TECHNICAL DATA

Note: To improve the performance, the specifications are subject to change without notice.

CHAPTER 1.

INTRODUCTION

Engine Type

Displacement

Fuel Tank Capacity

Fuel Mixture Ratio

Revolution(idling)

Revolution(loaded, impact)

Revolution(non loaded, max)

Maximum Output

Maximum Torque

Compression Rate

Fuel Consumption Rate

:Two Stroke, Forced, Air Cooled, Single Cylinder

: 46.5cc, Φ43x32mm(Inner bore size x stroke)

: 1 liter

: 25:1(gasoline : 2 cycle oil)

: 2700 rpm ±250

: 7120 rpm

: 9880 rpm

: 2.3 Ps/7500 rpm

: 0.34 kg-m/5500 rpm

: 7.1 : 1

: 380 g/Ps.h

Ignition Type

Spark Plug Type : Electronic

: NGK BPMR6A

Vibration Unloaded

Loaded : 4m/S2

: 19m/S2

Noise Idle

Loaded : 78dBA

: 100dBA

Carburetor Type : Diaphragm

Impact Square Drive Size

Fastening Torque Range

Free Speed

: 25.4 mm(1")

: 1030Nm(Full Throttle : 760ft. lbf)

800Nm(Half Throttle : 590ft. lbf)

: 1200 rpm

Capacity Bolt Diameter : 32 mm (1 1/4")

Weight Without fuel : 19.50 kg (42.99 lbs.)

Overall Dimensions Length

Height

Width

: 700mm (28")

: 330mm (13")

: 390mm (15")

Accessories Hex Key Wrench

Spark Plug Wrench

Spanner

4mm 1pc.

5mm 1pc.

6mm 1pc.

1pc.

10-13mm 1pc.

GT-3500GE GASOLINE ENGINE IMPACT WRENCH is ahigh quality tool with self-contained

heavy duty and high power two cycle engine as power source. And its unique designof impact

mechanism withVESSEL pneumatic V-Hammer ultra light weight impact wrench series,even

small engine (46.5 cc) can create higher fastening torque with enormous light weight only

19.50kg (42.99 lbs.)

Because of self-contained high power two cycle engine, it is veryeasily mobile to carry by one

man to any construction sites in the rain forest, hill or desertsuch remote areas where electricity

supply or air compressor, generator are not available.

The capacityof this tool is 32mm (1 1/4") bolt size and ideal for fastening and loosening bolts

of wood sleepers at railroad construction and many more applications.

2

1

●

●

●

●

●

●

●

●

●

●

●

●

●

WARNINGS AND SAFETY INSTRUCTIONS

CHAPTER 2.

Read these instructions carefully before operating, maintaining or servicing this tool.

Please keep these instructions in a safe accessible place.

Read to fully understand and

observe the following safety

precautions and warnings.

Careless or improper use of

tool may cause serious or fatal

injury.

WARNING!

Indicates instant possibility of

severe personal injury or loss

of life, if instructions are not

followed.

Always wear eye, head and

ear protectors when using this

tool.

CAUTION!

Indicates apossibility of per-

sonal injury or equipment dam-

age, if instructions are not

followed.

Always wear a safety face shield or goggles.

Always wear heavy, long pants, boots and

gloves. Do not wear loose clothing, jewellery,

short pants, sandals or go barefoot. Secure

hair so it is above shoulder length.

Do not operate that tool when you are tired,

ill or under the influence of alcohol,drugs or

medication.

Never let achild or inexperienced person

operate the machine.

Wear hearing protection.

Never start or run the engine inside a closed

room or building. Breathing exhaust fumes

can kill.

Keep handles free of oil and fuel.

Keep hands away from anvil.

Do not grab or hold the unit by rotating anvil.

Hold the handles firmly with both hands and

make sure to stand on the firm base or ground.

Do not touch spark plug, high voltage cord du-

ring operation as it may cause electric shock.

To avoid burn do not touch those places like

engine, muffler, exhaust where get very hot

during in use or even after stop engine until

it gets cool for the time being.

When operation is prolonged, take abreak

from time to time so that you may avoid pos-

sible whitefingerdiseasewhich is caused

by vibration.

Operator safetyInspectthe entire tool before each use. Re-

place damaged parts. Check for fuel leaks and

make sure all fasteners are in place and se-

curely fastened.

Replace parts that are cracked, chipped or

damaged in any way before using the tool.

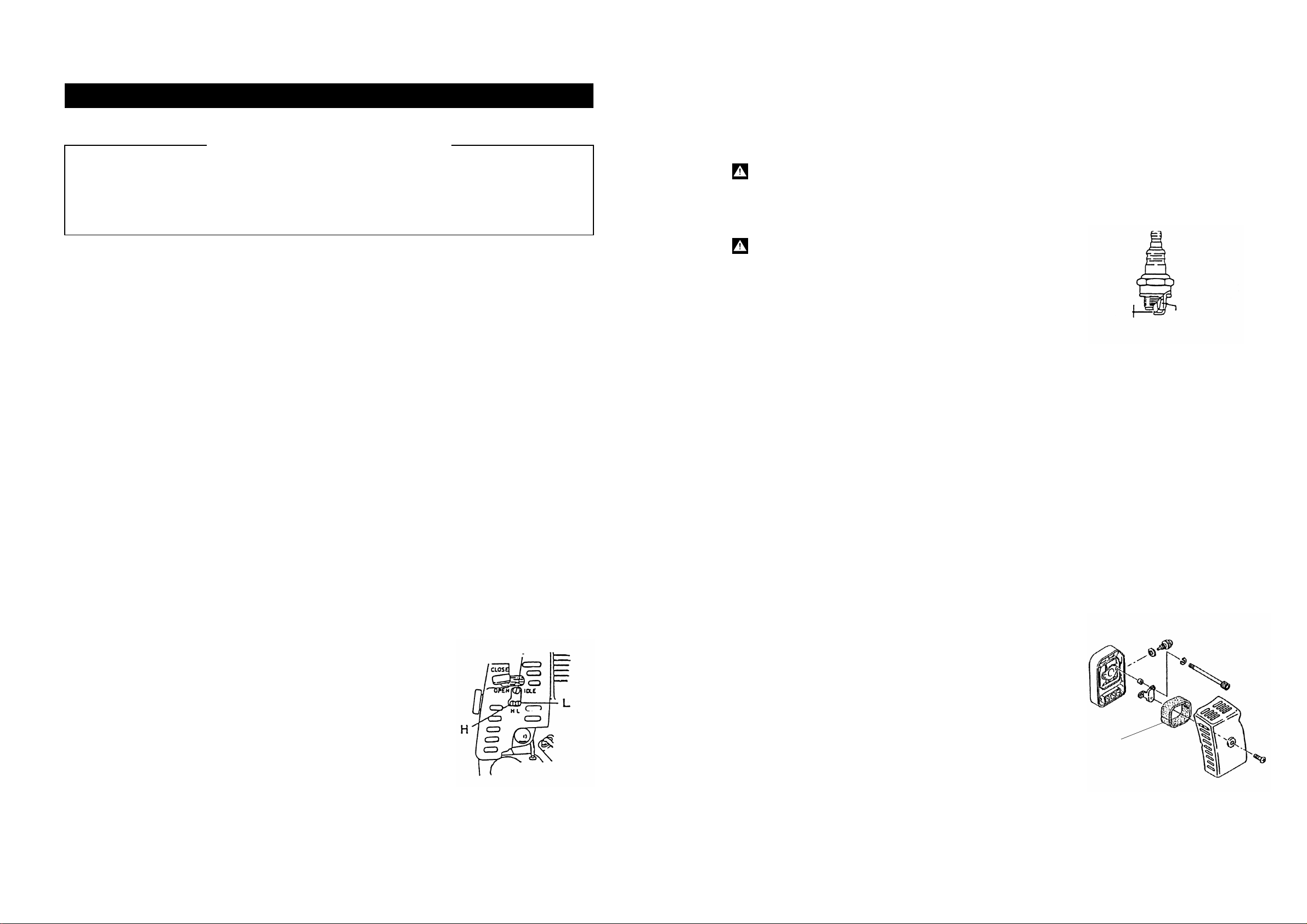

Keep others away when making carburetor

adjustments.

Use only accessories as recommended for this

tools by the manufacturer.

●

●

●

●

Tool safety

Never modify the tool in any way. Do not use

your tool for any job except that for which it is

intended.

●

●

●

●

●

Fuel safety

Mix and pour fuel outdoors and where there

are no sparks or flames.

Use a container approved for fuel.

Do not smoke or allow smoking near fuel or

the tool or while using the tool.

When filling up fuel, stop engine and make

sure engine is cool and choose the places

where no flamables and well ventulation.

Wipe up all fuel spills before starting engine.

WARNING!