FUEL

SPECIFICATIONS

VICTA RECOMMENDS

"BP

ZOOM

25"

WHICH IS COLOURED

GREEN

FOR

EASY IDENTIFICA-

TION.

An

acceptable alternative fuel

is

a mixture

of

"BP

EZimix," or an equivalent high grade two-stroke oil,

and regular petrol in a ratio

of

approximately 25:1 (fuel

to

oill.

To obtain the correct

fuel/

oil mixture pour the appropriate

quantity

of

two-stroke oil into a can and

fill

with

petrol (examples:

for

a 5 litre can add 200

mL

of

oil;

for

a 4.2 litre can add 160

mL

of

oill.

Ensure contents are thoroughly mixed.

Note:

Super

may

be

used

if

regular

is

not

available.

Care

must

be

taken

to

ensure

that

all utensils

are

clean and that no

dirt

or

foreign matter

is

permitted

to contaminate the

fuel/oil

during the mixing process.

The

use

of

the fuel mixture specified above is a condition

of

the edger Warranty.

Warning:

-The use

of

car oils (multigrade) in two-stroke engine fuel will reduce engine life.

TO

START

ENGINE

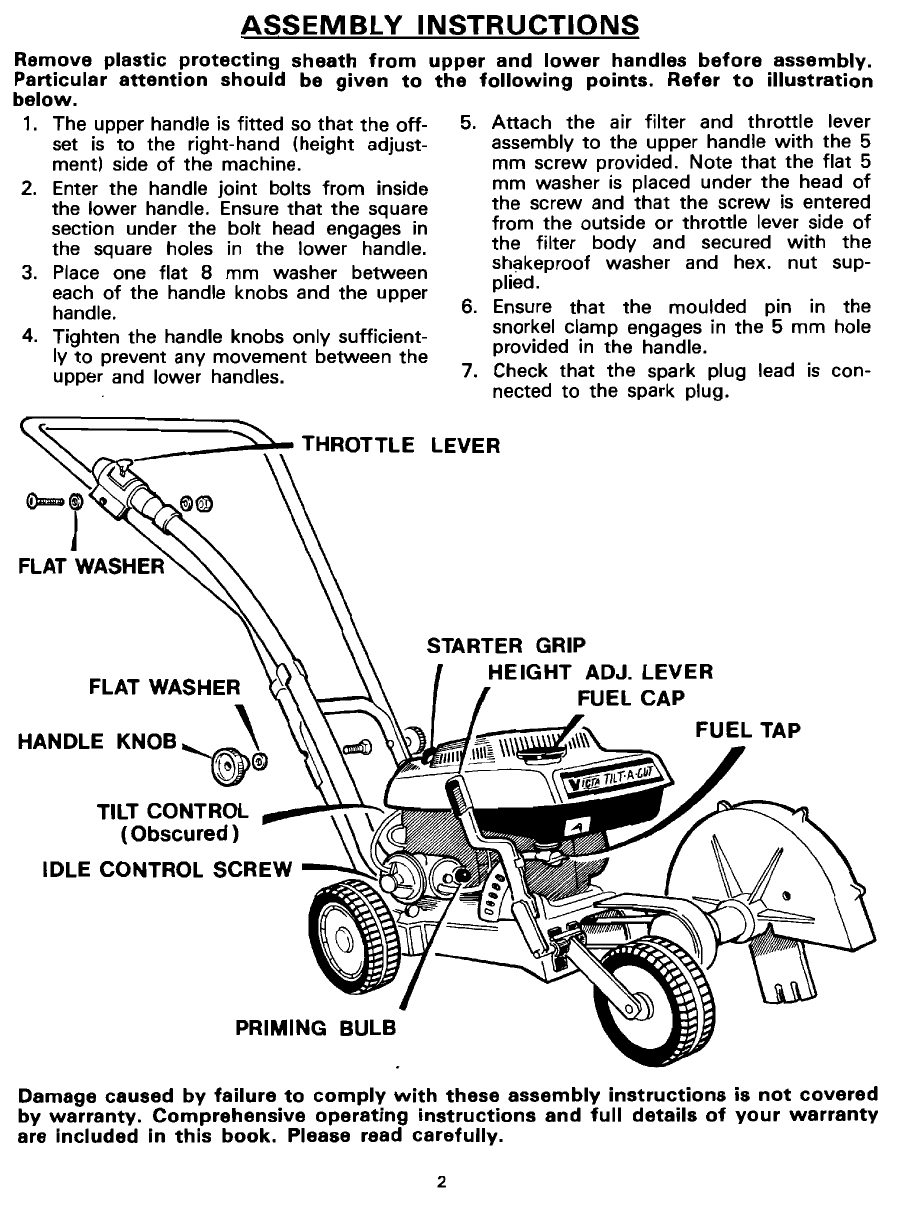

1.

CUTIING

HEIGHT. Before attempting

to

start the engine, the height adjustment should be set in the maximum

height position.

2.

FUEL. Ensure

that

the fuel tank is filled

with

the correct fuel

as

specified.

3.

FUEL TAP. The Victa Edger is normally despatched

from

the

factory

with

the fuel tap in the

"ON"

position.

Check

that

the red tap

is

turned anti-clockwise

to

the position indicated on the label directly above the fuel·tap.

Pause

for

approximately ten (10) seconds

to

allow the fuel

to

reach and fill the carburettor. See Fig. 1 opposite.

4.

THROTILE

CONTROL. The

throttle

control has five (5) settings, STOP, COLD

START,

SLOW, HOT

START

and

GRASSCUTIING.

These positions are marked on the air filter body.

COLD

START

HOT

START

(The first start

of

the day) (Engine has been running before on

that

day)

A.

Set the

throttle

lever

to

"COLD

START."

A.

Set

throttle

lever

to

"HOT

START."

Before attempting

to

start an engine which has been

stored

for

any

length

of

time, move the

throttle

control lever

to

"GRASSCUTIING".

This will

operate an internal cam in the carburettor

to

ensure

that the contacts in the ignition cut

out

switch

have

been freed.

Then set the

throttle

lever

to

"COLD

START".

B.

PRESS BLACK PRIMING BULB

ON

CARBURETIOR

B. DO NOT OPERATE PRIMING

BULB.

ONCE ONLY (See Fig. 2 oppositeL

C.

Stand

to

the right-hand (height adjustment) side

of

C.

PULL STARTER GRIP AS

IN

"COLD

START"

STEP

the edger and brace the machine

by

holding

the

up-

C.

per handle

with

the

left

hand.

With

the

toe

of

the

right

foot

on

the

rear wheel and the heel

on

the

ground

to

steady the edger, take hold

of

the

starter

grip in the right hand and pull

it

smartly towards

you.

While

still holding the starter grip,

allow

the

cord

to

rewind. Repeat pulling action

if

necessary.

After

starting a cold engine,

it

may be necessary

to

allow

it

to

run

for

a

few

seconds,

with

the

throttle

lever remaining in the

"COLD

START"

position, NOTE:

If

the engine does

not

start

first

pull. one

before adjusting the

throttle

lever

to

operating press on

the

priming

bulb

will assist. Leave

position.

throttle

lever in

"HOT

START"

position.

NOTE: STARTING A

NEW

ENGINE

Until your engine

is

fully

run-in the COLD

START

setting

of

the

throttle

lever may

not

be required.

If the engine does

not

start readily, when the COLD

START

instructions are followed,

move

the

THROTILE

LEVER

to

the HOT

START

position and continue pulling starter grip.

It should

not

be necessary

to

press primer bulb again.

3

-) 5

-r