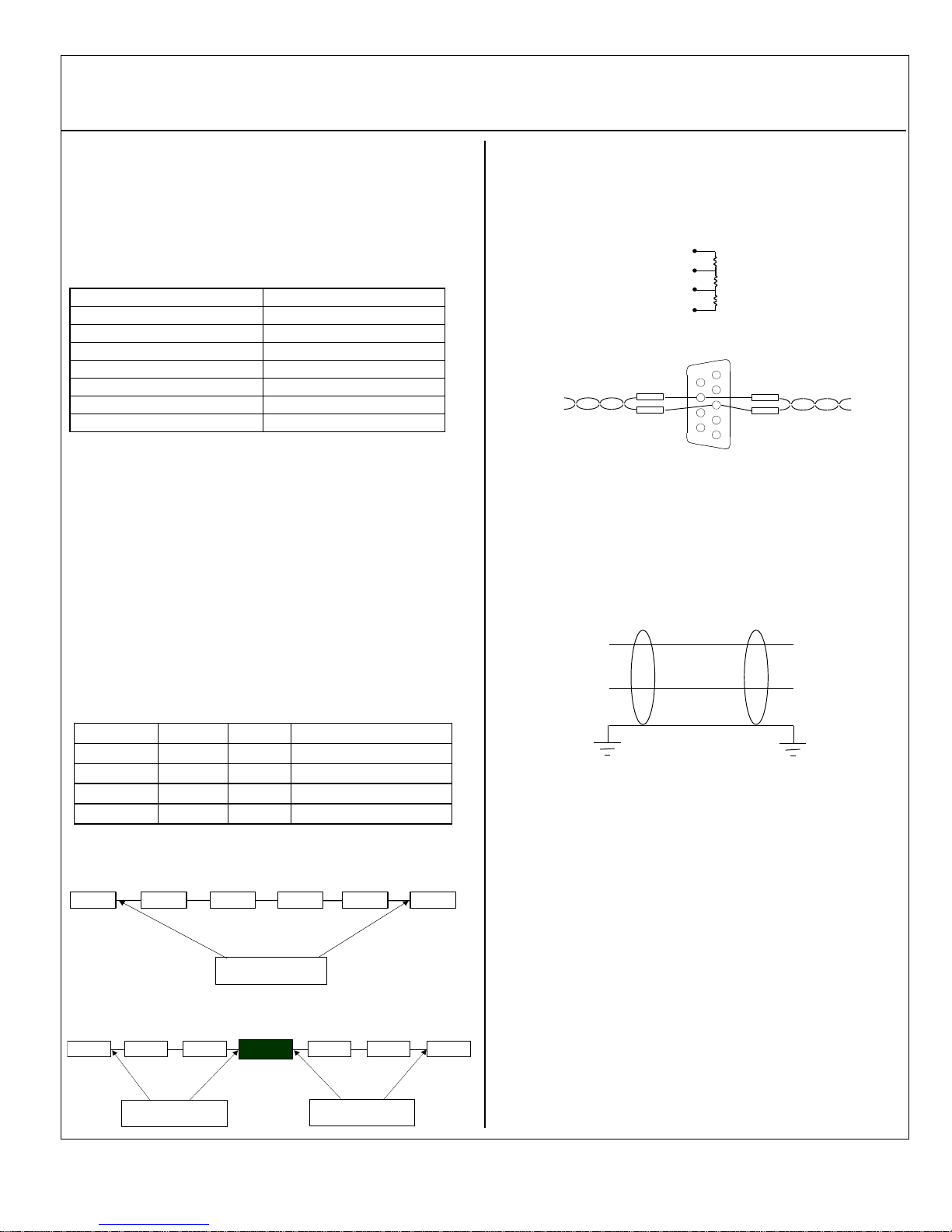

4. Connect the communications bus to the to the connector on

the front of the Network Interface Unit. (Refer to the heading

Bus Installation Guidelines for detailed bus installation

instructions.)

5. Remove the connector cover on the right-hand side of the

NIU. Do not discard this cover; you will need to install it on the

last carrier. It protects the connector pins from damage and

ESD during handling and use. Do not remove the connector

cover on the left-hand side.

6. Install additional modules by mounting modules on their

carriers and sliding them along the DIN rail to fully engage the

connectors in the sides of the carriers.

7. Power up the NIU. The modules in the I/O station will

automatically be configured, starting at slot 1 in each rack

including expansion racks. If an empty slot or faulted module is

encountered, auto-configuration for that rack stops. Auto-

configuration then skips to the next rack and continues until all

racks are configured.

Note: If the I/O station includes any additional power supplies,

those power supplies should be turned on at the same time.

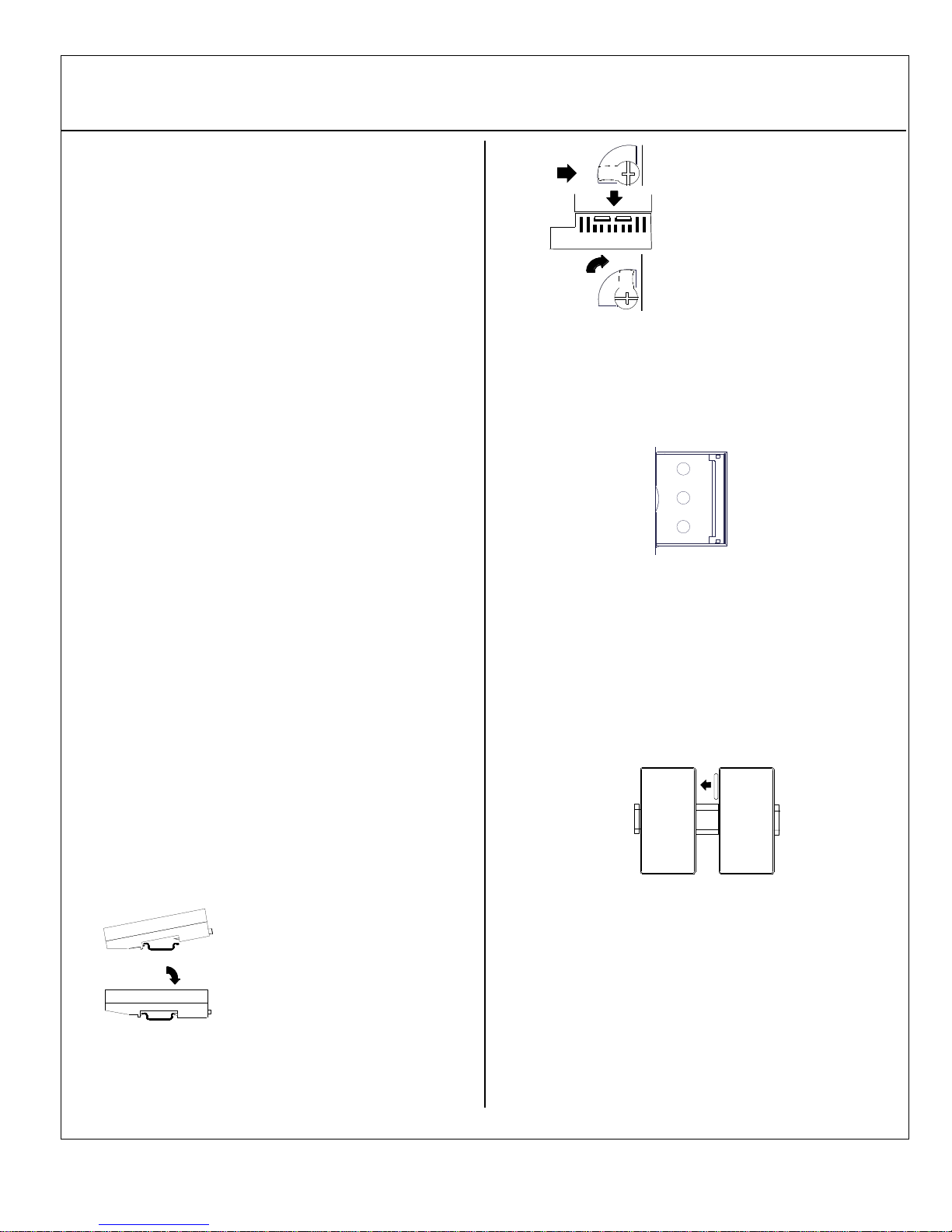

8. Observe the Module LEDs. The LEDs indicate the presence of

power and show the operating mode and status of the NIU.