Table of Contents

Product Description

Operating Principle..........................................................................................1

Software ..........................................................................................................1

Getting Started

Components of the M Series System .............................................................2

PC System Requirements ...............................................................................2

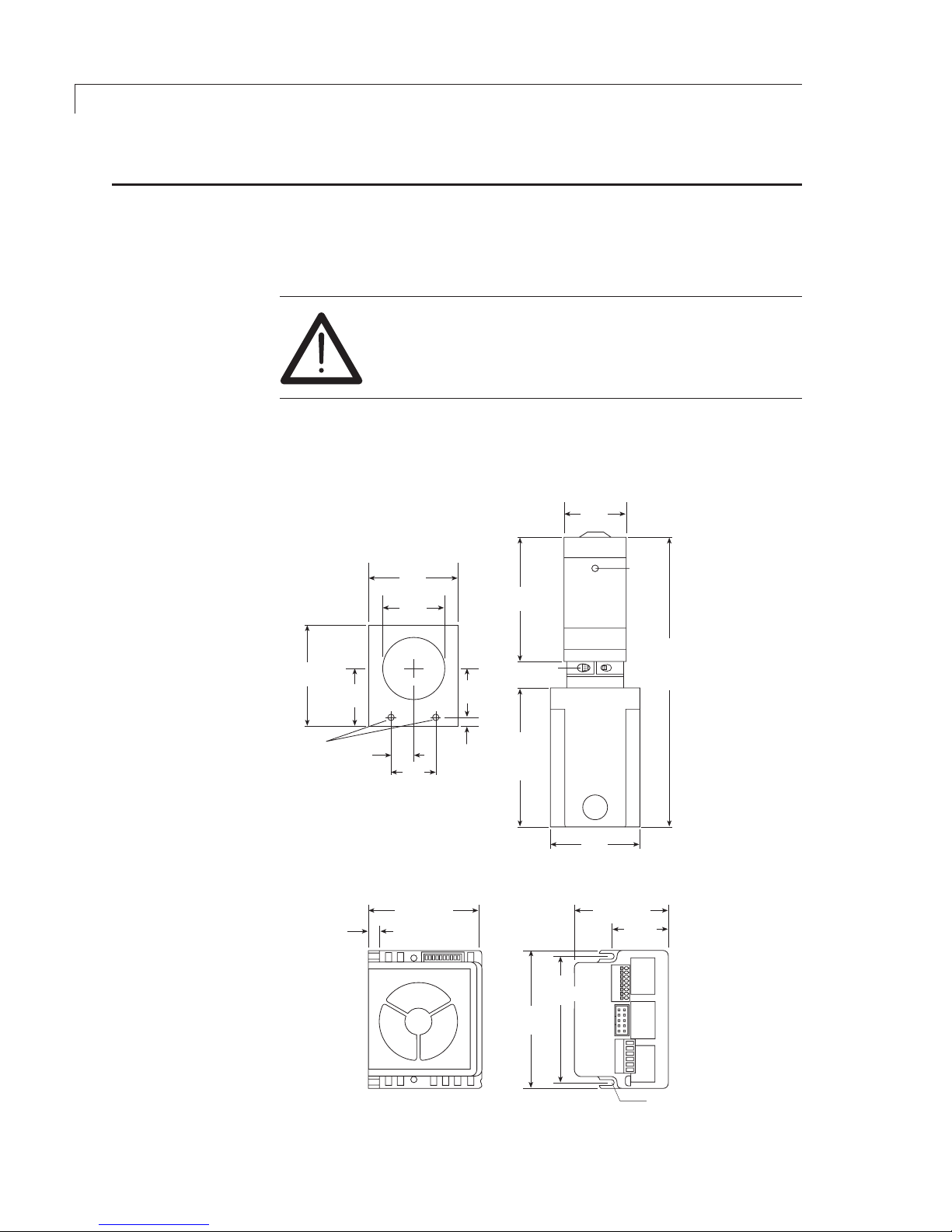

Hardware Installation

Mounting .........................................................................................................4

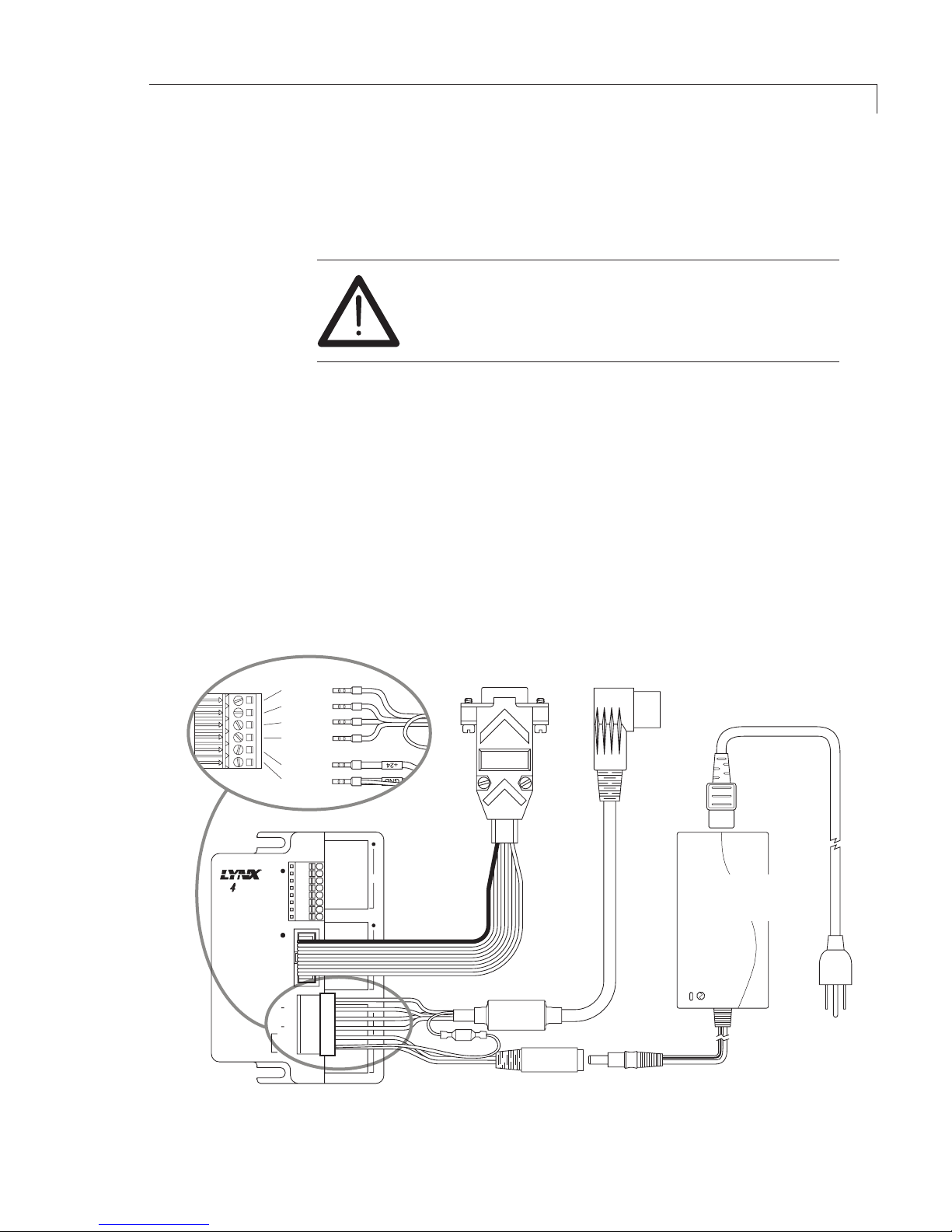

Connections ....................................................................................................5

Initial Setup

M6-LHS Software Installation ..........................................................................6

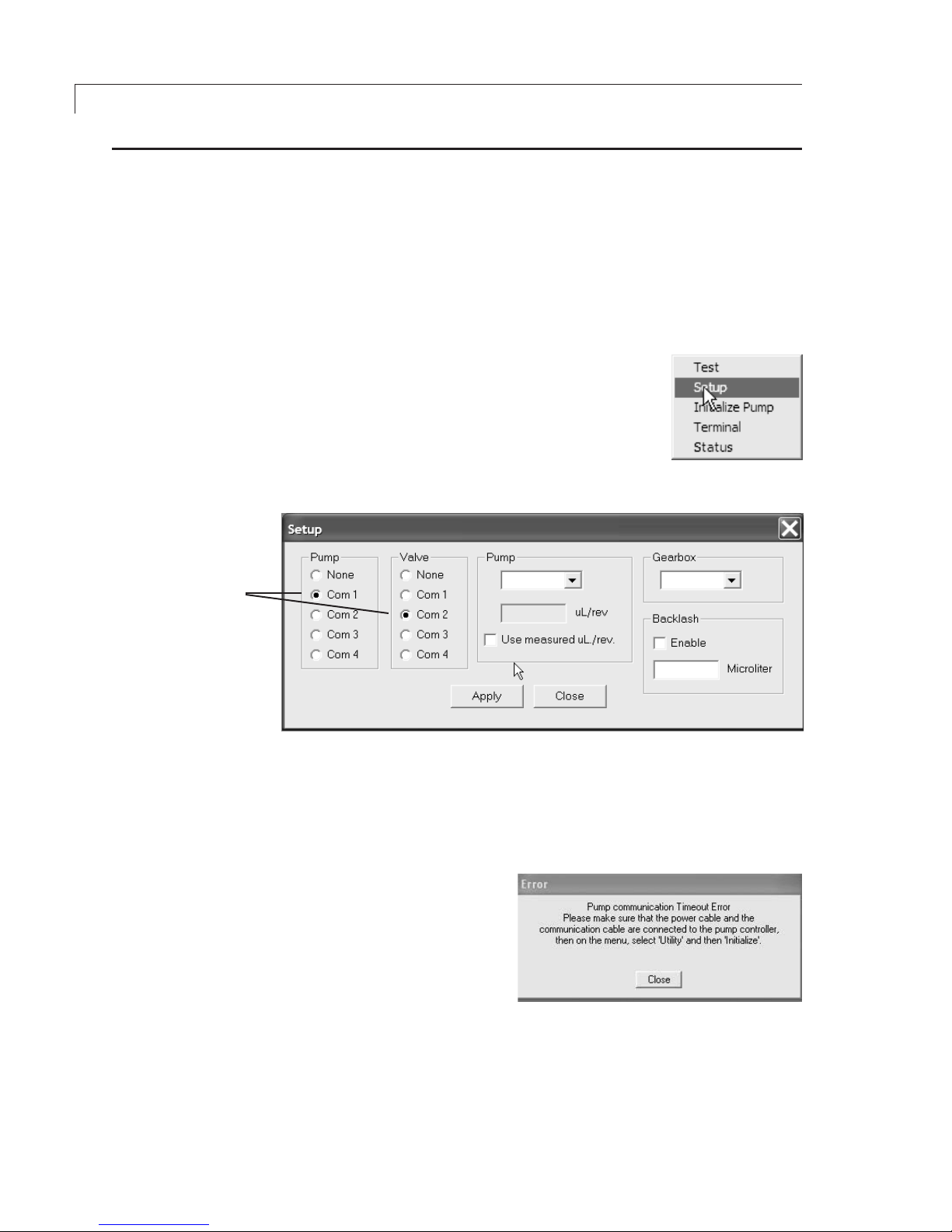

COM Port Assignment ....................................................................................6

Initialization .....................................................................................................6

Selecting Pump and Gearbox Values ..............................................................7

Setting the Backlash and Volume/Revolution Values ......................................7

Priming and Testing the Pump

Tubing Connections (M6 shown) ................................................................... 10

Initial Priming ................................................................................................10

Programming Application Methods

Method Screen Functions .............................................................................12

Example Application Methods

1. Prime System ................................................................................... 14

2. Aspirate and Dispense .....................................................................14

3. Dispense Selected Reagents ...........................................................16

Maintenance

Routine Maintenance ....................................................................................17

Routine Cleaning...........................................................................................17

Chemical Compatibility of Wetted Surfaces

Model M6 ......................................................................................................18

Model M50 ....................................................................................................19

Technical Support ................................................................................................ 20

Returning Pumps for Repair ................................................................................20

Operational and Technical Specifications ............................................................21

Appendix A: MicroLYNX Terminal Section

Terminal Programming Mode ........................................................................22

Appendix B: Setup for Multipump Operation

Connections ..................................................................................................24

Setting the Address of each MicroLYNX .......................................................25

Troubleshooting Party Mode Communications ..............................................28

Warranty ..............................................................................................................30