Virginio Nastri SAV 1 Series Operating instructions

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

VIBRATION SEPARATOR

SAV 1 Series

User and maintenance manual

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

2

DECLARATION OF CONFORMITY

VIRGINIO NASTRI S.R.L., Via Seconda Strada, 161 - 36071 Arzignano (Vicenza) Italy Tel. +39 -

0444 - 45.06.20, fax +39 - 0444 - 61.18.40

declares under its own responsibility that the following machine:

Type: Vibration separator, Mod. SAV/1

Serial number: 21905/13

Year of production: 2013

is IN CONFORMITY with the essential safety requirements dictated by Machines Directive nr.

2006/42/CE.

is IN CONFORMITY with the 2004/108/CE and 2006/95/CE Directives.

The following harmonised norms have been applied:

EN 50081 - 2 electromagnetic compatibility – Generic emission standard, part 2

industrial environment

EN 50082 - 2 electromagnetic compatibility – Generic emission standard, part 2

industrial environment

The signer of the declaration is:

Surname: Virginio

Name: Domenico

Position in the company: PRESIDENT of VIRGINIO NASTRI S.R.L.

Place and date: Arzignano, 04/02/2013

Signature:

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

3

INSTRUCTION MANUAL INDEX

INTRODUCTION

P.1Machineinformation Page 4

P.2 How to use and keep this manual Page 4

P.3Safetywarnings Page 5

SECTION A: GENERAL INFORMATION ON HOW TO USE THE MACHINE SAFELY

A.1Authoriseduse Page 6

A.2 Information on residue risks and emergency situations Page 6

A.3 Reference standards and provisions Page 6

SECTION B: INFORMATION ON HOW TO USE THE MACHINE

B.1 Machine technical description and layout Page 7 - 8

B.2Commands Page 9

B.3 Regulations Page 9 - 10

B.4 Transportation and installation Page 11

SECTION C: INFORMATION ON MAINTENANCE AND REPAIRS

C.1 Maintenance instructions Page 12

C.2Platesandwarnings Page 13

C.3Spareparts Page 14

C.4Wiringdiagram Page 15

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

4

INTRODUCTION

P.1 MACHINE DATA

Producer:

VIRGINIO NASTRI srl

Via Seconda Strada, 161 - Z.I.

36071 ARZIGNANO (VI)

Technical data regarding the SAV 1 series vibration separator (refer to the drawing on page 8)

SAV Series 1

Electric supply voltage (Volt) 400

Installed power (KW) 0.37

DIMENSIONS AND MASS

Length (mm) 1040

Useful width (mm) 410

Pipe diameter (mm) 30

Total mass (Kg) 148

Noise level at the operator’s position in dB(A) < 70

For technical assistance and information:

VIRGINIO NASTRI srl

Via Seconda Strada, 161 - Z.I. ARZIGNANO (VI)

Tel. 0444/450620 - 451520

Fax 0444/671840

Nota Bene: The user instruction manual is an integral part of the machine itself. Familiarity with the points contained in this

manual is essential for safe machine use. This booklet is the Instruction Manual of the previously identified

machine and was compiled in accordance with the EEE 89/392 Directive, Annex I, par.1.7.4

P.2 HOW TO USE AND KEEP THE INSTRUCTION MANUAL

This instruction manual describes machine use as forecasted by design hypothesis, supplies information on how to transport, use,

carry out maintenance on and dismantle the machine, and also how to order spare parts.

The instruction manual is a part of the machine and must be kept “for future reference” until final dismantling. It must be kept in

the most opportune manner in the place where the vibratin separator is used, and must always be easily reachable.

This manual mirrors the technical state of the machine at the machine marketing date.

VIRGINIO NASTRI srl reserves the right to update production and manuals without the obligation to update previous production

and manuals.

A new manual can be requested if the one supplied with the machine is lost or damaged, or if another copy is necessary. When

requesting a new copy, please refer to the data given on the CE plate on the machine.

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

5

P.3 SAFETY WARNINGS

In order to ensure maximum working reliability, VIRGINIO NASTRI srl accurately selects the materials and components used to

produce the machine, and regularly tests it before shipment. Good machine return through time depends on correct use and suitable

maintenance, in accordance with the instructions indicated in this manual.

All the construction elements, as well as the connection and command organs, have been designed and produced with a safety level

that permits resistance to stress that is abnormal or at least above those levels indicated in this manual. The materials are of the best

quality and their entry into the company, their storage and their use is constantly controlled in order to guarantee the absence of

damage, deterioration and malfunctions.

It should, however, be remembered that:

1) THE MACHINE MUST NOT BE USED NOR INTERVENTIONS CARRIED OUT ON IT IF THIS MANUAL AND

ALL ITS PARTS HAVE NOT BEEN FULLY READ AND UNDERSTOOD.

2) IT IS NECESSARY TO USE ALL THE PRECAUSTIONS LISTED IN SECTION A: “SAFETY PRESCRIPTIONS

AND INFORMATION”.

3) IT IS FORBIDDEN TO USE THE MACHINE IN CONDITIONS OR MANNERS THAT ARE DIFFERENT FROM

THOSE INDICATED IN THE MANUAL. VIRGINIO NASTRI SRL CANNOT BE HELD RESPONSIBLE FOR

FAULTS, INCONVENIENCES OR INJURY CAUSED BY THE NON-OBSERVANCE OF THIS POINT.

This manual has been divided into three parts:

SECTION A: which looks at “SAFETY PRESCRIPTIONS AND INFORMATION”

SECTION B: in which the MACHINE CHARACTERISTICS – OPERATION – TRANSPORTATION aspects are indicated.

SECTION C: which describes the MAINTENANCE AND LUBRICATION INTERVENTIONS with an annexed LIST AND

DESCRIPTION OF THE SPARE PARTS

To make reading easier, the following terms have been used:

DANGER

The term DANGER is used in situations where not respecting the regulations or tampering with organs can cause serious injury to

people.

ATTENTION

The term ATTENTION is used in situations where not respecting the instructions can damage the machine or other elements

associated with it or the surrounding environment.

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

6

SECTION A

General information on how to use the machine safely

A.1 AUTHORISED MACHINE USE

This series of separators should be used prevalently to separate plastic parts coming from the moulding machines and going

towards the accumulation area

The separator angle can be varied and the following adjustments are possible:

- height and angle of the separator;

- regulation of the distance between one pipe and the other.

ATTENTION:

The maximum weight of the parts to be separated should not exceed a total of 20 Kg. The vibration separators are not suitable for

separating loose material, such as liquids and powders in general.

The vibratin separators can be easily used by all people who operate the plant in which they are installed, and if used correctly do

not present any risks for the operator.

We recommend reading this manual, however, before using the machine.

VIRGINIO NASTRI srl declines any responsibility in the following cases:

- if the separators are used in evident contrast to the manner indicated in this instruction booklet;

- if there are supply faults;

- if the necessary maintenance is not carried out as indicated;

- if unauthorised modifications are made;

- if unauthorised spare parts or spare parts that are not specifically for the model are used;

- in cases of exceptional events.

A.2 INFORMATION ON RESIDUE RISKS

Residue risk: a risk that remains in spite of all the precautions adopted, or a potential risk that is not evident (Directive 89/392/

par.1.7.2.).

This series of separators does not present residue risks for the operator, as long as the instructions given in this manual are

followed. In spite of this, however, the following indications are valid according to usage conditions:

High temperature: the vibration separator should be used to separate newly moulded parts which are hot. Should it be necessary to

intervene, use protective gloves (in particular regarding the piece fall point).

A.3 REFERENCE STANDARDS AND PROVISIONS

- The separators of this series were designed and manufactured to satisfy the Essential Safety requirements as dictated by the

89/392 Directive, Annex I.

- Reference is made to the EN 60204 – 1 Standard, September 1993 edition, for electric equipment.

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

7

SECTION B

Information on how to use the separator

WARNING: Before reading this section you must be familiar with what is indicated in section A, an integral part of the user

manual which must be understood for using the machine SAFELY.

B.1 MACHINE TECHNICAL DESCRIPTION AND LAYOUT

The separators of this series are made up of a support sheet (1), with an entry chute (2) at one end. The chute moves the moulded

pieces above the separation pipes (4) that are supported by springs (5) which transmit the vibration of the motor (6). The motor is

commanded by a switch (7).

The vibrating pipes separate the pieces: the smallest pieces are collected under the separator, while the bigger pieces exit from the

unload chute (3).

The separator is supported by telescopic supports (10) complete with casters with locking device (13), which make it easier to move

the machine in the work area.

The noise level at the operator’s work place is < 70 dB(A).

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

8

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

9

B.2 COMMANDS

The control commands are positioned in the piece

loading area. The switch complete with starting

pushbutton and stop pushbutton can be found here.

(fig. A)

Emergency stop: when necessary remove the

blender power plug.

B.3 REGULATIONS

Regulating the height of the separator (fig. B)

ATTENTION:

This operation should be carried out by at least two people.

Loosen the nuts (12), extract the screws (11) and raise or

lower the telescopic supports (10). When the necessary

height has been reached, rethread the screws (11) and tighten

the nuts (12).

Regulating the separator angle (fig. B)

ATTENTION:

The separator does not remain balanced when the stop nuts

(9) are loosened.

Two people are necessary for carrying out this operation, one

to hold and regulate the separator, the other to loosen and

tighten the stop nuts (9).

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

10

Regulating the distance between the pipes (fig. C)

To regulate the distance between the pipes firstly loosen the screws (14) and lower the chutes (2-3). After this, loosen the screws

(15) and reposition the pipes (4) at regular intervals, using shims (16) according to the dimensions of the pieces to be separated.

Once the pipes have been positioned correctly, tighten the screws (15) and close the chutes (2-3).

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

11

B.4 TRANSPORTATION AND INSTALLATION

Transportation

The vibration separators are packed using stretch film and

the electric panel and gearmotor are also protected by

sponge rubber.

ATTENTION

The packaging material (plastic film and sponge rubber)

should not be disposed of in the environment but in

accordance with current norms.

The vibration separators should be raised using a fork lift

truck. The overall dimensions and mass of the separators in

this series are given in para. P1.

DANGER

For operator safety and machine integrity, please refer to fig.

D, which shows where to insert the forks in order to raise

the separator in a stable manner.

Once on the lorry loading surface, the machine should be

fixed using levers to block the wheels. Suitable slings or

fixing methods should also be prepared to ensure stability

during transportation.

Installation

No particular preliminary operations are necessary when starting the vibration separator for the first time.

The separator should be connected to an outlet having suitable characteristics. Use the supplied plug.

When laying the cables, please make sure that they are protected against damage and that they cannot trip the operators.

ATTENTION:

Before starting the vibration separator:

- make sure that the supply voltage corresponds to the one indicated on the plate. The plate can be found next to the overload

cutout;

- make sure that the motors are rotating in the correct direction.

ATTENTION:

When the machine has been installed, lock the casters using the levers on each wheel.

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

12

SECTION C

Information on maintenance and repairs

C.1 MAINTENANCE INSTRUCTIONS

GENERAL NOTES

The operator must ensure that the machine is kept clean of foreign material such as deposits, oil or others.

The machine should therefore be cleaned at the end of each work shift when it has stopped and is in a stable condition.

ATTENTION:

Before starting, the operator should switch off the separator and extract the mains plug to avoid any possibility of accidental

starting.

If compressed air is used to clean the machine, protective goggles with additional mask should be used. Any people in the

surrounding area should also be removed to avoid the danger of being hit and injured by material and dust.

Do not use pressurised water directly on the electric apparatus.

It is forbidden to use flammable liquids for cleaning.

Periodically check the state of the plates and replace them if necessary.

Once the machine has been cleaned, the operator should make sure that there are no parts that are worn or damaged (if there are,

immediately request the intervention of the maintenance technician) or parts that are not solidly fixed (do as much as possible).

The operator and possible maintenance technician must wear suitable working clothes that do not fly about, and should not wear

chains, bracelets or other items that could easily catch in the moving mechanical organs. Operators with long hair should use a

hairnet to prevent the risk of entanglement.

The protection and safety devices must not be removed unless a repair and/or maintenance operation is to be carried out.

These devices must be replaced as soon as the reason for their temporary removal has been corrected, and in any case before the

machine is started again.

ATTENTION:

At the end of each machine intervention, use the relative levers to lock the wheels.

This series of separators does not require particular maintenance operations, just some simple interventions.

Inspect to ensure that:

- the motors are not leaking lubricant;

- the electric cable insulation sheath is in good condition (approx. every 2000 working hours).

ATTENTION:

Before carrying out this operation the machine must be put out of service. In order to do this disconnect the plug from the mains

socket after switching off the separator.

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

13

C.2 PLATES AND WARNINGS

The following danger symbol is present on the wrapping of terminal boards that can be powered:

The plate shown below is also present on the blender:

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

14

C.3 SPARE PARTS

Whenever it is necessary to order spare parts, please refer to the address given in para. P1. When ordering, always give the part

code and the requested quantity of each part ordered.

Note: Only original spare parts supplied by VIRGINIO NASTRI srl guarantee operation reliability.

It should be noted, in particular, that some components have safety characteristics for the personnel, therefore these pieces should

only be replaced with the parts recommended by VIRGINIO NASTRI srl.

SPARE PARTS AND CODES

SAV CODE VIBRATION SEPARATOR

CODE

SAV 001

SAV 002

SAV 003

SAV 004

SAV 005

SAV 006

SAV 007

SAV 008

SAV 009

SAV 010

SAV 011

SAV 012

SAV 013

DESCRIPTION

SUPPORT FRAME

ENTRY CHUTE

EXIT CHUTE

SEPARATION PIPE COMPLETE WITH SHAFT

SPRING

VIBRATION MOTOR

SWITCH

SUPPORT SHAFT

SCREW M10

TELESCOPIC SUPPORTS

SCREW M10

CAP NUT, M10

CASTERS WITH BRAKE

VIRGINIO NASTRI srl

Via Seconda Strada,161 – Z.I. - 36071 ARZIGNANO (VI) ITALY

Tel. ++39-0444 450 620 - ++39-0444 651 520 – Fax ++39-0444 671 840

E-mail: info@virginionastri.com - Web Site: www.virginionastri.com

15

C.4 WIRING DIAGRAM

Table of contents

Popular Water Filtration System manuals by other brands

Water Control Corporation

Water Control Corporation MF Series owner's manual

ECH2O Tec.

ECH2O Tec. 900-BHL- 2 owner's manual

Everpure

Everpure EV3034-83 Installation and operation guide

Philips

Philips Pure Taste WP3861 manual

Vega

Vega VEGATRENN 149A EX manual

FILTRON

FILTRON K 1307-2х Installation instruction

Hydropath

Hydropath HydroFLOW i Series manual

Beretta

Beretta Connect MIX STAND ALONE INSTRUCTIONS FOR THE INSTALLER AND THE TECHNICAL ASSISTANCE SERVICE

Pentair

Pentair ONGA FREEFLO FFSF-21-40 owner's manual

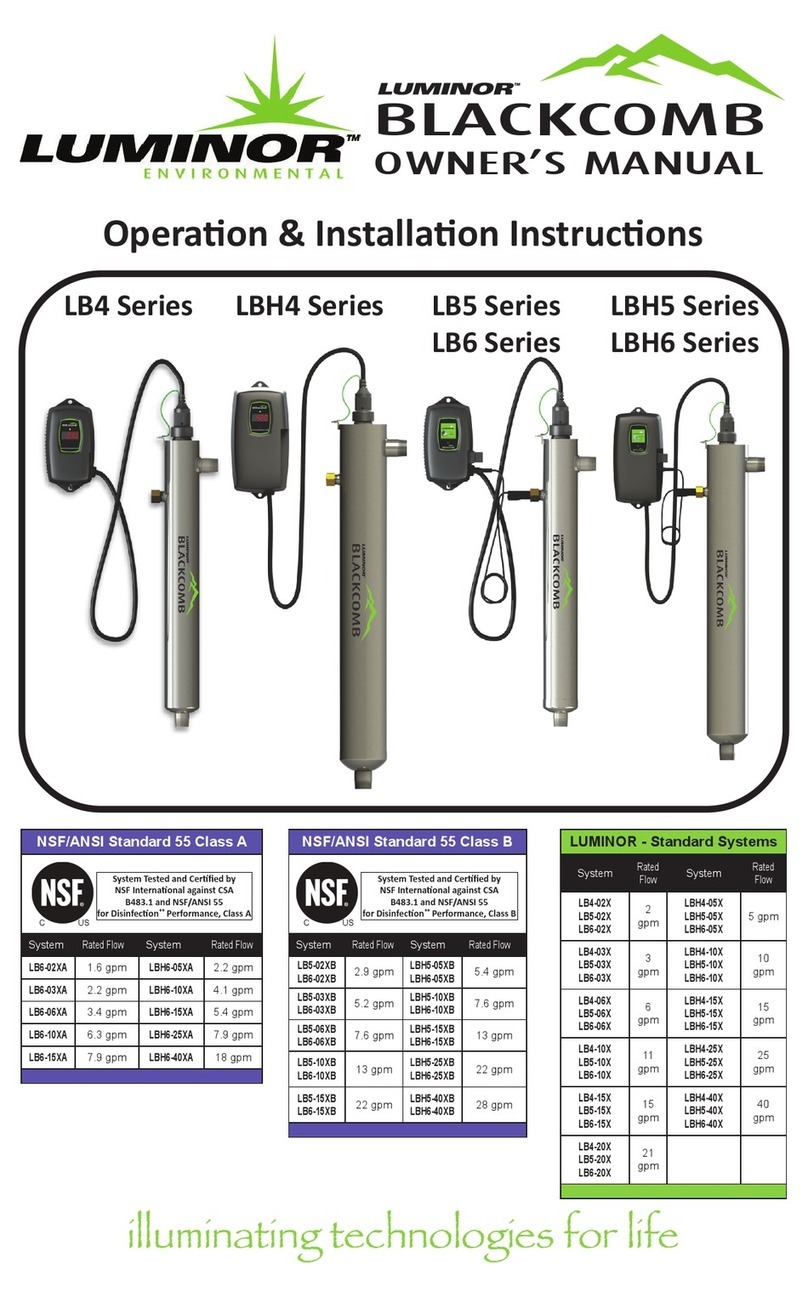

Luminator

Luminator BLACKOMB LB6-02 A Series owner's manual

Omnifilter

Omnifilter OT32 Series A installation instructions

Alb Filter

Alb Filter Element user manual