VIROSMART VS-300 User manual

VS-300 ULV FOGGER

0

User Manual

VS-300 ULV USER MANUAL -THIS MUST BE READ BEFORE USE

VIROSMART is a trading name of DARS Management Co Ltd

Company Registrtion Number: 11947523

Tel: +44 1452 865255 Email: [email protected]

www.virosmart.co.uk

VS-300 ULV FOGGER

1

User Manual

VS-300 Overview

Can be used for disinfection, pest control, odour control and

plant protection.

The VS-300 works by expelling a fine, almost invisible mist

into the atmosphere which eventually settles on all surfaces

including those impossible to reach by conventional methods.

The machine is compact, lightweight and robust.

The ability to adjust the fogger output from a mist of just 6 μm

up to 35 μm, and flow rate up to 49 litres per hour makes this

machine suitable for the application of disinfectants, biocides,

fungicides and pesticides.

Regular fogging with an approved disinfectant such a Virosol

as will help prevent the cross-infection of viruses such as

MRSA, Covid 19 Coronavirus (human and feline), Strangles,

Ringworm and many more.

Overview

VS-300 ULV FOGGER

2

User Manual

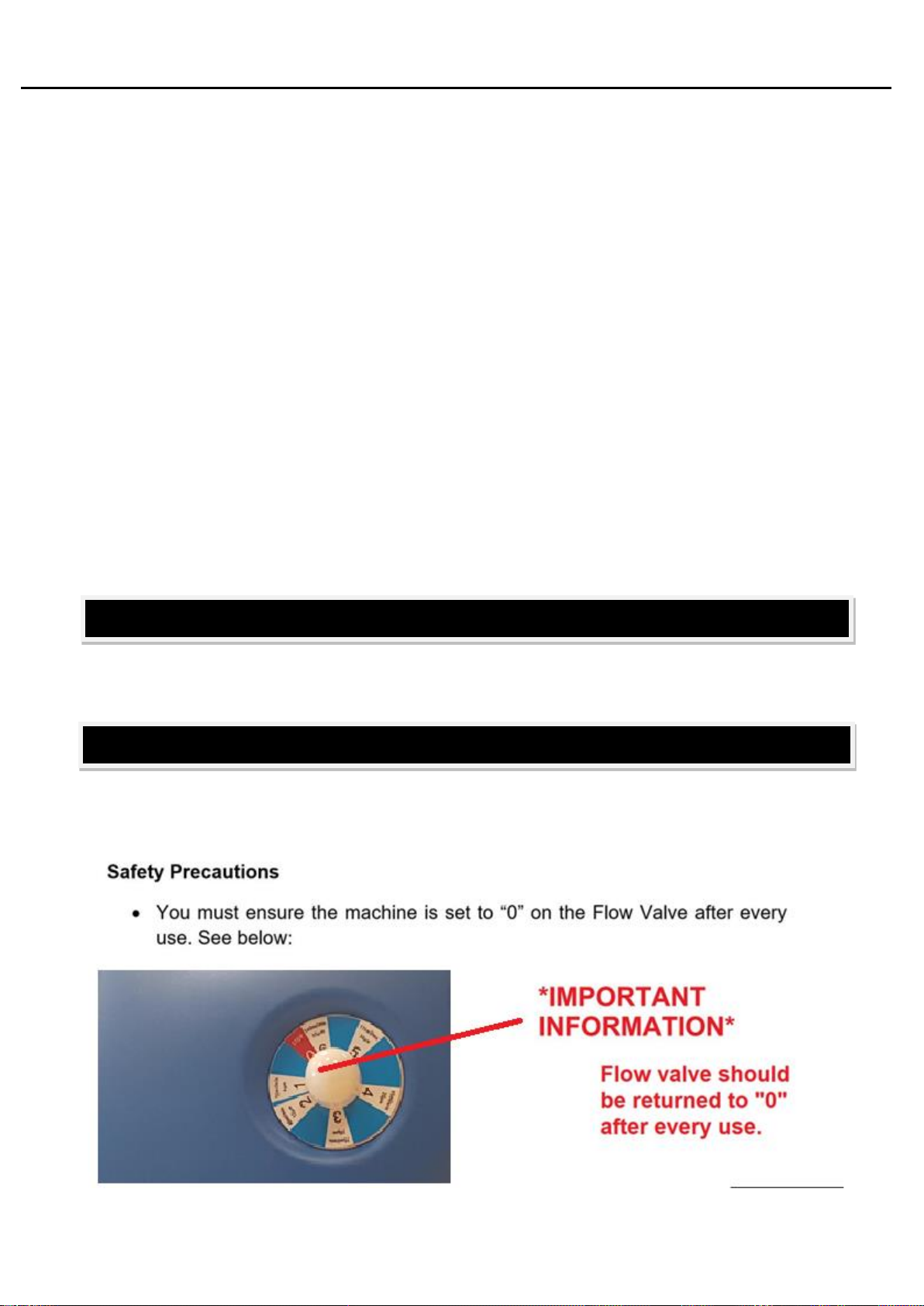

Safety Precautions

•You must ensure the machine is connected to the correct power supply. Connecting the

machine to the wrong voltage could cause the motor to overheat and cause a fire.

•Always use a 13A RCD Adaptor plug between the fogging machine and your 230v power supply.

•Only connect to 220 - 230v power supply.

•Do not connect to a 110v power supply.

•Never move the machine by pulling on the power cord.

•In case of any exposed wiring, damage to the machine or any of its components, turn off

immediately at the wall socket and do not use. Take to an authorised centre for repair.

•Do not modify the machine –this will void the warranty and compromise the safety of the

machine.

•Do not Inhale the fog/mist when spraying. The micro-droplets are quickly absorbed into the

lungs. Depending on the chemical being used this could result in serious injury or death.

•Do not fog a flammable liquid. The motor produces heat and could be a source of ignition.

•You must wear protective equipment (face/breathing mask, gloves and protective clothing).

Ensure you have studied the safety data sheet of the chemical you are using and protect yourself

accordingly.

•Keep the machine away from children.

•For further Government guidelines see http://coshh-tool.hse.gov.uk/assets/live/sr03.pdf

Prior to operating the unit, please read the owner’s manual carefully, and most importantly, observe

all safety rules.Observe the maintenance guidelines closely to ensure the long service life of your

equipment.Your dealer will be glad to assist you with any questions.

EC declaration of conformity -The EC declaration of conformity is available on request.

Packaging and Disposal

Please keep the original packaging in order to protect the equipment against transport damage in case

you ever need to ship it or transport it. If the packaging materials are no longer required then they must

be disposed of properly in accordance with applicable local regulations. Cardboard packaging materials

are raw materials which can be recycled or reused. At the end of the equipment’s service life, please

make sure that you dispose of it properly, in accordance with the official directives and regulations that

apply in your area.

VS-300 ULV FOGGER

3

User Manual

The following symbols are used in this manual and on the product:

Always handle this power tool with particular care

Keep open flames away from the power tool and the fuel can

Thoroughly read these operating instructions before undertaking any maintenance, installation

and cleaning steps

Wear ear defenders and a face shield before starting the engine

Wear protective gloves when handling and working with the equipment

A breathing mask should be worn when using poisonous chemicals

Pesticides can be flammable.

Never smoke near the power tool or where the equipment is refuelled!

Symbols

VS-300 ULV FOGGER

4

User Manual

2.1. Maintenenance and Repair

Maintenance and repair of modern motorized devices, as well as their safety-relevant assemblies,

require qualified, specialized training and a workshop equipped with special tools and test devices.

Thus HSC recommends that you have a specialized HSC workshop carry out all work that is not

described in these operating instructions. Your HSC specialist has the required training, experience,

and equipment at his disposal to provide you with the most cost-effective solution and can help you in

many ways with advice and service.

2.2. Replacement Parts

Dependable operation and the safety of your device also depend on the quality of the replacement

parts that you use. Use only original HSC replacement parts. Only original parts come from the

production of the device and thus guarantee the highest possible material quality, dimensional

accuracy, function, and safety. Original replacement parts and accessory parts are available from

your dealer. He also maintains the requisite replacement part lists to determine the required

replacement part numbers, and he is constantly provided with information concerning detail

improvements and innovations in the replacement part offering. Please note as well that guarantee

performances from HSC are not possible if parts other than HSC original parts are used.

2.3. Guarantee 1 Year from date of purchase.

HSC guarantees problem-free quality and will assume the costs for defect remediation by replacing

the defective parts in the case of material or manufacturing defects that occur within the guarantee

period after the date of purchase. Please note that specific guarantee conditions apply in some

countries. Ask your sales person if you have any questions. As vendor of the products he is

responsible for the guarantee. We request your understanding that no guarantee can be assumed for

damages due to the following:

•Not to be charged properly in time

•Non-compliance with the operating instructions.

•Neglecting required maintenance and repair work.

•Normal wear and tear.

•Obvious overload through persistently exceeding the upper performance limits.

•The use of force, improper handling, misuse, or accident.

•Damages that can be traced to implementation conditions from the rental business.

Cleaning, care, and adjustment work are not recognized as guarantee performances. All guarantee

work must be carried out by a HSC dealer.

2. Workshop service, replacement parts and guarantee

VS-300 ULV FOGGER

5

User Manual

Before starting the machine, fit either the nozzle (5) or the hose (7). The yellow tubing needs to be

securely fastened onto the hose fitting. See the picture below.If the hose is not required –remove

nozzle from the end of the hose and attach in the same method.

3. Important Components

1-Power Button

2-Belt hole

3- 3 lt Tank Refill

7- Nozzle can be

replaced with

hose attachment

5- Nozzle

6- Debi regulator/Flow Rate Valve

Attaching the hose (Optional)

VS-300 ULV FOGGER

6

User Manual

4.1. Correct use / Application

The machine may only be used for the following areas of application:

•The VS-300 ULV is suitable for applying pesticides approved by the national regulatory

authorities. Closely observe the instructions provided by the pesticide or disinfectant

manufacturer.

•According to its type designation, this equipment is suitable for:

Agriculture, horticulture, orchards, green spaces, vineyards, nurseries, inside buildings (see note on

droplet size page 8) the VS-300 may only be used for the jobs it has been designed for.Always

observe all safety hints while using the machine.

4.2. General safety instructions

Read the operating instructions carefully before placing in service and keep them in a safe

place. First time users should be instructed by the seller or an expert.

The operator is liable towards others within the operating area of the ulv fogger. Only operate

the ulv fogger when in good physical condition. Fatigue and illness lead to carelessness and

accidents.

Proceed in a careful and alert manner.

• Never use a machine while under the influence of alcohol or drugs.

• The air exit speed from the nozzle is high. Never point the nozzle towards persons or animals.

Always wear appropriate clothing and protective equipment whenever this power tool is

used.

•Clothing should suitable, i.e. tight without being obstructive. Do not wear a scarf,

necktie, jewellery or any clothing which can get caught on shrubs or branches.

•Wear firm shoes with good traction, preferably safety shoes.

Wear protective gloves with non-slip grip.

Use personal ear protection (such as ear muffs, ear plugs or similar) and a face mask or

safety goggles to protect against spray drift or airborne debris.

When using spray medium that can be hazardous to health, wear a breathing mask to

prevent poisoning.

• Any clothing soaked with chemical or petrol should be changed immediately. Always

observe accident prevention regulations issued by local trade organizations or workers compensation

boards.

4. Safety

VS-300 ULV FOGGER

7

User Manual

After fogging an additional period of 45 ‐60 minutes is required to allow the droplets to settle and

reduce the risk of operators inhaling thechemical droplets. This time may be longer or shorter

depending on the volume of fog and the particle size. You must assess carefully before re-entering

without PPE.

•No other persons should be in the vicinity of the machine unless wearing appropriate

PPE. Keep away from children and animals. Objects carried by the air stream can

deflect and injure nearby persons.

•After fogging an additional period of 45 ‐60 minutes is required to allow the droplets to

settle and reduce the risk of operators inhaling thechemical droplets. This time may be

longer or shorter depending on the volume of fog and the particle size. You must

assess carefully before re-entering without PPE.

Be aware of your surroundings

•Watch out for animals which may be within your work area

•Be aware that noise is harmful to the environment. Inquire about and respect possible local

rest periods.

•Some smoke detection aparatus may be triggered by fogging –please take the necessary

precautions.

•After each process, add distilled water and start to device to rinse the lines. To Avoid

corrosion.

1. Check the tank, If needed fill up the tank with the suitable disinfectant

2. Use the Debi Regulator (Flow Valve) to set the required micron size –remember to always

return this to the “0” position after use.

5. Maintenance and care

6.Starting/Stopping the device

VS-300 ULV FOGGER

8

User Manual

6.Starting/Stopping the devic

1. Preparing Your Sanitisation Fluid

Dilute Virosmart Virosol at 1:50 according to the table below;

If using an alternative to Virosol ensure you comply with the manufactures guidelines.

2. Setting the Fluid Particle Size and Flow Rate

For internal areas such as offices, domestic properties, and vehicles it is important to use a ‘dry fog’ so as not

to dampen or wet any surfaces or objects. The settings on the dial range between 1 and 6, with each number

corresponding to a micron size and flow rate. The lower the number, the smaller the particle size and the less

the flow rate. A particle size of 20 microns or less is termed as a ‘dry fogging’. However, in areas that are more

sensitive such as offices where there is electronic equipment it is recommended to use a particle size of 12

microns or less.

When fogging areas such as stables or other outdoor environments a larger particle size can be used,

producing a wetter fog. If precipitation occurs when sanitizing, then the particle size is too large –adjust as

necessary to ensure your disinfectant does not begin to drip or run-down surfaces.

Model

Instance

Virosol

Water

VS-500

Regular Fogging

100 ml

5000ml (5Litres)

VS-300

Regular Fogging

60ml

3000ml (3Litres)

Dial Setting

Flow Rate (ml / min)

Droplet Size (Microns)

1

12

6

2

40

12

3

75

20

4

95

25

5

115

30

6

140

35

7. Operating Guidelines

VS-300 ULV FOGGER

9

User Manual

3. Switch the fogger on as shown below.

After fogging an additional period of 45 ‐60 minutes is required to allow the droplets to settle and

reduce the risk of operators inhaling thechemical droplets. This time may be longer or shorter

depending on the volume of fog and the particle size. You must assess carefully before re-entering

without PPE.

Use biocides safely. Always read the label and product COSHH information before use

Motor

1400 W –220-230 V AC 50-60

Hz

Solution Tank

Capacity

3 Litre

Air flow rate

80 m/min

Solution Droplet Size

6 - 35 micron

Empty Wight

4,2 KG

Dimensions (cm)

24x50x36 cm

8.Technical Specifications

VS-300 ULV FOGGER

10

User Manual