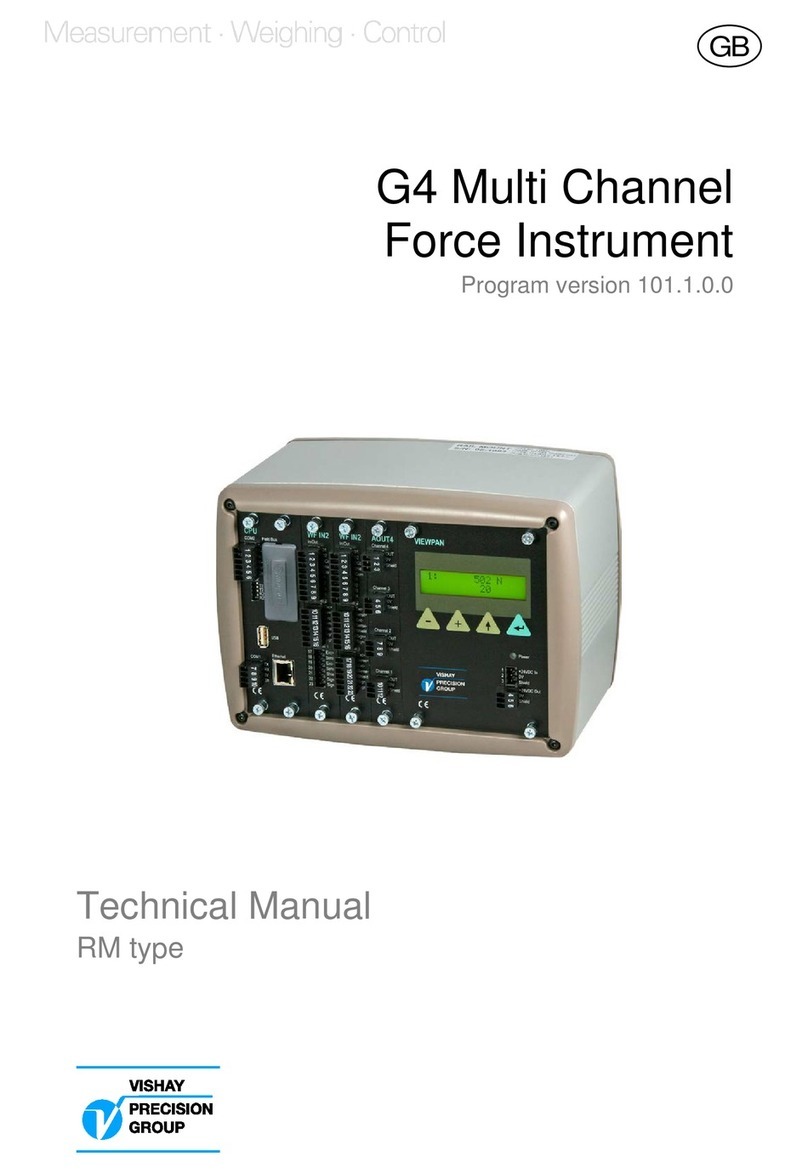

G4 Multi Channel Weighing Instrument

Introduction

General

G4 is a high performance multi channel weighing instrument intended for industrial

systems. Its basic function is to convert the signals from strain gauge transducers to

useful weight information. Several types of communication interfaces are supported

by G4, which makes it easy to integrate the instrument into industrial processes.

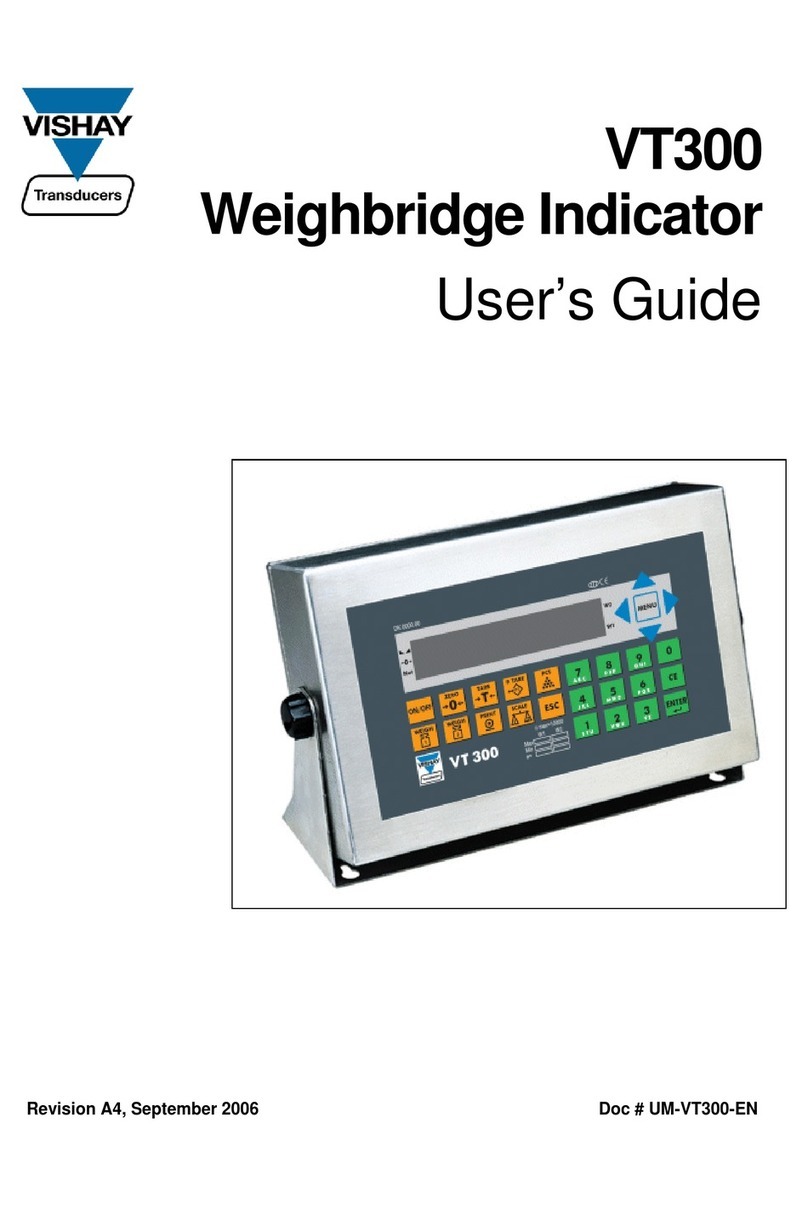

The front panel of G4, types PM/DT/HE, is flat, dustproof, and waterproof. It has

a back lighted graphical colour LCD display with touch sensitive screen for weight

information, set-up information and error messages.

It also has function keys and a numeric keypad for entry of digits.

The basic configuration of the instrument performs weighing and flow rate

calculation. All functions are controlled by set-up parameters.

‘Operating instructions, Quick installation’ for G4, types PM/DT/HE, includes basic

installation and set-up information, required for correct measuring with the instrument.

This description deals with the following points:

•Weighing with G4, types PM/DT/HE.

•Flow rate measurement.

•Quick installation.

•Data sheet calibration.

•Deadweight calibration in two points.

Additional installation and set-up of more instrument functions, not covered by this

description, can also be performed, for example:

•Complete installation.

•Complete set-up.

•Setting of communication parameters.

•Table calibration.

•Level supervision.

For a complete instrument description, refer to:

G4 Multi Channel Weighing Instrument

Technical Manual PM/DT/HE types

Power supply

Power supply to the weight indicator should not be turned off during weekends and

over-night. Continuous power supply to electronics and transducers prevents moisture

condensation in the units.

Start-up

As soon as power is connected to the instrument, a start-up period begins.

The text ‘Start up Please wait!’ and a WAIT symbol (hour-glass) will be displayed

after some seconds.

Then G4 automatically switches to normal measuring operation.

If the instrument is set for operator start-up, the text

‘Press ENTER to start operation!’ will be shown.

If a warm up time has been set, the text ‘Warming up Please wait!’ will be displayed

before the instrument switches to measuring operation.

If any error is detected, the start-up stops and an error message will be displayed.

1