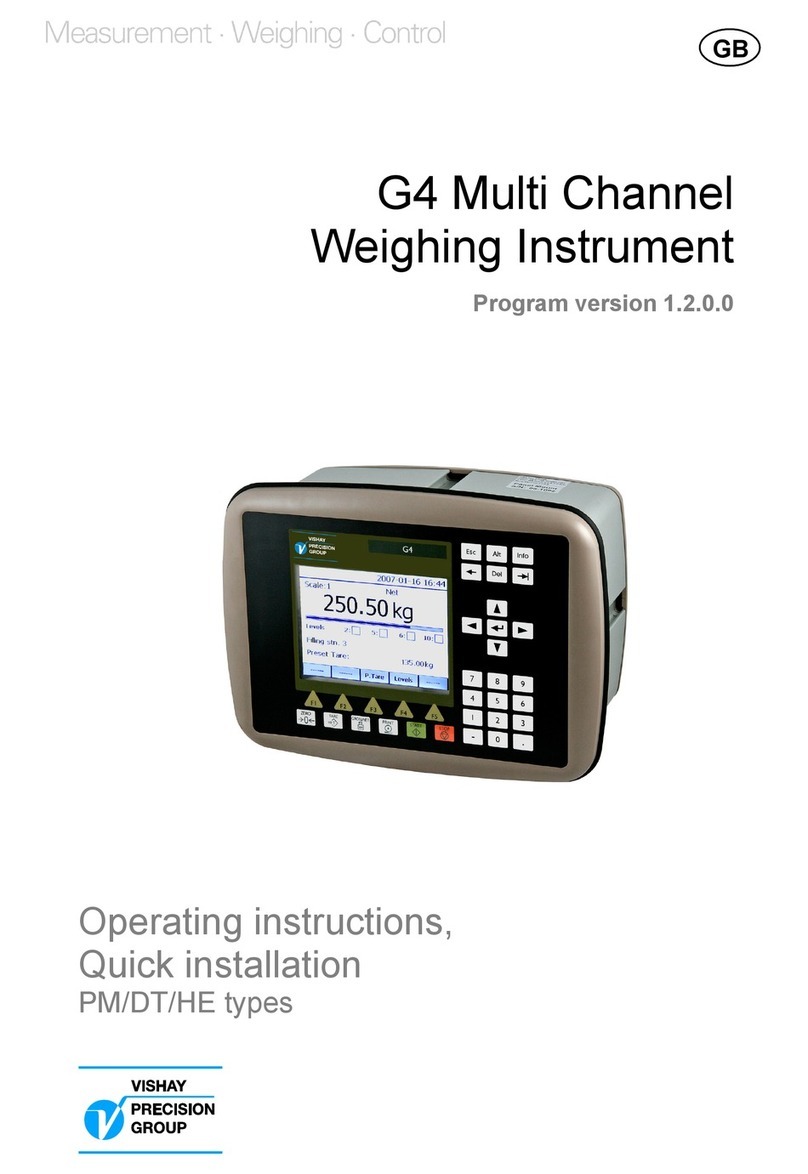

G4 Multi Channel Force Instrument

1. Introduction

Manual updates .....................................1-1

General ..................................................1-1

Functions ...............................................1-2

Maintenance ..........................................1-4

Safety information ..................................1-4

Technical data .......................................1-5

Ordering information ..............................1-12

2. Installation

Mechanical installation ...........................2-1

Electrical installation ..............................2-2

CPU unit.................................................2-3

VIEWPAN module .................................2-5

WF IN, WF IN2 and HS WF2 .................2-6

AOUT1 and AOUT4 ...............................2-9

DIO8 ......................................................2-10

Profibus-DP Fieldbus Adaptor ................2-11

DeviceNet Fieldbus Adaptor ..................2-13

3. Instrument Functionality

General...................................................3-1

Function Block........................................3-1

4. Set-up

General ..................................................4-1

Operators interface ................................4-2

Menu structure .......................................4-6

Parameters ............................................4-8

5. Calibration

General ..................................................5-1

Common parameters .............................5-2

Calibration using datasheet ...................5-3

Using parameters values from

a previous calibration ............................. 5-4

Calibration with known forces.................5-5

6. Operation

General ..................................................6-1

Power supply .........................................6-1

Power-up sequence ...............................6-1

Operating display ...................................6-2

Security locks ........................................6-3

Zero setting ............................................6-3

Main menu .............................................6-4

Level supervision ...................................6-5

Use of inputs and outputs ......................6-6

Filter function .........................................6-7

7. Communication

General ..................................................7-1

Serial interface........................................7-1

Modbus RTU Slave ................................7-1

Modbus TCP Slave ................................7-2

Modbus protocol ....................................7-3

Fieldbus interface....................................7-28

8. Remote Access

General ..................................................8-1

Browser requirements.............................8-1

Using the Remote Access ......................8-2

Security...................................................8-2

Remote Access Login and Logout ..........8-3

Remote / Local Access ...........................8-6

Remote Set-up........................................8-7

Remote Access Maintenance .................8-10

9. Maintenance

General ..................................................9-1

Diagnostics .............................................9-1

File handling ...........................................9-4

Create Backup .......................................9-5

Restore Backup .....................................9-5

Set Default..............................................9-5

Program Upgrade ...................................9-5

Instrument Restart ..................................9-6

10. Troubleshooting

General...................................................10-1

Error codes ............................................10-1

Appendix

Declaration of Conformity........................App.1

Contents