DGT DGT60 DGTQ DGTP

2

INDEX

1. REQUIREMENTS FOR AN EFFECTIVE INSTALLATION ...................................................................................... 3

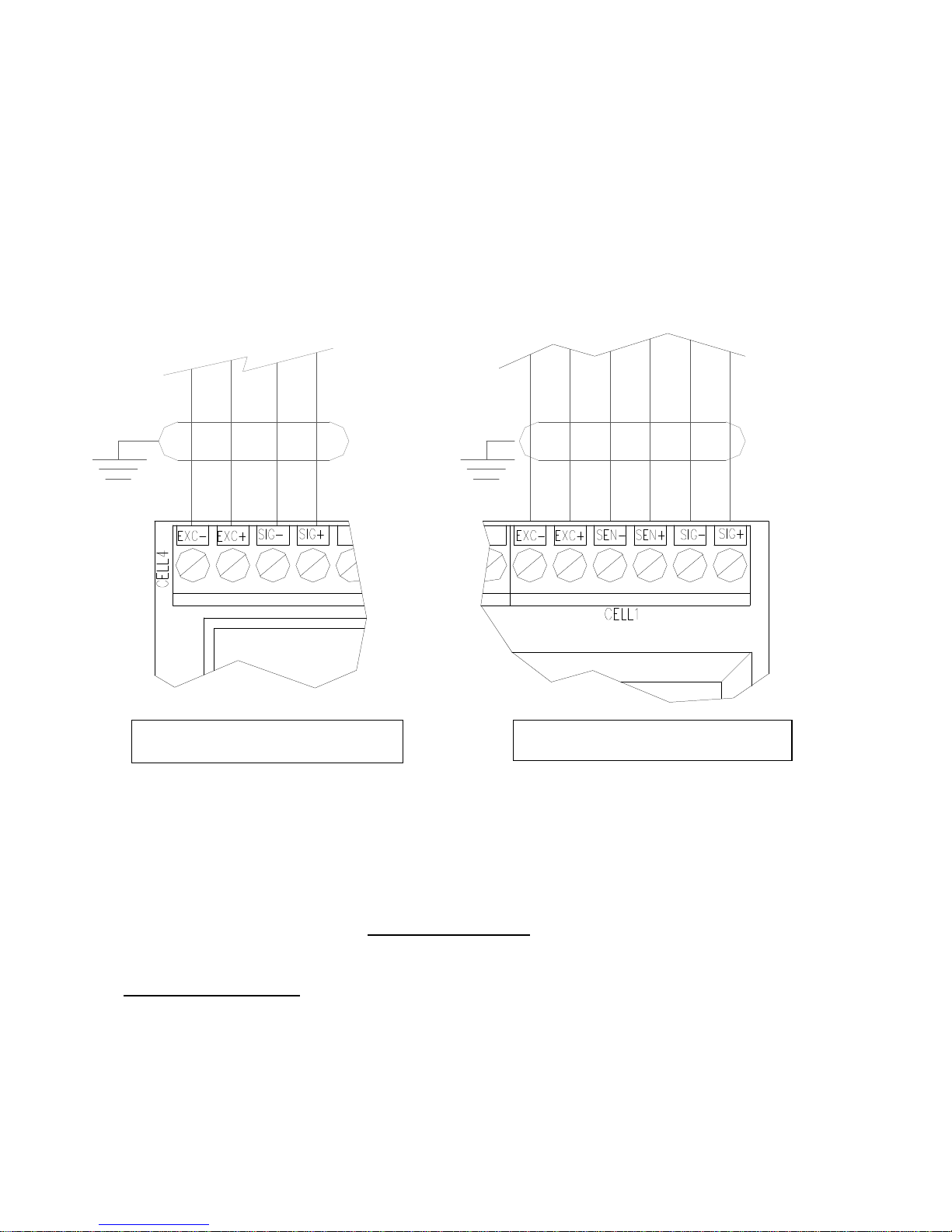

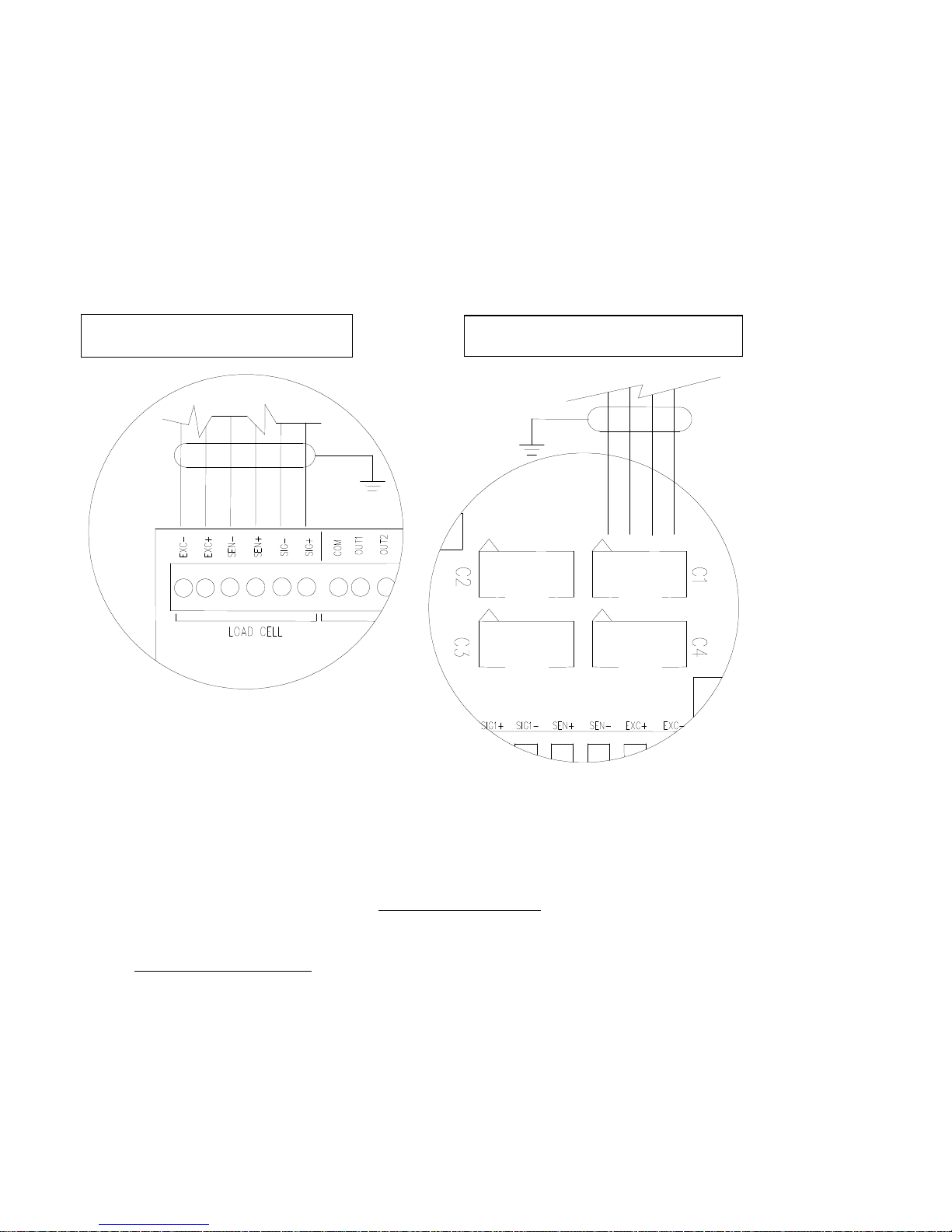

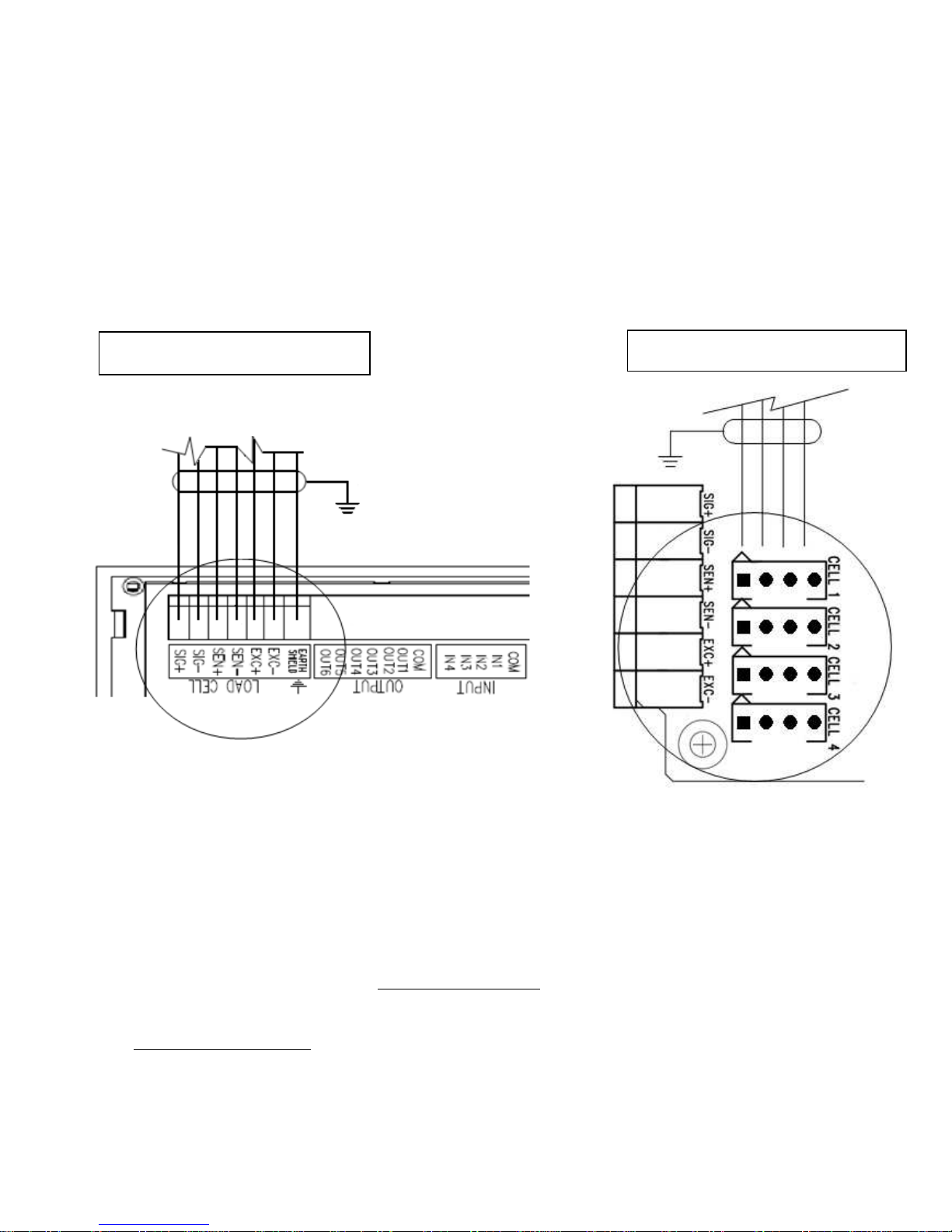

2. CONNECTION TO THE LOAD RECEIVER............................................................................................................. 4

2.1 DGT and DGT60 Models .................................................................................................................................... 4

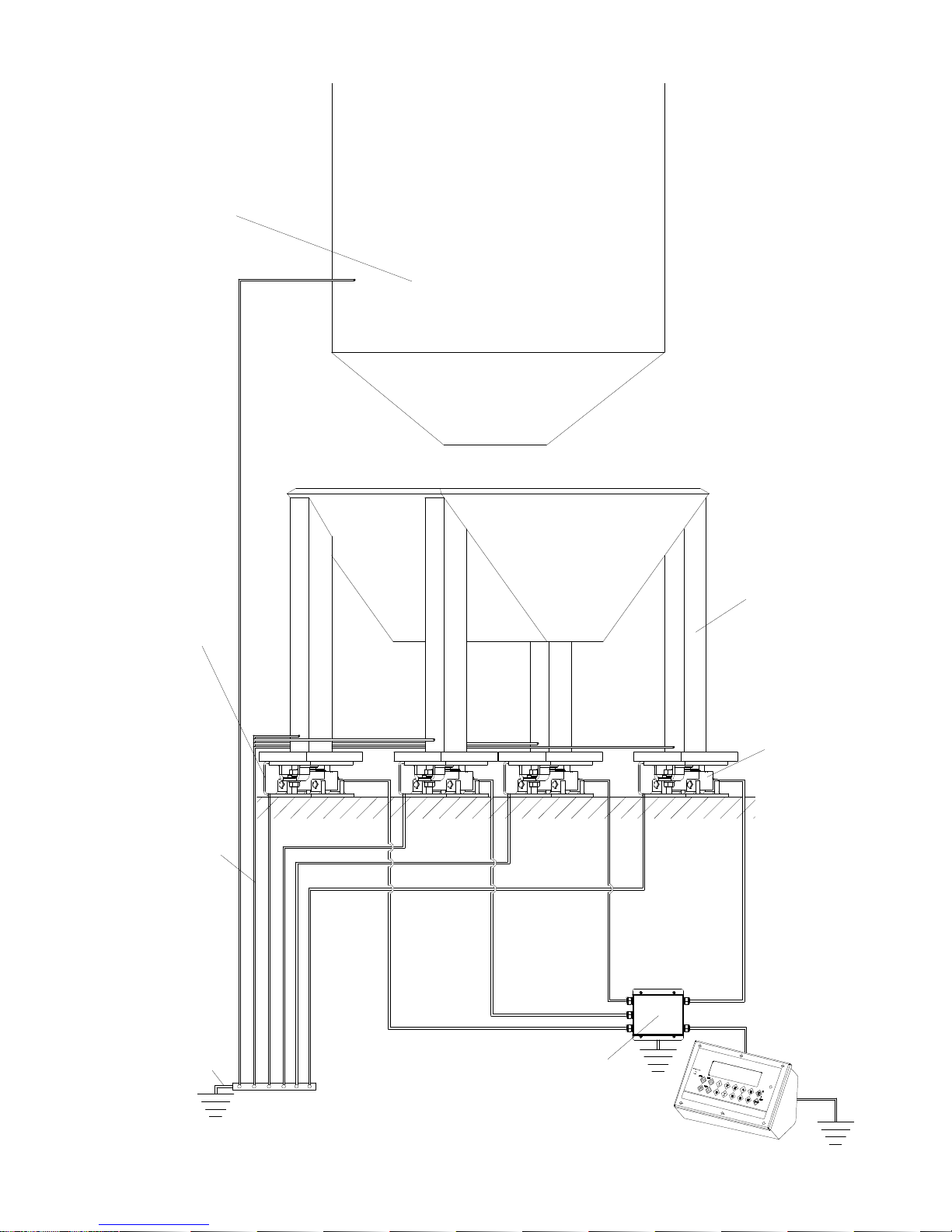

2.2 DGTQ Model....................................................................................................................................................... 5

2.3 DGTP Model...................................................................................................................................................... 6

2.4 EARTHING SYSTEM......................................................................................................................................... 7

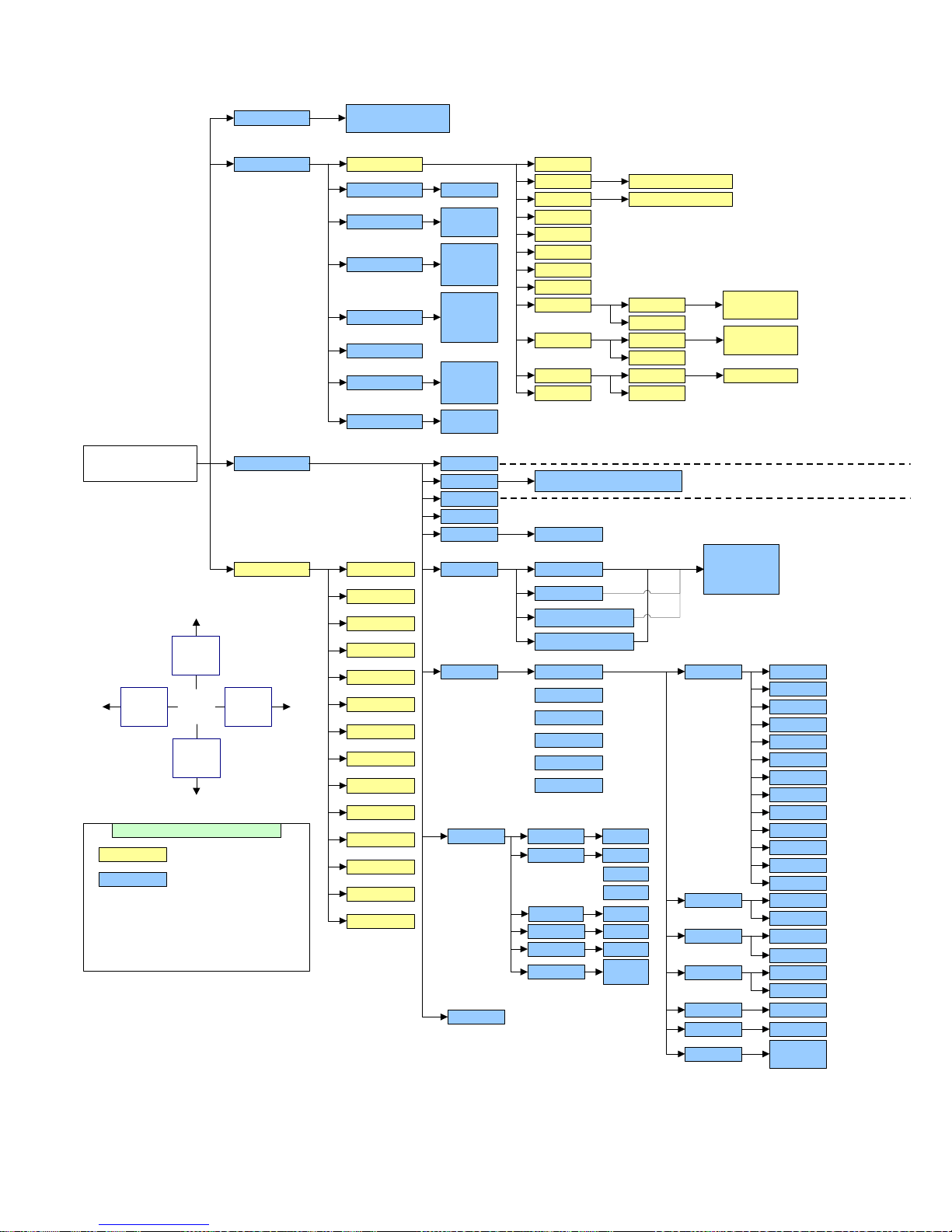

3. SETUP ENVIRONMENT .......................................................................................................................................... 9

3.1 SET UP ENVIRONMENT BLOCK DIAGRAM................................................................................................... 10

3.2 DESCRIPTION OF THE STEPS....................................................................................................................... 13

4. CALIBRATION....................................................................................................................................................... 26

4.1 Calibration procedure for the INDEPENDENT CHANNELS and "TRANSM" MODE ........................................ 26

4.2 Calibration procedure for DEPENDENT CHANNELS MODE (could eventually be digitally equalized) ............ 28

4.3 IN CASE THE ZONE OF USE IS DIFFERENT FROM THE CALIBRATION ZONE ONE SHOULD:................ 29

4.4 QUICK CALIBRATION OF ZERO..................................................................................................................... 30

4.5 THEORETICAL CALIBRATION........................................................................................................................ 30

5. GRAVITY ACCELERATION AND CORRECTION OF THE WEIGHING ERROR. ................................................ 31

5.1 INDICATION OF THE GRAVITY ACCELERATION VALUE............................................................................. 31

5.2 CORRECTION OF THE WEIGHING ERROR introduced by a different g value between the calibration and

utilisation zone (compulsory for legal type instruments).......................................................................................... 31

6. SERIAL OUTPUTS ................................................................................................................................................ 31

6.1 RS485 (DGT4 / DGT60 / DGT4 AN) or COM1 (DGTQ / DGTQ AN/ DGTP / DGTP AN) SERIAL PORT ......... 31

6.2 RS232 or COM2 SERIAL PORT....................................................................................................................... 33

6.3 PROFIBUS PORT (DGT4PB, DGTQPB and DGTPPB version)....................................................................... 34

6.4 SERIAL PORT TRANSMISSION MODES........................................................................................................ 34

6.4.1 PC PORT SELECTION.............................................................................................................................. 34

6.4.2 PC PORT ................................................................................................................................................... 35

6.4.3 PRN PORT................................................................................................................................................. 37

6.5 SERIAL COMMANDS FORMAT....................................................................................................................... 37

6.6 TRANSMISSION PROTOCOLS ....................................................................................................................... 48

6.6.1 STANDARD STRING................................................................................................................................. 48

6.6.2 EXTENDED STRING ................................................................................................................................. 49

6.6.3 MULTISCALE STRING .............................................................................................................................. 50

7. ANALOGUE OUTPUT (DGT4 AN, DGTQ AN and DGTP AN version)................................................................ 51

8. PROGRAMMING THE PRINTOUTS...................................................................................................................... 52

8.1 FORMATTING DATA AND LAYOUT................................................................................................................ 55

8.2 SAVING THE LABEL IN THE LABELLER’S PERMANENT MEMORY............................................................. 62

9. PRINTING THE HEADING..................................................................................................................................... 63

10. ERROR MESSAGES ........................................................................................................................................... 64

11. CONNECTION SCHEMES................................................................................................................................... 65

11.1 DGT4 / DGT60 / DGT4 AN MOTHERBOARD ................................................................................................ 65

11.2 DGT4 PB MOTHERBOARD ........................................................................................................................... 68

11.3 DGTQ / DGTQ AN BOARDS .......................................................................................................................... 71

11.4 DGTQ PB BOARDS........................................................................................................................................ 76

11.5 DGTP / DGTP AN / DGTP PB MOTHERBOARD ........................................................................................... 81

The maximum power of the outputs 48 Vac 0,15 A max (or 60 Vdc 0,15 A max), the maximum voltage applicable

to the inputs is between 12 ÷ 24 Vdc with current from minimum 5 mA to maximum 20 mA.................................. 83

11.7 DGTP PB EXPANSION BOARD..................................................................................................................... 85

11.8 RS 485 SERIAL PORT ................................................................................................................................... 87

NOTE FOR THE TECHNICIAN:

Please take note that when the "StEP…. (USER MAN.REF.) is mentioned, this refers to the user manual.