Water Control Corporation MF Series User manual

MF SERIES

WATER SOFTENERS

An Employee-Owned Company

OWNER’S MANUAL

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

WC-OM-MF-FRONTPG © Water Control Corporation 030722

An Employee-Owned Company

TABLE OF CONTENTS

WARNINGS......................................................................3

BASIC PRINCIPLES.......................................................... 4

SOFTENING OPERATION..................................................5

SPECIFICATIONS .............................................................6

DIMENSIONS...................................................................8

SET-UP PROCEDURES..................................................... 9

INSTALLATION PROCEDURES.......................................... 10

INSTALLATION DIAGRAMS............................................... 11

WIRING DIAGRAMS.........................................................12

PROGRAMMING INSTRUCTIONS...................................... 14

START-UP PROCEDURES.................................................24

MAINTENANCE PROCEDURES......................................... 27

SERVICE..........................................................................29

TROUBLESHOOTING........................................................ 30

COMPONENTS................................................................. 33

OFFICIAL WARRANTY...................................................... 39

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

WC-OM-MF-TOC © Water Control Corporation 030722

An Employee-Owned Company

SYSTEM MUST BE INSTALLED AND MAINTAINED PER THE MANUFACTURER’S

RECOMMENDATIONS IN THIS MANUAL. FALURE TO DO SO MAY CAUSE INJURY, EQUIPMENT

FAILURE AND/OR DAMAGE, AND WILL RESULT IN WARRANTY BEING VOID.

RISK OF SHOCK! ELECTRICAL INSTALLATION SHOULD BE DONE BY QUALIFIED, TRAINED

ELECTRICIANS. INSTALLATION SHOULD BE TO LOCAL CODES.

ALWAYS TURN OFF THE UNIT, SHUT OFF THE FEEDWATER, RELIEVE PRESSURE, AND

DISCONNECT THE ELECTRICAL POWER BEFORE WORKING ON THE UNIT.

DO NOT USE WHERE THE WATER IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN

QUALITY WITHOUT ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM.

NEVER ALLOW THE UNIT TO FREEZE OR OPERATE WITH A FEEDWATER TEMPERATURE/

PRESSURE OUTSIDE THE RECOMENDED PARAMETERS (34-110°F / 20-125 PSI).

SYSTEM MUST BE INSTALLED IN ACCORDANCE WITH LOCAL PLUMBING CODES AND

REGULATIONS.CONTACTWCC(WATERCONTROLCORPERATION)FORMOREINFORMATION.

READ THE ENTIRE MANUAL BEFORE INSTALLING, OPERATING, OR MAINTAINING THIS

EQUIPMENT.

THIS SYSTEM CONTAINS FLOWING WATER, UNDER PRESSURE. ENSURE THAT INSTALL

LOCATION HAS ADEQUATE DRAINAGE AND WATERPROOFING TO ACCOMMODATE

POTENTIAL LEAKAGE AND/OR OVERFLOW SITUATIONS. FAILURE TO DO SO COULD RESULT

IN FLOODING/DAMAGE.

WARNINGS

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

WC-OM-WRN © Water Control Corporation

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

Phone: 763-427-9638 •Fax: 763-427-5665

www.watercontrolinc.com ©Water Control Corporation 1021

An Employee-Owned Company

BASIC PRINCIPLES

A water softener works via a process known as Ion Exchange. In this process, a special media bed is used to exchange undesirable hardness minerals,

including calcium, potassium, and magnesium (as well as low levels of iron and manganese) for something more desirable -- in this case, a small amount

of sodium.

A water softener uses a mechanically driven control valve. During normal operation, this valve distributes the ow of raw (hard) water evenly over the

top of the media bed. As the hard water passes down through the media, hardness minerals -- primarily calcium, which exists in solution in a calcium

bicarbonate form -- are removed from solution and axed to the media. In place of this calcium, trace amounts of sodium ions are released. What was

calcium carbonate dissolved in the water becomes sodium bicarbonate (i.e., baking soda).

Once the resin has absorbed all the hardness minerals, and released all the sodium, that it can, regeneration is required. Regeneration is the process of

removing calcium/hardness minerals from the media and resetting it with fresh sodium ions. To achieve this, a piston in the softener control valve changes

position. The media is rst backwashed, to lift and unpack the bed. Next, it is bathed in a supersaturated brine (sodium chloride) solution. This bombards

the media with sodium ions, forcing the calcium/hardness minerals o and sending them down the drain. A relatively small percentage of sodium ions

remain on the media, though the majority pass to the drain as well. After this brine cycle, the media is rinsed o, the brine tank is relled, and the system

goes back into service.

When a single tank water softener regenerates, an internal bypass is opened in the control valve. This allows the facility to be served by hard water during

the regeneration period. Typically, this occurs in the middle of the night (2AM being the standard setting). Multi-tank systems regenerate one tank at a time,

with the non-regenerating tanks remaining online (with no periods of hard water being sent to the facility).

Many multi-tank commercial softening systems feature a Progressive Flow functionality. When building ow rates are low, only one tank is online/active.

As water usage increases, more and more units come online. Conversely, as usage decreases, tanks are progressively removed from service and put back

into standby mode. By bringing tanks on and oine, based on demand, we can maximize the softening capacity and eciency of the media in each tank.

The electronics in the control valves keep track of usage time for each individual tank. Tanks are rotated on and oine in a manner that equalizes usage

across all tanks over the course of 24 hours.

Another common option on larger commercial softening systems is Brine Reclamation, which utilizes an electronic control system and a 3-way motorized

valve to recycle a portion of the supersaturated brine (salt) water that is normally sent down the drain during regeneration. When the recycle interval ends,

the water eventually does go to drain. This ensures fresh brine for each new regeneration. By utilizing Brine Reclamation, a facility will normally see a salt

usage reduction of around 25%-35%, without any negative eects on softener capacity, eciency, or lifespan.

For more information on commercial water softening systems, please visit WCC’s website at: watercontrolinc.com or call us at 763-427-9638.

We thank you for your business!

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

Phone: 763-427-9638 •Fax: 763-427-5665

www.watercontrolinc.com ©Water Control Corporation 1021

An Employee-Owned Company

SOFTENER OPERATION

As water enters the softener, it passes over a resin bed in a special tank. The resin consists of tiny beads of a plastic called styrene. These beads attract and

hold sodium ions and exchange the sodium for hardness ions when encountered. Over time, the resin becomes saturated with hardness ions and no longer

removes hardness materials. The softener goes into a “regeneration” to ush hardness materials to the drain and refresh the resin with sodium. Regeneration

of single tank systems is typically programmed to take place in the middle of the night when little or no water is in use. Regeneration of individual tanks in

a multi-tank system occurs immediately (as needed), with the other tanks remaining online/ available.

REGENERATION CONSISTS OF FOUR CYCLES:

1. CYCLE: BACKWASH POSITION

Backwash is a rapid upward ow of water that loosens the resin bed and ushes iron particles, dirt and sediments ltered in the bed out to the drain.

2. CYCLE: BRINE DRAW / SLOW RINSE POSITION

Brine Draw is the process in which brine is drawn out of the brine cabinet and passed through the resin in a downward direction. This rinses the resin

and large amounts of sodium ions re- place the hardness ions accumulated during service.

Slow Rinse. After brine is completely removed from the brine cabinet into the resin tank the brine valve closes. Water replaces any remaining brine

from the resin, ushing hardness ions removed from the resin to drain.

3. CYCLE: FAST RINSE POSITION

Fast Rinse is a fast ow of water down through the resin tank that follows a Backwash. This ushes all remaining brine from the tank and packs the

resin bed for softening eciency.

4. CYCLE: BRINE FILL

Brine is water saturated with large amounts of a salt (sodium chloride). During Brine Fill, water ows into the salt storage area after each

regeneration and dissolves salt. During the regeneration process, hardness ions on the resin beads are replaced or exchanged for sodium ions from

the brine solution.

NOTE: SERVICE

When the softener is in service, normal operation is occurring. Water is owing through the softener and hardness minerals are being removed from

the water.

Model

Series

Number

Exchange Capacity*

(grains) Flow Rate (GPM) Pipe Size (in) Back

Wash

(GPM)

Resin

(cu.ft.)

Brine

Tank

Capacity

(lbs)

Regen.

Time

(min)

Tank Size (in) Approx.

Ship

Weight

(lbs)

Min Mid Max Valve

Size (in) Cv 7 psid

Cont.

15 psid

Peak

25 psid Service Drain Resin Salt

MF-48 36800 43200 48000 1.5 8.3 22 32 42 1.5 ⁄ 4 1.6 225 90 12 X 52 18 X 33 150

MF-60 46000 54000 60000 1.5 8 18 28 40 1.5 ⁄ 3 2 225 90 12 X 52 18 X 33 175

MF-90 69000 81000 90000 1.5 8.4 22 30 42 1.5 ⁄ 5 3 650 90 14 X 65 24 X 50 300

MF-120 92000 108000 120000 1.5 9 24 33 45 1.5 ⁄ 7 4 650 92 16 X 65 24 X 50 375

MF-150 115000 135000 150000 1.5 8.2 22 30 41 1.5 ⁄ 5 5 625 94 16 X 65 24 X 50 425

MF-150X 115000 135000 150000 1.5 10.3 28 38 52 1.5 1 8 5 625 96 18 X 65 24 X 50 450

MF-180 138000 162000 180000 1.5 10.2 27 40 51 1.5 1 12 6 600 90 21 X 62 24 X 50 600

MF-210 161000 189000 210000 1.5 10.4 28 40 52 1.5 1 10 7 575 92 21 X 62 24 X 50 650

MF-240 184000 216000 240000 1.5 11.2 30 42 56 1.5 1 15 8 550 94 24 X 72 24 X 50 725

MF-300 230000 270000 300000 1.5 10.8 29 40 54 1.5 1 12 10 500 96 24 X 72 24 X 50 825

- FOR TWIN TANK AND TRIPLEX SYSTEMS, CV RATNGS, EXCHANGE CAPACITIES, FLOW RATES AND RESIN QUANTITIES SHOULD BE DOUBLED OR TRIPLED RESPECTIVELY.

Based on 7 lbs salt per cubic foot.

Based on 10 lbs salt per cubic foot.

Based on 13 lbs salt per cubic foot.

All “MF” Series softeners utilize series 2850 NXT2 controllers.

* Exchange capacity based on treating water with 10 gpg total hardness as CaCo3 and 400 ppm total dissolved solids. Capacities may vary with dierent inuent water characteristics and other factors.

Due to varying water conditions, tank sizes and water pressures, the above should only be used as a guideline.

MF SERIES

WATER SOFTENERS

WCC’s “MF” Series softeners feature 1½” service connections, heavy duty

electronic control valves, high-strength berglass-reinforced mineral tanks,

and long-lasting synthetic cation resin. This series is perfectly designed for

apartments, commercial laundry, schools, hospitals, industrial facilities, and

cooling towers. Available options include single, twin, and triplex systems.

Steel resin tanks, brine reclamation, and Accu-Pipe skid systems are also

available.

SPECIFICATIONS

An Employee-Owned Company

ADVANCED CONTROLLER

· Real-time diagnostics

Flow rates, totalizer, capacity, avg. usage, alarm history, and more

· Remote input for forced regeneration and regeneration lockout

· 2 programmable relays for auxiliary equipment, BAS indication, remote alarms, etc.

WITH OVER 50 YEARS OF EXPERIENCE IN THE WATER CONDITIONING AND PLUMBING INDUSTRIES, WCC CAN DESIGN

AND MANUFACTURE EQUIPMENT FOR VIRTUALLY ANY APPLICATION. WE OFFER A COMPLETE MENU OF SERVICES, INCLUDING WATER TESTING, SYSTEM SIZING, BIM

MODELING (REVIT®), DELIVERY, SETUP, STARTUP, AND AFTER-MARKET SERVICE PLANS. WE MAINTAIN A UNIQUE FOCUS ON MECHANICAL ENGINEERS, CONTRACTORS,

AND THE PLUMBING INDUSTRY. DEPEND ON US TO PROVIDE QUALITY, INNOVATIVE SOLUTIONS FOR ALL YOUR COMMERCIAL WATER CONDITIONING NEEDS.

HOW TO SPECIFY “MF”SERIES SOFTENERS:

ORDER CODE:

MODEL (from other side)

SYSTEM SIZE

Single Tank:

Two Tank*:

Three Tank*:

*Parallel operation only -- no progressive ow option

Additional Options: (check options below)

☐ Brine Reclamation: Re-uses brine solution for signicant salt savings (approx 30%)

☐ Steel Tank(s) (optional ASME Rating)

☐ Accu-Pipe Skid-Mounted System (pre-plumbed**, pre-wired system, mounted on heavy-duty powder-coated steel skid)

☐ Accu-Pipe LS: Same as Accu-Pipe System, less skid base (piping/wiring only)

☐ Brine Silo (large volume salt storage / brine generation & delivery system)

☐ Salt Sock and Access Door (lockable) for blow-in salt delivery

**Standard piping is grooved, type L copper, other materials available.

For a detailed, model-specic specication, please contact WCC (Water Control Corporation). Detailed drawings also available upon request (CAD®or Revit®).

Water softening system requires a minimum inlet water pressure of 30 psig and maximum of 120 psig. If resin tank is subject to vacuum, an adequate vacuum relief valve must be properly

installed. Tank warranty is void if subjected to vacuum. Feed water temperature shall be between 40⁰F and 100⁰F. Each control valve requires a 120 volt wall outlet (2-prong , 1.3FLA, 60Hz).

SIMPLEX (MR)

TWIN

TRIPLEX

MF - -

We look forward to working with you!

Go to www.watercontrolinc.com, where

you’ll nd detailed product specication

info and application design questionnaires.

VISIT US ONLINE

Call 1-866-405-1268 or email

SPEAK DIRECTLY WITH ONE OF

WCC’S DESIGN ENGINEERS

To nd your authorized WCC representative,

please visit: www.watercontrolinc.com/

representative-locator/.

CONTACT YOUR LOCAL

SALES REPRESENTATIVE

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

WC-MF © Water Control Corporation 0122

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

An Employee-Owned Company

SPECIFICATIONS

All dimensions are approximate and subject to change without notice. Please consult our technical department for additional system information.

Single

Tank (MR) Models

WATER SOFTENER DIMENSIONS

Model

Series

Number

(A) (B) (C) (D) (E) (F)

Resin Tank

Diameter

(+/-0.5 in)

Resin Tank

Height

(+/-1 in)

Inlet/

Outlet

Height

(in)

Overall

Height

(in)

Brine Tank

Diameter

(in)

Overall

Length

(in)

EF-30-MR 10.0 44.6 46.0 57.0 18.0 32.0

EF-48-MR 10.0 47.7 54.0 60.0 18.0 32.0

EF-60-MR 12.0 53.4 55.0 65.0 18.0 34.0

EF-90-MR 14.0 66.1 68.0 78.0 24.0 42.0

EF-120-MR 16.0 66.2 68.0 78.0 24.0 44.0

EF-150-MR 16.0 66.2 68.0 78.0 24.0 44.0

EF-150X-MR 18.0 67.0 69.0 79.0 24.0 46.0

EF-180-MR 21.0 67.0 69.0 79.0 24.0 49.0

XF-30-MR 10.0 44.6 46.0 57.0 18.0 32.0

XF-48-MR 10.0 47.7 54.0 60.0 18.0 32.0

XF-60-MR 12.0 53.4 55.0 65.0 18.0 34.0

XF-90-MR 14.0 66.1 68.0 78.0 24.0 44.0

XF-120-MR 16.0 66.2 68.0 78.0 24.0 44.0

XF-150-MR 16.0 66.2 68.0 78.0 24.0 44.0

XF-150X-MR 18.0 67.0 69.0 79.0 24.0 46.0

XF-180-MR 21.0 67.0 69.0 79.0 24.0 49.0

SF-30-MR 10.0 47.7 50.0 54.0 18.0 32.0

SF-48-MR 12.0 53.4 55.0 60.0 18.0 34.0

SF-60-MR 12.0 53.4 55.0 60.0 18.0 34.0

SF-90-MR 14.0 66.1 68.0 73.0 24.0 42.0

SF-120-MR 16.0 66.2 68.0 73.0 24.0 44.0

SF-150-MR 16.0 66.2 68.0 73.0 24.0 44.0

MF-48-MR 12.0 53.4 55.0 60.0 18.0 34.0

MF-60-MR 12.0 53.4 55.0 60.0 18.0 34.0

MF-90-MR 14.0 66.1 68.0 73.0 24.0 44.0

MF-120-MR 16.0 66.2 68.0 73.0 24.0 44.0

MF-150-MR 16.0 66.2 68.0 73.0 24.0 44.0

MF-180-MR 21.0 67.0 69.0 74.0 24.0 49.0

MF-210-MR 21.0 67.0 69.0 74.0 24.0 49.0

MF-240-MR 24.0 74.2 76.0 81.0 24.0 52.0

MF-300-MR 24.0 74.2 76.0 81.0 24.0 52.0

Model

Series

Number

(con’t)

(A) (B) (C) (D) (E) (F)

Resin Tank

Diameter

(+/-0.5 in)

Resin Tank

Height

(+/-1 in)

Inlet/

Outlet

Height

(in)

Overall

Height

(in)

Brine Tank

Diameter

(in)

Overall

Length

(in)

LF-90-MR 14.0 66.1 68.0 78.0 24.0 42.0

LF-120-MR 16.0 66.2 68.0 78.0 24.0 44.0

LF-150-MR 16.0 66.2 68.0 78.0 24.0 44.0

LF-150X-MR 18.0 67.0 69.0 79.0 24.0 46.0

LF-180-MR 21.0 67.0 69.0 79.0 24.0 49.0

LF-210-MR 21.0 67.0 69.0 79.0 24.0 49.0

LF-240-MR 24.0 74.2 76.0 86.0 24.0 52.0

LF-300-MR 24.0 74.2 76.0 86.0 24.0 52.0

LF-360-MR 30.0 78.9 81.0 91.0 30.0 64.0

LF-450-MR 30.0 78.9 81.0 91.0 30.0 64.0

LF-600-MR 36.0 80.4 83.0 92.0 39.0 79.0

HF-300-MR 24.0 77.0 82.0 92.0 24.0 52.0

HF-450-MR 30.0 79.7 85.0 95.0 30.0 64.0

HF-480-MR 30.0 79.7 85.0 95.0 30.0 64.0

HF-600-MR 36.0 82.3 87.0 97.0 39.0 79.0

HF-810-MR 42.0 72.5 78.0 88.0 39.0 85.0

HF-900-MR 42.0 72.5 78.0 88.0 50.0 96.0

HF-990-MR 48.0 72.5 87.0 97.0 50.0 102.0

HF-1200-MR 48.0 72.5 87.0 97.0 50.0 102.0

HF-1800-MR 63.0 86.0 104.0 114.0 50.0 117.0

We look forward to working with you!

Go to www.watercontrolinc.com, where

you’ll nd detailed product specication

info and application design questionnaires.

VISIT US ONLINE

Call 1-866-405-1268 or email

SPEAK DIRECTLY WITH ONE OF

WCC’S DESIGN ENGINEERS

To nd your authorized WCC representative,

please visit: www.watercontrolinc.com/

representative-locator/.

CONTACT YOUR LOCAL

SALES REPRESENTATIVE

WC-SNG © Water Control Corporation 0222

An Employee-Owned Company

SET-UP PROCEDURES

IInspect distributor assembly inside of each tank for damage. The distributor assembly is shipped secured to the resin tank, but damage can occur during

shipping. If the distributor is damaged, do not ll resin tank with gravel/media as it will need to be removed for distributor repair.

Contact WCC at 763-427-9638.

1. Unpackage the resin tanks and place them into/near their installation location. Leave the knockout plug on the distributor tube. This will be removed

after the gravel/media has been loaded into the resin tanks.

2. Load the gravel into the resin tanks using the supplied funnel. The funnel is shipped in the brine tank. See gravel chart for number of gravel bags per

tank.

3. Load the softening media into the resin tanks using the supplied funnel. The funnel is shipped in the brine tank. See chart for number of resin bags

to install per tank.

4. Remove the knockout plug on the distributor tube.

5. Snap on black deector onto the bottom of valve.

6. Screw valve onto resin tank.

7. Install ow meter on outlet side of the softener valve

8. Contact WCC for setup instructions : (763) 427-9638.

MODEL

SERIES

NUMBER

# OF

RESIN BAGS

(per tank)

# OF

GRAVEL BAGS

(per tank)

MF-48 1.6 0.5

MF-60 2 0.5

MF-90 3 1

MF-120 4 1

MF-150 5 1

MF-150X 5 2

MF-180 6 2

MF-210 7 2

MF-240 8 2

MF-300 10 2

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

WC-OM-MF-SETUP © Water Control Corporation 030722

An Employee-Owned Company

INSTALLATION PROCEDURES

1. IDENTIFY INSTALLATION LOCATION FOR WATER SOFTENER. Piping should be such that all hard water, except for outside hydrants, ows through

softener. This system and installation must comply with state and local laws and regulations.

2. CONNECT WATER PIPING. See install diagrams for plumbing layout. Important: Make all sweat-solder connections within 6 inches of softener before

applying threaded ttings. Overheating may cause damage to valve. Note: WCC recommends installing isolation valves on the inlet and outlet of each

control valve, as well as a full system bypass.

3. CONNECT DRAIN LINE. Be sure not to submerse drain line end into drain, as a 1-1/2” minimum air gap must be maintained to prevent potential

backow hazard. Firmly secure at drain, while maintaining a minimum 1-1/2” air gap. Note: Floor drain must be capable of handling full backwash

ow rate (see page 6 for backwash rates).

4. CONNECT BRINE LINE. Connect brine line (supplied in parts bag) to tting on brine tank, and on the control valve. Tighten both ttings with an

adjustable wrench. Note: If you have purchased a setup/startup service, startup agent will connect brine line on site.

5. INSTALL BRINE TANK OVERFLOW LINE. Install overow tting into hole inside of brine tank. An owner-supplied overow line should then be attached

and run to a nearby drain. Failure to run overow line could cause ooding and water damage should the brine tank overow. See the table below

for brine tank overow recommended line size. Note: Line sizes over 0.5 inches are to be hard plumbed to the drain.

6. CONNECT TO ELECTRICAL POWER SOURCE. Connect power cord to a separate 120v, 15-amp, ground fault interrupt (GFI) outlet. Note: Each control

valve should have a dedicated 120V outlet

NOTE: This system is not intended to be used for treating water that is microbiologically unsafe or of unknown quality without disinfection before or

after the system.

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

WC-OM-INSTALL © Water Control Corporation

BLFC

(gpm) SOFTENER CAPACITY

(kgrains) BRINE TANK

OVERFLOW (in)

1up to 150 0.5

2150X - 300 0.75

5360 - 600 1

10 800 and up 1.5

Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

Phone: 763-427-9638 •Fax: 763-427-5665

www.watercontrolinc.com ©Water Control Corporation 1121

An Employee-Owned Company

SIMPLEX INSTALLATION DIAGRAM

Date

Drawn by

Simplex

Commercial Softener

Installation Diagram

07/21/2021

TMD

Drain Line

System Inlet

System Outlet

Bypass Valve

Outlet Isolation Valve

Inlet Isolation Valve

Brine Line

Overflow

Resin Tank

Control Valve

Brine Tank

Flow Meter

44404 Rev A

44403 Rev A

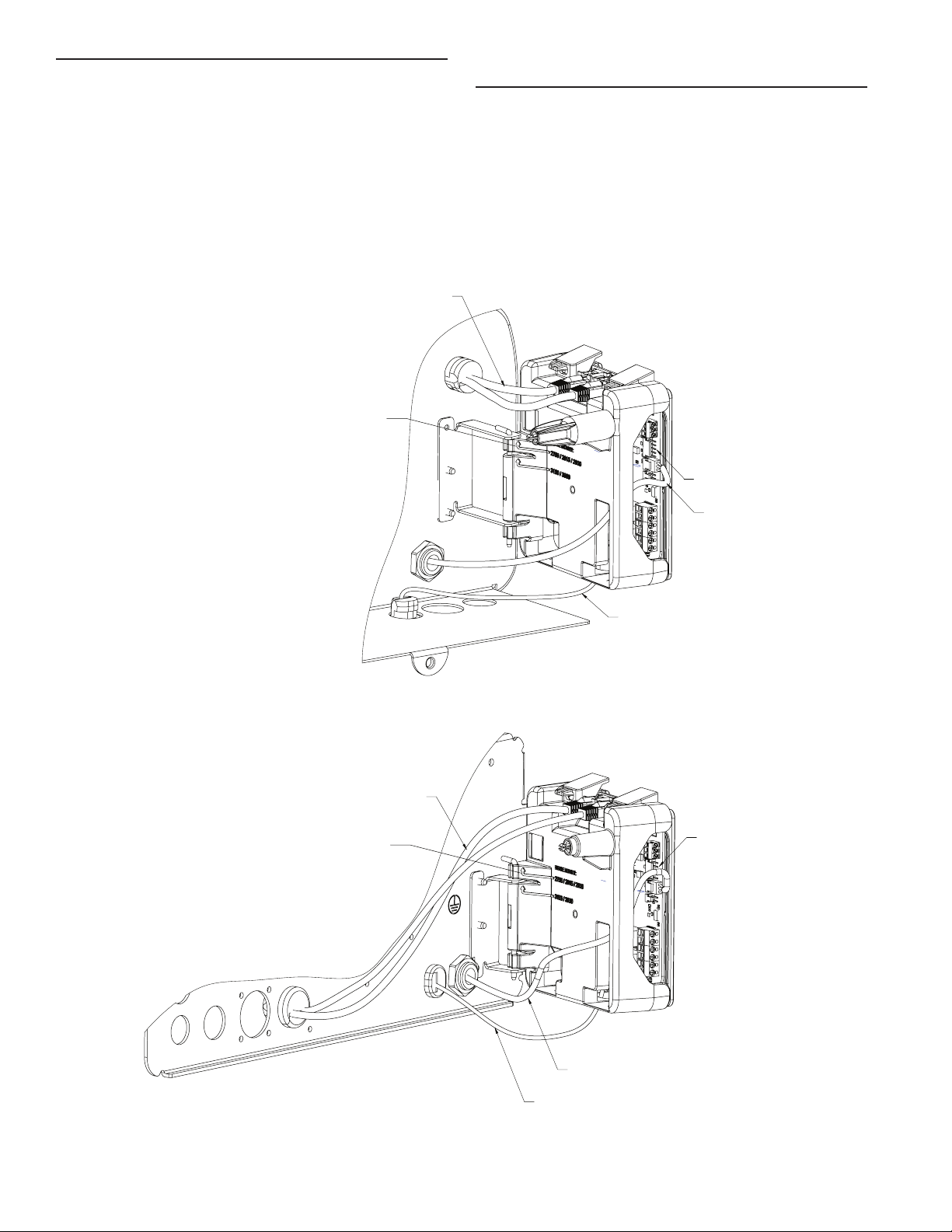

POWER SUPPLY CONNECTIONS

2510/2750/2815/2850/2900 Valves:

3150/3900 Valves:

Installing the Power Supply:

NOTE: Power Supply includes a harness with 2 black wires

that connect to circuit board, see page 15.

1. Insert black and black transformer wires into 24VDC input

of control.

Communication Cables

Hinge Mount: mount per valve model noted

Meter Cable

Power Supply

Wire Harness

Communication Cables

Power Supply

Meter Cable

Wire Harness

Hinge Mount: mount per valve model noted

NETWORK/COMMUNICATION CABLES

AND CONNECTIONS

Use a CAT5 or better Network/Communication cable.

Connect the network/communication cable rst before

programming.

The maximum cable length between timers is 100 feet.

Connect each unit in series (do not form a loop) together from

one communication port to the next communication port. It

does not matter which one goes to the next one.

18 • Fleck NXT2 Timer

WIRING DIAGRAM

VDM

VDM

IMPORTANT: DO NOT USE P18 TO POWER

NON-PENTAIR DEVICES; USE AUX1 & AUX2 INSTEAD

On-screen multilingual support:

English, Franăais, Deutsch,

Italiano, Español, Nederlands,

Português

Time of day super capacitor

backup for 12-hour power loss

2 to 4 line scrolling text OLED

display, high contrast easy to

read in low light conditions and at

a distance

Full functional user interface

with easy programming allowing

forward and backwards menu

navigation

Network two to eight valves via CAT5

or better cables

LED Status Indicator

- Blue: In Service

- Flashing Blue: Regeneration

Queued

- Green: Regeneration

- Flashing Green: Standby

- Red: Error condition present

Two Programmable Auxiliary relay

outputs

- Time-based

- Volume based (Chemical pump)

- Alarm-based

- Cycle-based

- Standby

Remote input

- Remote Lockout

- Remote Regeneration

Easy installation with plug-in wiring

harnesses

Assistance Name and Phone Number

³®ÈvÈï¨Ã

Error Log History

Water Usage Daily (up to 13 weeks)

Push Settings

Capacitive Touch buttons

Two Regeneration Lockout Windows

Reset to factory default settings or

from savable custom settings

Full calendar display

Master Programming Lockout

- Code-based

- Time-based

- Delayed

Icons for easy system status

®Èïvȳ®

Dynamic network addressing

Diagnostics

- Real-time Flow Rate

- Peak Flow Rate (can be reset)

- Totalizer (can be reset)

- Reserve Capacity

- Use Since Last Regeneration

- Last Regeneration

ư *®Èïv¨O³ÈÜvÀ_Àó®

- Total Number of Regenerations

- Regeneration Interval

- Last Settings Change

- Error Log History

- Average Daily Usage

(per weekday, 3 month history)

NXT2 CONTROLLER

ADVANCED SYSTEM NETWORK CONTROLLER

NXT2 CONTROLLER SPEC SHEET WATERPURIFICATION.PENTAIR.COM

Coated Stock - CMYK

FEATURES • BENEFITS

FLECK

4FDUJPO1SPHSBNNJOH*OTUSVDUJPOT

4005307 Rev A JL18

13845 Bishops Dr. |Suite 200 |À³³§ï¨Ɯ`*űůŬŬű|V®ÈOÈvÈÃ

P: 262.238.4400 |ËÃȳÀvÀƝŴŬŬƛŮųŵƛŵŰŬŰ|ÈưÃ˽½³ÀÈǩ½®ÈvÀƛ³

§$³ÀvÈv¨¨ÃȳÜÀI®ÈvÀÈÀvvÀ§ÃvÀÀÃÈÀƜ½¨vÃÛÃÈÜvÈÀ½ËÀïvȳ®ƛ½®ÈvÀƛ³ƨÀv®Ãƛ

I®ÈvÀÈÀvvÀ§Ãv®¨³³ÃvÀ³Ü®âI®ÈvÀ½¨³ÀÈÃví¨vÈÃƛSÀ½vÀÈâÀÃÈÀv®Ë®ÀÃÈÀ

ÈÀvvÀ§Ãv®¨³³ÃvÀȽÀ³½ÀÈâ³ÈÀÀýÈ۳ܮÀÃƛ

ǭŮŬŭŴI®ÈvÀLîÈv¨$¨ÈÀvȳ®Ɯ44ƛ¨¨ÀÈÃÀÃÀÛƛ

13845 Bishops Dr. |Suite 200

À³³§ï¨Ɯ`*űůŬŬű|V®ÈOÈvÈÃ

P: 262.238.4400 |ËÃȳÀvÀƝŴŬŬƛŮųŵƛŵŰŬŰ

ÈưÃ˽½³ÀÈǩ½®ÈvÀƛ³

§For a detailed list of where Pentair trademarks are registered, please

ÛÃÈÜvÈÀ½ËÀïvȳ®ƛ½®ÈvÀƛ³ƨÀv®ÃƛI®ÈvÀÈÀvvÀ§Ãv®

¨³³ÃvÀ³Ü®âI®ÈvÀ½¨³ÀÈÃví¨vÈÃƛSÀ½vÀÈâÀÃÈÀ

v®Ë®ÀÃÈÀÈÀvvÀ§Ãv®¨³³ÃvÀȽÀ³½ÀÈâ³ÈÀ

ÀýÈ۳ܮÀÃƛ

ǭŮŬŭŴI®ÈvÀLîÈv¨$¨ÈÀvȳ®Ɯ44ƛ¨¨ÀÈÃÀÃÀÛƛ

SYSTEM SYSTEM DESCRIPTION NUMBER OF TANKS/CONTROLS TYPE

4 Single Unit 1

Time Clock: No Meter

Immediate: One Meter

Delayed: One Meter

Remote: No Meter

5 Interlocked From 2 up to 8 Immediate: All Meters

Remote: No Meter

6Series

Regeneration From 2 up to 8

Immediate: One Meter

Delayed: One Meter

Remote: No Meter

7Twin

Alternaiting 2

Immediate: One Meter

Remote: No Meter

8 Alternating Delayed 2 Immediate Transfer, Delayed Regeneration

9Multiple Tank

Alternating From 2 up to 8

Immediate: All Meters

Remote: No Meter

14 Demand Recall From 2 up to 8 Immediate: All Meters

VALVE SPECIFICATIONS

System Type 4, 5, 6, 7, 8, 9, 14

SPECIFICATIONS

VALVE TYPE

2750

2850

2900s

3150

3900

2815

REGENERATION TYPE

Meter Delayed Fixed Reserve

Meter Immediate

Remote Signal Start Immediate

Time Clock Delayed

REGENERATION TYPE

³Ü®ð³Ü

V½ð³Ü$¨¨$ÀÃÈ

V½ð³ÜÀ®$ÀÃÈ

ELECTRICAL RATING

24V DC Power Supplies

100V-240V AC input; 24V DC output

GENERIC METER GUIDELINES

Open collector output

Pulse rate generated must not exceed 100 pulses per

second (100Hz) or 6,000 pulses per minute

Support for meter outputs in the range of 1-255 gallons

(25.5m3) for every 1-255 pulses

Meter must operate at 5 VDC

Display Icons

Valve State: Service

Valve State: Standby

Flow Indicator (flashing)

Regeneration

Master Unit (auto-assigned)

Network Indicator - Connected

Network Indicator - Disconnected

Network Indicator - Unit Missing

USB Connected (Field Programmer)

Error Condition Present

Remote Lock

Lock Window

Initializing

Upper Drive Movement

Lower Drive Movement

Remote Regeneration

Master Programming

User Programming

Diagnostics

Time of Day Programming

TIMER DISPLAY

System

Number

Network

Indicator

Valve

State

Flow

Indicator

Time

of Day

Master

Indicator

Status

LEDs

Display Screen

Alternates between

Date, Flow Rate, and

Volume Remaining

(If a regeneration is

queued, displays time

until regeneration)

Left Button

Press:

Navigate to previous

menu option

Press and Hold:

Enter Diagnostic menu

Blue LED

On - Unit in Service

Blinking - Regeneration Queued

Green LED

On - Unit in Regeneration

Blinking - Unit in Standby

Red LED

On - Error present

Down Button

Press:

Adjust menu value down

Press and Hold:

Enter Time of Day menu

Up Button

Press:

Adjust menu value up

Press and Hold:

Enter Time of Day menu

Left Button + Down Button

Press and Hold -

Enter Master Programming

Down Button + Up Button

Press and Hold -

Enter User Programming

Extra Cycle Button

Press:

Navigate to next

menu option

Press and Hold:

Initiate a regeneration

Fleck NXT2 Timer

TIMER OPERATION

Setting the Time of Day

NOTE: Set Time of Day on any unit and the rest of the units in

the system will update the Time of Day automatically.

1. Press and hold the Up button for 2 seconds.

The "Time" value is displayed. Press the Up or Down

buttons to adjust as desired.

2. Press the Extra Cycle button to advance to the "Year" field.

Press the Up or Down buttons to adjust as desired.

3. Press the Extra Cycle button to advance to the "Month"

field. Press the Up or Down buttons to adjust as desired.

4. Press the Extra Cycle button to advance to the "Calendar

Day" field. Press the Up or Down buttons to adjust as

desired.

5. Press the Extra Cycle button to return to the normal display

screen.

NOTE: Press and hold the Left button to exit without saving.

Manually Initiating a Regeneration

1. When timer is In Service or Standby, press and hold the

Extra Cycle button on the main screen.

2. The timer advances to Regeneration Cycle Step #1, and

begins programmed time count down.

3. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #2 (if active).

4. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #3 (if active).

5. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #4 (if active).

6. Press the Extra Cycle button once to advance valve to

Regeneration Cycle Step #5 (if active).

7. Press the Extra Cycle button once more to advance the

valve back to In Service.

NOTE: A manually initiated or queued regeneration can be

cleared by pressing and holding the Back button.

A system queued regeneration can only be cleared

by stepping through a manual regeneration. If

regeneration occurs for any reason prior to the

delayed regeneration time, the manual regeneration

request shall be cleared. Pressing the Extra Cycle

button while in regeneration will cause the upper

drive to advance to the next step immediately.

Timer Operation During Regeneration

In the Regeneration Cycle step display, the timer shows the

current regeneration cycle name the valve is in, or has reached,

and the time remaining in that step. Once all regeneration

steps are complete, the timer returns to In Service and

resumes normal operation.

CYCLE 1/5

BACKWASH 00:10:00

CYCLE 2/5

DRAW 00:60:00

CYCLE 3/5

RAPID RINSE 00:10:00

CYCLE 4/5

TANK REFILL 00:12:00

3UHVVWKH([WUD&\FOHEXWWRQGXULQJDV\VWHP

TXHXHG5HJHQHUDWLRQ&\FOHWRLPPHGLDWHO\

DGYDQFHWKHYDOYHWRWKHQH[WF\FOHVWHSSRVLWLRQ

DQGUHVXPHQRUPDOVWHSWLPLQJ

Timer Operation During Programming

The timer enters the Program Mode in Standby or Service

Mode as long as it is not in regeneration. While in the Program

Mode, the timer continues to operate normally monitoring

water usage. Timer programming is stored in memory

permanently.

Timer Operation During A Power Failure

All program settings are stored in permanent memory. Current

valve position, cycle step time elapsed, and time of day are all

stored during a power failure, and will be restored when power

is re-applied. Time is kept during a power failure, and time of

day is adjusted upon power up (as long as power is restored

within 12 hours).

NOTE: The time of day on the main display screen will flash

for 5 minutes when there has been a power outage.

The flashing of the time of day can be stopped by

pressing any button on the display.

Flow Meter Equipped Timer

As treated water is used, the Volume Remaining display counts

down from the calculated system capacity to zero. When zero

is reached, a Regeneration Cycle begins if no other units are in

regeneration.

Fleck NXT2 Timer

TIMER FEATURES

Regeneration Types

Softener/Filter Meter Delayed - When volume remaining

reaches zero and the scheduled regeneration time is reached

(default 2 a.m. softener; 12 a.m. filter), the unit will regenerate.

Softener/Filter Meter Immediate - When volume remaining

reaches zero, the unit will regenerate.

Time Clock - Once volume remaining reached zero and the

selected regeneration time is reached (default 2 a.m. softener;

12 a.m. filter), the unit will regenerate.

Day of the Week - Once volume remaining reaches zero and the

selected Day of the Week is reached, the unit will regenerate.

Remote Regeneration - Regeneration begins or is queued

after a contact closure meets or exceeds for the length of

time specified in the Remote Signal Duration (Range 1-30

seconds Service; 60-300 seconds Standby). Unit regenerates

will occur based on the Remote Regeneration specified

method (Immediate or Delayed). Immediate Regeneration will

immediately initiate a regeneration. Delayed Regeneration will

initiate a regeneration based on the programmed regeneration

time selected.

Reset to Factory Defaults

While powering up the unit, when the Pentair logo appears,

press and hold the Extra Cycle button to access the Reset

menu then select Reset to Factory Defaults. Press the Extra

Cycle Button to confirm your selection and to advance to the

service screen. Furthermore, you may select

Reset to Non-Factory Defaults to save a set of unique control

parameters.

RESET

PRESS & HOLD

BACK

RESET TO FACTORY DEFAULTS

RESET TO NON-FACTORY DEFAULTS

END

Power on the unit.

When Pentair logo appears,

press and hold the Extra Cycle button.

The Reset menu appears.

Use the up/down buttons to select.

Press the Extra Cycle button to set the

desired option and return to the

Service screen.

Lock Window

Lock Window prevents the unit from regenerating during a

specified time frame. Two lock windows are available (Lock

Window #1 and Lock Window #2). In Master Programming,

enable a Lock Window then select the desired Lock Start time

and Lock End time.

Settings Review

To prevent unintentional changes to Master Programming,

enable Settings Review to view and navigate through Master

Programming settings without the ability to edit.

Remote Lock

The timer does not allow the unit/system to go into

Regeneration until the Regeneration Lockout Input signal to the

unit is cleared. This requires a contact closure to activate the

unit. The recommended gauge wire is 16 AWG with a maximum

wire length run of 50 feet.

Regeneration Day Override Feature

If the Day Override option is turned on and the valve reaches

the set Regeneration Day Override value, the Regeneration

Cycle starts if no other unit is in Regeneration. If other units

are in regeneration, it is added to a regeneration queue. This

occurs regardless of the remaining volume available.

Lock Settings (access to Master Programming)

Lock Settings prevents the user from accessing Master

Programming. In Master Programming, select the desired Lock

Settings option (Off, Time Based, Delayed, or Enter Code).

Time Based - User must set clock to 12:01 pm to unlock

Delayed - User must press and hold the Left and Down buttons

for 60 continuous seconds to unlock

Enter Code - User must input code "1201" to unlock

Capacitive Buttons

Capacitive button entry warrant different consideration than

tactile button entry. Do not wear gloves. Be sure to keep

your hands and the capacitive buttons free of debris, grease,

or water. Buttons may become temporarily unresponsive if

environmental conditions change such as sudden humidity or

temperature changes. If buttons become unresponsive, wait 5

to 10 minutes for the buttons to recalibrate.

LED Status indicator

Blue - Unit in Service

Flashing Blue - Regeneration Queued

Green - Regeneration

Flashing Green - Standby

Red - Error with codes

Power Loss Backup

Time of day super capacitor backup for power loss; rated to

last minimum 12 hours

Continuous Flow Detect

Alert appears when specified continuous flow rate is detected

during service over a specified duration. Continuous flow rate

is adjustable from 0.1 to 999.9 GPM/LPM (accuracy of flow rate

detected will vary based on capability of meter). Duration range

is adjustable from 1 to 255 hours.

Remote Regeneration

Ability to trigger a regeneration via a remote input.

Fleck NXT2 Timer

Auxiliary Relays

The NXT2 has two auxiliary relays available based on cycle,

time, or volume.

Activates during selected cycle step

Activates upon selected start time

(Range: 0-91 minutes)

Deactivates upon selected end time

(Range: Start Time plus 1 minute)

Activates when selected volume (gallon)

is reached (Range: 0-99999)

Selected Duration in Seconds

(Range: 0-9999 seconds)

AUX.1: CYCLE BASED

SP BW BD RR RF SB

AUX.1:TIME BASED-START TIME #1

1 M

AUX.1:TIME BASED-END TIME #1

5 M

AUX.1:VOLUME BASED - VOLUME-G

00100

AUX.1:VOLUME BASED - DURATION-S

0010

TIMER FEATURES continued...

Push Settings

The ability to transmit settings from one unit to all other

connected units. Select the desired Master Programming

settings on one unit then push the same settings to all other

connected units. After push settings are complete, you may still

make unique changes to individual units.

Fleck NXT2 Timer

SYSTEM DEFINITIONS

System 14 (2-8 Units) Demand Recall

Meter input is required on each tank. Unit #1 will begin In

Service with #2, #3, and #4 (if installed) will begin in Standby.

At least one unit is In Service at all times. When flow rate to the

Primary Service Unit increases to a user specified rate, the

next unit in sequence will move from Standby to Service. As

the flow rate falls below the user specified rate, subsequent

tanks will return to Standby. When the Primary Service Unit

regenerates, the next unit in sequence will becomethe new

Primary Service Unit. As each units capacity is reached, the

controller will initiate a Regeneration of that unit. Depending

on the number of units in the system and flow rate demand,

the regenerated unit will then be placed either into Standby or

Service. Only one unit will be in Regeneration at a time.

System 4 - Single Unit

Single Tank configuration Time Clock: No Meter Immediate: One

Meter Delayed: One Meter Remote Signal Start

System 5 (2-8 Units) Parallel Interlock)

All tanks in parallel supplying treated water. Each unit in the

system will have its own flow meter/sensor input. The control

will delay the start of Regeneration if another unit is already

in Regeneration. Once that unit has completed a Regeneration

cycle, and has returned to Service, the unit with the longest

regeneration queue time will begin Regeneration. No more than

one unit will be in Regeneration at at time.

System 6 (2-8 Units) Parallel Series Regeneration

All tanks in parallel supplying treated water. Only #1 control

will monitor flow meter/sensor input. When a regeneration is

required for the system, it will regenerate valve address #1

first, immediately followed by #2, then #3, then #4 if installed.

No more than one unit will be in Regeneration at a time.

System 7 (2 Units) Alternating Immediate

One tank online supplying treated water, one tank in Standby.

Only #1 control will monitor its flow meter/sensor input.

Regeneration of a unit will begin after the other control has left

Standby and returned to Service. When the Regeneration cycle

is complete, the regenerated unit will enter Standby. Standby

on each tank is controlled by the relay on the NXT2 circuit

board.

System 8 (2 Units) Alternating Delayed

Immediate Transfer Delayed Regeneration One tank online

supplying treated water, one tank in Standby. Only #1 control

will monitor its flow meter/sensor input. Online unit depletes

its volume. Once this occurs the offline unit comes online. The

previously online unit goes offline and delays its regeneration

until the programmed regeneration time has been reached.

System 9 (2-8 Units) Alternating with Standby

Units

Up to 7 tanks online supplying treated water, one tank

in Standby. Meter/sensor input is required on each tank.

Regeneration of a unit will begin after the other control has left

Standby and returned to Service. When the Regeneration cycle

is complete, the regenerated unit will enter Standby. Standby

on each tank is controlled by the relay on the NXT2 circuit

board.

Fleck NXT2 Timer

This manual suits for next models

10

Table of contents

Other Water Control Corporation Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Vizion

Vizion TAP-42x Series owner's manual

Adey

Adey MagnaClean Micro2 Installation and servicing

Water Right

Water Right ECLIPSE WRO-35 Installation, operation & service manual

Kessel

Kessel NS 2 MANUAL FOR INSTALLATION, OPERATION AND MAINTENANCE

Du Pont

Du Pont QuickTwist WFRO60X-1 Series installation instructions

CAB

CAB MAESTRO 3E/450 Operator's manual