4

Operating Manual Reprint

Description of Operating FunctionsDescription of Operating Functions

Description of Operating FunctionsDescription of Operating Functions

Description of Operating Functions

Monitor

Press the assigned Soft key momentarily to override (dis-

able) the Tone squelch.

Background noise or incoming signals will now be heard

whether or not a matching tone is present on the signal).

Press and hold in the assigned Soft key for more than 1

seconds to override both the Noise and Tone squelch. Again

press and hold in the assigned Soft key for more than 1

seconds (or press the assigned Soft key twice) to resume

normal (quiet) Noise and Tone squelch action.

Low Power

Press the assigned Soft key to set the radio's transmitter

to the “Low Power” mode, thus extending battery life.

Press the assigned Soft key again to return to “High

Power” operation when in difficult terrain.

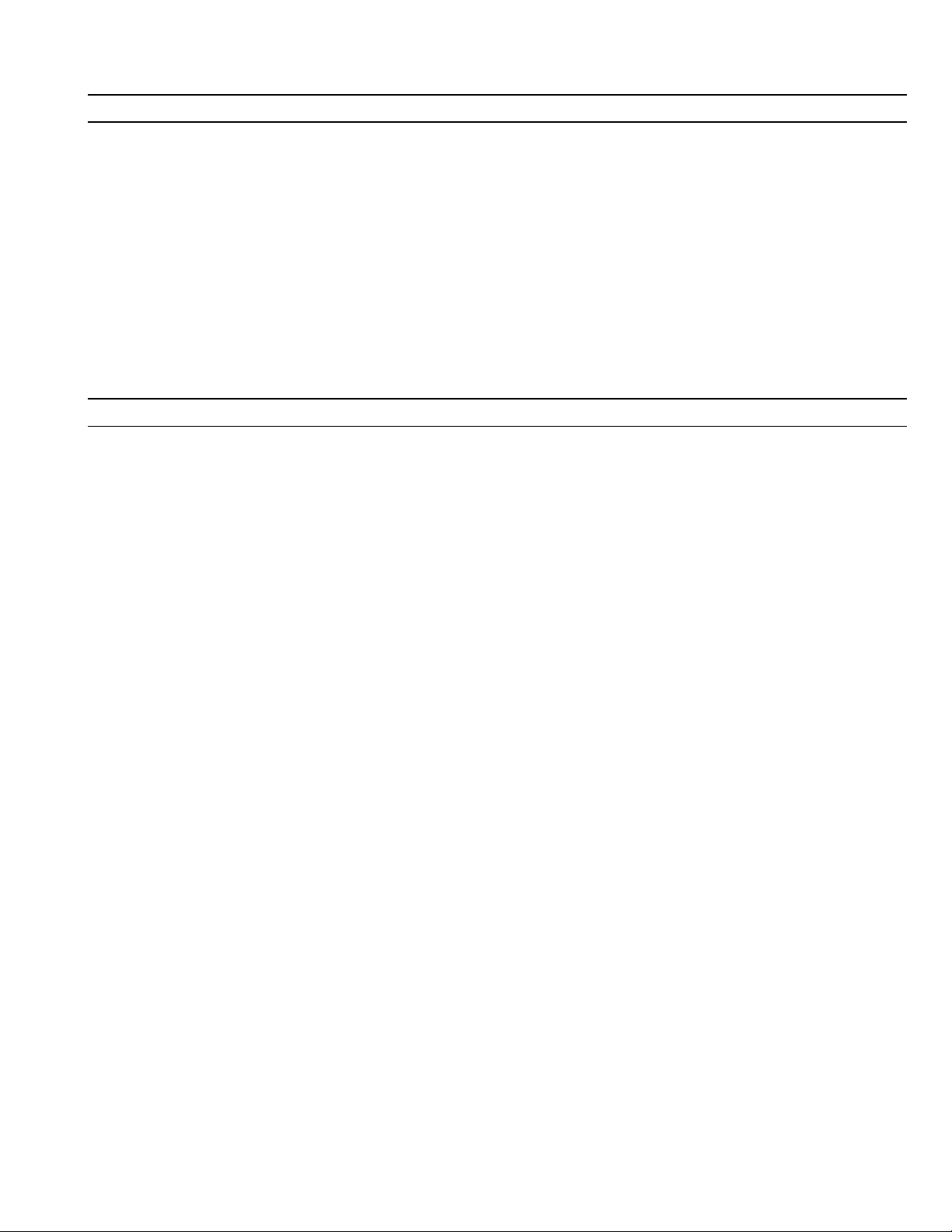

Lock

Press the assigned Soft key to lock the Soft keys (except

Lock and Monitor key); thus, the [A], [B], [C], and MONI-

TOR keys can be disabled to prevent radio settings from

being disturbed.

Lamp

Press the assigned Soft key to illuminate the LCD for

five seconds.

Channel Up

Press the assigned Soft key to switch to a higher operat-

ing channel number.

Channel Down

Press the assigned Soft key to switch to a lower operating

channel number.

Scan

The Scanning feature is used to monitor multiple chan-

nels programmed into the transceiver. While scanning, the

radio will check each channel for the presence of a signal,

and will stop on a channel if a signal is present.

UTo activate scanning:

Press the assigned Soft key.

The scanner will search the channels, looking for ac-

tive ones; it will pause each time it finds a channel on

which someone is speaking.

UTo stop scanning:

Press the assigned Soft key.

Operation will revert to the channel to which the CH

knob is set.

Follow-Me Scan

“Follow-Me” Scan feature checks a User-assigned Prior-

ity Channel regularly as you scan the other channels. Thus,

if only Channels 1, 3, and 5 (of the 8 available channels)

are designated for “Scanning,” the user may nonetheless

assign Channel as the “User-assigned” Priority Channel

via the “Follow-Me” feature.

Press the assigned Soft key to activate “Follow-Me” scan-

ning, then turn the CH selector knob to the channel which

you want to designate as the “User-Assigned Priority Chan-

nel”. When the scanner stops on an “active” channel, the

User-assigned Priority Channel will automatically be

checked every few seconds.

Dual Watch

The Dual Watch feature is similar to the Scan feature, ex-

cept that only two channels are monitored: the current

operating channel, and the “Priority” channel.

UTo activate Dual Watch:

Press the assigned Soft key.

The scanner will search the two channels; it will pause

each time it finds a channel on which someone is speak-

ing.

UTo stop Dual Watch:

Press the assigned Soft key.

Operation will revert to the channel to which the CH

knob is set.

Talk Around

Press the assigned Soft to activate the Talk Around fea-

ture when you are operating on duplex channel systems

(separate receive and transmit frequencies, utilizing a “re-

peater” station). The Talk Around feature allows you to

bypass the repeater station and talk directly to a station

that is nearby. This feature has no effect when you are

operating on “Simplex” channels, where the receive and

transmit frequencies are already the same.

Note that your dealer may have made provision for “Talk

Around” channels by programming “repeater” and “Talk

Around” frequencies on two adjacent channels. If so, the

key may be used for one of the other Pre-Programmed

Functions.

Add/Del

The Add/Del feature allows the user to arrange a custom

Scan.

Press the assigned Soft key to delete/restore the current

channel to/from your scanning list.

When you delete a current channel, “SKIP” will appear

on the LCD after pressing the Soft key. When you re-

store a current channel, “SKIP” indicator on the LCD will

turn off.