HBD, MANUAL.doc

Copyright 2016 Vestil Manufacturing Co. 5 of 20

Inspections

Before each use, inspect the listed components:

1. Wires: look for frays;

2. Hydraulic system: check lines for chafes, pinches or leaks, and

the reservoir for punctures or leaks;

3. Container-restraining tube (and the openings in the chute that

receive each end of the tube): damage deformation, looseness

of fit;

4. Frame: check the cylinder brackets, vertical and horizontal

frame members, horizontal cross-member, and angle cross

member, hinge blocks, and pivot shaft and spacer assemblies

for cracking, deformation and corrosion;

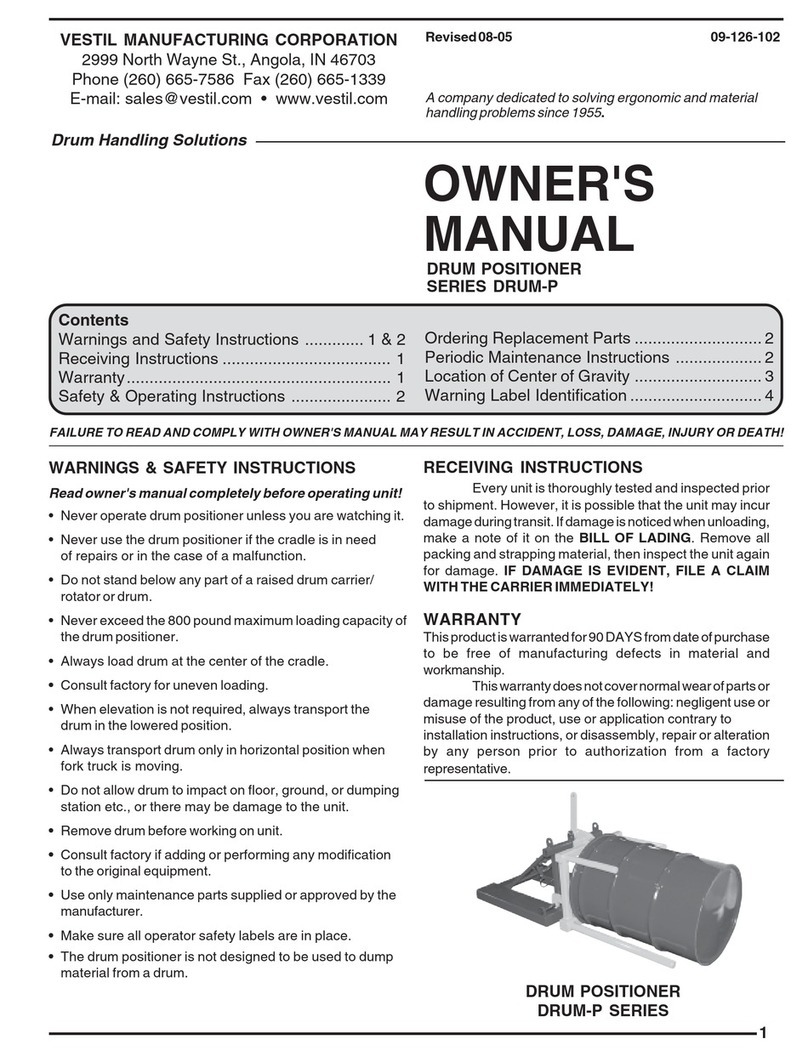

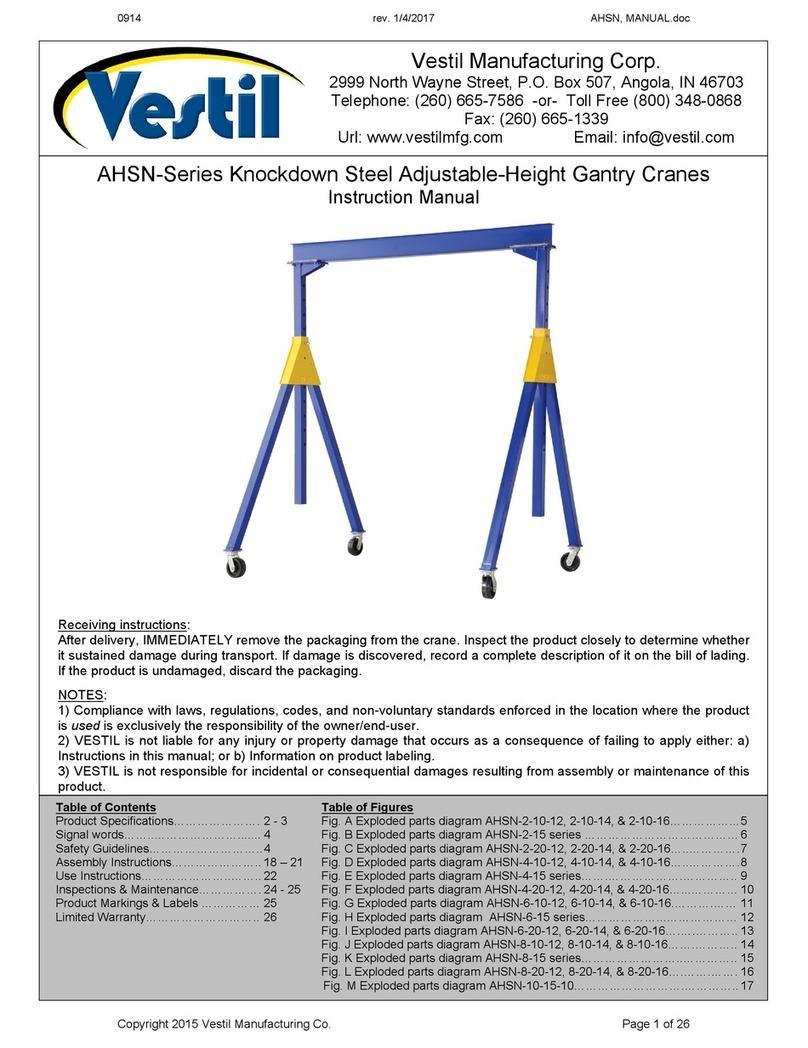

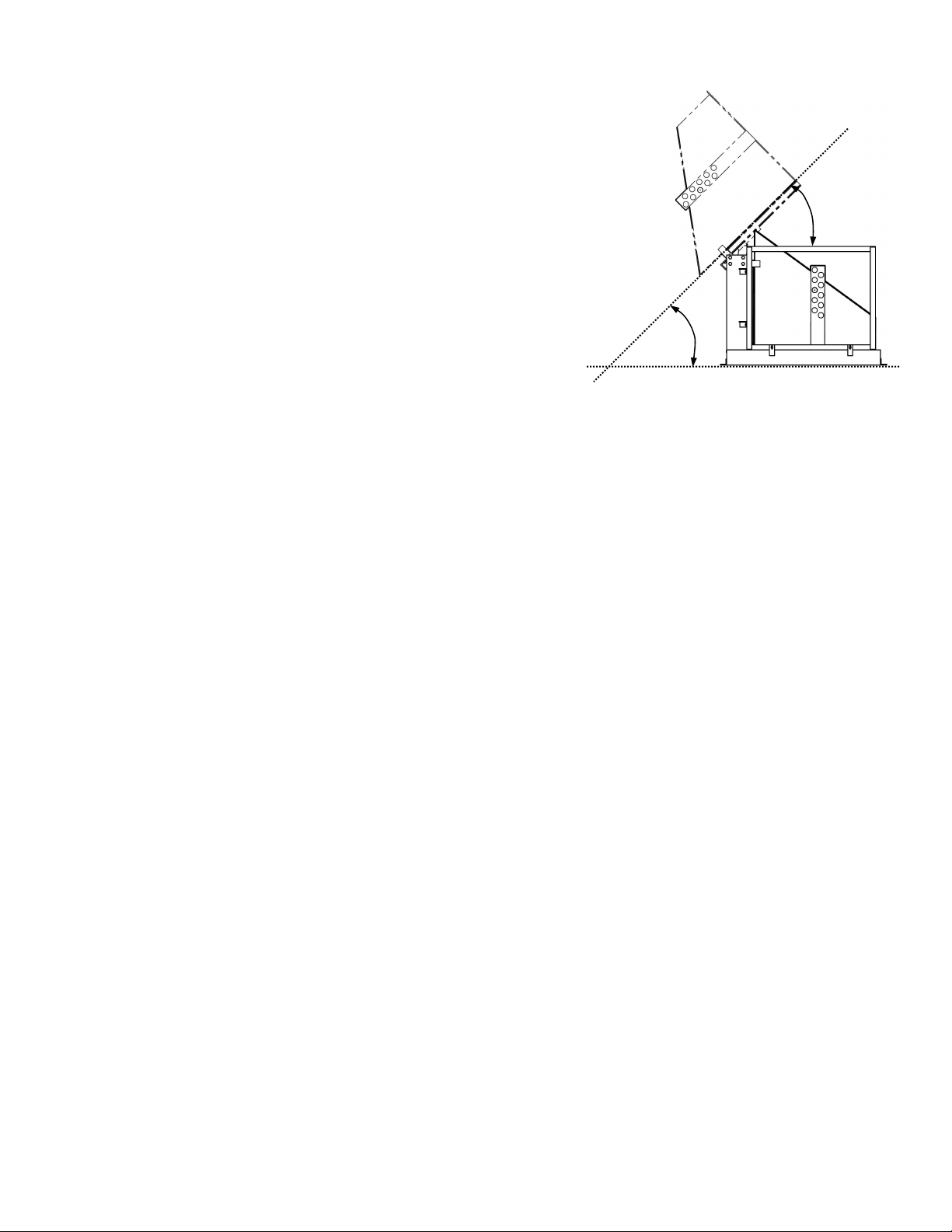

5. Limit switches: verify normal function. The chute should not

rotate beyond approximately 45 degrees or below 0 degrees.

(See FIG. 1).

Also listen for unusual sounds that might indicate binding or

grinding during operation and watch for erratic movement(s).

Contact maintenance personnel if you observe any unusual

sound or movement and do not use the dumper until approved for

service.

At least once per month, inspect the dumper as follows:

1. Oil level: fully raise the chute (to the 45°) “dumping position,” and then observe the level of oil in the reservoir. The

surface of the oil should be 1 to 1½ inches below the fill hole.;

2. Pivot points: check the dumper for excessive wear at the pivot points between hydraulic cylinders and cylinder

brackets, and between pivot shafts and hinge blocks;

3. Floor connection points: anchor bolts should prevent the frame from lifting off of the ground during chute

operation. Concrete around each anchor bolt should be intact—no cracking or flaking;

4. Fasteners: check each fastener connection. Tighten any loose connection;

5. Hoses and wires: check each wire and hose for damage (fraying, binding, etc.);

6. Labels: labels should be easily readable and undamaged, affixed to the dumper in the locations as shown in FIG.

8 on p. 14.

7. Container-restraining tube (and the openings in the chute that receive each end of the tube): inspect the tube for

damage deformation, looseness of fit.

At least once per year, change the hydraulic oil if it becomes gritty or looks milky (water present in the oil). With

the chute in the fully lowered position, drain the oil and replace it with either Dexron transmission fluid or anti-wear

hydraulic oil, viscosity grade 150 SUS at 100°F (ISO 32 cSt at 40°C.

Power unit operation

The box dumper utilizes an electric motor directly coupled to a gear pump to pressurize the hydraulic fluid. Fluid

pressure moves the cylinders up or down, and this movement performs the work required to raise and lower the

chute. A hydraulic manifold bolted directly onto the gear pump houses the hydraulic control components; each

component is rated for 3,000psi working pressure.

Important components of the power unit include:

Electric motor: when ordered, the owner of this box dumper selected either a single-phase or three-phase AC

motor. Regardless of phase capabilities, every motor is dual-voltage capable.

Gear pump: shaft coupled directly to the shaft of the electric motor. Several displacements are available are

correspond to the horsepower of the motor selected.

Check valve (HBD-2-## and HBD-4-## models): prevents backflow of fluid through the pump and thereby allows

the chute maintain a given position indefinitely.

Pressure relief valve: opens a path for fluid to flow back to the reservoir if fluid pressure exceeds 3,000psi.

Lowering solenoid valve: electrically-operated cartridge valve with an integral screen to keep contaminants from

entering the valve.

Counterbalance valves (6,000lb. rated load models only): allow smooth motion in double-acting hydraulic circuits.

Pressure compensated flow control spool (2,000lb. & 4,000lb. rated load models only): located beneath the

lowering valve, and regulates the fluid flow to the reservoir. This component allows the table to lower at the

constant rate independent of the weight of the dumper and contents. Several sizes are available.

Hydraulic cylinders: 2,00lb. and 4,00lb. rated load models utilize displacement style cylinders. Each cylinder

includes a bleeder valve (located at top end) for removing air from the hydraulic system.

6,000lb. HBD models use double action cylinders.

45°

Dumping

position:

chute fully

raised

Loading position:

chute fully lowered

FIG. 2: Limit

switch effect on

dump angle

Rev. 04/2016

45°