Dorner Mfg. Corp. 2 851-873-EU Rev. B

2200 Series Modular Belt Conveyors

Table of Contents

Introduction ......................................................................... 3

Warnings −General Safety ................................................. 4

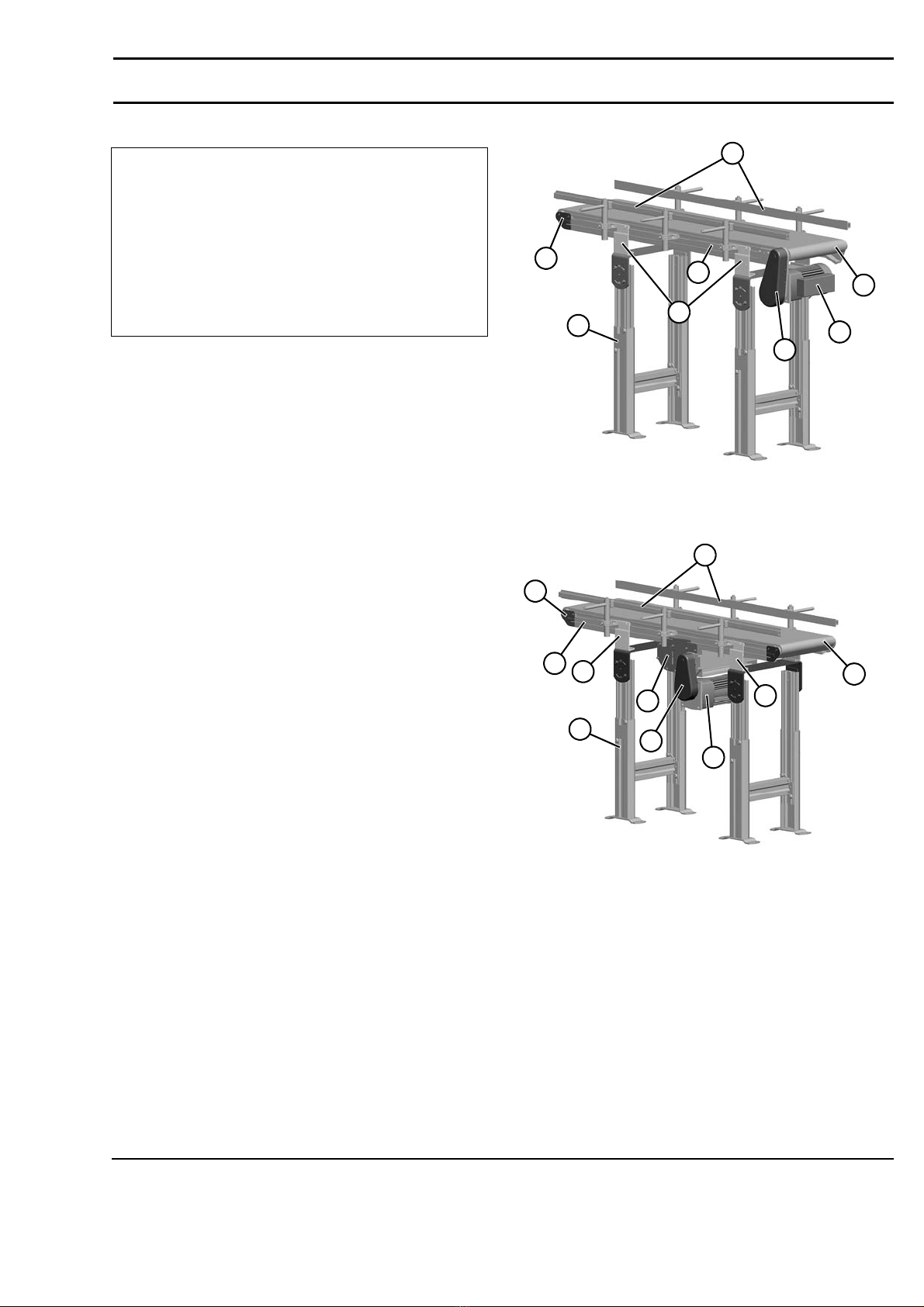

Product Description ............................................................. 5

Specifications ...................................................................... 6

Models: ............................................................................ 6

Flat Belt End Drive Conveyor...................................... 6

Cleated Belt End Drive Conveyor................................ 6

Flat Belt Center Drive Conveyor ................................. 6

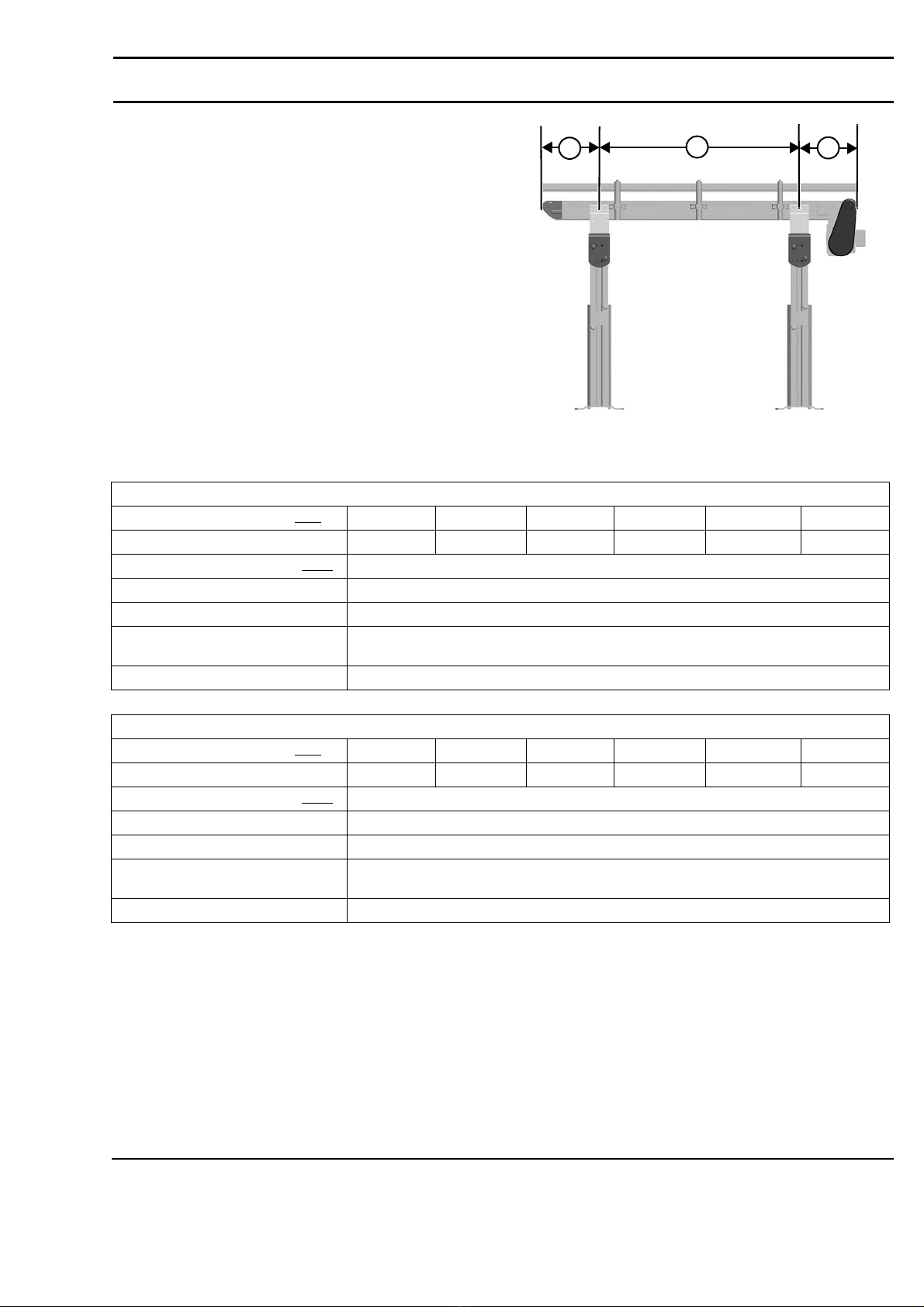

Conveyor Supports: ......................................................... 7

Maximum Distances:.................................................... 7

Conveyor Specifications:................................................. 7

Installation ........................................................................... 8

Required Tools................................................................. 8

Recommended Installation Sequence .............................. 8

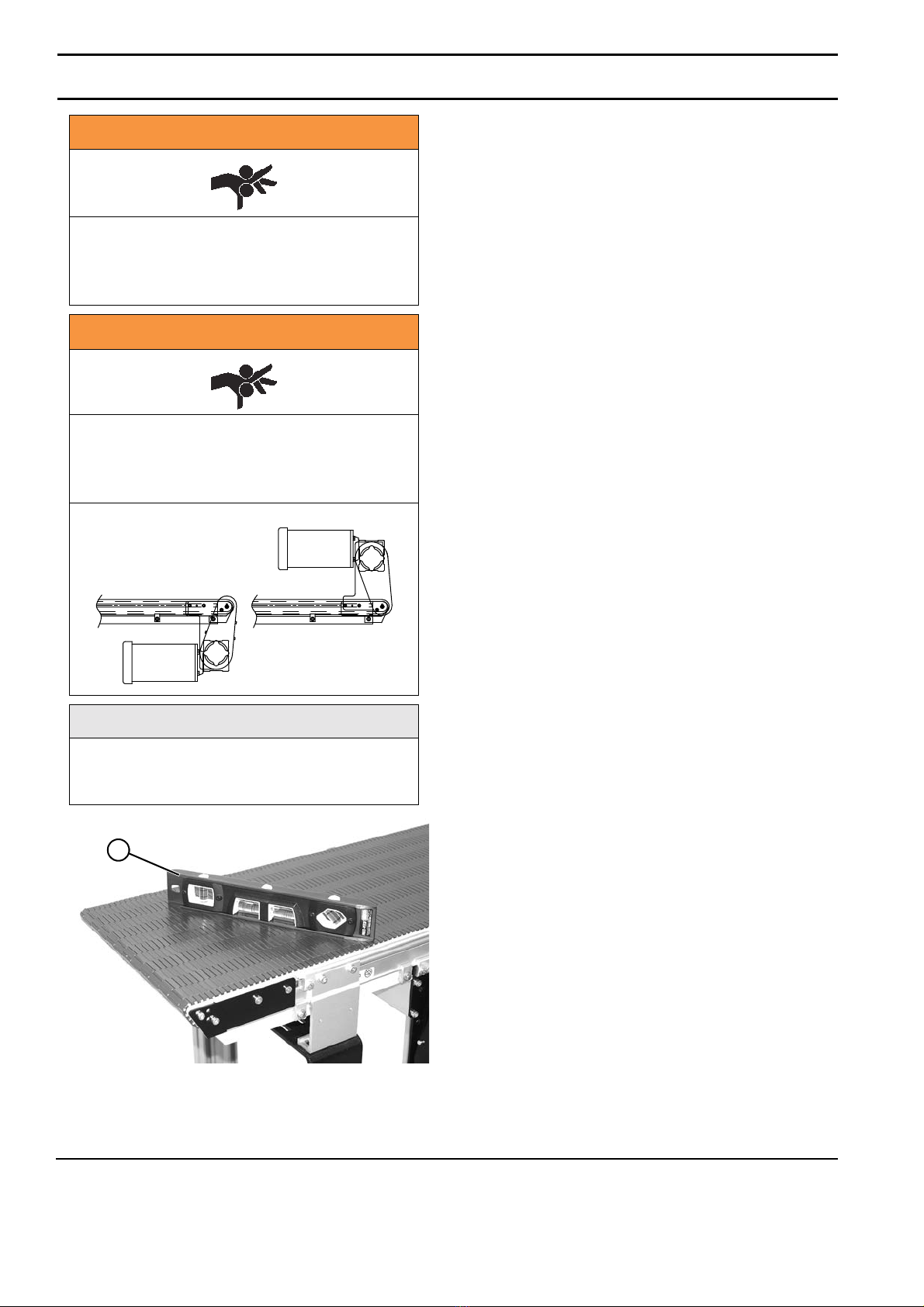

Conveyors Up to 3048 mm .............................................. 8

Conveyors Longer Than 3658 mm .................................. 9

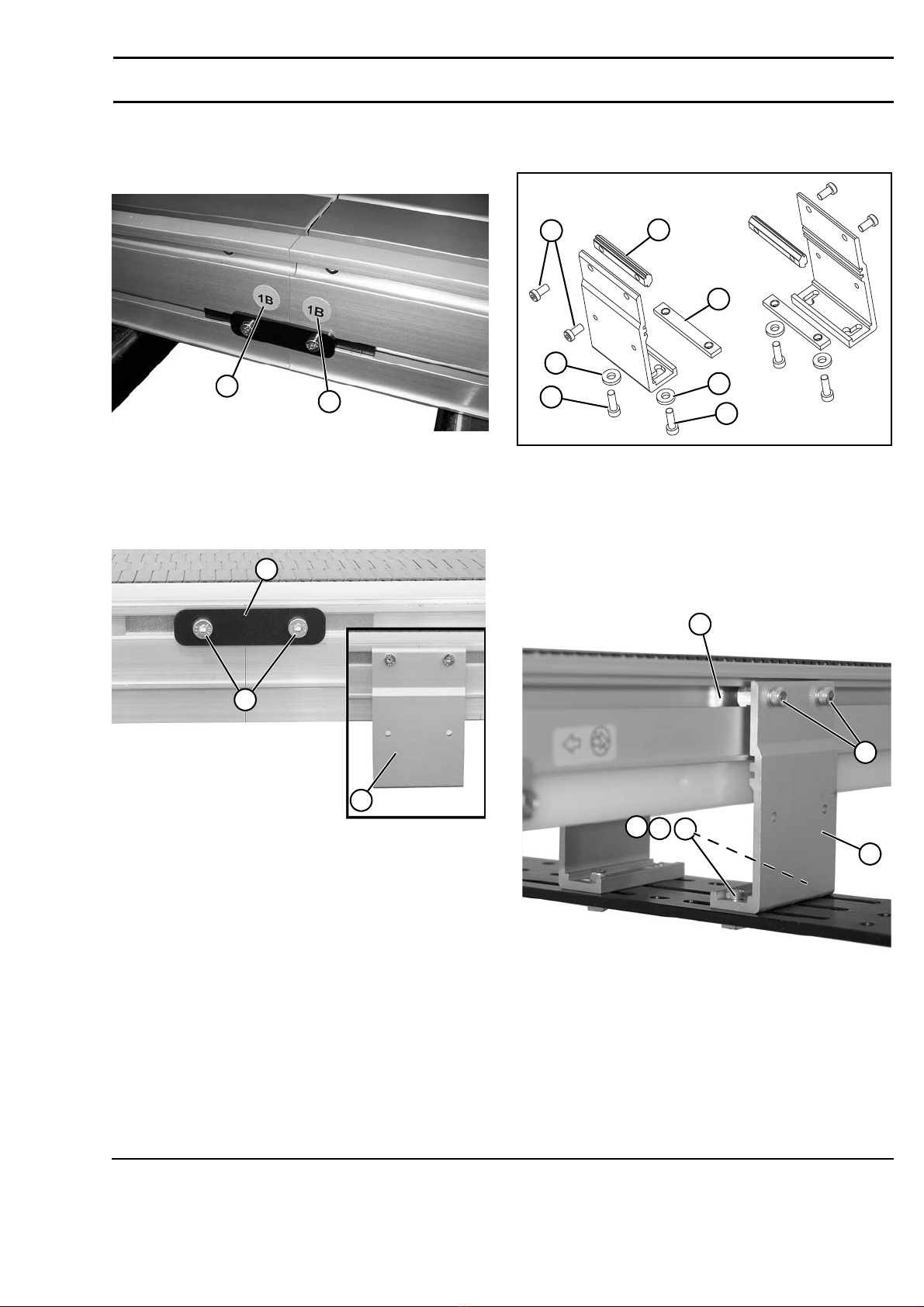

Mounting Brackets........................................................... 9

Installing Plastic Belt ..................................................... 10

Guide Clips .................................................................... 11

Adjustable Guides.......................................................... 11

Preventive Maintenance and Adjustment.......................... 13

Required Tools............................................................... 13

Standard Tools............................................................ 13

Special Tools .............................................................. 13

Checklist ........................................................................ 13

Lubrication..................................................................... 13

Maintaining Conveyor Belt ........................................... 13

Troubleshooting ......................................................... 13

Cleaning ..................................................................... 13

Conveyor Belt Replacement .......................................... 13

Conveyor Belt Replacement Sequence ...................... 13

Belt Removal.............................................................. 14

Belt Installation .......................................................... 15

Conveyor Belt Tension .................................................. 15

Removal of Belt Links ............................................... 16

Micropitch Belts ..................................................... 16

Metalworking Belts ................................................ 17

Pulley Removal.............................................................. 18

A −End Drive Conveyor ........................................... 18

B −Center Drive Conveyor ....................................... 19

Bearing and Sprocket Removal and Replacement......... 21

Removal ..................................................................... 21

Replacement ............................................................... 21

Idler End Wear Items..................................................... 22

A - Standard Idler Tail ............................................... 22

B - Nose Bar Idler Tail............................................... 23

Frame Wear Strip Replacement..................................... 23

Center Rail Replacement ............................................... 24

Tail Plate Shaft Knockout Removal .............................. 25

Service Parts ...................................................................... 26

End Drive Tail ............................................................... 26

Idler Tail for Conveyors up to 6096 mm Long.............. 28

Idler Tail for Conveyors Over 6096 mm Long.............. 29

Nose Bar Idler Tail ........................................................ 30

Center Drive Module ..................................................... 31

Frame Assembly ............................................................ 32

#04 Profile - 76 mm Aluminum Side ............................. 33

#05 Profile - 38 mm Aluminum Side ............................. 34

#13, 33 & 43 Profile - Adjustable Guiding .................... 35

#14, 34 & 44 Profile - Tool-Less Adjustable Guiding ... 36

25 mm Cleated Profiles .................................................. 37

51 mm Cleated Profiles .................................................. 38

Flat Belt Mounting Brackets .......................................... 39

Cleated Belt Mounting Brackets .................................... 39

Flat Belt Mounting Brackets for Short Conveyors......... 40

Cleated Belt Mounting Brackets for Short Conveyors... 40

Flat Belt Connecting Assembly with Stand Mount........ 41

Cleated Belt Connecting Assembly with Stand Mount.. 41

Connecting Assembly without Stand Mount.................. 42

Micropitch Conveyor Belting......................................... 43

Metalworking Conveyor Belting.................................... 43

Return Policy...................................................................... 44