NT-50906901-KSDR-ECOWATT-48-88-120-AN-170907 2/68

ENGLISH

SOMMAIRE

1. GENERAL POINTS ............................................................................................................................ 3

1.1 Warnings .................................................................................................................................. 3

1.2 Safety guidelines ...................................................................................................................... 4

1.3 Receipt - Storage...................................................................................................................... 4

1.4 Warranty ................................................................................................................................... 4

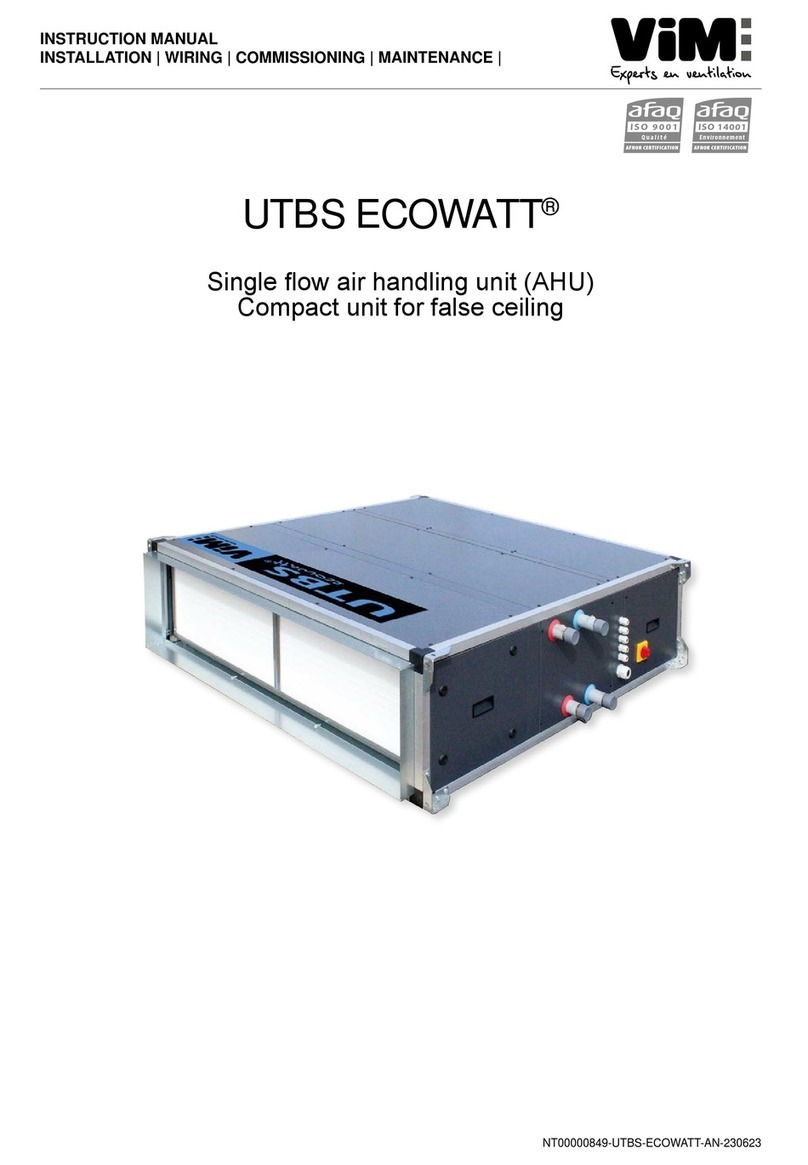

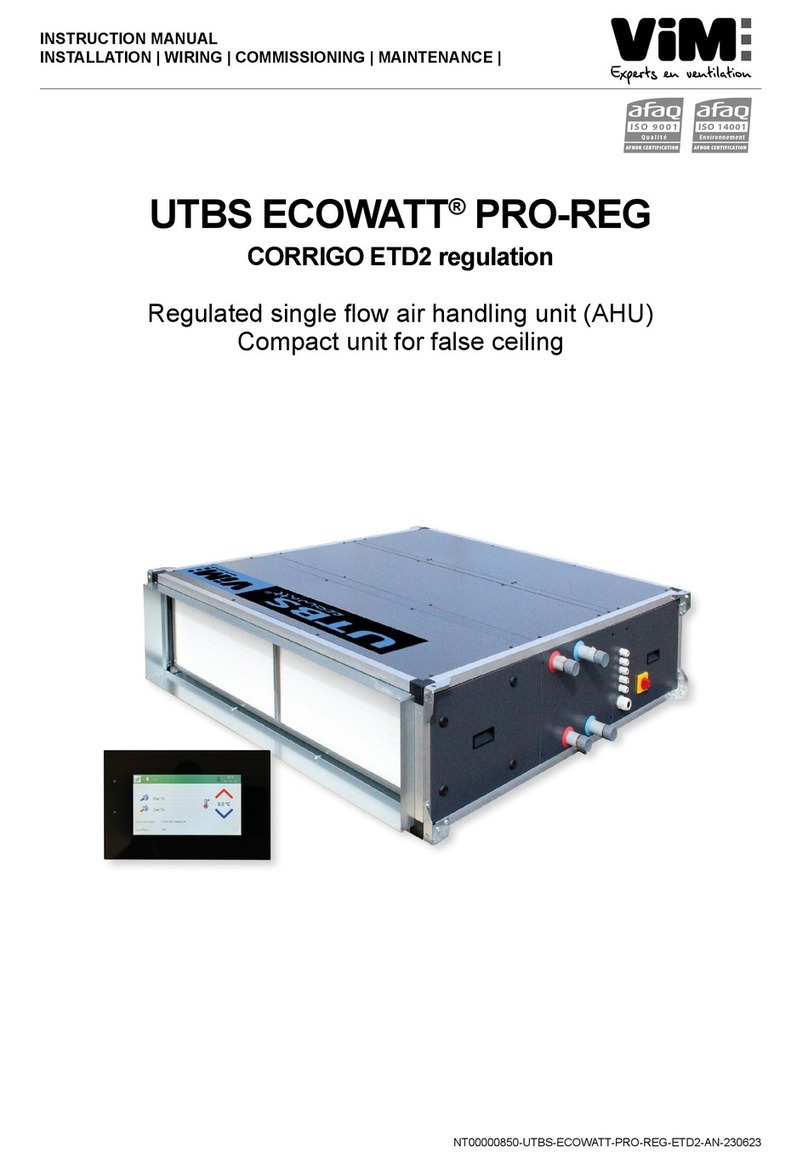

2. PRESENTATION OF RANGE - PRODUCT ....................................................................................... 5

2.1 Range ....................................................................................................................................... 5

2.2 Products - Main components .................................................................................................... 5

3. INSTALLATION .................................................................................................................................. 7

3.1 Identifi cation of unit/Symbols .................................................................................................... 7

3.2 Dimensions and weights........................................................................................................... 7

3.3 Handling ................................................................................................................................... 8

3.4 Location and Attachment .......................................................................................................... 8

4. HYDRAULIC CONNECTION ............................................................................................................ 8

4.1 Wiring of water coils ................................................................................................................. 8

4.2 Connection of valves and antifrost sensor................................................................................ 9

4.3 Connection direct expansion coils .......................................................................................... 10

5. AIRFLOW CONNECTION ................................................................................................................ 10

5.1 Connection of ducts ................................................................................................................ 10

5.2 Connection of accessories ..................................................................................................... 10

6. ELECTRICAL CONNECTION .......................................................................................................... 12

6.1 Electrical characteristics ......................................................................................................... 12

6.2 Electric panel - power supply principle ...................................................................................13

6.3 Technical characteristics of the CORRIGO controller............................................................. 14

6.4 Connection of the control with ETD display ............................................................................ 15

6.5 Input - output tables (terminal block/signal/variable/function)................................................. 16

6.6 Controller display panels ........................................................................................................ 20

6.7 Wiring diagrams of external elements, CAV, VAV and COP adjustments............................... 22

7. COMMISSIONING ............................................................................................................................ 28

8. ADJUSTMENT - FUNCTIONS/PARAMETERS ............................................................................... 29

8.1 Simplifi ed menus/Access........................................................................................................ 30

8.2 Constant fl ow operation (CAV) ............................................................................................... 33

8.3 Variable fl ow operation (VAV) ................................................................................................. 34

8.4 Constant pressure operation (COP) ....................................................................................... 35

8.5 Temperature adjustment ......................................................................................................... 36

8.6 Menu expert – contrôle des entrées/sorties du régulateur ..................................................... 38

8.7 Time programming ................................................................................................................. 39

8.8 Override .................................................................................................................................. 41

8.9 Night-time Free Cooling.......................................................................................................... 41

8.10 Anti-freeze protection of the hot water coil .............................................................................43

8.11 Entry for an external fi re signal ............................................................................................... 43

8.12 Measuring air fl ows - modifying the coeffi cient K ................................................................. 44

8.13 List of faults ............................................................................................................................ 44

9. COMMUNICATION ........................................................................................................................... 45

9.1 Connection to a Centralised Building Management in Modbus RTU language ..................... 45

9.2 Connection to a Centralised Building Management in BACnet IP language .......................... 45

9.3 Integrated web server application........................................................................................... 54

9.4 Rebooting the CORRIGO controller ....................................................................................... 62