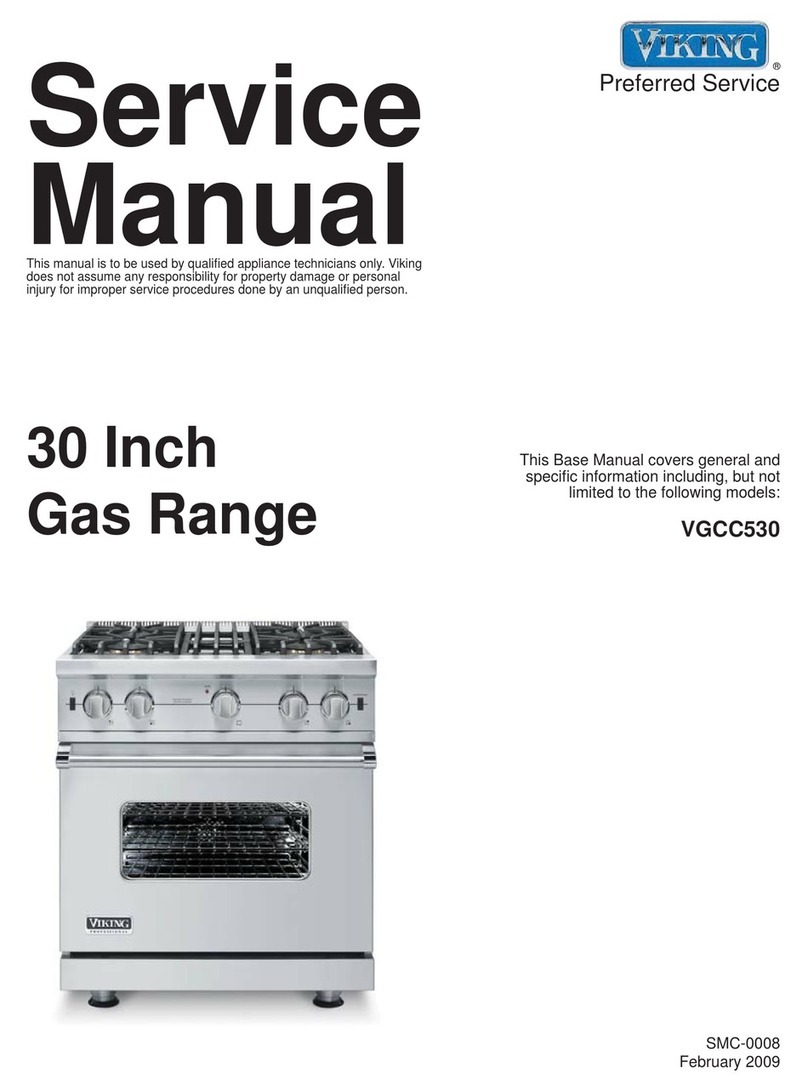

Viking Installation Summary

Note: I the eve t electro ic capabilities or i ter et access is ot available, please HALT the i stallatio

process u til pri ted docume ts are available. You will receive, free of charge, a complete set of

pri ted docume ts by co tacti g Viki g Customer Service at 1-888-Viki g1 (845-4641).

Designer Freestanding

30” Dual Fuel Range

F20650 EN (091009J)

VIKING RANGE CORPORATION

111 Front Street • Greenwood Mississippi 38930

USA • (662) 455-1200

IMPORTANT– Please Read and Follow

• Before beginning please read these instructions

completely and carefully.

•DO NOT remove permanently affixed labels

warnings or plates from product. This may void

the warranty.

• All local and national codes and ordinances must

be observed. Installation must conform with local

codes or in the absence of codes the National Fuel

Gas Code ANSI Z223.1 NFPA54-latest edition.

• The installer must leave these instructions with the

consumer who should retain for local inspector’s use

and for future reference.

In Canada: Installation must be in accordance with the

current CAN/CGA B149.1 & 2 Gas Installation codes

and/or local codes. Electrical installation must be in

accordance with the current CSA C22.1 Canadian

Electrical Codes Part 1 and/or local codes.

In Massachus tts: All gas products must be installed

by a “Massachusetts” licensed plumber or gasfitter. A

“T” type handle manual valve must be installed in the

gas supply line to the appliance.

DA N G E R

H z rds or uns fe pr ctices

which WILL result in severe person l

injury or de th

Your s fety nd the s fety of others is

very import nt.

e have provided many important safety

messages in this manual and on your

appliance. Always read and obey all

safety messages.

This is the safety alert symbol. This

symbol alerts you to hazards that

can kill or hurt you and others.

All safety messages will be preceded by

the safety alert symbol and the word

“DANGER,” “ ARNING” or “CAUTION.”

These words mean:

WA R N I N G

H z rds or uns fe pr ctices

which COULD result in severe person l

injury or de th

CA U T I O N

H z rds or uns fe pr ctices which

COULD result in minor person l injury or

property d m ge

All safety messages will identify the

hazard, tell you how to reduce the chance

of injury, and tell you what can happen if

the instructions are not followed.

D A N G E R

FIRE/EXPLOSION

HAZARD

IF THE INFORMATION IN THIS

MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY

RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

•DO NOT store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

–DO NOT try to light any appliance.

–DO NOT touch any electrical switch.

–DO NOT use any phone in your building.

–Immediately call your gas supplier from a

neighbor’s phone.

–Follow the gas supplier’s instructions.

–If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be performed

by a qualified installer, service agency, or

the gas supplier.

DA N G E R

ELECTRICAL SHOCK

HAZARD

To avoid risk of electrical shock,

personal injury or death; verify

your appliance has been properly grounded in

accordance with local codes or in absence of

codes, with the National Electrical Code

(NEC), ANSI/NFPA 70-latest edition.

W A R N I N G

CHEMICAL HAZARD

To avoid risk of property

damage and/or personal injury

or death; this appliance is not to

be used as a heating source.

• Benzene is a chemical which is part of the

gas supply to this cooking product, which is

consumed in the flames during combustion.

Exposure to a small amount of benzene is

possible if a gas leak occurs. Formaldehyde

and soot are by-products of incomplete

combustion.

• This appliance contains or produces

chemicals which can cause serious injury or

death and which are known to the state of

California to cause cancer, birth defects or

other reproductive harm. To reduce the risk

from substances in the fuel or from

fuel combustion make sure this appliance

is installed, operated, and maintained in

accordance to the instructions in this

document.

WA R N I N G

MOVING HAZARD

To avoid risk of severe personal

injury; this appliance requires

two or more personnel while

handling and moving. Possible use of

appliance moving devices is recommended.

D A N G E R

GAS LEAK HAZARD

To avoid risk of personal injury

or death; leak testing of the

appliance must be conducted

according to the manufacturer’s

instructions. Before placing appliance in

operation, always check for gas leaks with

soapy water solution.

• DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS.

W A R N I N G

TIPPING HAZARD

To reduce the risk of property

damage or personal injury;

install anti-tipping device

provided in accordance with the

installation instructions in this

document. Device must be

engaged properly to prevent

product from tipping over.

• This range can tip.

• Injuries to persons can result.

• Install anti-tip device packed with range.

• See installation instructions.

C A U T I O N

BURN HAZARD

To avoid risk of personal injury;

the use of cabinets for storage

above the appliance may result

in a potential burn hazard. Combustible

items may ignite, metallic items may become

hot and cause burns. If a cabinet storage is

to be provided the risk can be reduced by

installing a rangehood that projects

horizontally a minimum 5” (12.7 cm) beyond

the bottom of cabinets.

NOTICE

DO NOT use the handle or oven door to lift

the range. Remove door before installation

to ensure that it is not used to lift the unit.

DO NOT lift or carry the door by the handle.

Removing the door must be done by your

dealer, a qualified licensed plumber, or

certified gas installer.

IMPORTANT– Please Read and Follow (cont.)

Performance

Checklist

A qualified installer should carry out the following

checks:

NCheck top burner ignition.

See drawing for proper

flame height on HI. The

low flame should light at every

port.

NCheck oven bake function—

bake element on full power

center and outside broil elements at partial power.

NConvection bake function—bake and broil

elements the same with the convection fan on.

NCheck TruConvec™ function—TruConvec

element (behind convection fan cover) on and

convection fan on.

NCheck HI broil function–both broil elements at

full power.

NCheck LOW broil function—inner broil

element only.

NCheck convection broil function—both broil

elements at full power with convection fan on.

NCheck self-clean function—door will lock in

approximately 30 seconds the center and outside

broil elements will turn on and the bake element

will turn on at partial power. Check broil elements

through window to make sure they are on then

abort self-clean cycle to unlock door.

NOTICE

hen conducting performance test, DO NOT

run self-clean cycle for more than 10

minutes with oven racks inside oven. This

could cause them to discolor due to the high

temperature required for self-cleaning.

Electrical & Gas

Requirements (cont.)

Manual shut-off valv :

This installer-supplied valve must be installed in the gas

service line before the appliance in the gas stream and

in a location where it can be reached quickly in the

event of an emergency.

In Massachus tts: A “T” handle type manual

valve must be installed in the gas supply line to the

appliance.

IMPORTANT: Any conv rsion r quir d must b

p rform d by your d al r or a qualifi d lic ns d

plumb r or gas s rvic company. Please provide the

service person with this manual before work begins.

Pr ssur R gulator:

• All heavy-duty commercial type cooking equipment

must have a pressure regulator on the incoming

service line for safe and efficient operation since

service pressure may fluctuate with local demand.

External regulators are not required on this range

since a regulator is built into each unit at the factory.

Under no condition bypass this built-in regulator.

• Manifold pressure should be checked with a

manometer natural gas requires 5.0” W.C.P. and LP

gas requires 10.0” W.C.P. Incoming line pressure

upstream from the regulator must be 1” W.C.P.

higher than the manifold pressure in order to check

the regulator. The regulator used on this range can

withstand a maximum input pressure of 1/2” PSI

(14.0” W.C.P.). If the line pressure is in excess of that

amount a step down regulator will be required.

• The appliance must be disconnected from the gas

supply piping system during any pressure testing of

that system.

Fl xibl Conn ctions:

If the unit is to be installed with flexible couplings

and/or quick-disconnect fittings the installer must use

a heavy-duty AGA design-certified flexible connector of

at least 1/2” (1.3 cm) ID NPT (with suitable strain reliefs)

in compliance with ANSI Z21.41 and Z21.69.

In Canada: CAN 1-6 10-88 metal connectors for

gas appliances and CAN 1-6.9 M79 quick disconnect

devices for use with gas fuel.

In Massachus tts: This appliance must be installed

with a 36” (3-foot) long flexible gas connector.

Electrical & Gas Requirements

El ctrical R quir m nts

This product is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire agency

approved power supply kit with closed loop terminals

rated per the National Electric Code ANSI/NFPA 70-

latest edition (See Rating chart below).

RATING* Sp cifi d Rating of Pow r Supply Cod Kit

and Circuit Prot ction

120/240 Volts 120/208 Volts Amps

12.5 - 16.5 KW 9.2 - 12.5 KW 40 or 50

16.5 - 17.5 KW 12.5 - 13.5 KW 50

*The National Electric Code calculation for Electrical

Load is less than the Total Connected Electrical Load

listed on the model/serial rating plate.

A GFI shall be used if required by NFPA-70 (National

Electric Code), federal/state/local laws, or local

ordinances

•The required use of a GFI is normally related to the

location of a receptacle with respect to any

significant sources of water or moisture.

• Viking Range Corporation will NOT warranty any

problems resulting from GFI outlets which are not

installed properly or do not meet the requirements

below.

If the use of a GFI is required it should be:

•Of the receptacle type (breaker type or portable

type NOT recommended)

•Used with permanent wiring only (temporary or

portable wiring NOT recommended)

•On a dedicated circuit (no other receptacles

switches or loads in the circuit)

• Connected to a standard breaker of appropriate

size (GFI breaker of the same size NOT

recommended)

•Rated for Class A (5 mA +/- 1 mA trip current) as

per UL 943 standard

•In good condition and free from any loose-fitting

gaskets (if applicable in outdoor situations)

• Protected from moisture (water steam high humidity)

as much as reasonably possible

Commonw alth of Massachus tts:

•Installations and r pairs must b pr form d by a

qualifi d or lic ns d contractor, plumb r, or gas

fitt r, qualified or licensed by the state province or

region where this appliance is being installed.

•Us only gas shut-off valv s approv d for us

within the state province or region where this

appliance is being installed.

•A Fl xibl gas conn ctor, wh n us d, must not

xc d 3’ (.9m).

California Proposition 65

Burning gas cooking fuel generates some by-products

that are on the list of substances known to cause cancer

or reproductive harm. To minimize exposure to these

substances always operate this unit according to the

instructions contained in this book and provide good

ventilation

Gas Conn ction

The gas supply (service) line must be the same size or

greater than the inlet line of the appliance. This range

uses a 1/2” (1.3 cm) ID NPT (Sch40) inlet. Sealant on all

pipe joints must be resistive to LP gas.

Th rang is d sign d sp cifically for natural gas

or liquid propan (LP) gas. B for b ginning

installation v rify that th mod l is compatibl

with th int nd d gas supply.

W A R N I N G

ELECTRICAL SHOCK

HAZARD

To avoid the risk of electrical

shock, personal injury or death;

verify electrical power is turned off at the

breaker box and gas supply is turned off until

the oven is installed and ready to operate,

installation by an authorized installer only.

C A U T I O N

To prevent possible damage to cabinets

and cabinet finishes, use only materials and

finishes that will not discolor or delaminate

and will withstand temperatures up to

194° F (90° C). Heat and moisture resistant

adhesive must be used if the product is to be

installed in laminated cabinetry. Check with

your builder or cabinet supplier to make sure

that the materials meet these requirements.