NT-50897201-CAD-O-INTEGRAL-ETD2-AN-2301232/96

ENGLISH

INDEX

1. GENERAL........................................................................................................................................... 3

1.1 Warnings .................................................................................................................................. 3

1.2 Safety instructions .................................................................................................................... 4

1.3 Acceptance – Storage .............................................................................................................. 4

1.4 Warranty ................................................................................................................................... 4

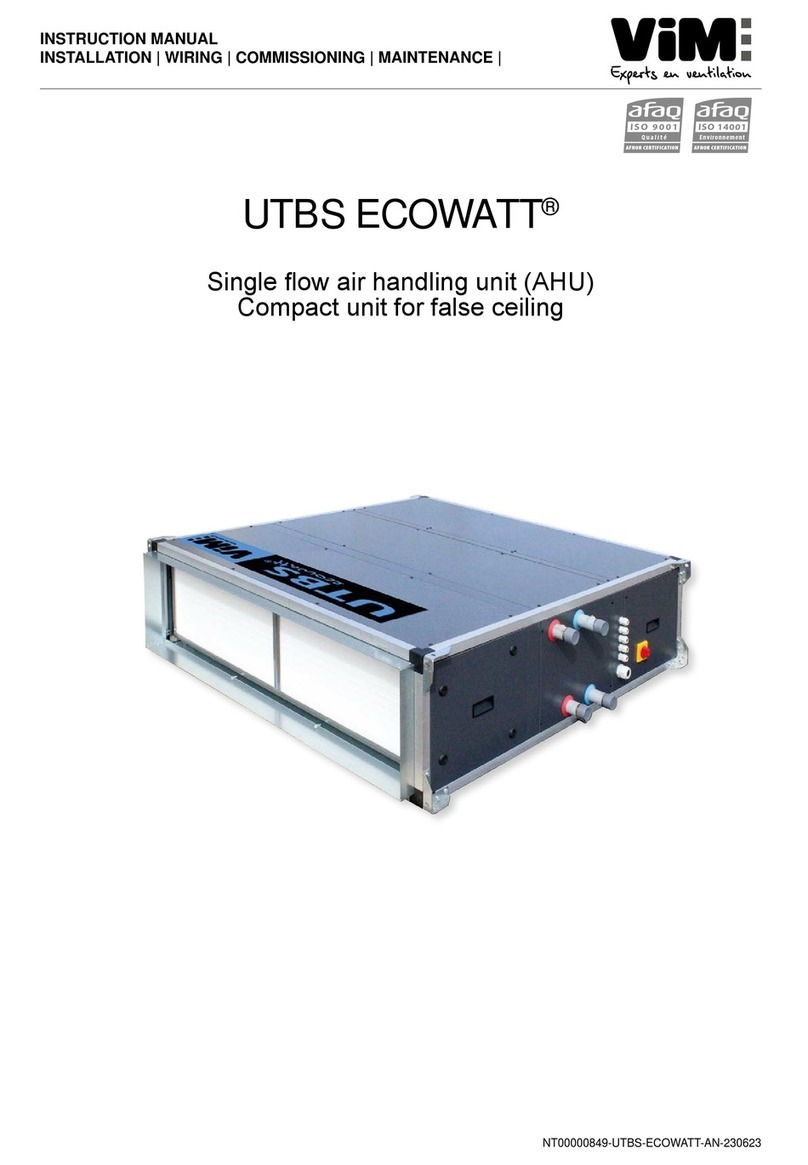

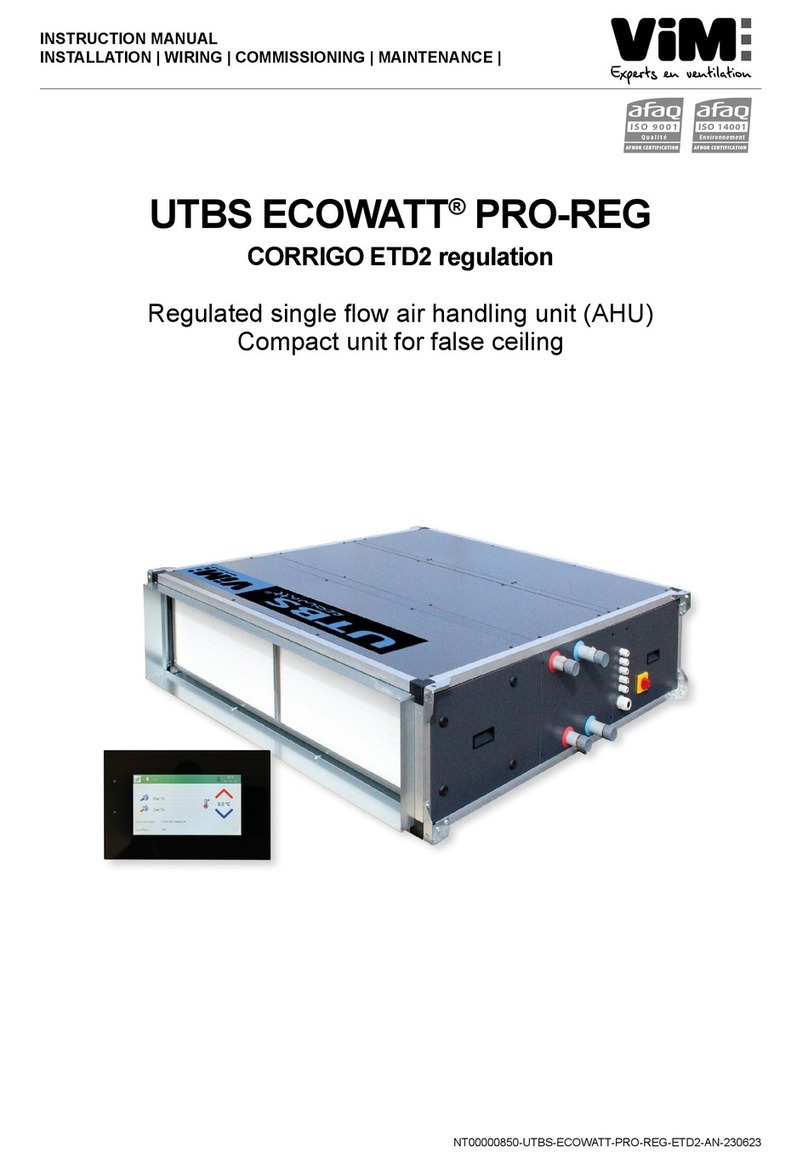

2. PRODUCT RANGE PRESENTATION................................................................................................ 5

2.1 Range....................................................................................................................................... 5

2.2 Main components ..................................................................................................................... 6

3. INSTALLATION .................................................................................................................................11

.............................................................................................11

3.2 Dimensions and weight .......................................................................................................... 12

3.3 Handling ................................................................................................................................. 20

3.4 Placement and attachment point ........................................................................................... 21

.......................................................................... 25

................................... 28

4. HYDRAULIC AND FLUID CONNECTION ....................................................................................... 29

4.1 Water coils connection ........................................................................................................... 29

................................................................................................................... 31

4.3 Connection of direct expansion coils...................................................................................... 32

5. AIR DUCT CONNECTION................................................................................................................ 32

5.1 Ducts connection.................................................................................................................... 32

5.2 Accessories connection.......................................................................................................... 33

6. ELECTRIC CONNECTION............................................................................................................... 36

6.1 Electrical data......................................................................................................................... 36

.................................................................. 40

6.3 Controller CORRIGO - Technical data ................................................................................... 41

6.4 Display (ETD2) control connection......................................................................................... 42

6.5 External components connection drawings (examples) ......................................................... 45

6.6 Synoptic installation diagrams (examples) ............................................................................. 53

7. COMMISSIONING ............................................................................................................................ 55

8. CONTROL - FUNCTIONS / PARAMETERS .................................................................................... 56

.................................................................................................................. 57

8.2 Temperature control................................................................................................................ 59

8.3 Special case: temperature control with EX direct expansion coil ........................................... 61

................................................................... 61

8.5 Hot water coil frost protection................................................................................................. 63

................................................................................................................. 64

............................................................................................................. 65

................................................................................................... 65

8.9 Clock and time programming.................................................................................................. 65

9. ALARMS AND FAULTS ................................................................................................................... 66

10. USING AND CONFIGURING THE CONTROL VIA THE TOUCH DISPLAY ETD2 ......................... 67

10.1 Presentation of the ETD2 touch display ................................................................................. 67

...................................................................................... 71

.............................................................................................. 73

10.4 Settings common to all fan operating modes ......................................................................... 74

11. ADVANCED SETTINGS VIA ETD2 TOUCH DISPLAY.................................................................... 75

11.1 Schedule programming .......................................................................................................... 75

11.2 Communication protocol settings ........................................................................................... 77

11.3 Backup - Restore.................................................................................................................... 78

.................................................................................................................. 79

12. COMMUNICATION ........................................................................................................................... 83

.................... 83

12.2 Connection to a Centralized Technical Management (BMS) in BACnet language ................. 85

12.3 Resetting the CORRIGO controller ........................................................................................ 86