ESCUTCHEON MATERIALS

1. Adjustable Standard Dry Escutcheon:

Brass UNS-C26000 or UNS-C26800

2. Recessed Dry Escutcheon: Cold

Rolled Steel UNS-G10080

ACCESSORIES

Standard Dry Sprinkler Wrench: Part

No. 07297W/B

Recessed Dry Sprinkler Wrench: Part

No. 07565W/B***

***Requires a separate ½" ratchet (not available

from Viking).

Replacement Escutcheons:

1. Adjustable Standard Dry Escutcheon:

Base Part No. 08086F

2. Recessed Dry Escutcheon: Base Part

No. 05459A

AVAILABLE FINISHES

•Recessed: Chrome-Enloy®(patents

pending) or White Polyester

•Standard Adjustable: Chrome-Enloy®

•Plain Barrel: Chrome-Enloy®or Brass

(sprinkler only)

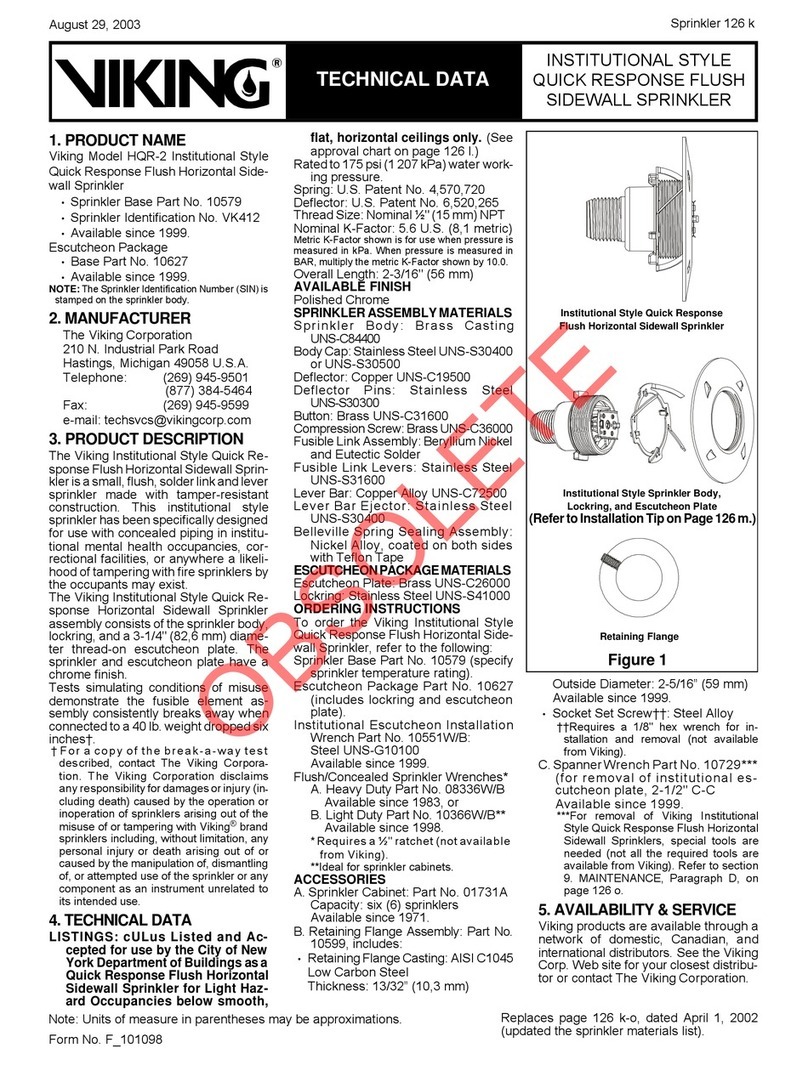

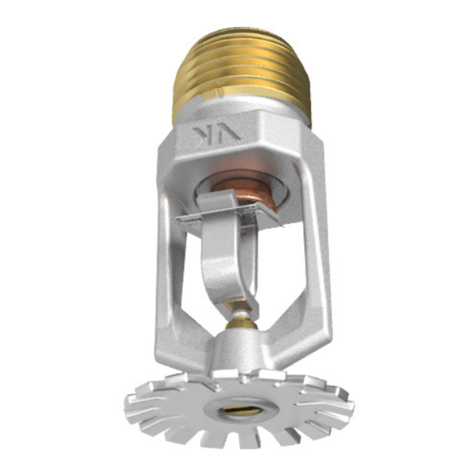

5. ORDERING INFORMATION

For proper shipment, specify model, fin-

ish, temperature rating, escutcheon

type, and length (“A” Dimension. Dry

horizontal sidewall sprinklers are or-

dered in specific lengths noted as the “A”

dimension (see Figures 1 through 4).

The “A” dimension is the distance from

the face of the fitting (tee) to the finished

surface of the wall in which it is to be in-

stalled. The dry horizontal sidewall

sprinkler must be ordered and manufac-

tured specifically for one of three styles

of installation: with the adjustable re-

cessed escutcheon (see Figure 1), with

the adjustable standard escutcheon (see

Figures 2 and 3), or with the plain barrel

(see Figure 4). For limits of adjustment for

the recessed escutcheon, see Figure 1.

Details and limits of adjustment for the

standard escutcheon style, with 2" (50,8

mm) of adjustment, are shown in Figure 2.

6. INSTALLATION

WARNING: Viking sprinklers are manu-

factured and tested to meet the rigid re-

quirements of approving agencies. The

sprinklers are designed to be installed in

accordance with recognized installation

standards. Deviation from the standards

or any alteration to the sprinkler after it

leaves the factory including, but not lim-

ited to: painting, plating, coating, or modifi-

cation, may render the sprinkler inopera-

tive and will automatically nullify the ap-

proval and any guarantee made by Viking.

A. Viking sprinklers are to be in-

stalled in accordance with the lat-

est edition of Viking technical

data, the latest standards of NFPA,

FM Global, Loss Prevention Coun-

cil, Assemblee Pleniere, VdS or

other similar organizations, and

also with the provisions of gov-

ernmental codes, ordinances, and

standards, whenever applicable.

The use of dry horizontal sidewall

sprinklers may be limited due to

occupancy and hazard. Refer to

the AHJ prior to installation.

B. Sprinklers must be handled with care.

They must be stored in a cool, dry place

in their original container. Never install

sprinklers that have been dropped,

damaged in any way, or exposed to

temperatures in excess of the maxi-

mum ambient temperature allowed (re-

fer to Table 1). Such sprinklers

should be destroyed. Never install

any glass-bulb sprinkler if the bulb is

cracked or if there is a loss of liquid from

the bulb. If a glass bulb lacks the ap-

propriate amount of fluid, it should be

set aside and returned to Viking (or

an authorized Viking distributor) for

analysis as soon as possible. If the

sprinkler is not returned to Viking, it

should be immediately destroyed.

C. Viking Standard Response Dry Hori-

zontal Sidewall Sprinklers are not in-

tended for use in corrosive environ-

ments. Use only sprinklers listed for

corrosive environments when sub-

ject to corrosive atmospheres.

WARNING: Viking dry sprinklers are

to be installed in the 1" outlet or run of

malleable or ductile iron threaded tee

fittings that meet the dimensional re-

quirements of ANSI B16.3 (Class

150), or cast iron threaded tee fittings

that meet the dimensional require-

ments of ANSI B16.4 (Class 125),

even at branch line ends. The

threaded end of the dry sprinkler is de-

signed to allow the seal to penetrate

and extend into the fitting to a prede-

termined depth. This prevents con-

densation from accumulating and

freezing over the sprinkler seal.

1. DO NOT install the dry sidewall

sprinkler into a threaded elbow,

coupling, or any other fitting that

could interfere with thread penetra-

tion. Such installation will dam-

age the brass seal.

2. DO NOT install the dry sidewall sprin-

kler into a coupling or fitting that will

allow condensation to accumulate

above the seal, when located in an

area subject to freezing.

3. NEVER try to modify the dry horizon-

tal sidewall sprinkler. The sprinklers

are manufactured for specific “A” di-

mensions and cannot be modified.

D. The sprinkler must be installed after

the piping is in place to prevent me-

chanical damage. Keep sprinklers with

protective caps or bulb shields con-

tained within the caps or shields during

installation and testing, and any time

the sprinkler is shipped or handled.

1. Before installing the sprinkler, make

certain the “A” dimension is correct

and the sprinkler is the appropriate

model and style, orifice size, and

temperature rating.

Sprinkler 102 b

TECHNICAL DATA

½" (12,7 mm)

3-1/16"

(77,8 mm)

4" (102 mm) Minimum

6" (152 mm) Maximum

For "A" Dimension:

1. Determine the distance from face of tee to face

of finished wall.

2. Round to nearest 1/4" (6,35 mm) between 3-1/4"

and 47-1/2” (82,5 mm and 1 207 mm).

NOTE: The sprinkler will be recessed approximately

5/16" (7,9 mm) with 5/8" (15,8 mm) horizontal

adjustment

available.

Minimum ceiling hole size:

2-1/8" (54 mm) diameter.

Maximum ceiling hole size:

2-1/2" (63,5 mm) diameter.

Ceiling

Wall

Figure 1: Adjustable Recessed Dry Horizontal Sidewall Sprinkler

5/16" (7,9 mm) Outward Adjustment

1-7/8" (47,6 mm) Minimum

2-1/2" (63,5 mm) Maximum

Available

Adjustment

5/16" (7,9 mm) Inward Adjustment

STANDARD RESPONSE

DRY HORIZONTAL

SIDEWALL SPRINKLERS

December 17, 2004