Table of Contents Rev. 7/12/2023 CRF, MANUAL

Table of Contents Copyright 2023 Vestil Manufacturing Co. Page 6 of 8

NATIONAL STANDARDS

According to US Federal Occupational Safety and Health Administration (OSHA) Rule 1910.178 (29 CFR

1910.178; the “Rule”), this device is a front end attachment for a lift truck whenever it is mounted on the forks of

a lift truck. The Rule incorporates American National Standard ANSI/ITSDF B56.1 (the “Standard”) published by

the Industrial Truck Standards Development Foundation (ITSDF) on its website (www.itsdf.org). The standard is

freely downloadable at http://www.itsdf.org/cue/b56-standards.html. Before putting this drum carrier into

service, you must acquire a copy of the Standard. Apply all relevant parts of Part II: For the User. Lift truck users

must mark/label the truck to identify the boom, show the weight of the truck and boom combination, and show

the capacity of the truck with the boom at maximum elevation with the load laterally centered. If instructions in

this manual conflict with instructions in the Standard then the instructions in the Standard should be applied.

Please contact our TECHNICAL SERVICE department if you believe that these instructions conflict with the

Standard. Contact information for TECHNICAL SERVICE appears on the cover page of this manual.

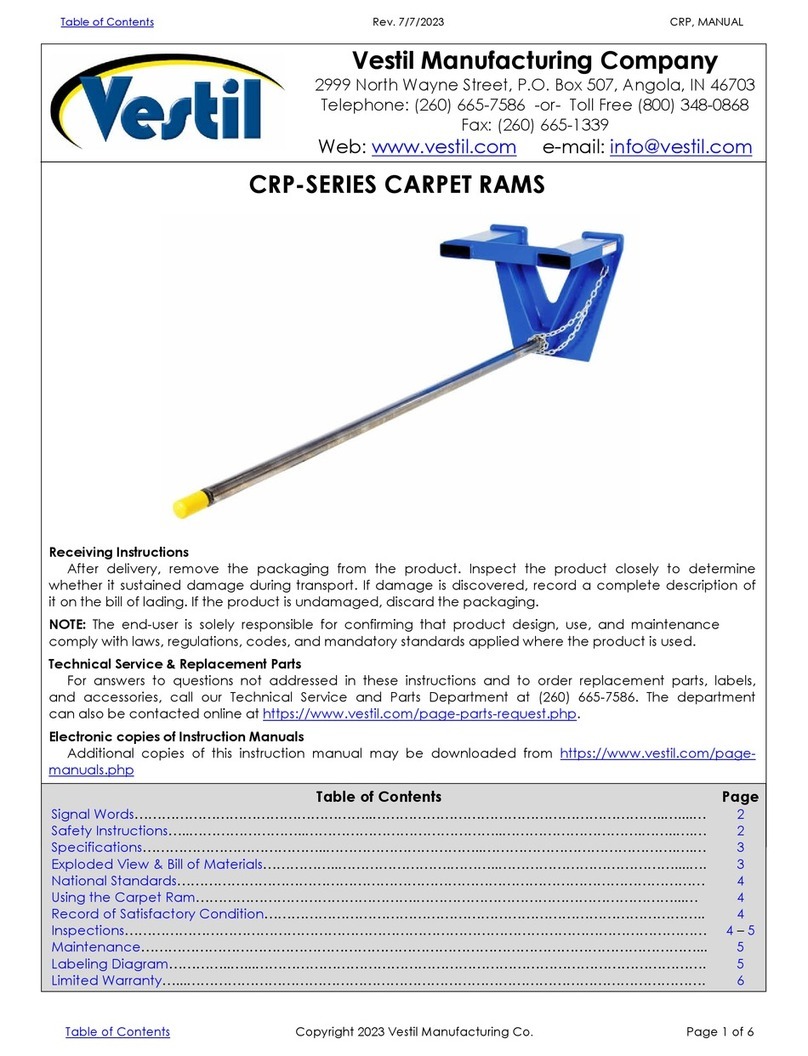

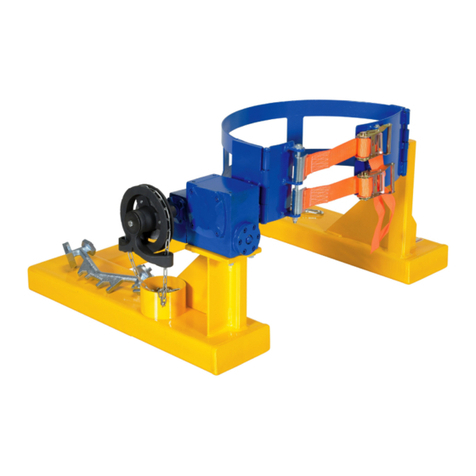

USING THE CARPET RAM

Step 1: Insert the forks of your lift truck into the fork pockets of the frame.

Drive forward until the end of the frame contacts the heels of the forks.

Step 2: To prevent the ram from sliding on the forks, attach the safety

chain to the carriage of your lift truck without slack.

Step 3: Insert the pole into the core of a roll of carpet. Drive forward until

the end of the roll contacts the receiver. The yellow end of the pole must

extend beyond the end of the roll. Do not use the carpet ram to lift

and/or move a carpet roll unless the pole is long enough to extend

beyond the end of the carpet roll.

Step 4: Raise the forks only as high as necessary to lift the roll of carpet off of the ground and to avoid contact

with objects during transport. DO NOT leave a raised roll unattended. Always unload the carpet ram before

leaving the forklift.

RECORD OF SATISFACTORY CONDITION

Before using the ram for the first time, make a written record of its appearance. Describe the condition of the

frame, pole, clamping bolts, safety chain, and snap hook. Take photographs of each item and add them to the

record. Take photographs of all labels applied to the ram. Describe where each label is located. This record

establishes satisfactory condition. When conducting the following inspections, compare your observations to the

record to determine if a component is in satisfactory condition. Do not use the carpet ram unless every

component is in satisfactory condition. Cosmetic changes, like damaged paint/powder coat do not constitute

changes from satisfactory condition. However, touchup paint should be applied to all affected areas as soon as

damage occurs.

INSPECTIONS

Inspections and repairs should only be performed by qualified persons. Compare the results of each inspection

to the RECORD OF SATISFACTORY CONDITION (the “RECORD”). Do not use the carpet ram unless all parts are in

satisfactory condition. Replace parts that are not in satisfactory condition before returning the ram to service.

DON’T GUESS! If you have any questions about the condition of your ram, contact the TECHNICAL SERVICE

department. The phone number is provided on the cover page of this manual. Never make temporary repairs of

damaged or missing parts. Only use manufacturer-approved replacement parts. Replace the entire unit if it

cannot be restored to satisfactory condition.

Before each use —perform the following inspections.

1. Check the surface of the pole for dirt or other matter.

2. Confirm integrity of hardware and fasteners, including but not limited to bolts, nuts, pins, snap hook,

quick link.

3. Abnormal, unstable or noisy movement during use.

4. Examine pole and pole clamp for looseness or excessive wear, damage, or indications of metal fatigue.

5. Inspect the fork tubes for damage such as severe wear, thinned walls, significant corrosion, and warps.

6. Confirm that the safety chain is in satisfactory condition. Look for broken, elongated, and twisted links.

7. Check labels. See LABELING DIAGRAM on p. 7. Replace labels that are damaged, missing, or not easily

readable.

8. Examine the whole structure for rusting/metal erosion. Remove rust/corrosion with a steel bristle brush or

steel wool. Clean the area and apply touchup paint.

Attach safety

chain to forklift

carriage

without slack