Contents

1 Product Description ............................................................................................................4

1.1 General Description .......................................................................................................4

1.2 Areas of Application .......................................................................................................5

1.2.1 Retrotting Older Intercom & Telephone Systems ......................................................5

1.2.2 Remote IP Intercom Locations In New Buildings ........................................................5

2 Upgrading Conventional Star-Wired Infrastructure .........................................................6

2.1 The Conventional System .............................................................................................6

2.2 Power on Conventional Infrastructure ...........................................................................7

2.3 Precaution & Limitations ................................................................................................7

2.4 Recommendations .........................................................................................................7

2.5 System Conguration with Central Powering of Remote Intercoms ..............................8

2.6 System Conguration with Local Powering of Remote Intercoms .................................9

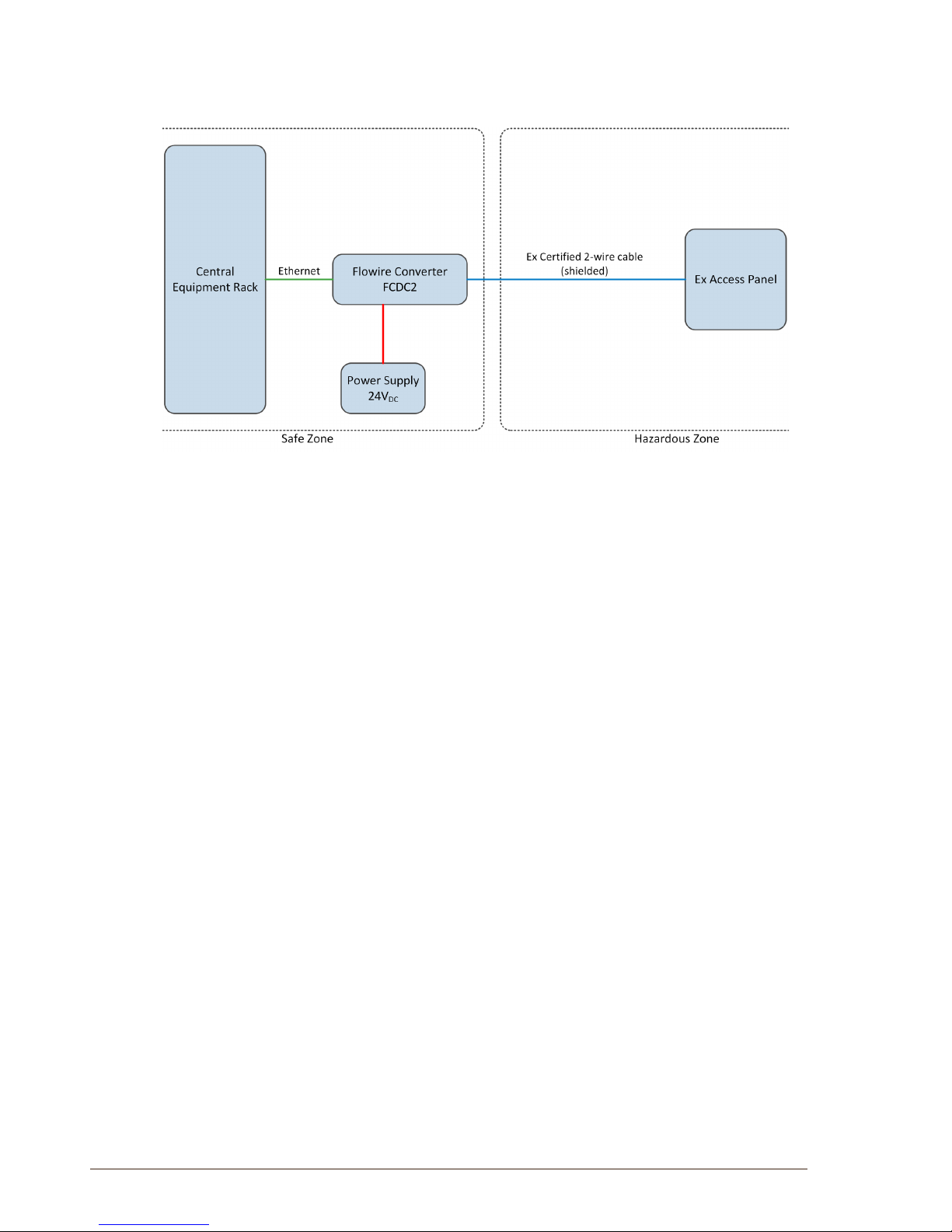

2.7 System Conguration with Ex Equipment ...................................................................10

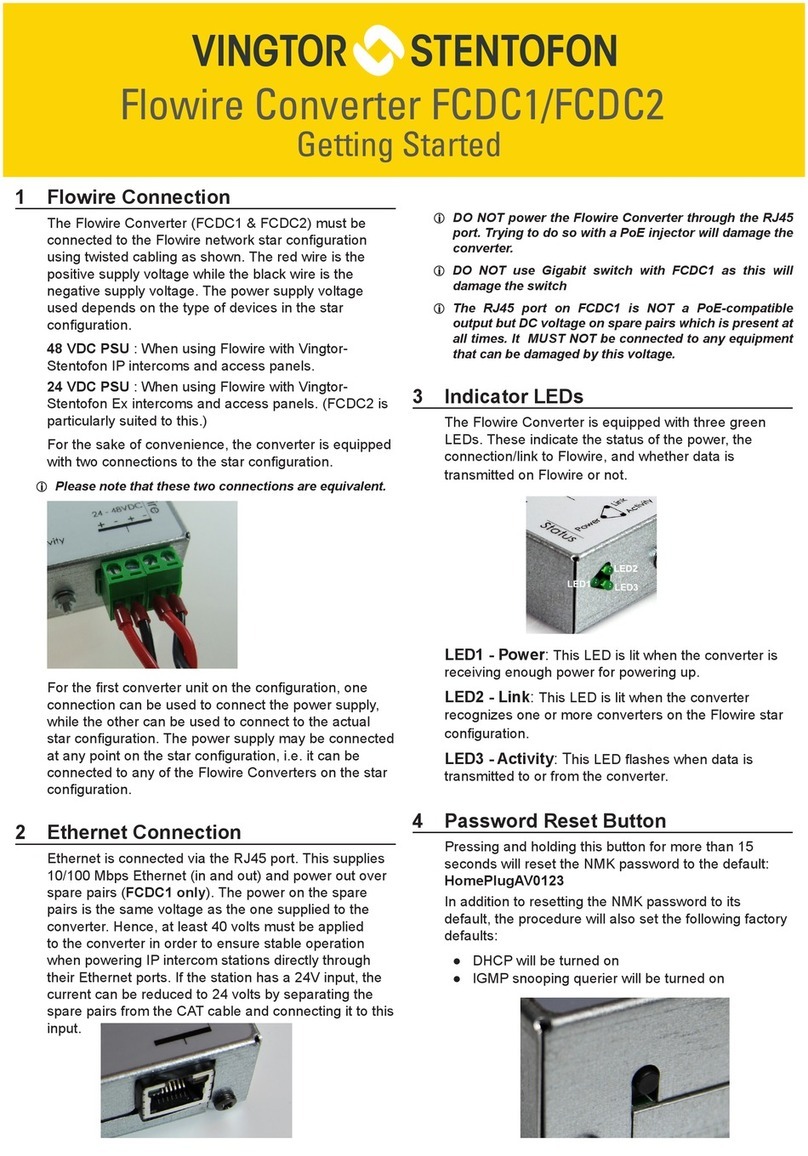

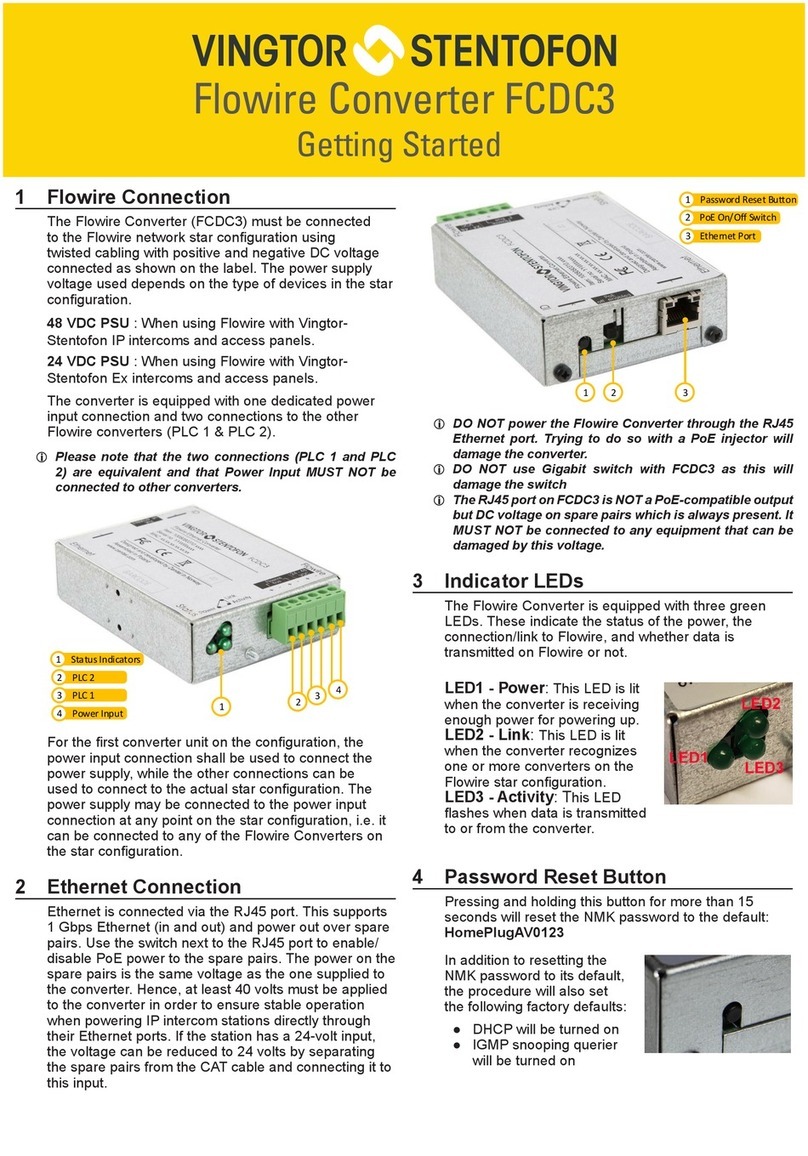

3 Connections & Indications ............................................................................................... 11

3.1 Flowire Connection ...................................................................................................... 11

3.2 Ethernet Connection .................................................................................................... 11

3.3 Indicator LEDs ............................................................................................................. 11

3.4 Password Reset Button ............................................................................................... 11

4 Mounting & Recommendations........................................................................................12

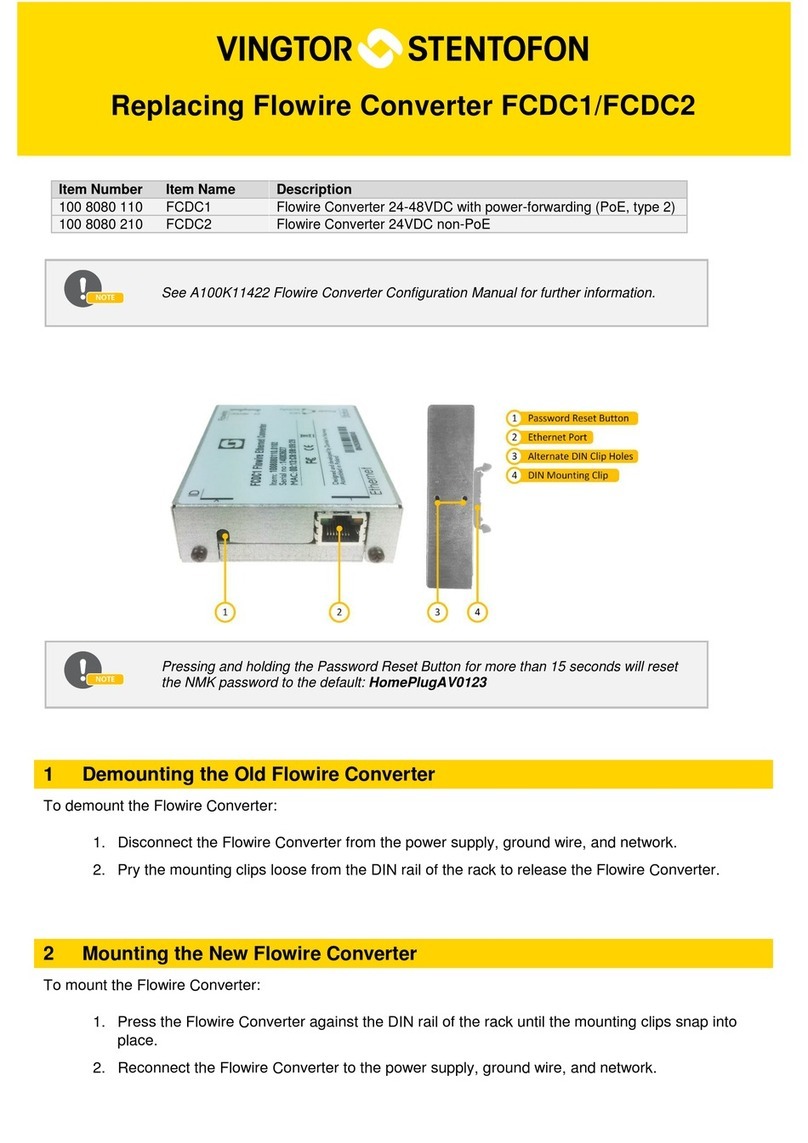

4.1 Mounting the Flowire Converter ..................................................................................12

4.2 Power Requirements ...................................................................................................12

5 Troubleshooting ................................................................................................................13

5.1 Power for Stable Connection at Remote Site ..............................................................13

5.2 Cables & Bandwidth ....................................................................................................13

5.3 Collecting Trace Logs ..................................................................................................13

A: Power Consumption & Distances for Typical Cables ....................................................15

B: AdvancedConguration...................................................................................................16

B.1 Setting a Static IP Address ..........................................................................................16

B.2 Disabling DHCP ..........................................................................................................17

B.3 Network Management Key (NMK) Conguration ........................................................18

2.1 IGMP Settings..............................................................................................................19

2.1.1 IGMP Querier ............................................................................................................19

2.1.2 IGMPv2 Compatability ..............................................................................................19

2.2 CCo Settings ...............................................................................................................20

C: Software Upgrade..............................................................................................................21

C.1 Upgrading via VS-IMT on PC ......................................................................................21

C.2 Upgrade via Web Interface on Flowire Device ............................................................24

C.2.1 TFTP Server Setup ...................................................................................................24

C.2.2 Flowire Device Web Interface ...................................................................................24

Figures

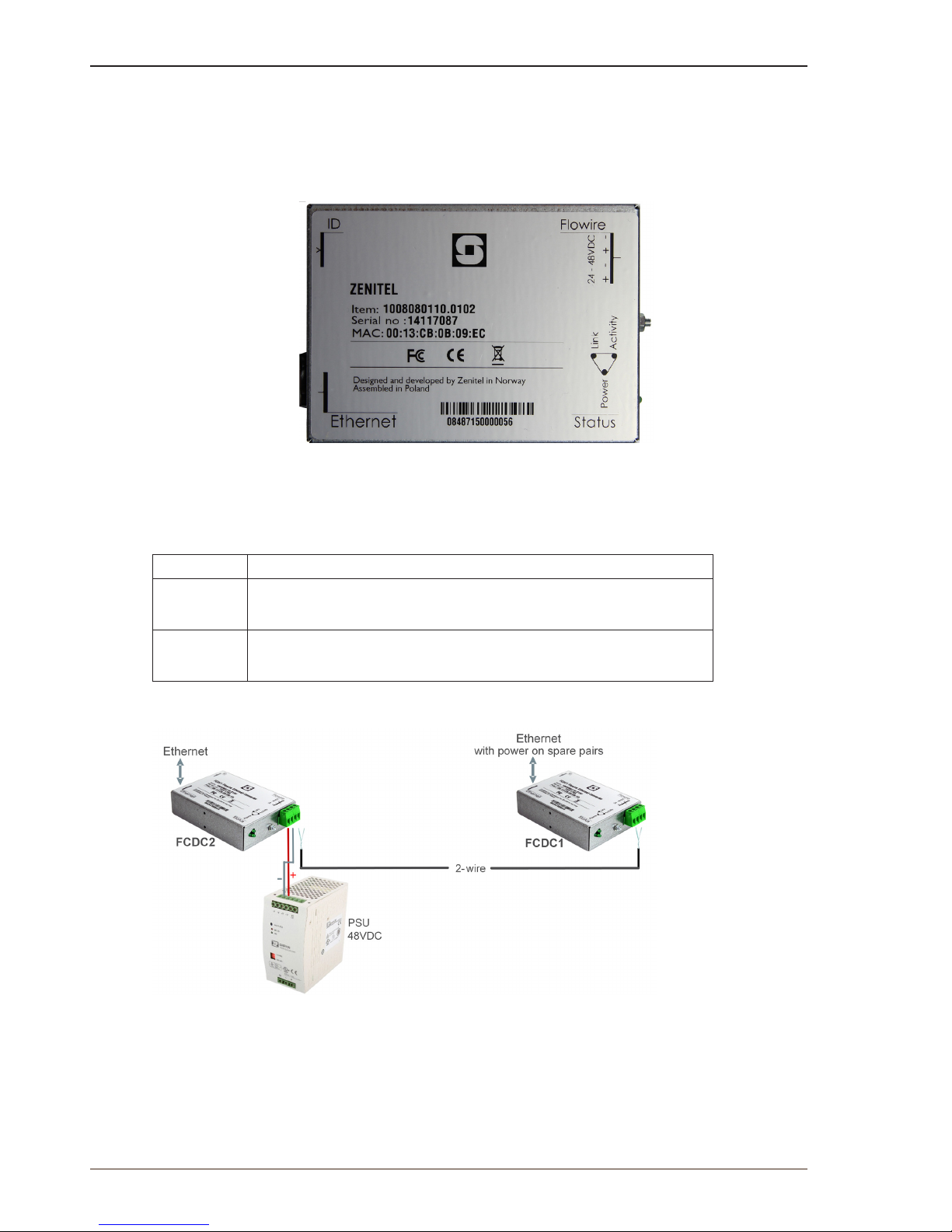

Figure 1 FCDC1 Flowire Converter .......................................................................................................................... 4

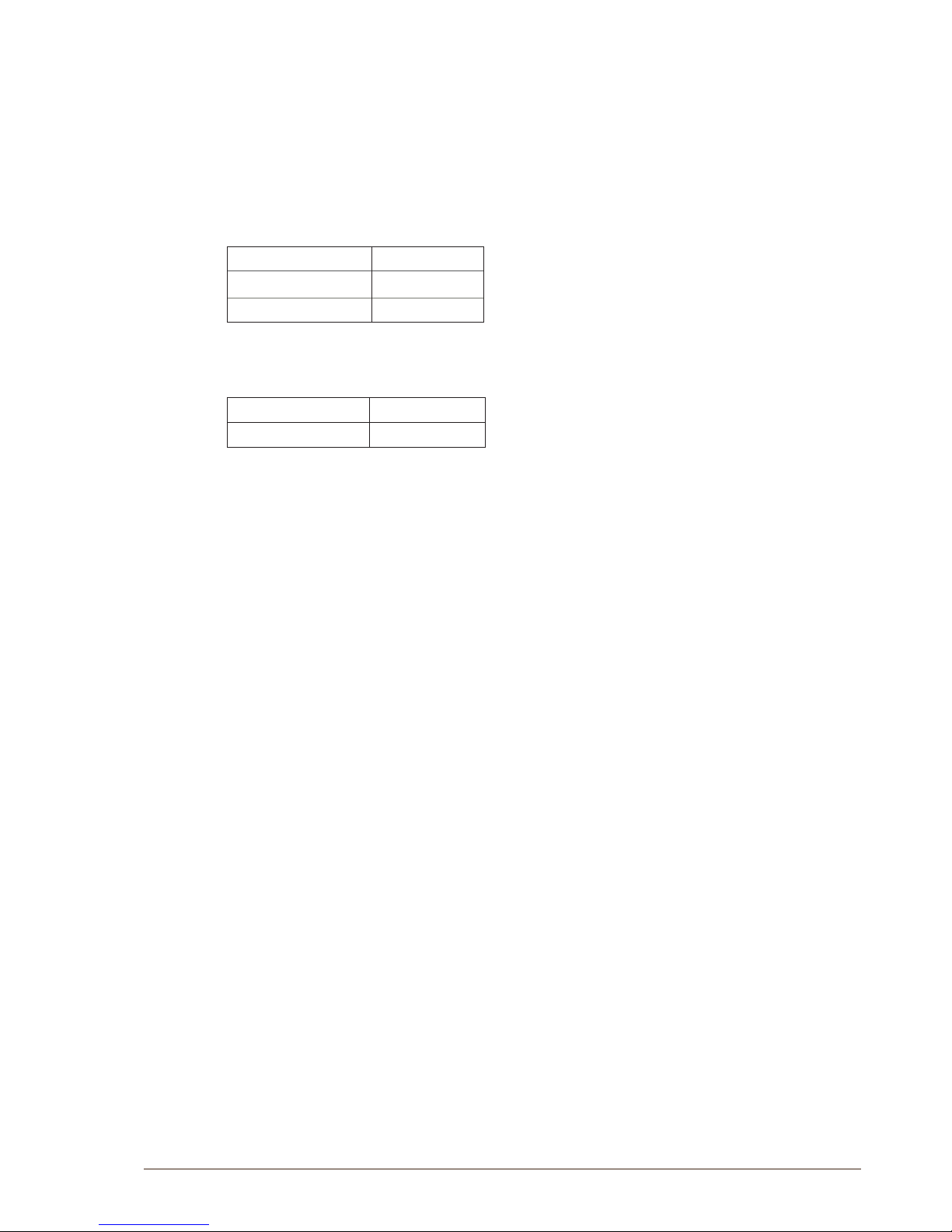

Figure 2 FCDC1 and FCDC2 .................................................................................................................................... 4

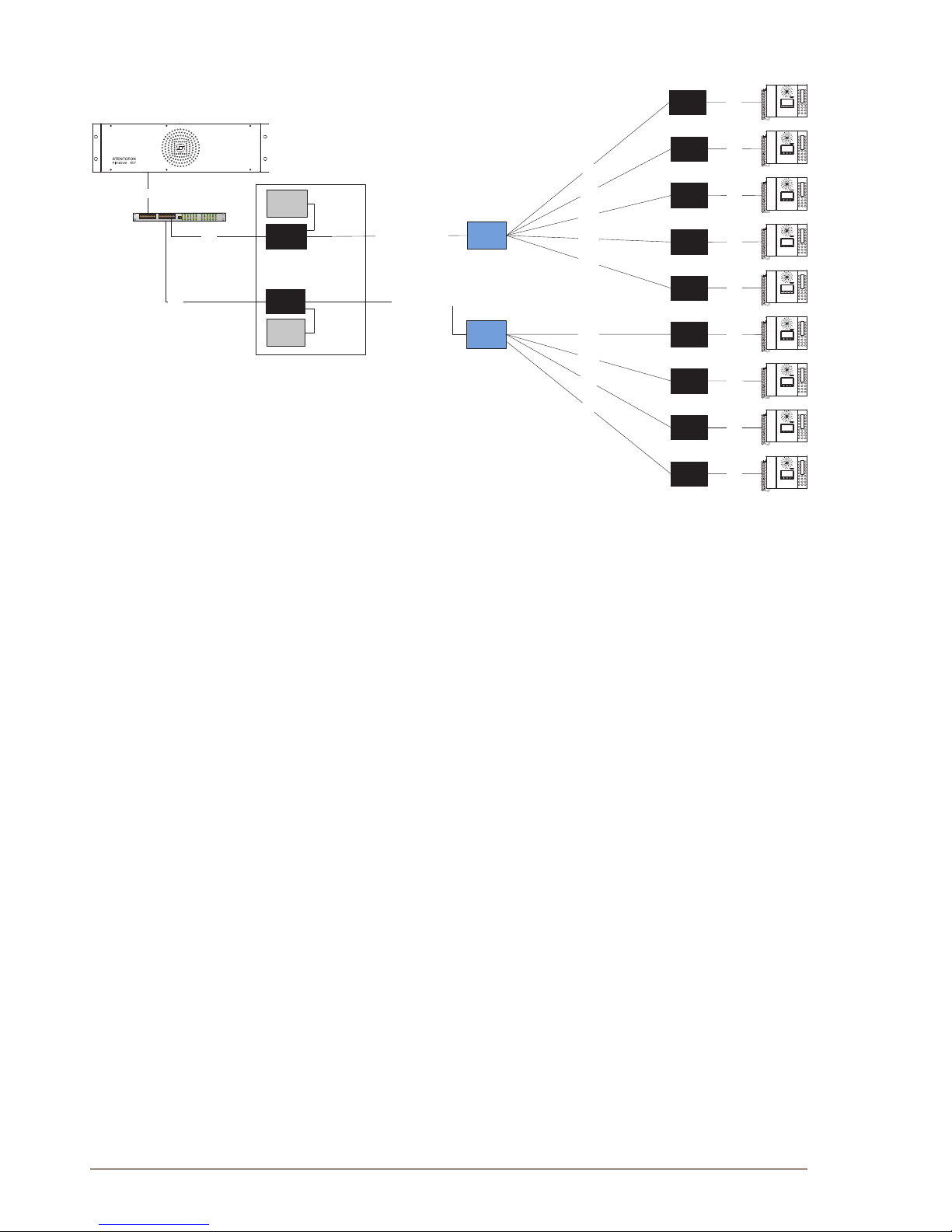

Figure 3 Conventional star-wired infrastructure ........................................................................................................ 6

Figure 4 Conventional star infrastructure with multi-pair cables and junction boxes ................................................ 6

Figure 5 Flowire Upgraded conguration with central power distribution. ............................................................... 8

Figure 6 Conventional analog/digital system conguration....................................................................................... 9

Figure 7 Flowire Upgraded conguration with local power at remote locations. ...................................................... 9

Figure 8 Cabling in Ex Zone using FCDC2 ............................................................................................................. 10

Figure 9 Flowire Converter Dimensions.................................................................................................................. 12

Figure 10 IGMP Settings ........................................................................................................................................... 19

Figure 11 Congured PLC Role - CCo, Not CCo, Auto ............................................................................................ 20