6.2.1 To Set Up Lead/Lag Operation 66

6.3 Setting a Rotation Schedule 67

6.3.1 Unit Rotation Options 67

6.3.2 Manually Rotating the Operating and Standby Units 68

7 External Monitoring andBuilding ManagementSystems 69

7.1 BMS and IntelliSlot Settings 69

7.1.1 Configuring BMS Communication with IntelliSlot Card 69

7.1.2 Setup Communication with a Card 70

7.1.3 Setting BMS Control Settings 70

8 Configuring Auxiliary Devices 73

8.1 Fluid Temperature Monitoring 73

8.1.1 Fluid Sensor Options 73

8.2 Wired Remote Sensors 73

8.2.1 Wired Remote Sensor Set Up Options 74

8.2.2 Wired Remote Sensor—Sensor Property Options 75

8.3 Supply Sensors 76

9 Administering Firmware, Settings, and Security 77

9.1 iCOM Firmware Upgrades 77

9.1.1 Compatibility with Earlier Versions of iCOM 77

9.1.2 Updating iCOM Display Firmware 77

9.1.3 Updating iCOM Control Board Firmware 77

9.1.4 Control Board Firmware Upgrade Options 78

9.2 Backing Up, Importing/Exporting and Restoring Display Settings 79

9.2.1 To Back Up or Restore Display Settings 79

9.2.2 Resetting Display Settings to Defaults 79

9.3 Backing Up and Restoring Control Board Settings 80

9.3.1 Control Board Back Up and Restore Options 80

9.4 Managing Access Permission and Passwords 81

9.5 Configuring with the Start Up Wizard 82

9.5.1 To Update System Information Using the Wizard 82

9.5.2 Start Up Wizard Options 82

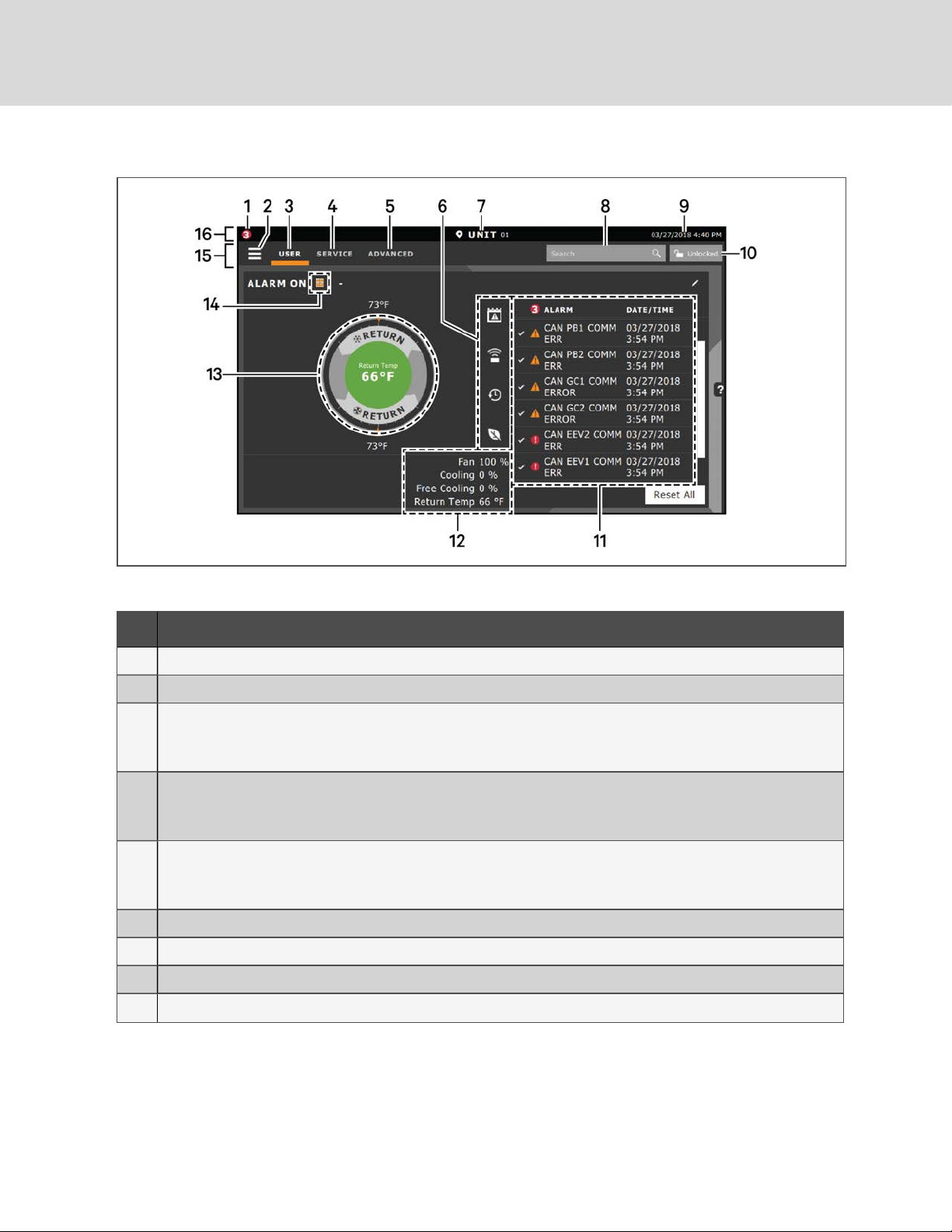

10 Performing Diagnostics 83

10.1 Cooling Unit Status LED 83

10.2 Enabling Manual Mode for Diagnostics 83

10.2.1 Disabling Diagnostics Manual Mode 84

10.3 Diagnosing Evaporator Fan Issues 84

10.3.1 Diagnostics—Evaporator Fan Options 84

10.4 Diagnosing Compressor Circuit Issues 85

10.4.1 Diagnostics—Compressor Circuit Options 85

10.4.2 Resetting High Pressure Alarm Code 87

10.4.3 Resetting Low Pressure Alarm Code 87

10.4.4 Resetting High Temperature Alarm Counter 87

Vertiv | Liebert® iCOMInstaller/User Guide | iii