- 2 -

•There is a gravity drain line and the unit shall be installed level or with a

slight angle toward the drain connection. If rise-up is needed, a

condensation pump must be used.

4. Air Sensor

•The air sensor can be located in the wine room 5 ft above the floor or the

return air area, but not the supply air area or air dead area.

•If the temperature controller is mounted outside the wine room but the air

sensor is located inside the wine room, use 18 gauge wires to extend the

air sensor if needed.

5. Refrigeration Piping, Evacuating, Charging and Starting

CAUTION:

•ALWAYS USE THE SUPERHEAT AND SUBCOOLING, PRESSURE

READINGS TO CHARGE REFRIGERANT PROPERLY, THE LISTED

CHARGES ARE FOR REFERENCE ONLY.

•CHARGE 15% MORE REFRIGERANT IN THE SUMMER IF THE UNIT IS

EQUIPPED WITH A LOW AMBIENT CONDITION KIT.

•The installation order starts from condensing unit (including the receiver,

discharge valve), liquid line filter-drier, moisture-liquid indicator/sight glass,

liquid line, to evaporator unit (including liquid line connection, solenoid

valve, expansion valve, and suction line connection), returning to insulated

suction line, suction valve and then condensing unit.

•Use inverted siphons to prevent liquid from flooding back to the

compressor and aid oil returning to the compressor.

•Charge the system after pipe brazing, leak testing and evacuating.

•The subcooling at the condensing unit shall be around 10° F. The charge

may be complete when there are no more bubbles forming in the sight

glass.

•The evaporator’s constant pressure expansion valve is set around 35-

40°F at factory. This pressure setting gives a dew point to maintain the

humidity for storing wine.

•The superheat at the evaporator unit shall be around

9-18°F under low - high load at 75°F ambient

temperature.

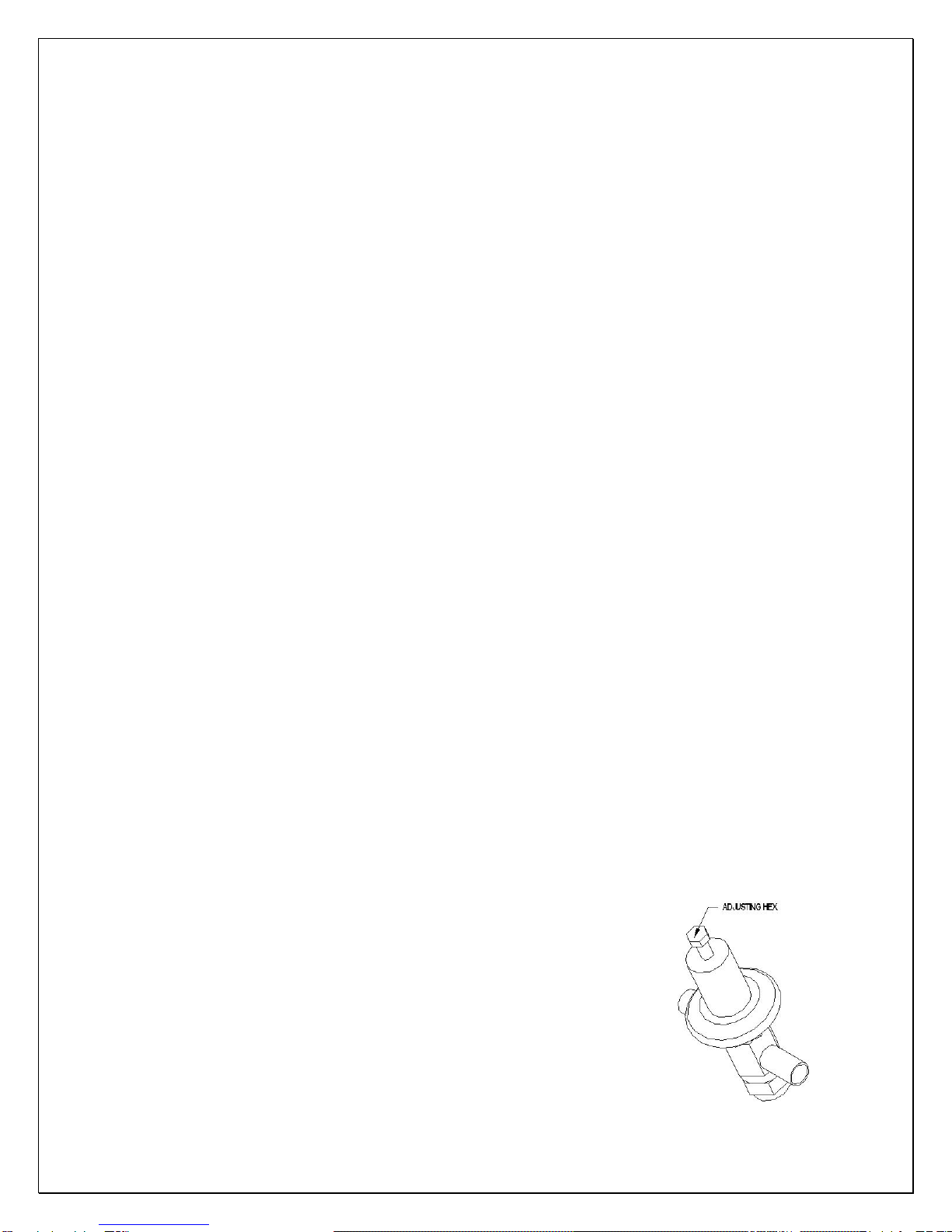

•If the superheat is high, check the subcooling first to

know if the refrigerant charge is sufficient. If the

charge is not sufficient, add more refrigerant. If the

charge is good, then increase the evaporator suction

pressure by turning the hex nut (5/16”) clockwise.

•If the superheat is low, then decrease the evaporator

suction pressure by turning the hex nut (5/16”)

counter-clockwise.