Vertiv™ NetSure™ Inverter System User Manual

Proprietary and Confidential © 2023 Vertiv Group Corp.

•In the DC Input Only Power Mode, each inverter module operates with the 48 VDC nominal input to supply 120 VAC power to

the loads.In the event DC power fails or becomes abnormal or an inverter module fails, the inverter module shuts off.

The inverter system contains an EPO (Emergency Power Off) function. Connection points for a normally closed external EPO switch

are provided on the customer interface board. If an external EPO switch is wired to the customer interface board, activating the

switch to open the circuit activates the EPO function. The EPO function shuts down and locks out the inverters. When the EPO

switch is returned to normal (closed loop), the inverters remain off. The inverters will restart when the AC and DC power inputs are

removed and restored after 30 seconds or more (until the LEDs on the modules extinguish) (depending on the synchronizing time

with the system). (Note that there is an EPO shorting link factory installed that can be replaced with a customer provided switch.)

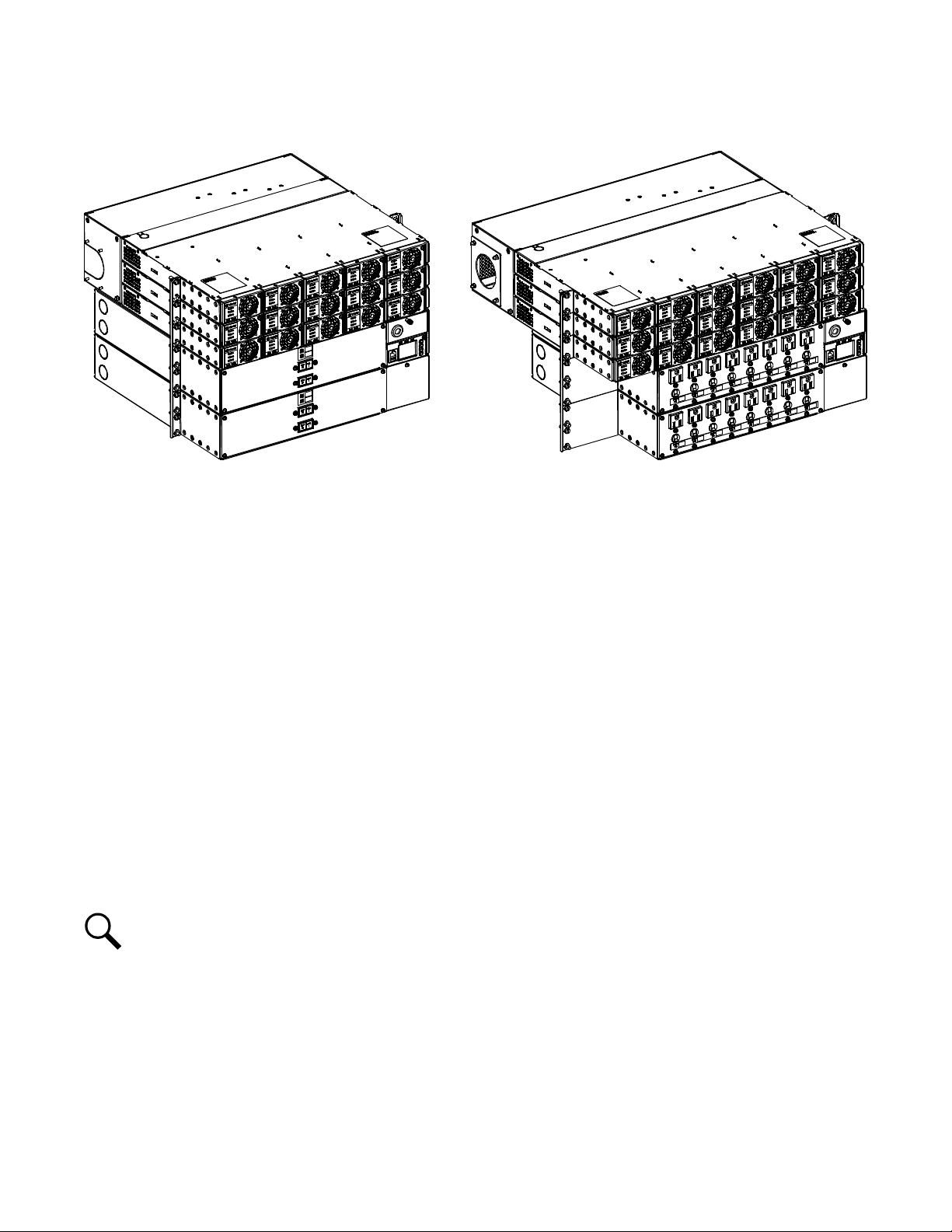

This inverter system consists of the following components. These components are factory packaged to provide the inverter system

configurations listed in Table 2.1. See Figure 2.1 for an overview illustration. Note the ratings are not only determined by the maximum

number of inverters the system can be provided with, but also the rating of the AC distribution panel. The overall system rating

cannot exceed the AC distribution panel rating.

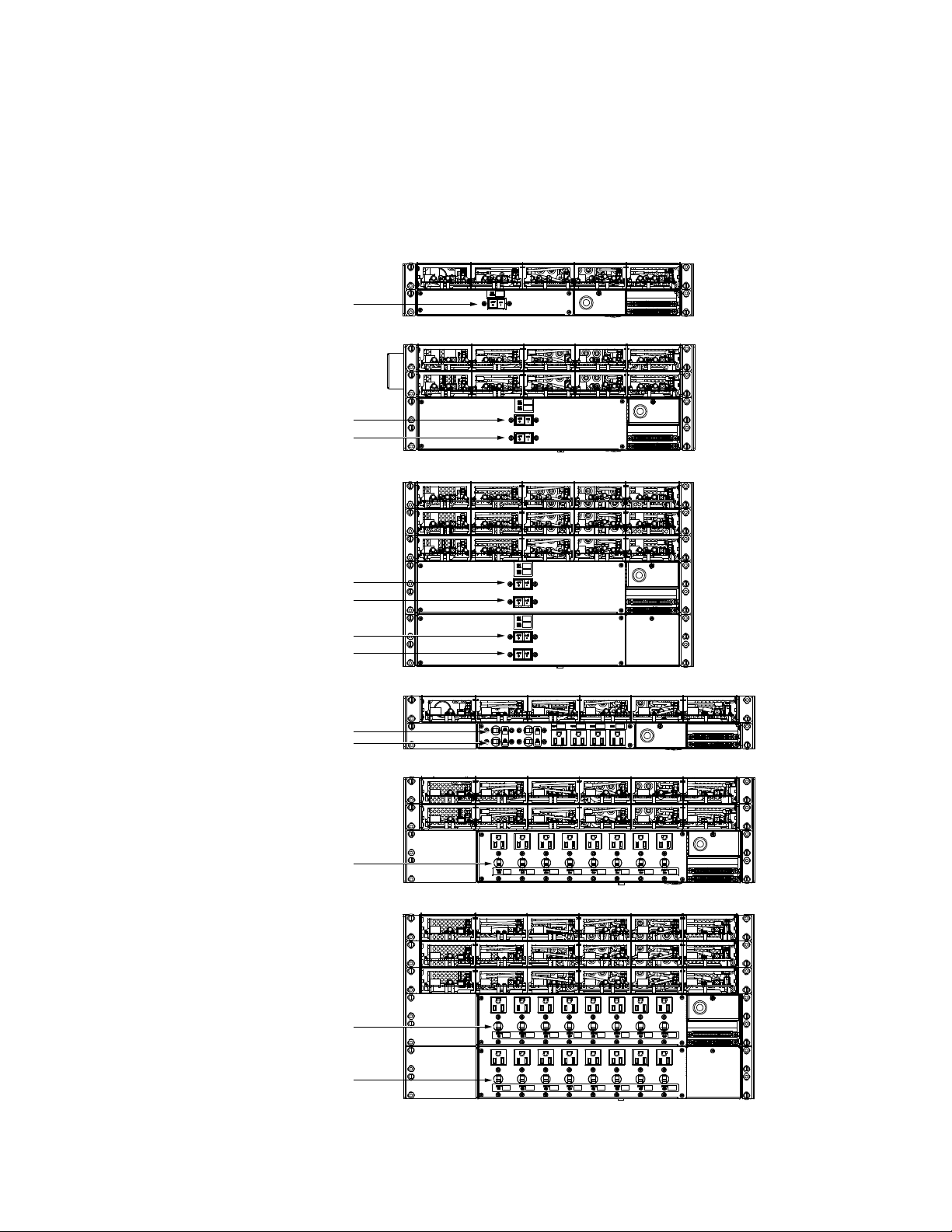

Inverter Module Mounting Shelf(s)

The inverter system consists of one or more inverter module mounting shelves, depending on power rating. The inverter module

mounting shelves house the inverter modules.

Inverter Modules

The inverter system utilizes 1 kVA/1 kW inverter modules (1 kVA at 40 °C and 0.5 kVA at 65 °C), supplying 120 VAC power from a

commercial AC power source or from a 48 VDC nominal input. Refer to the Inverter Instructions (UM1I1201000) for more information.

AC Load Distribution Shelf(s)

The inverter system consists of one or more AC load distribution shelves, depending on power rating. A choice of a bulk output AC

load distribution shelf or a NEMA output AC load distribution shelf is provided.

NCU (NetSure™ Control Unit) Controller

The controller provides inverter control, metering functions, monitoring functions, and local/remote alarm functions. The controller

also provides data acquisition and system alarm management. The controller contains a color LCD display and keypad for local

access. The controller provides an Ethernet port and comes with comprehensive webpages for remote access. The controller has

SNMP capability for remote system management. The controller supports software upgrade via its USB port. Refer to the NCU

Controller Instructions (UM1M830BNA) for more information.

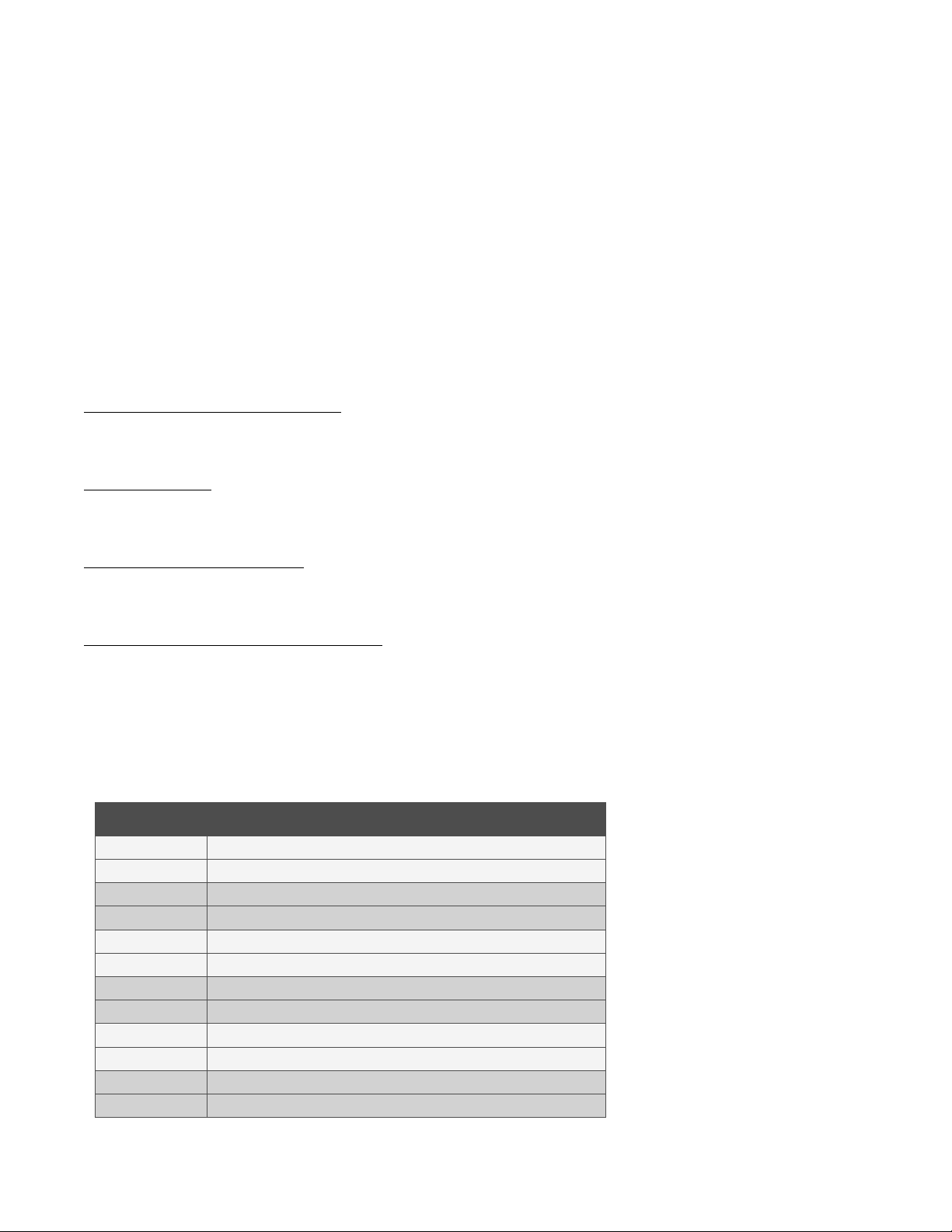

Table 2.1 Inverter System Configurations

List Number Configuration

584130100 List 01 19”, 5 kVA maximum, Bulk Output Shelf

584130100 List 01E 19”, 6 kVA maximum, Bulk Output Shelf

584130100 List 02 23”, 6 kVA maximum (5.76 kVA per NEC breaker de-rating), NEMA Output Shelf

584130100 List 02E 23”, 6 kVA maximum (5.76 kVA per NEC breaker de-rating), NEMA Output Shelf

584130100 List 03 19”, 10 kVA maximum, Bulk Output Shelf

584130100 List 03E 19”, 12 kVA maximum, Bulk Output Shelf

584130100 List 04 23”, 12 kVA maximum (11.5 kVA per NEC breaker de-rating), NEMA Output Shelf

584130100 List 04E 23”, 12 kVA maximum (11.5 kVA per NEC breaker de-rating), NEMA Output Shelf

584130100 List 05 19”, 15 kVA maximum, Bulk Output Shelf - DC INPUT ONLY

584130100 List 05E 19”, 20 kVA maximum, Bulk Output Shelf - DC INPUT ONLY

584130100 List 06 23”, 18 kVA maximum (18 kVA per NEC breaker de-rating), NEMA Output Shelf

584130100 List 06E 23”, 24 kVA maximum (23 kVA per NEC breaker de-rating), NEMA Output Shelf