Manual VIPA System 300S SPEED7 Contents

HB140E - CPU - RE_317-4PN12 - Rev. 12/05 i

Contents

About this manual....................................................................................1

Safety information....................................................................................2

Chapter 1 Basics..............................................................................1-1

Safety Information for Users................................................................. 1-2

Operating structure of a CPU ............................................................... 1-3

CPU 317-4PN12................................................................................... 1-6

Chapter 2 Assembly and installation guidelines............................2-1

Overview .............................................................................................. 2-2

Installation dimensions ......................................................................... 2-3

Assembly SPEED-Bus ......................................................................... 2-4

Assembly standard bus ........................................................................ 2-8

Cabling............................................................................................... 2-10

Installation guidelines ......................................................................... 2-11

Chapter 3 Hardware description .....................................................3-1

Properties............................................................................................. 3-2

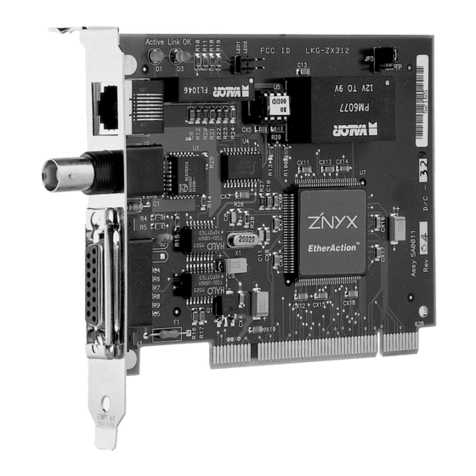

Structure .............................................................................................. 3-3

Technical data...................................................................................... 3-9

Chapter 4 Deployment CPU 317-4PN12..........................................4-1

Assembly.............................................................................................. 4-2

Start-up behavior.................................................................................. 4-2

Addressing ........................................................................................... 4-3

Hardware configuration - CPU.............................................................. 4-6

Hardware configuration - I/O modules.................................................. 4-7

Hardware configuration - Ethernet PG/OP channel .............................. 4-8

Hardware configuration - SPEED-Bus................................................ 4-10

Setting standard CPU parameters...................................................... 4-15

Setting VIPA specific CPU parameters............................................... 4-20

Project transfer................................................................................... 4-25

Access to the internal Web page........................................................ 4-29

Operating modes................................................................................ 4-31

Overall reset....................................................................................... 4-34

Firmware update ................................................................................ 4-36

Factory reset ...................................................................................... 4-39

Slot for storage media ........................................................................ 4-40

Memory extension with MCC.............................................................. 4-41

Extended know-how protection........................................................... 4-42

MMC-Cmd - Auto commands ............................................................. 4-44

VIPA specific diagnostic entries ......................................................... 4-46

Using test functions for control and monitoring of variables................ 4-51

Chapter 5 Deployment PtP communication ...................................5-1

Fast introduction................................................................................... 5-2

Principle of the data transfer ................................................................ 5-3

Deployment of RS485 interface for PtP................................................ 5-4

Parameterization .................................................................................. 5-7

Communication .................................................................................. 5-10

Protocols and procedures .................................................................. 5-16

Modbus - Function codes ................................................................... 5-20

Modbus - Example communication..................................................... 5-24