Page 2of 16

Version 1.0 –June 2021

All machinery, especially CNC machinery, has inherent dangers and risks. It is the responsibility of

the system designer to ensure that any systems built using any Viking Machinery Ltd. products are

safe for use. Any technical information is provided as a reference only, and does not constitute a

recommendation as to the fitness of use in any particular application.

Viking Machinery Ltd. strongly urges customers to seek expert advice when dealing with potentially

dangerous electrical voltages and sources of mechanical energy. Information contained in this

document does not constitute a substitute for expert advice.

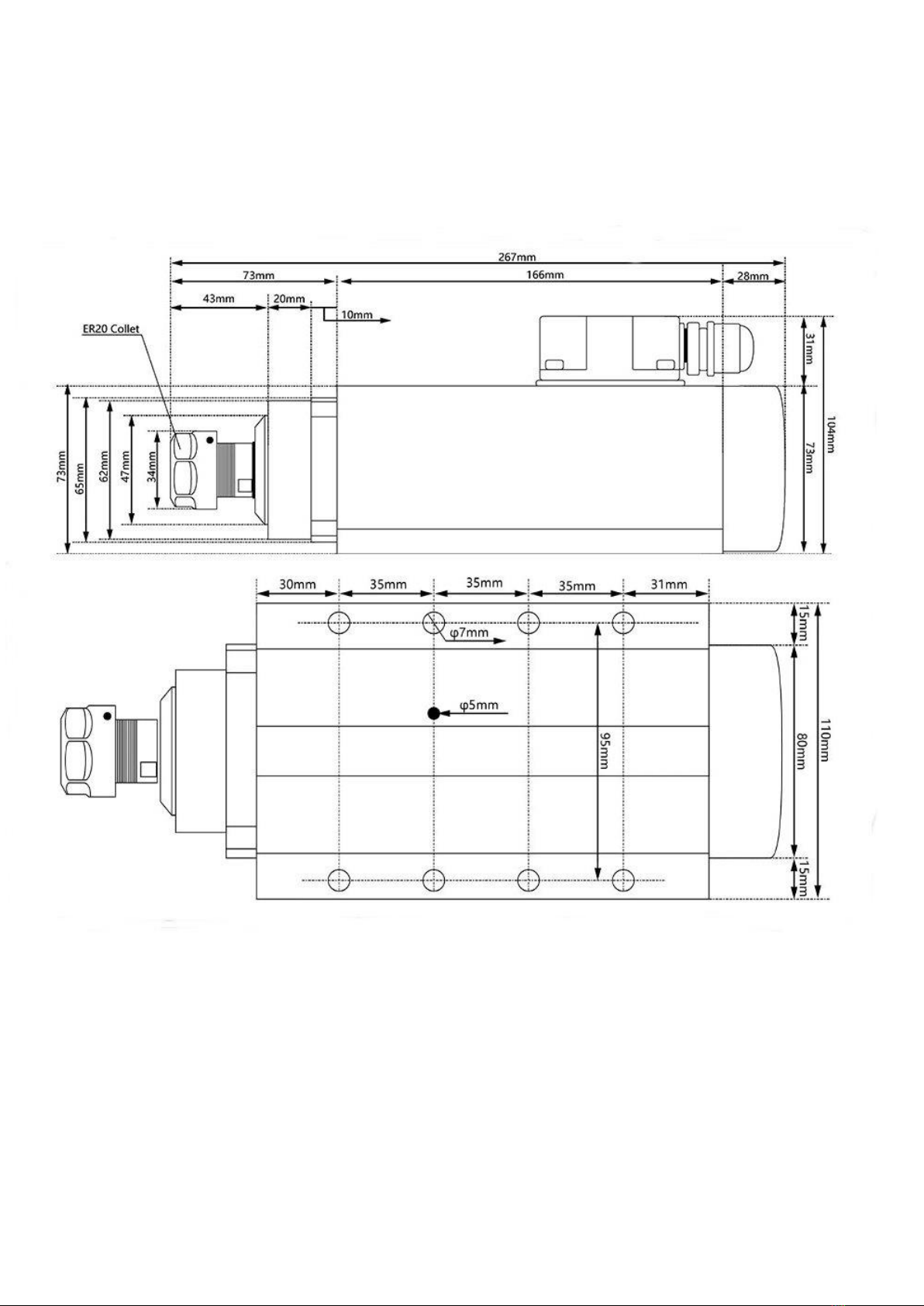

•Spindle Power –2.2kW

•Spindle Maximum Speed –18,000 rpm

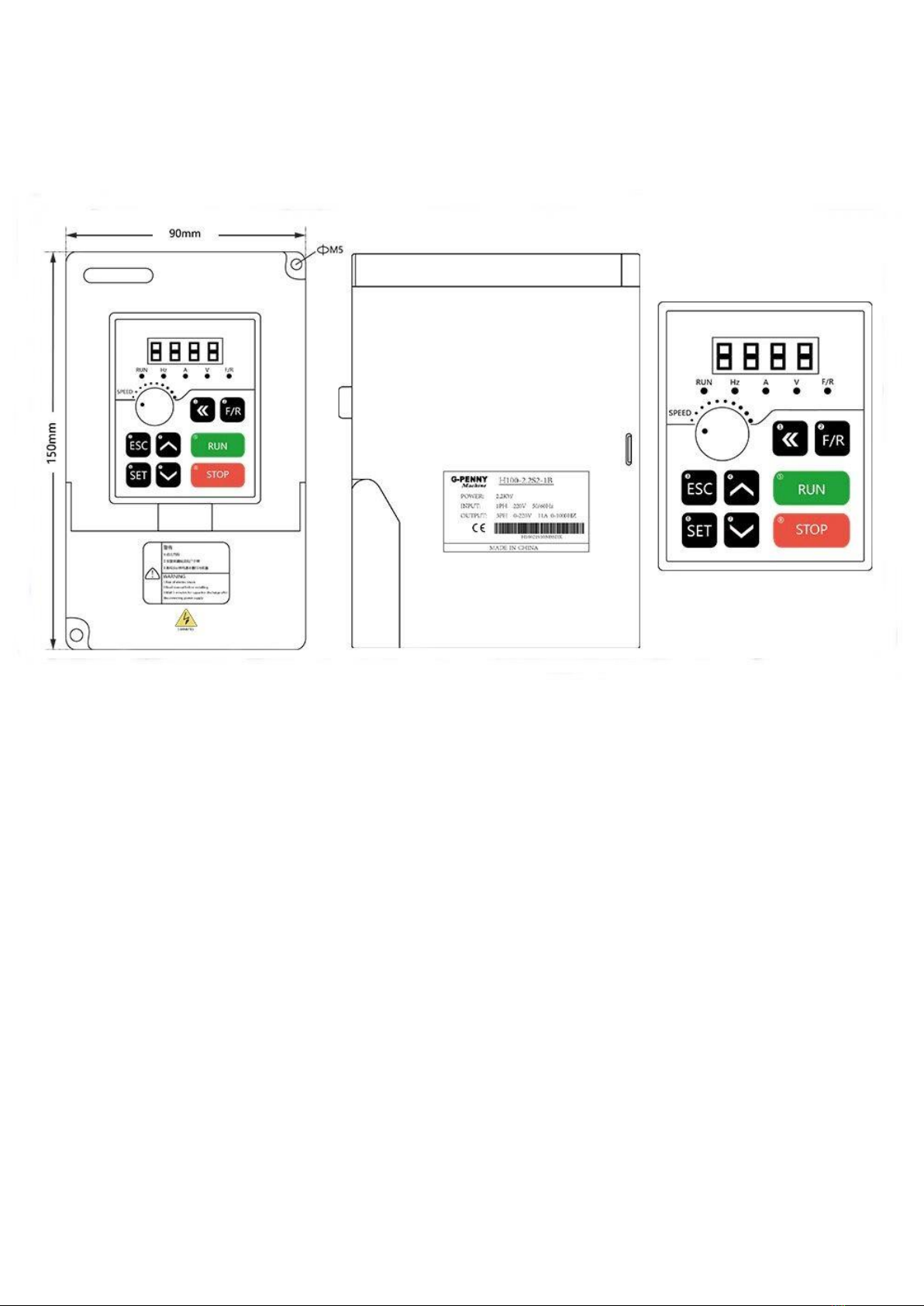

•VFD Supply Voltage –230V AC

•VFD Maximum Current –9.5A

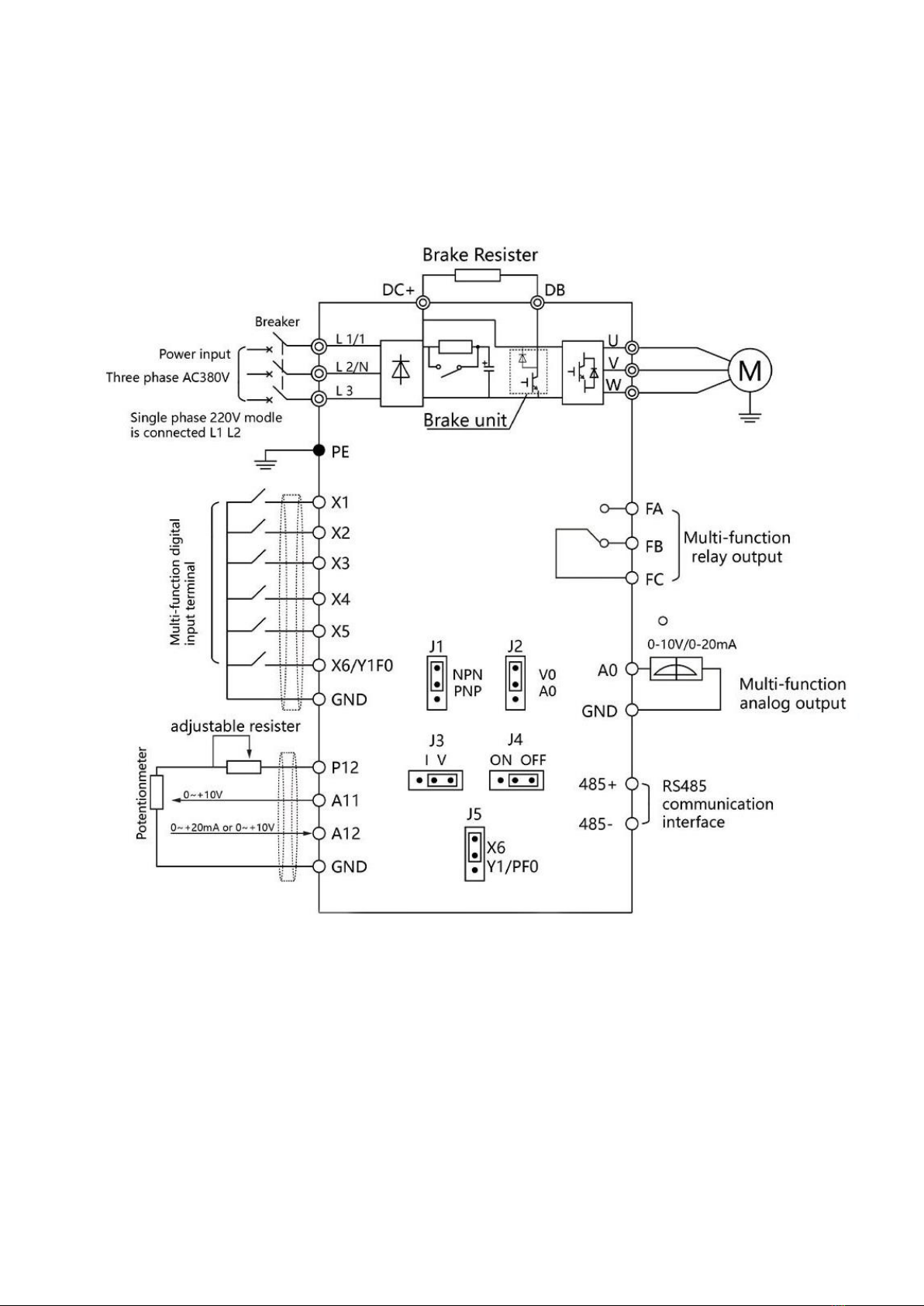

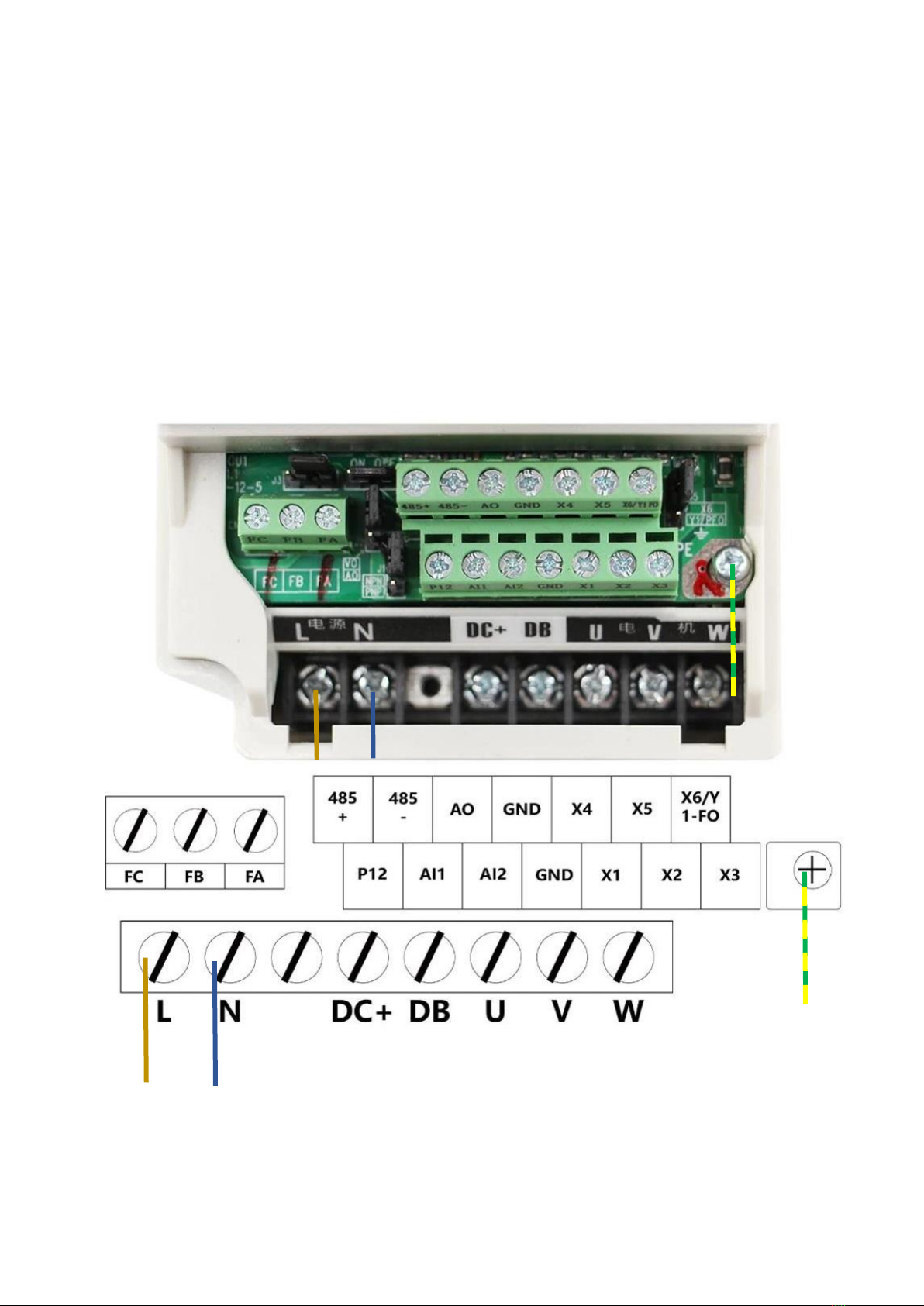

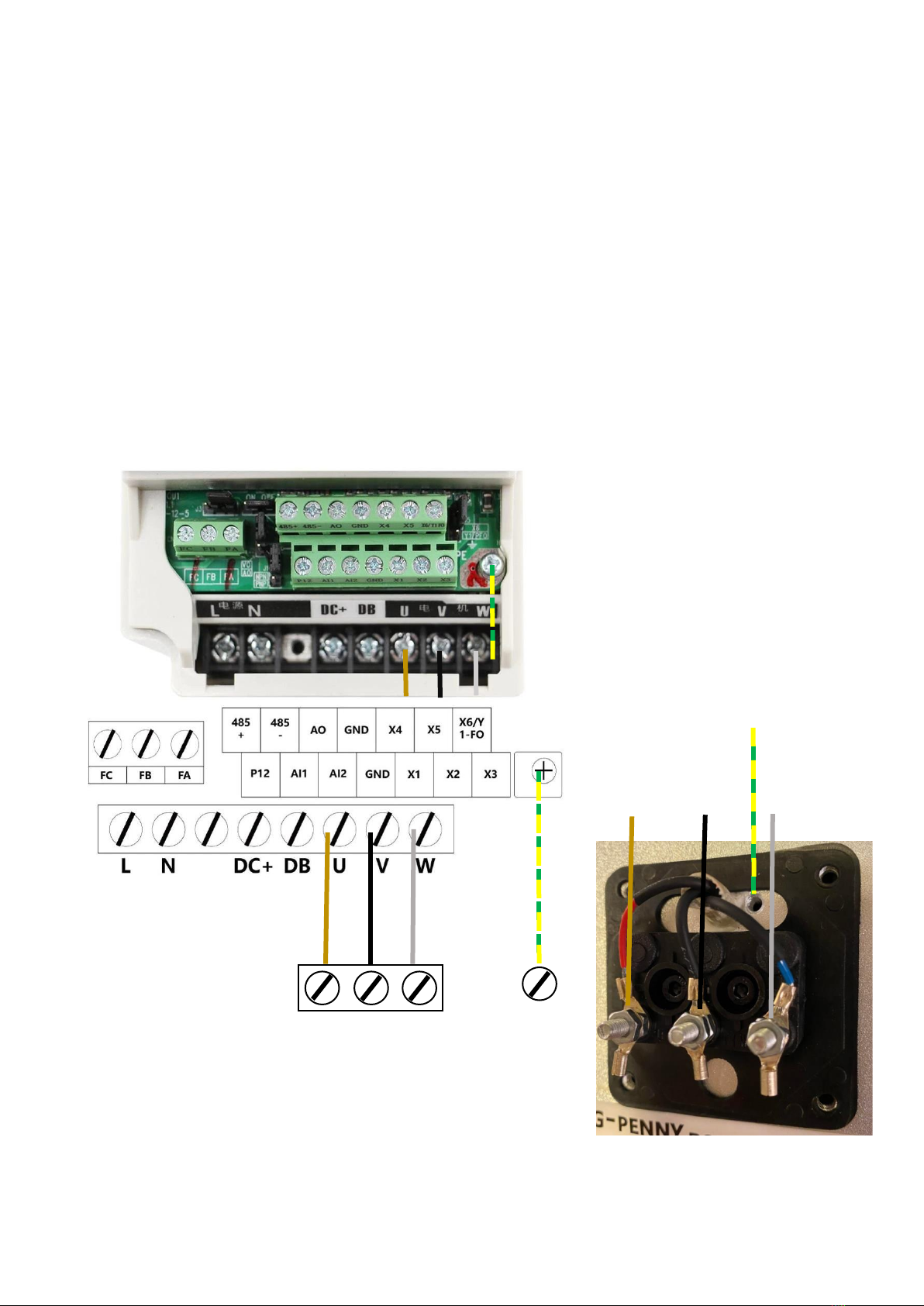

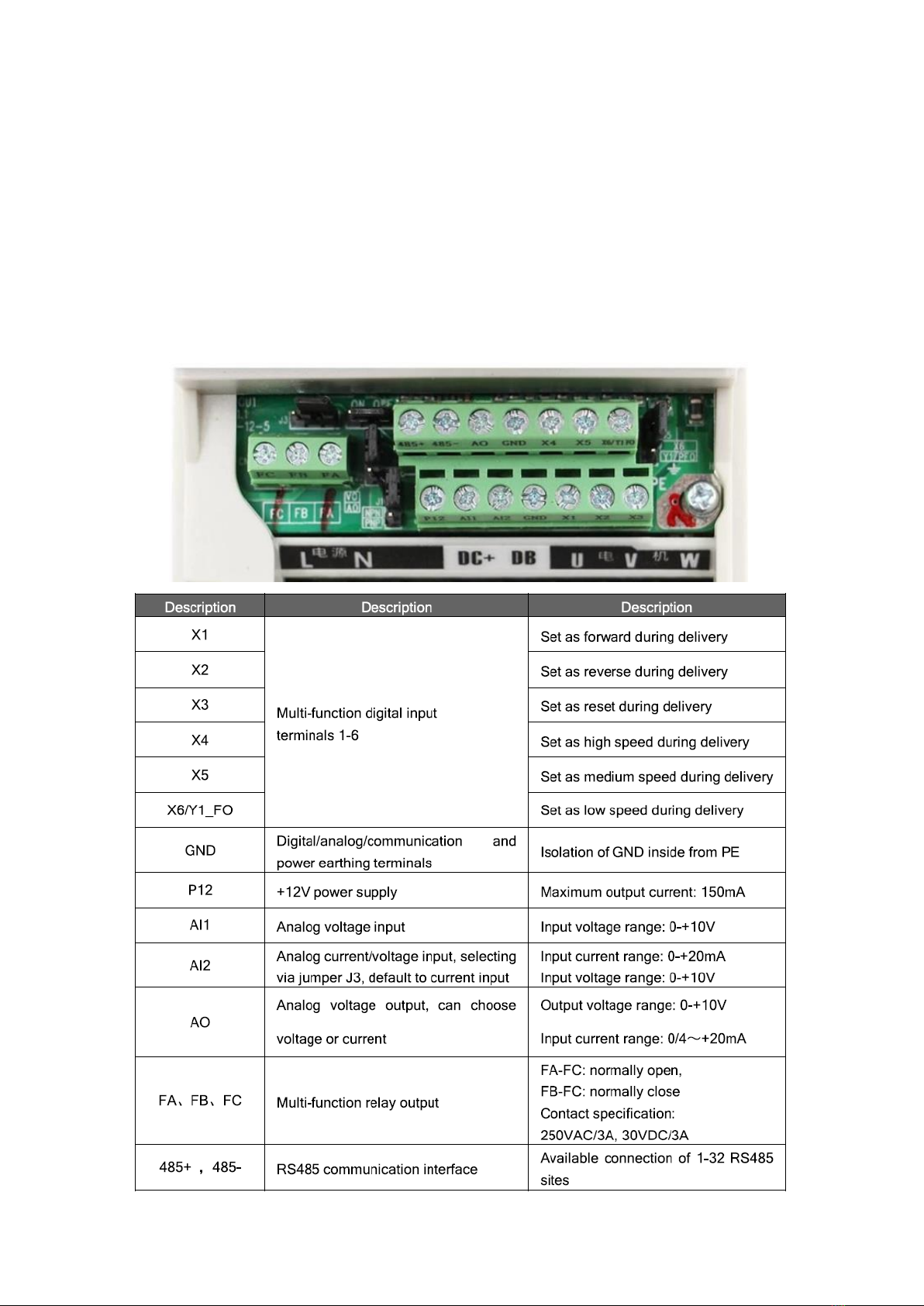

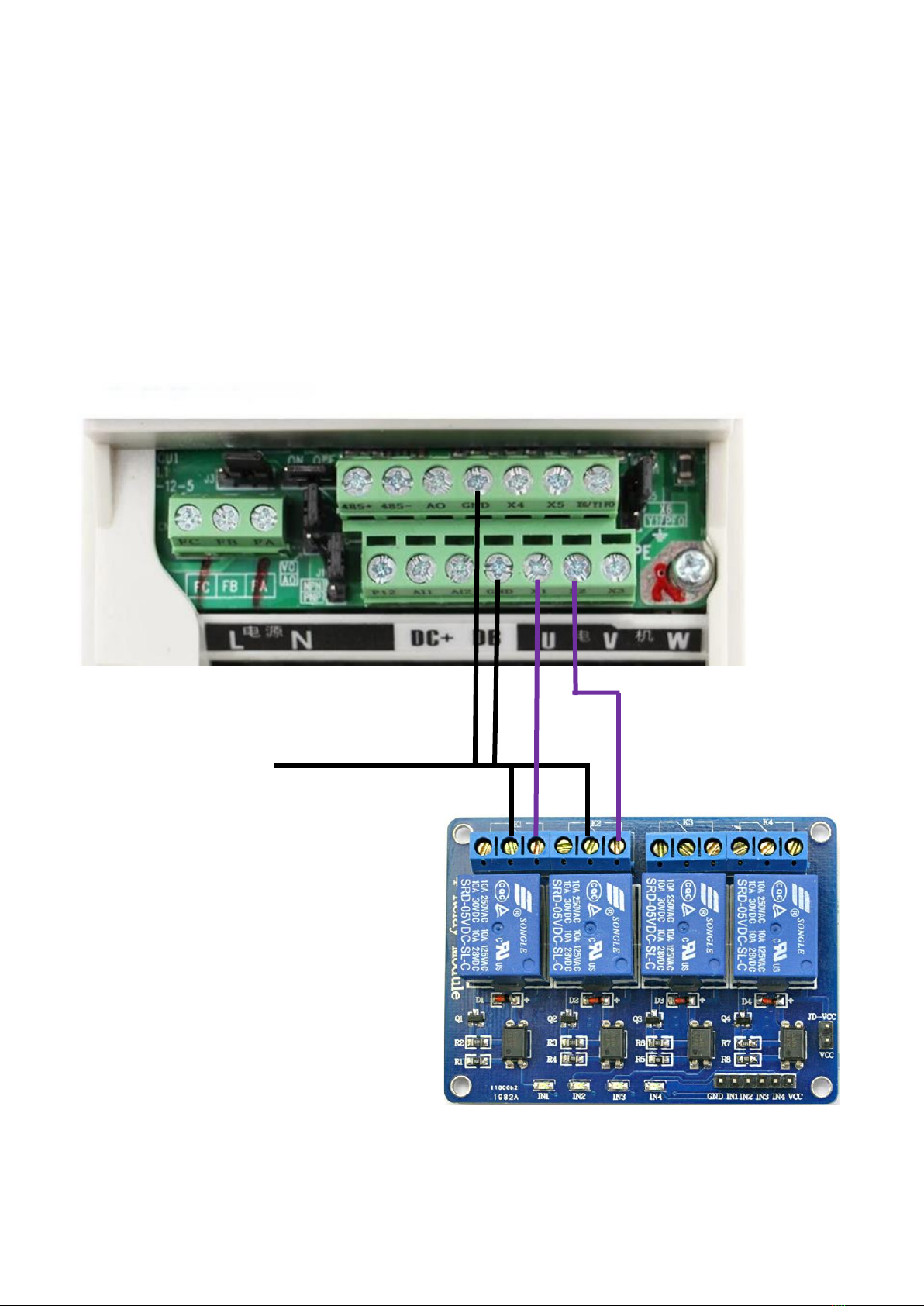

This document is designed to give an overview of the wiring options for the aircooled ER20 spindle

and H100 VFD products. The H100 VFD accepts several input / control wiring set ups, but only those

commonly used in CNC applications will be discussed here.

There is a factory supplied user manual for the H100 VFD. It is available for download HERE. Please

familiarise yourself with this document as it contains much technical information that will not be

covered in this document.

Software setting examples are given for Mach 3 only, but other CNC software will also work with the

board.