AB

A = A’

B = B’

Securely glue together. If coming off during

flight, you lose control of your air plane.

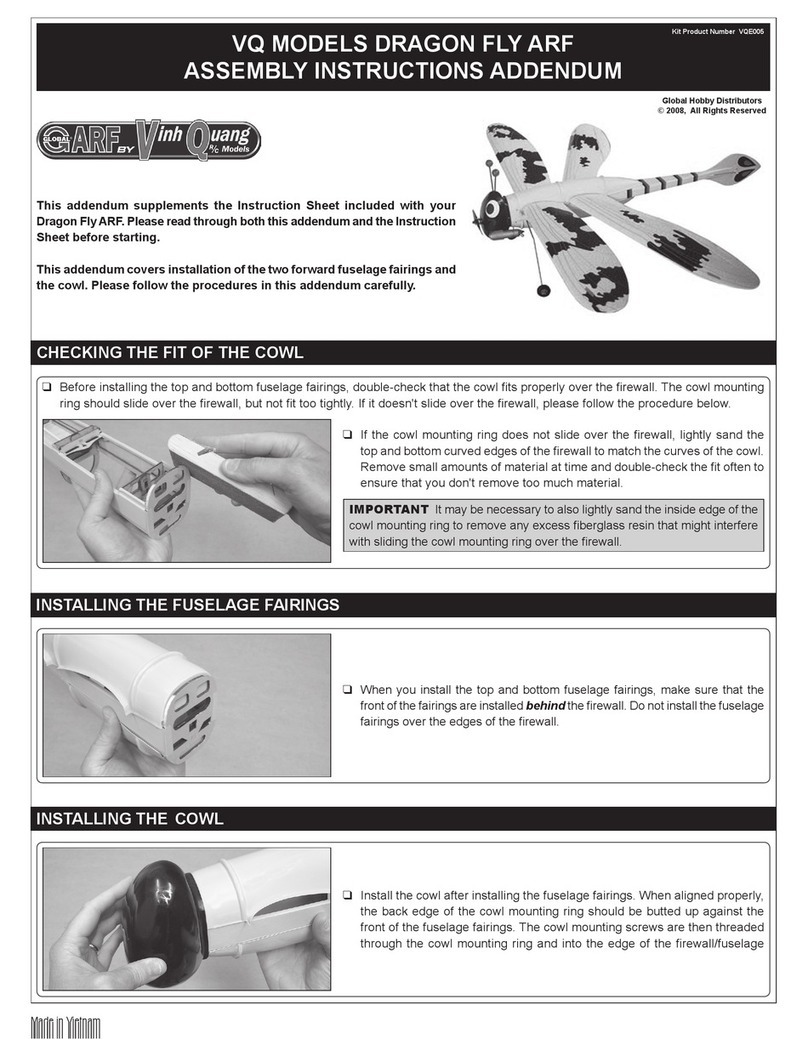

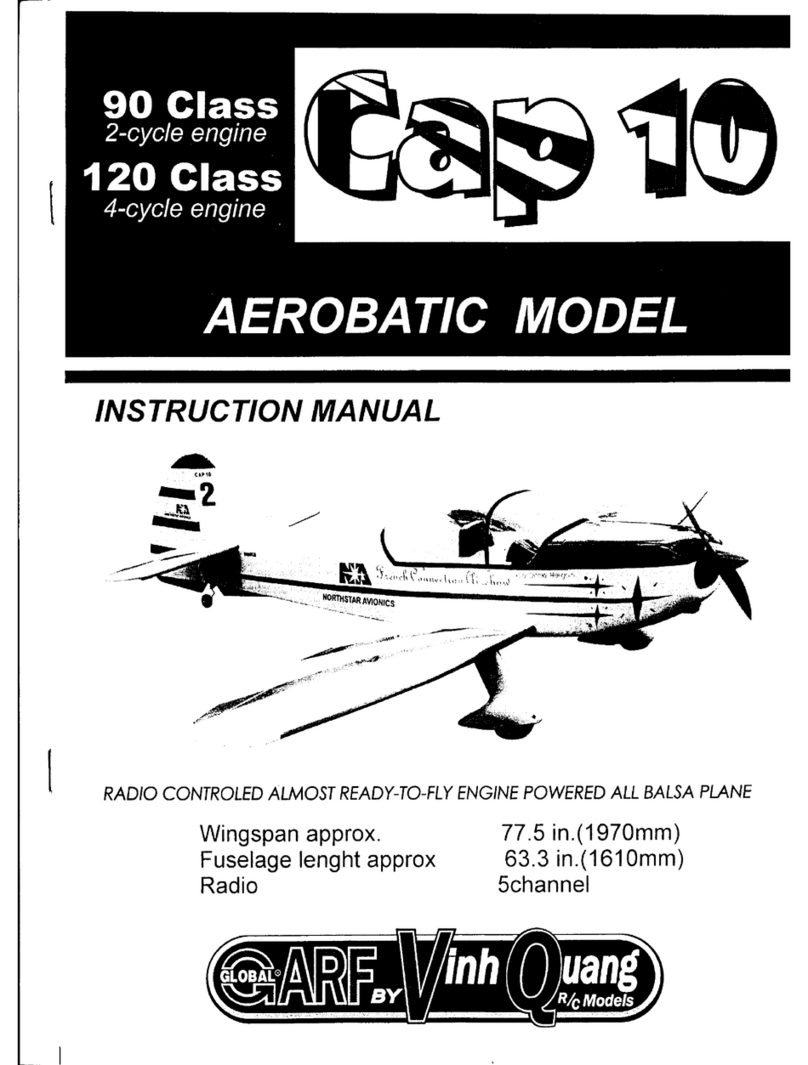

Cut away only the covering

both the top and bottom side

Both the top and

bottom side

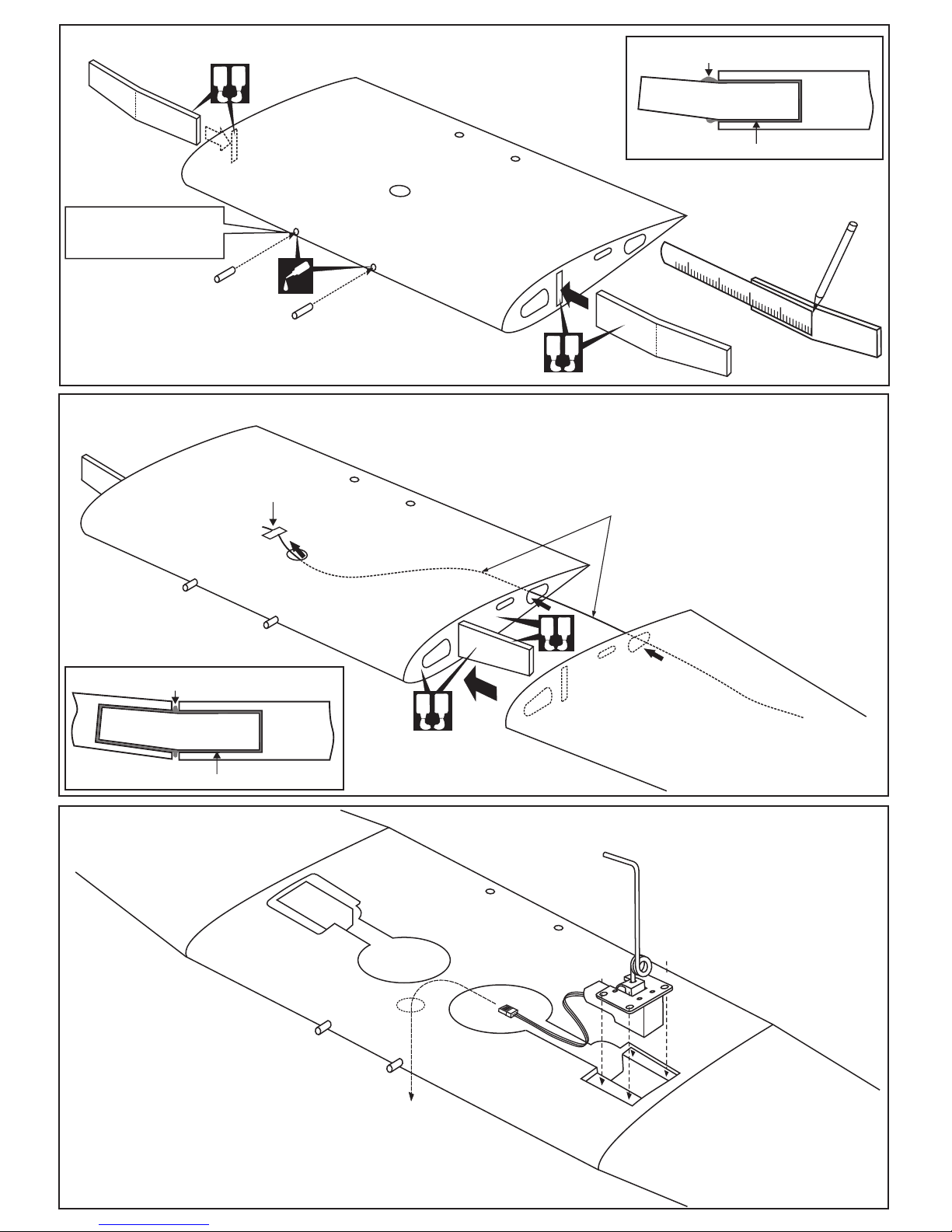

Cut away only the covering

both the right and left side

BB’

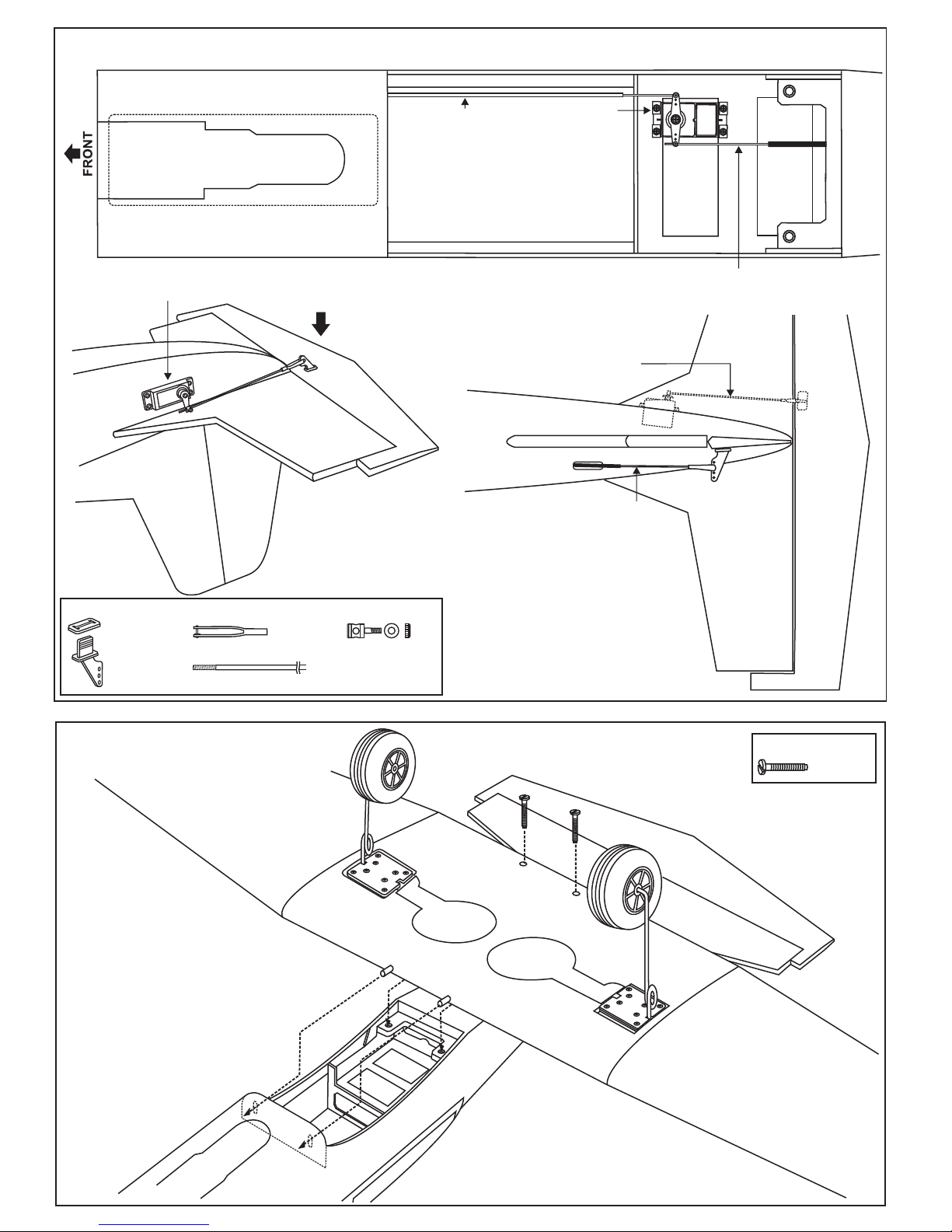

1-Trial fit the horizontal stabilizer in place .

Check the alignment of the horizontal

stabilizer. When you are satisfied with the

alignment, use a pencil to trace around the top and

bottom of the stabilizer where it meets the fuselage.

2-Remove the horizontal stabilizer from the fuselage. Using the

sharp hobby knife, carefully cut away the covering inside the

lines which were marked above.

3-Spread epoxy (30 minute) onto the top and bottom of the horizontal stabilizer

along the area where the covering was removed and to the fuselage where the

horizontal stabilizer mounts.

4-Install the horizontal stabilizer into the fuselage and adust the alignment as described in steep 1.

Vergewissern Sie sich, sauber geklebt

zu haben. Andernfalls konnen Probleme

mit der Flugeigenschaft auftreten!

* WARNING: When removing any covering from the airframe, please ensure that you secure the cut edge with CA or similar

cement. This will ensure the covering remain tight.

AA’

90O90O

1-Trial fit the vertical stabilizer in place . Check the

alignment of the vertical stabilizer. When you are

satisfied with the alignment, use a pencil to trace

around the right and left of the stabilizer where it

meets the fuselage.

2-Remove the vertical stabilizer from the fuselage.

Using the sharp hobby knife, carefully cut away the

covering inside the lines which were marked above.

3-Spread epoxy (30 minute) onto the right and left and

bottom of the vertical stabilizer along the area where

the covering was removed and to the fuselage where

the vertical stabilizer mounts.

4-Install the vertical stabilizer into the fuselage and

adust the alignment as described in steep 1.

Allow the epoxy to cure before proceeding to next step.

AB

Cut away only the covering both

the right and left side*

C = C’

Both the left and

right side

CC’

Securely glue together. If coming off during flight,

you lose control of your air plane.

IMPORTANT:

Please do not clean off the excess epoxy with strong solvent or pure alcohol, only use kerosene to keep the colour of your

model not fade.

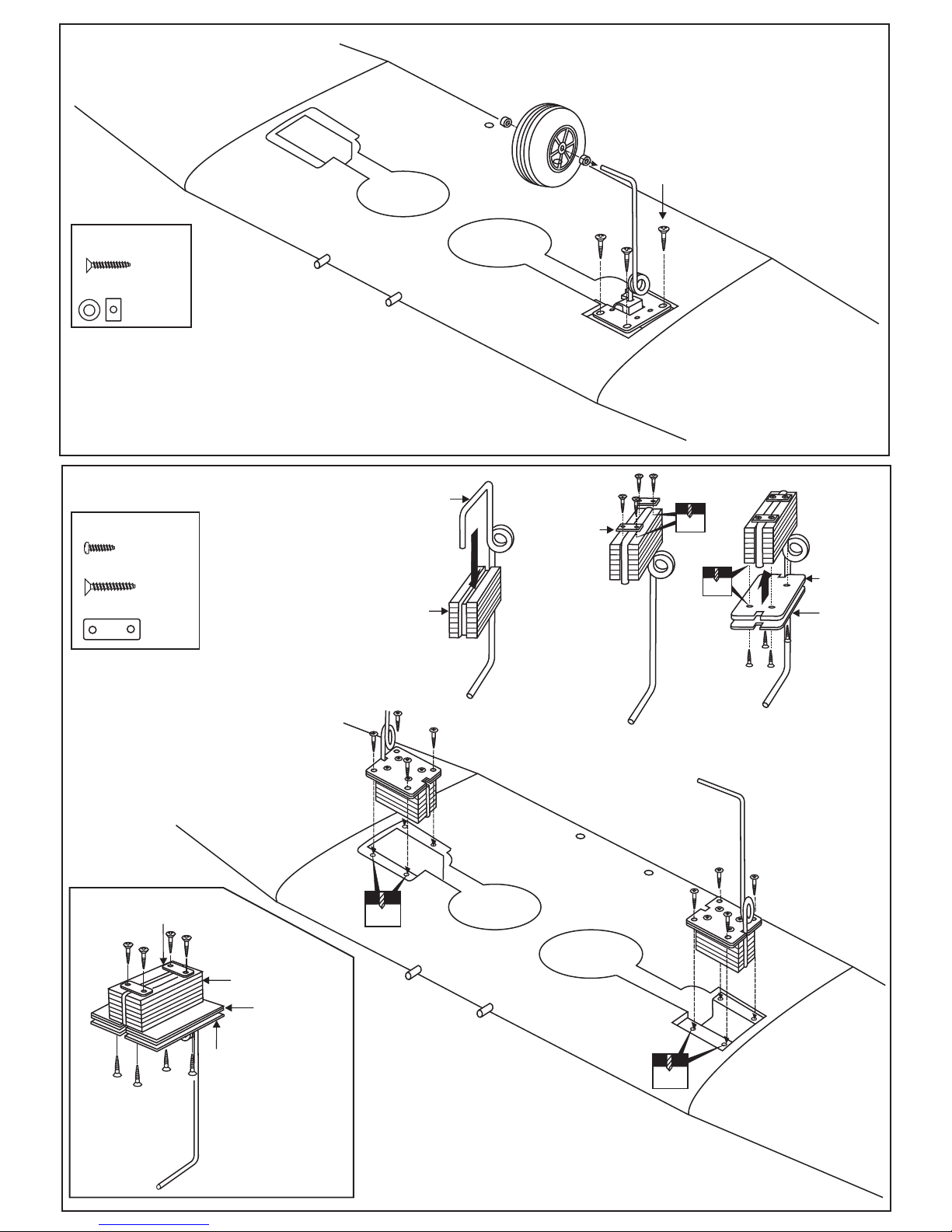

CA

Thin CA

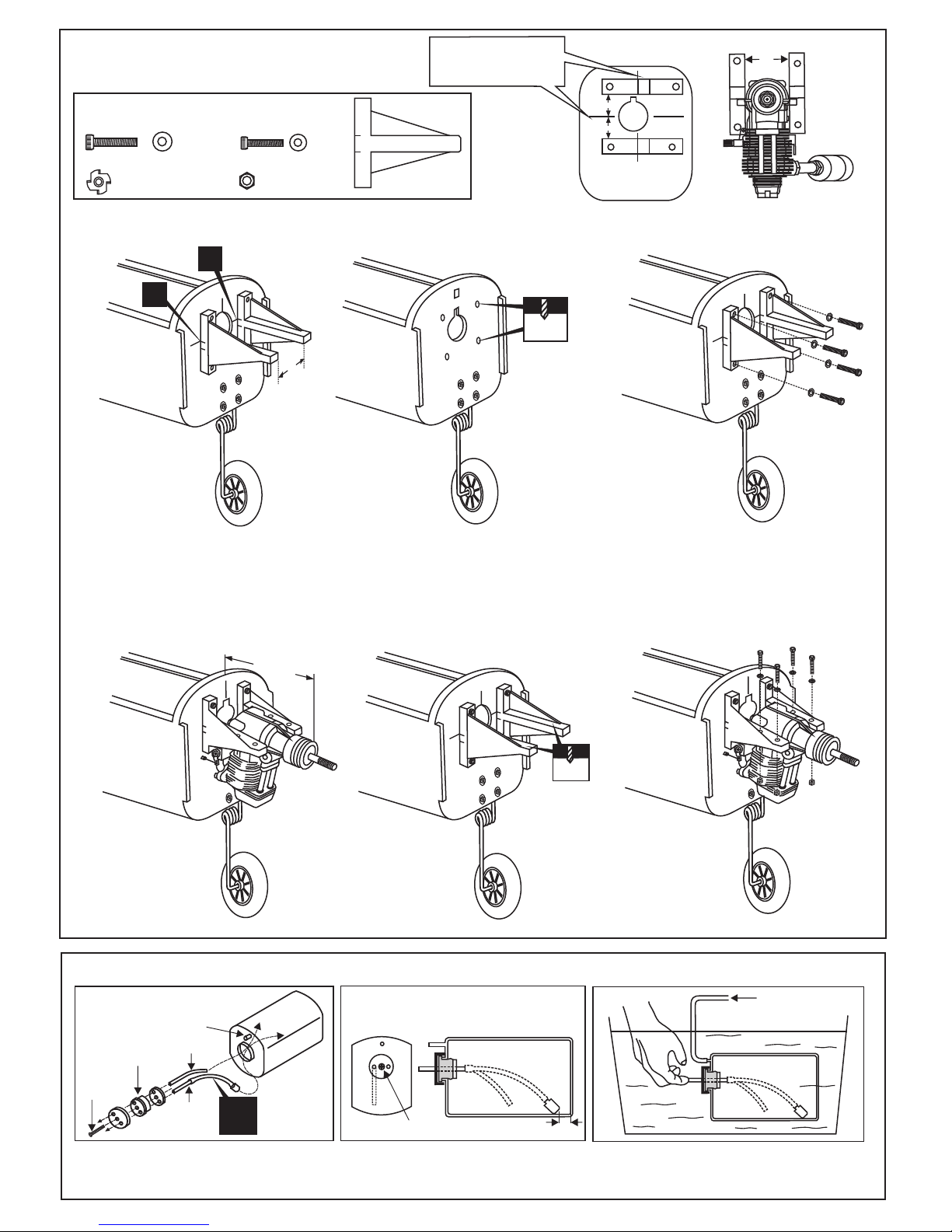

Note: The slots for the control horn installation are pre- cut

at factory.

5-Trial fit the hon. Actuate rudder linkage manually it

should not be hard spot. Adjust if necessary.

6-Insert the plate through the foot of the horn.

Bond with thin CA glue.

Plastic control horn

.....................1

FIN RUDDER

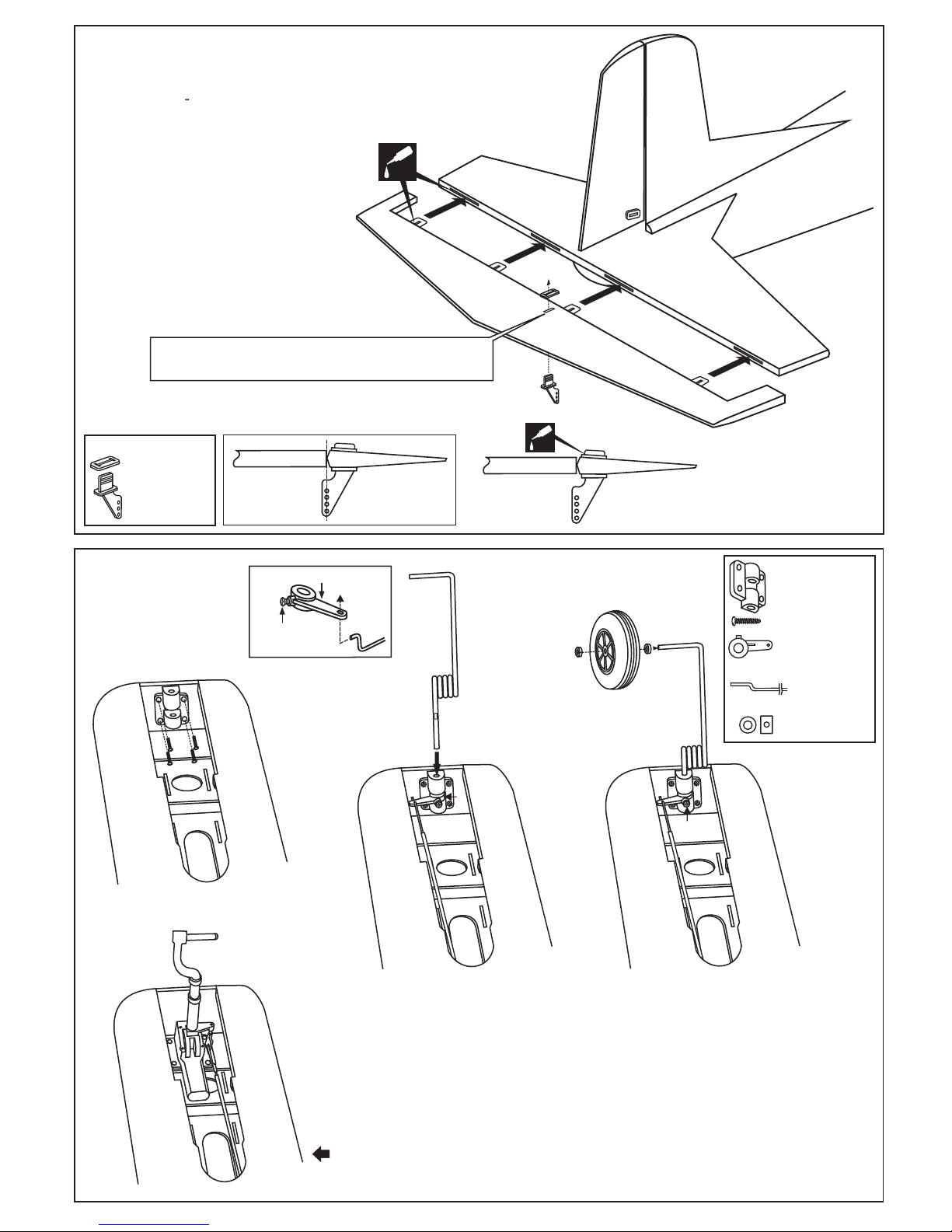

9- Horizontal Stabilizer

10- Vertical Stabilizer

CA

Thin CA

The slot for

rudder horn

is pre-cut

at factory