Prapared by Customer Technical Supoort Department in Vestel Washing Machine Plant –Manisa –Turkey

Page 2

Table of Contents

1. Safety Precautions ..................................................................................................................................................4

2. Specifications..........................................................................................................................................................5

3. Control Panel and Acronyms ...................................................................................................................................6

4. Test Mode...............................................................................................................................................................7

4.1. Autotest.......................................................................................................................................................................... 7

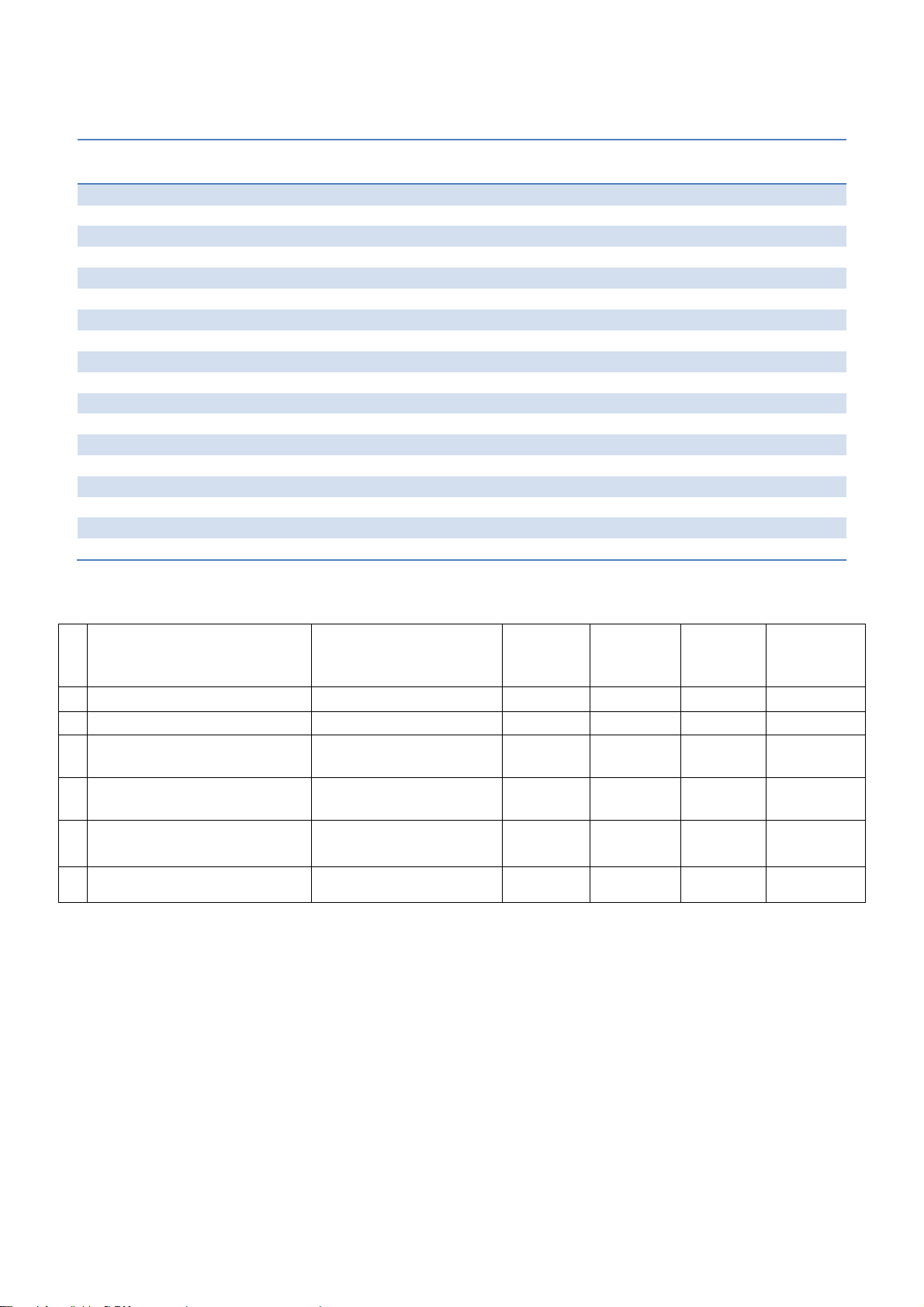

5. Service Mode ..........................................................................................................................................................9

5.1. Service Autotest............................................................................................................................................................... 9

5.2. Failure Codes .....................................................................................................................................................10

6. Critical Torque Values ...........................................................................................................................................10

7. Disassembly and Assembly Instructions.................................................................................................................11

7.1. Top Plate ....................................................................................................................................................................... 11

7.2. Door.............................................................................................................................................................................. 11

7.3. Spring Wire.................................................................................................................................................................... 12

7.4. Detergent Drawer.......................................................................................................................................................... 12

7.5. Control Panel................................................................................................................................................................. 13

7.6. Electronic Card............................................................................................................................................................... 13

7.7. Front Panel .................................................................................................................................................................... 14

7.8 Dryer Card ...................................................................................................................................................................... 16

7.9 Dryer Unit....................................................................................................................................................................... 16

7.10 Support Bracket............................................................................................................................................................ 17

7.11 Detergent Drawer Housing............................................................................................................................................ 18

7.12 Power Cable Group and EMI Filter................................................................................................................................. 18

7.13 Electronic Pressure Switch (EPS).................................................................................................................................... 19

7.15 DC CARD....................................................................................................................................................................... 19

7.16 Drain Pump................................................................................................................................................................... 20

7.17 Front Counterweight..................................................................................................................................................... 20

7.18 Heater .......................................................................................................................................................................... 21

7.19 Twinjet System ............................................................................................................................................................. 21

7.20 Tub Bellow Seal............................................................................................................................................................. 22

7.21 Transport Screw............................................................................................................................................................ 23

7.22 Upper Counterweight ................................................................................................................................................... 23

7.23 Washing Group............................................................................................................................................................. 23

7.24 Shock Absorber Pin....................................................................................................................................................... 24

7.25 Driven Pulley................................................................................................................................................................. 24

7.26 Driven Pulley................................................................................................................................................................. 24

7.27 Motor........................................................................................................................................................................... 25

7.28 Washer Group .............................................................................................................................................................. 25

8. Component Specifications.....................................................................................................................................27

8.1 Drain Pump..................................................................................................................................................................... 27

8.2 Circulation Pump* .......................................................................................................................................................... 28

8.3 Heater ............................................................................................................................................................................ 29

8.4 Washer NTC.................................................................................................................................................................... 30

8.5 Valve .............................................................................................................................................................................. 31

8.6 Electronic Pressure Sensor (EPS)* ................................................................................................................................... 32

8.7 Motor............................................................................................................................................................................. 33

8.8 DC Module Board............................................................................................................................................................ 34

8.9 Door Lock* ..................................................................................................................................................................... 35

8.10 Fan Group..................................................................................................................................................................... 36

8.11 Dryer Heater................................................................................................................................................................. 37

8.12 Component Control on PCB........................................................................................................................................... 38

8.13 Dryer NTC..................................................................................................................................................................... 41

9. Wiring Diagram* ...................................................................................................................................................42

10. Troubleshooting..................................................................................................................................................43