12

FULL OVERLAY PANEL INSTALLATION (con’t)

Step #3

SSiizziinngg tthhee OOvveerrllaayy PPaanneell

Step #4

AAttttaahhiinngg tthhee OOvveerrllaayy PPaanneell ttoo tthhee DDoooorr

1. Set the overlay panel on drawer front fa e and align edges. Clamp panel in position and mark pilot hole lo ations.

See Step #3 for nominal size and hole lo ations. Drill pilot holes (remove panel if ne essary, re-align and re- lamp

overlay to drawer fa e.)

2. Insert wood s rews through learan e holes and tighten to se ure overlay panel.

3. Reinstall gasket into hannel. Make sure the orners are inserted fully.

Step #

RReeaattttaahh DDrraawweerr FFrroonntt ttoo DDrraawweerr BBooddyy

Align mounting holes on drawer body with mounting holes on drawer front. Align the door liner to the front flanges by

using the erasable marker alignment lines that were applied prior to removing the door from the drawer. Reinstall

phillips head s rews and washers. Snug down, but do not tighten fully, final adjustment of drawer front will be done

after reinstalling the drawer.

Step #6

RReeiinnssttaallll tthhee DDrraawweerr

1. Fully extend drawer slides and pla e drawer on slides. Be sure that drawer sits evenly on both sides.

2. Lo k drawers into drawer slides. Push drawer lo ks down and then ba k to relo k the drawer into the slide.

Step #7

AAddjjuusstt DDrraawweerr FFrroonntt

1. Adjust drawer front to a hieve a 1/8” gap from the top of the drawer front to the top of the abinet or (for bottom

drawers) 1/8” from the top of the drawer front to the bottom of the top drawer, the drawer front should be entered

between the abinet edges.

2. Fully tighten phillips head s rews

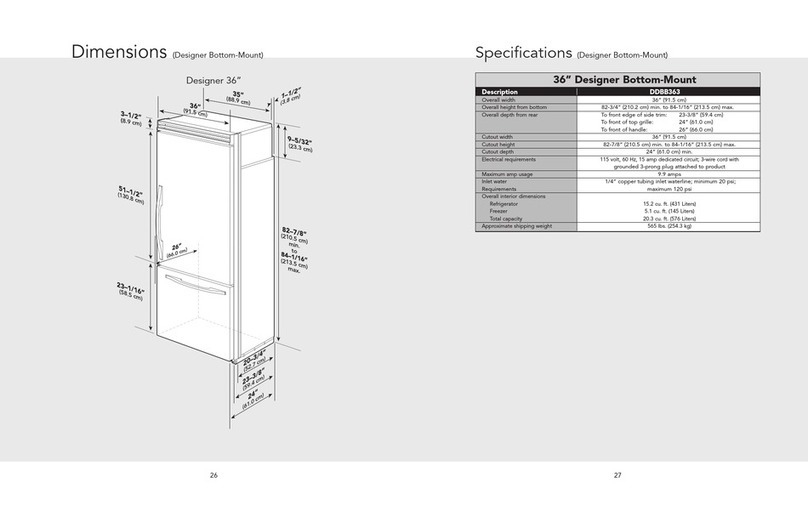

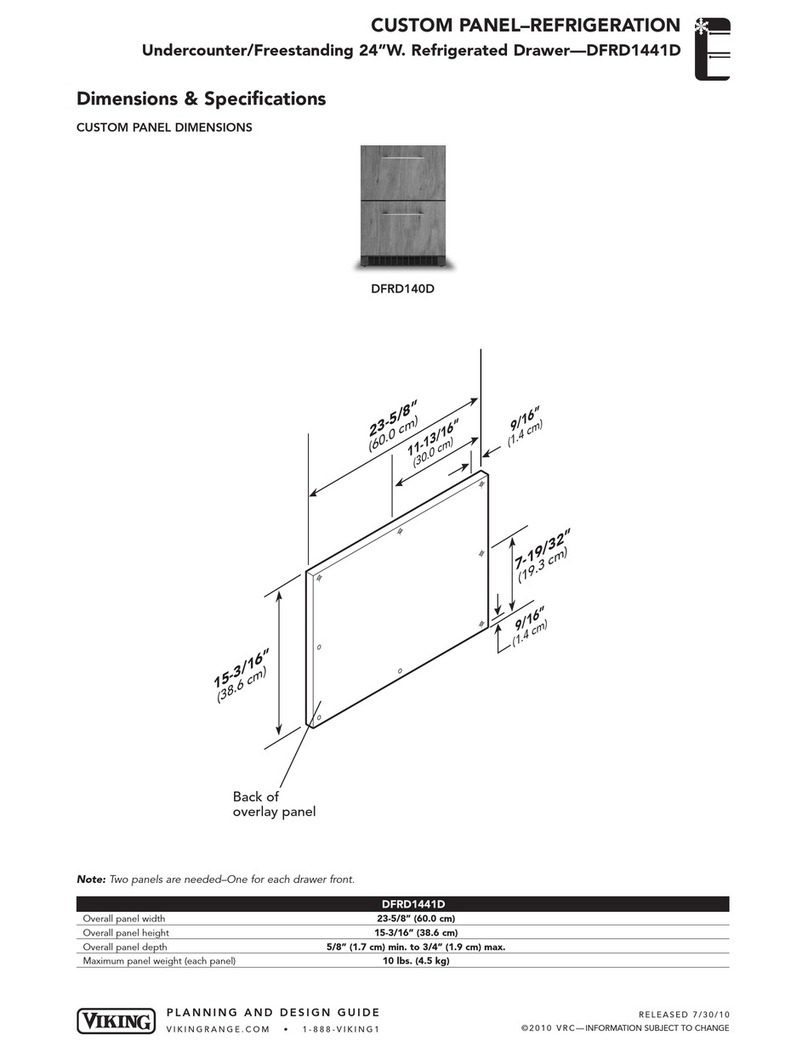

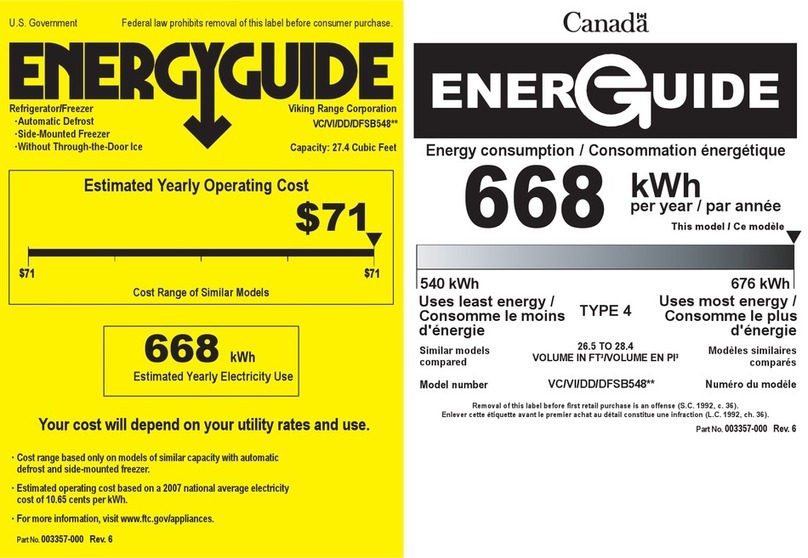

23-5/8” (60.0 m)

15-3/16”

(38.6 m)

14-5/8”

(37.1 m)

7-19/32”

(19.3 m)

9/16”

(1.4 m)

9/16” (1.4 m)

11-13/16” (30.0 m)

23-1/16” (58.6 m)

13

FINAL PREPARATION

1. Some stainless steel parts may have a plasti prote tive wrap whi h must be peeled off. The interior of the unit should be

washed thoroughly with hot, soapy water, rinsed and wiped dry to remove film residue and any installation dust or debris

before being used. Solutions stronger than soap and water are rarely needed.

2. All stainless steel parts should be wiped with hot soapy water. If buildup o urs, do not use steel wool, abrasive loths,

leaners, or powders. If it is ne essary to s rape stainless steel to remove en rusted materials, soak with hot, wet loths to

loosen the material, then use a wood or nylon s raper. Do not use a metal knife, spatula, or any other metal tool to s rape

stainless steel; s rat hes are almost impossible to remove.

ELECTRICAL CONNECTION

EElleettrriiaall RReeqquuiirreemmeennttss

A 115 volt, 60 Hz, AC only 15 amp fused ele tri al supply is required. (A time delay

fuse or ir uit breaker is re ommended.) It is re ommended that a separate ir uit,

serving only this applian e, be provided.

••EELLEECCTTRRIICCAALL GGRROOUUNNDD IISS RREEQQUUIIRREEDD OONN TTHHIISS AAPPPPLLIIAANNCCEE..

••DDOO NNOOTT UUNNDDEERR AANNYY CCIIRRCCUUMMSSTTAANNCCEESS RREEMMOOVVEE TTHHEE PPOOWWEERR SSUUPPPPLLYY CCOORRDD

GGRROOUUNNDD PPLLUUGG..

••DDOO NNOOTT UUSSEE AANN EEXXTTEENNSSIIOONN CCOORRDD

RReeoommmmeennddeedd GGrroouunnddiinngg MMeetthhooddss

For your personal safety, this unit must be grounded. This applian e is equipped with a 7’ (2.1 m) power supply ord having a 3-

prong grounding plug. To minimize possible sho k hazard, the ord must be plugged into a mating 3-prong grounding type wall

re epta le grounded in a ordan e with the National Ele tri al Code and lo al odes and ordinan es. If the ir uit does not have

a grounding type re epta le, it is the responsibility and obligation of the ustomer to ex hange the existing re epta le in

a ordan e with the National Ele tri al Code and appli able lo al odes and ordinan es. The third ground plug SHOULD NOT,

under any ir umstan es, be ut or removed. All UL listed refrigerated drawers are equipped with this type of plug.

Power Supply

with 3-prong

grounding plug

Grounding type wall

re epta le

ELECTRICAL SHOCK HAZARD

Fai ure to fo ow these instructions cou d resu t in fire or e ectrica

shock.

OPERATING INSTRUCTIONS

GGeenneerraall TTiippss aanndd SSuuggggeessttiioonnss

•After making a temperature adjustment, allow at least 24 hours for your unit to rea h a new temperature setting.

•The motor will start and stop often. It must do this to maintain the temperature setting.

•Unplug the unit before working on anything with the ele tri al system.

•Exer ise aution when sweeping, va uuming, or mopping near the front of the unit.

•Avoid leaning on the drawer fronts. You may bend the drawer slides or tip the unit.

WARNING