necessary,replaced after a specified

term of service. Refer to the installa-

tion standards and the Authority Hav-

ing Jurisdiction for the specified pe-

riod of time after which testingand/or

replacement is required. Sprinklers

that have operated cannot be reas

-

sembled or reused, but must be re-

placed. When replacing sprinklers,

use only new sprinklers.

C. The sprinkler discharge pattern is

critical for proper fire protection.

Nothing should be hung from the

sprinkler, attached to it, or otherwise

obstruct the discharge pattern. All

obstructions must be immediately re-

moved or, if necessary, additional

sprinklers installed.

D. When replacingexisting sprinklers,the

systemmustberemoved from service.

Refer to the appropriate system de

-

scription and/or valve instructions.

Prior to removing the system from ser-

vice, notify all AHJs. Consideration

should be given to employment of a

fire patrol in the affected area.

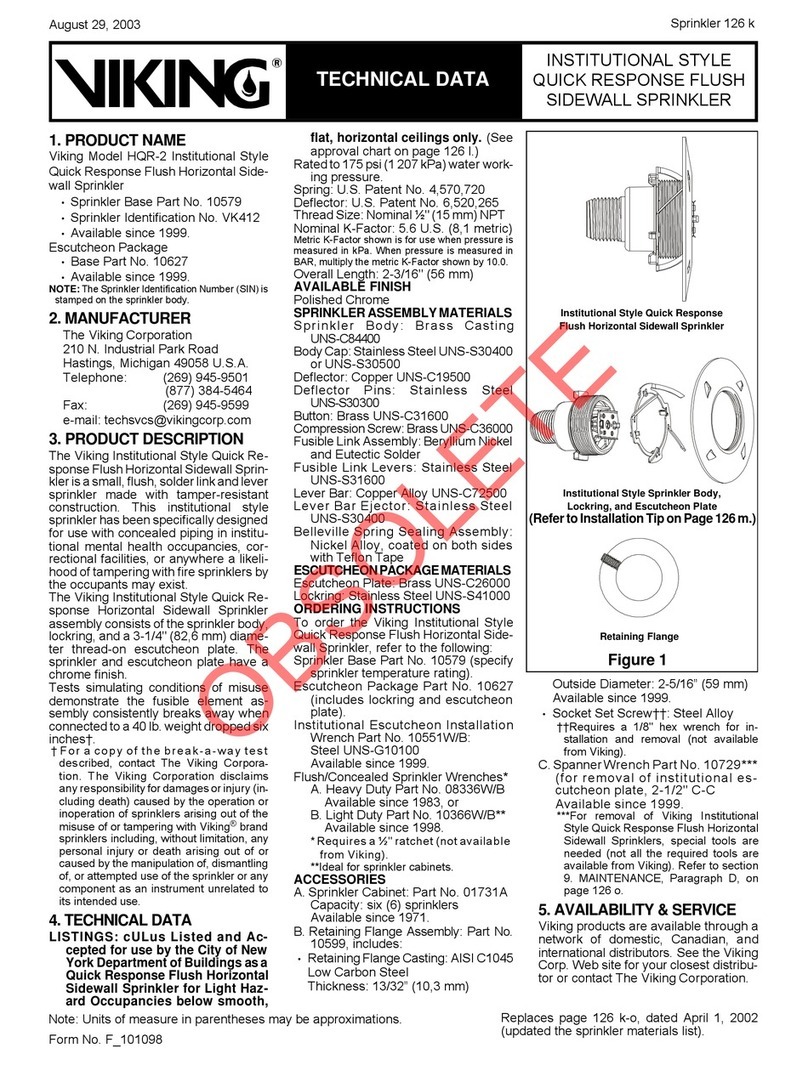

DISASSEMBLY: There are two meth

-

ods of sprinkler disassembly. In Method

1, the escutcheon plate and lockring

areremovedfirst, and then the remain-

ing sprinkler components can be re-

moved without being destroyed. The

second method of disassemblyresults

in complete destruction of the unit.

Disassembly Method 1:

1. Remove the system from service,

drain all water, and relieve all

pressure on the piping.

2. Use a drill (not available from Vi

-

king) sized appropriately for use

with a spanner wrench (see step

3) to make two holes through two

opposite indentations on the face

of the escutcheon plate.

3. Use a 2-1/2" C-C spanner wrench

(Viking P/N 10729) to unthread

the escutcheon plate by turning it

counterclockwise. Make sure that

the sprinkler body does not turn or

loosen.

4. Remove the lockring from the

sprinkler body.

5. Place a protective sprinkler shell

(from the spare sprinkler cabinet)

overthesprinklertoberemoved.

6. With the protective shell over the

sprinkler, place the special Flush/

Concealed Sprinkler Wrench over

the unit and turn it counterclockwise

to carefully unthread the sprinkler

body from the reducing coupling.

7.Install the new unit using the Flush/

Concealed Sprinkler Wrench.

Care must be taken to ensure that

the replacement sprinkler is the

proper model and style, with the

appropriate orifice size, tempera-

ture rating, and response charac

-

teristics. A fully stocked spare

sprinkler cabinet should be pro-

vided for this purpose. (Stock of

spare lockrings and escutcheon

plates should be available in the

spare sprinkler cabinet in addition

to the spare sprinkler heads.)

8. Place the system back in service

and secure all valves. Check for

and repair all leaks.

Disassembly Method 2:

1. Remove the system from service,

drain all water, and relieve all

pressure on the piping.

2. Disassemble and remove the fus-

ible element, and bend the deflec-

tor and sealing assembly to ex-

pose the waterway of the sprin

-

kler.

3. Insert an easy-out screw extractor

(Trade No. 6) into the waterway.

Turn the easy-out counterclock-

wise with a wrench to remove the

sprinkler assembly from the re-

ducing coupling.

4. Install the new unit using the

Flush/Concealed Sprinkler Wrench.

Care must be taken to ensure that

the replacement sprinkler is the

proper model and style, with the

appropriate orifice size, tempera

-

ture rating, and response charac-

teristics. A fully stocked spare

sprinkler cabinet should be pro-

vided for this purpose. (Stock of

spare lockrings and escutcheon

plates should be available in the

spare sprinkler cabinet in addition

to the spare sprinkler heads.)

5. Place the system back in service

and secure all valves. Check for

and repair all leaks.

E. Sprinkler systems that have been

subject to a fire must be returned to

service as soon as possible. The en

-

tire system must be inspected for

damage and repaired or replaced as

necessary. Sprinklers that have

been exposed to corrosive products

of combustion or high ambient tem

-

peratures, but have not operated,

should be replaced. Refer to the Au

-

thority Having Jurisdiction for mini-

mum replacement requirements.

Sprinkler 126 d

Form No. F_100998

NOTE: This method of

disassembly results in damage to

the escutcheon plate and lockring,

and they cannot be reused.

NOTE: This method of disassembly

results in complete destruction

of the unit. None of the sprinkler

components may be reused.

TECHNICAL DATA

Sprinkler Temperature

Classification Nominal Temperature

Rating (Fusing Point) Maximum Ambient

Ceiling Temperature1,2

Ordinary 165 °F (74 °C) 100 °F (38 °C)

Intermediate 220 °F (104 °C) 150 °F (66 °C)

Approval Chart

Institutional QR Flush Pendent Sprinkler

Thread Size Orifice

Size Nominal K-Factor Overall Length Sprinkler Base

Part No.3SIN

NPT BSP U.S.8metric4Inches mm

½" 15 mm Standard 5.6 8,1 2-9/32 57,9 10554 VK410

Standard Coverage Applications

Refer to minimum flow and pressure requirements

as specified in current NFPA Standards.

Listings5,6

cULus8FM NYC LPCB

A1 –B19–

Extended Coverage Applications

For Light Hazard Occupancies Only

Maximum Area of Coverage:

16' Wide x 16' Throw (4,9 m x 4,9 m)

Minimum Water Supply Requirements:

26 gpm @ 21.6 psi (98,4 L/min @ 148,6 kPa)

Listings5,7

cULus8FM NYC LPCB

A1 – – –

Temperature Ratings

A - 165 °F (74 °C) and 220 °F (104 °C)

B - 165 °F (74 °C) only

Available Finish

1 - Polished Chrome

1Based on NFPA-13. Other limits may apply, depending on fire loading, sprinkler location, and

other requirements of the AHJ. Refer to specific installation standards.

2 The temperature rating is stamped on the sprinkler.

3Base part number is shown. For complete part number, see Viking's current price list.

4Metric K-Factor shown is for use when pressure is measured in kPa. When pressure is mea-

sured in BAR, multiply the metric K-Factor shown by 10.0.

5This table shows the listings and approvals available at the time of printing. Other approvals

may be in process. Check with the manufacturer for any additional approvals.

6cULus Listed as a Quick Response Flush Pendent Sprinkler for standard areas of coverage.

7cULus Listed as a Quick Response Extended Coverage Flush Pendent Sprinkler for Light

Hazard occupancies only.

8Listed by Underwriters Laboratories Inc. for use in the U.S. and Canada.

9Accepted for use, City of New York Department of Buildings, MEA 89-92-E, Vol 16.

INSTITUTIONAL QUICK RESPONSE

STANDARD COVERAGE/

EXTENDED COVERAGE FLUSH

PENDENT SPRINKLER

Temperature Rating

Available Finish KEY

A1

Replaces page 126 a-d, dated August 8, 2002

(updated the sprinkler materials list).

December20,2002