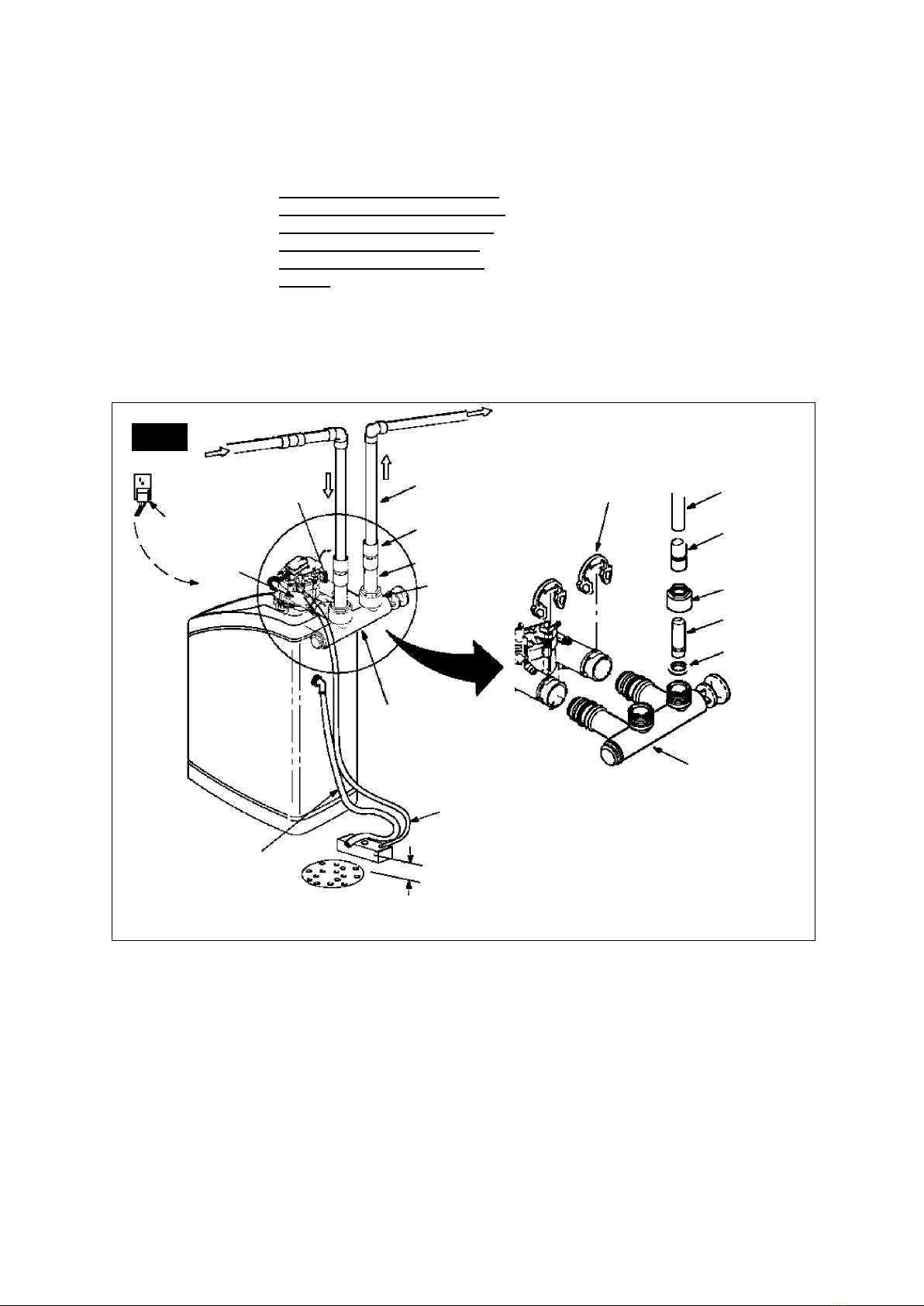

C. Checking hydraulic fittings at installation site

Tap water pressure

In order for the water softener to

function properly the pressure in the

water supply network must not be

lower than 1.4 bar and higher than 8.0

bars. If water pressure is below the

minimum, pressure raising pressure

tank must be used; if water pressure

exceeds the maximum value,

pressure regulator (pressure reducing

valve) must be installed.

Important notice!

If during daytime water pressure is

high, it is very likely that during night

time it will exceed the maximum value

of 8.0 bars. In this case, we

recommend to install a pressure

regulator. It is recommended to fit

pressure gauges on the installation, in

accordance with the schematic

diagram (figure 2), in order to control

operating water pressure in the

installation.

Water flow rate

In order for the water softener to

function properly the minimum water

flow rate at the water inlet should be

11.0 litres per minute.

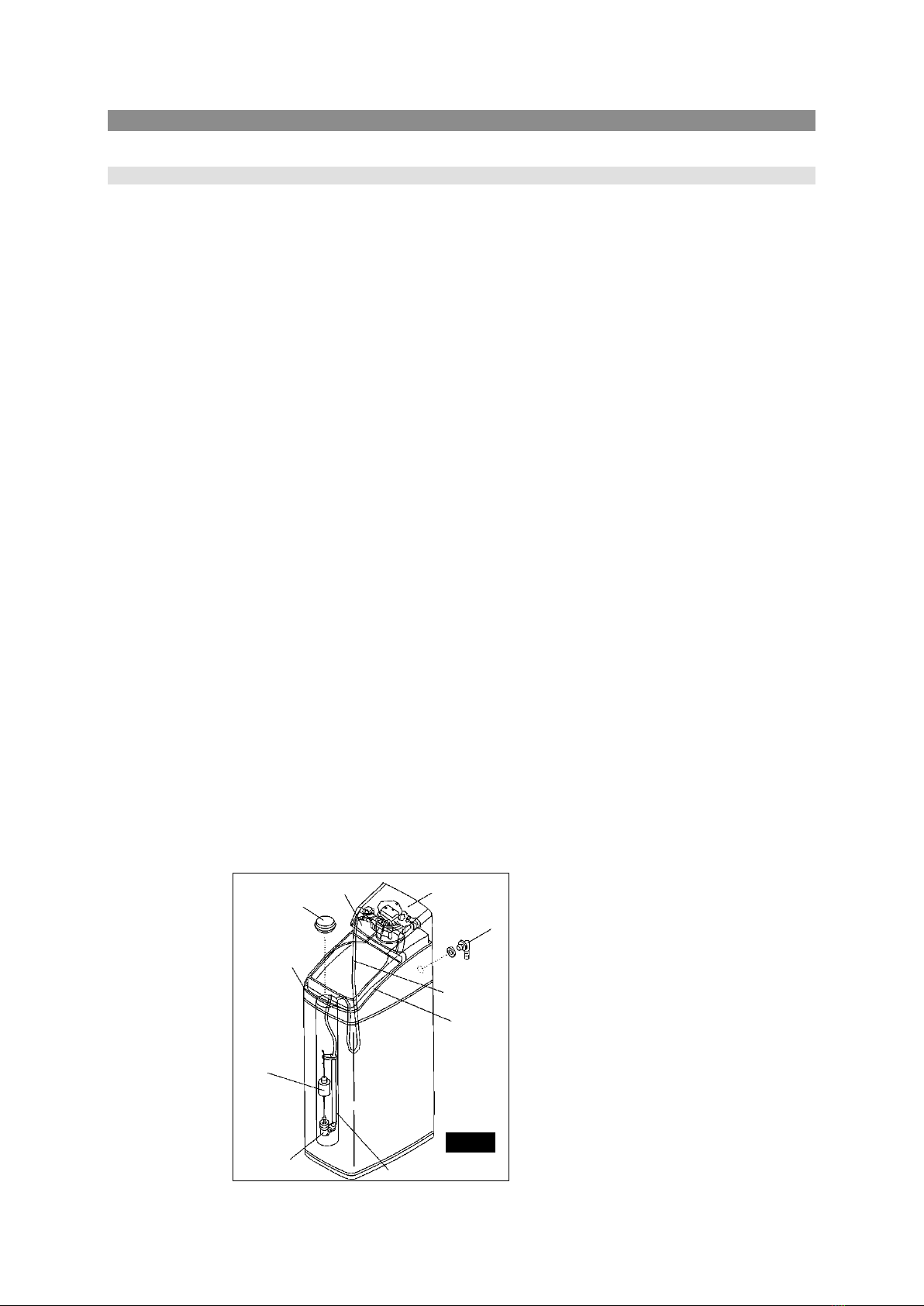

D. Selecting installation site for the device

The water softener should be

located as close as possible to

hydrophore (in case of supplying

water from private well [intake]) or

water meter measuring the whole

water in the household (in case of

supplying the household with tap

water). The device should be

located in the immediate vicinity of

the outlet drain.

When installing the device

upstream from the water heater (or

boiler unit), make sure that the

temperature of water at the

connection point does not exceed

490C. It is recommended that a

check valve is fitted between the

water softener and the water heater

(or boiler unit) in order to prevent

hot water backflow to the water

softener. Excessively hot water may

cause damage of control valve

elements as well as the ion

exchange resin.

Make sure that the valve for water

used outside of the house (such as

water used for garden watering) is

installed upstream from the water

softener. Softening of water used

outside of the house is not cost

effective (unless necessary).

Installation site of the water softener

must not be exposed to freezing. If

frozen, the water softener will be

damaged. Any damage resulting

from freezing is not covered by the

warranty.

The water softener is powered with

28 V. The transformer and power

cable are provided along with the

device. Earthed power socket for

the water softener should be

located within the immediate vicinity

of the device and should be

protected against rain and sub-zero

temperatures. The water must be

always connected to the power

supply source; the power socket

must not be fitted with a controller

that could be incidentally switched

off.

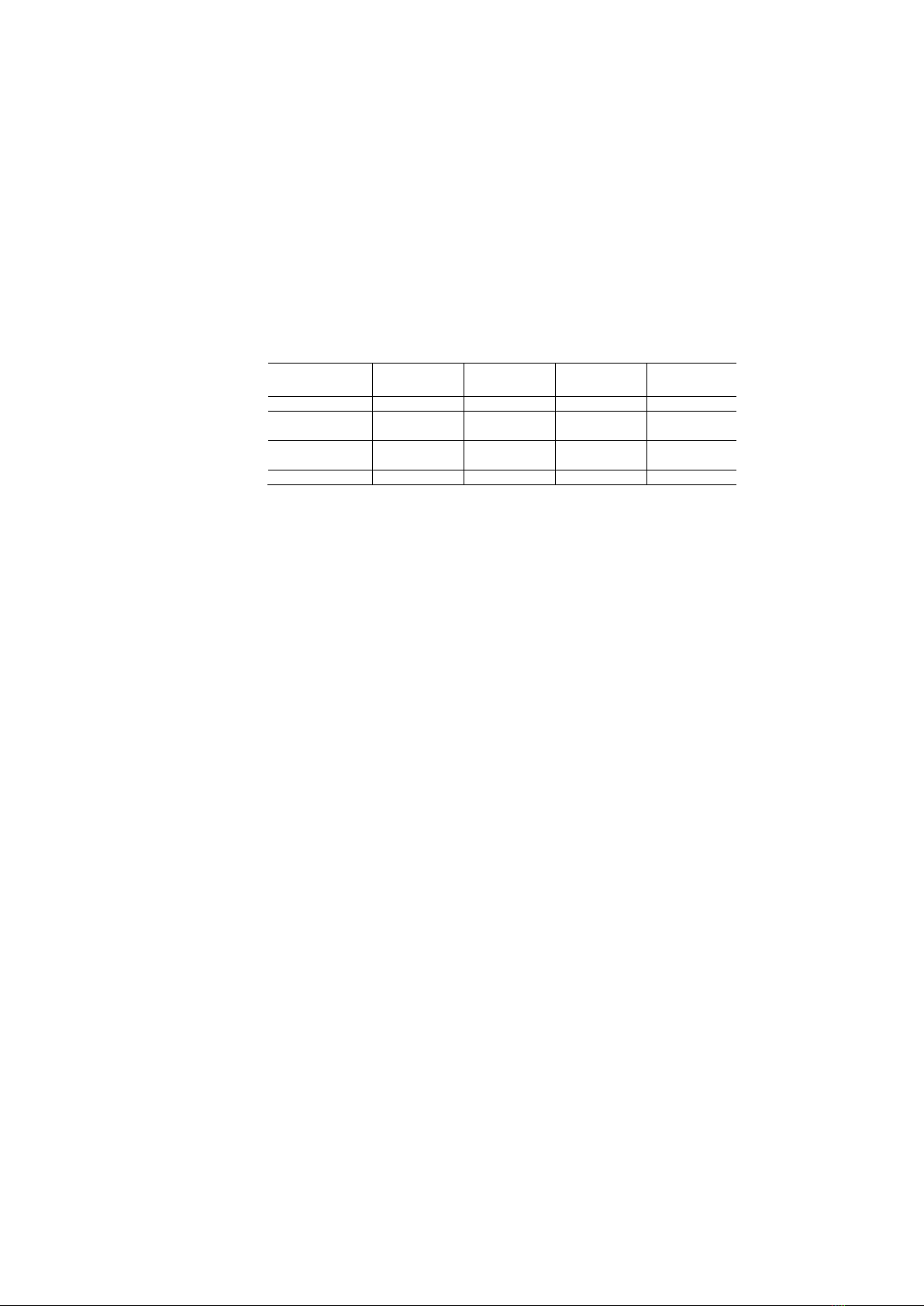

E. Materials

Before commencing installation of the device, it is

important to check relevant connection of inflow

and outflow of water to and from the water

softener. The water “inflow” connection is located

on the right side of the device and water “outflow”

connection on its left side, when facing the device

(fig. 3).