Vision Engineering Hawk MKII User manual

User Guide

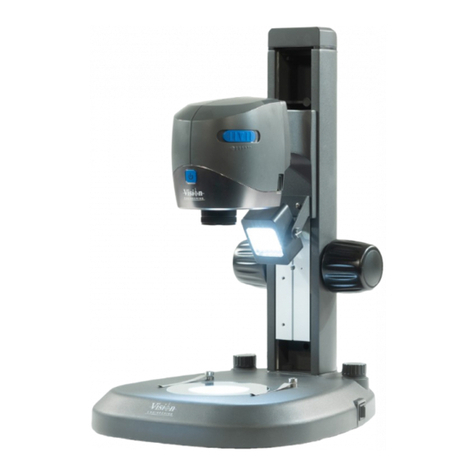

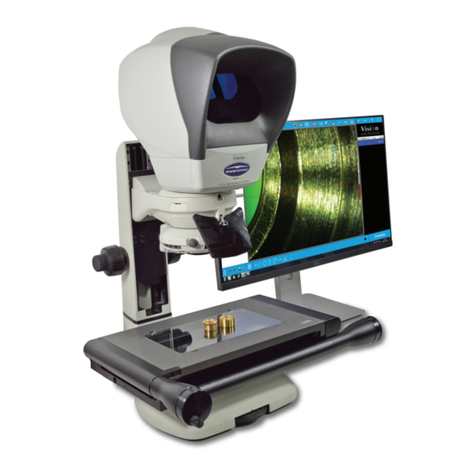

Hawk MKII 3-Axis Non-Contact Measurement Systems

INTRODUCTIONHAWK MKII 3-Axis Non-Contact Measurement Systems

Vision Engineering's Hawk family of 3-axis non-contact measuring systems are designed to achieve the highest levels

of accuracy and repeatability. With high precision measuring stages, and a range of illumination options to suit all

applications.

Health & Safety

Vision Engineering and its products conforms to the requirements of the EC Directives on Waste Electrical and

Electronic Equipment (WEEE) and Restriction of Hazardous Substances (RoHS).

EN61326-1:2006

FCC Part 15

EN61010-1:2010

WARNING: ALL EQUIPMENT PLUGGED INTO THIS UNIT MUST BE APPROVED TO EN60950-1:2001 AND

CHECK CURRENT RATING OF OUTPUT SOCKET IF USED.

HAWK EQUIPMENT – WARNING

This warning refers to CNC systems

Warning – hazardous moving parts.

To avoid entrapment, keep fingers and other body parts

away from moving parts

To stop all CNC movement in an emergency situation move the joystick in ANY direction.

This will interrupt the CNC programme and stop any movement.

In the case of a system failure or crash, to stop the CNC movement switch the Control Power Supply off or switch off

the mains power to the system.

WARNING

DISCONNECT THE MAINS POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE ROUTINE

UNPACKINGUnpacking the Hawk stand (all systems)

Hawk with M3 software manual system

Box 1 Stand

Box 2 Head

Box 3 PSU - Manual and lighting, and cables

Box 4 M3 software pre-installed PC, keyboard and mouse

Box 5 Monitor

Box 6 M3 USB interface box

Box 7 Manual stage (200mm x 150mm)

Box 8 Optional accessories

Hawk with M3-CNC software motorised system

Box 1 Stand

Box 2 Head

Box 3 PSU CNC, and cables

Box 4 Joystick

Box 5 Trackerball

Box 6 M3-CNC software pre-installed PC, keyboard, mouse

Box 7 Monitor

Box 8 M3-CNC USB interface box

Box 9 Motorised stage (200mm x 150mm)

Box 10 Optional accessories

Hawk QC-5000 manual system

Box 1 Stand

Box 2 Head

Box 3 PSU CNC, and cables

Box 4 Joystick

Box 5 Trackerball

Box 6 QC-5000 PC, keyboard and mouse

Box 7 Monitor

Box 8 Manual stage (150mm x 150mm or 200mm x 150mm)

Box 9 Optional accessories

Hawk QC-5000 motorised system

Box 1 Stand

Box 2 Head

Box 3 PSU CNC, and cables

Box 4 Joystick

Box 5 Trackerball

Box 6 QC-5000 PC, keyboard and mouse

Box 7 Monitor

Box 8 Motorised stage (200mm x 150mm)

Box 9 Optional accessories

UNPACKING

3

2

1

CONTENTSPACKING CONTENTS

Head pack 1

Stand pack 1

Stage pack 1

Control units 2

CNC control PSU 2

Joystick and trackerball 2

Control PSU manual and lighting control 2

Accessories 3

Macro 3

Micro 3

M3 USB Interface box 4

QC-5000 PC 4

ASSEMBLY

Removing the transit protection 5

Attaching the stage 5

Ringlight attachment 6

Macro EPI attachment 6

Macro EPI and ringlight attachment 7

Micro EPI and lens turret attachment 7

Attaching the head only 8

Mounting camera to rear 8

Attaching Unicam II 9

Attaching the anti-glare shield 9

Inserting the stage glass 10

Cable connection M3-VED (manual systems) 11

Cable connection M3-CNC (CNC systems) 12

Cable connection QC-5000 (manual systems) 13

Cable connection QC-5000 (CNC systems) 14

START UP / SHUT DOWN PROCEDURE

CNC start up procedure (PC / M3) 15

CNC shutdown procedure (PC /M3) 15

Manual lighting control PSU start up 15

Manual lighting control PSU shutdown 15

SETTING UP

Manual system controls 16

CNC system controls 17

Align head to stage 18

Stand levelling 18

Stage glass levelling 18

Camera Setup 18

CONTENTS

OPERATION

Objective lens 19

Episcopic illuminator 20

Symbols and icons 20

Manual and lighting controls 21

Ringlight control 22

Substage 23

ROUTINE MAINTENANCE

Graticule adjustment 24

Substage LED replacement 25

Episcopic LED replacement 25

General care 26

Consumable and replacement parts 26

Environmental conditions 26

ACCESSORIES & OPTIONS

SERVICE & CALIBRATION RECORD

WARRANTY

CONTENTS

PACKING CONTENTSSee packing list to clarify contents of delivery.

Head pack

Stand pack

Stage pack

150mm x 150mm

(manual)

200mm x 150mm

(manual)

200mm x 150mm

(motorised)

250mm X 150mm

(manual)

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

PACKING CONTENTS

1

1

2

1

2

3

3

4

4

Control units

CNC control PSU

Joystick and trackerball

Control PSU manual and lighting control

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

PACKING CONTENTS

2

Accessories

Macro Micro

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

PACKING CONTENTS

3

Macro Lens Options

x1

x2

x5

x10

Micro Lens Options

Micro Micro LWD Micro SLWD

x5 x10 x20

x10 x20 x50

x20 x50

x50 x100

Substage condenser lens Substage condenser lens

Object lenses Object lenses

Macro Episcopic

LED illuminator

Micro Episcopic

LED illuminator

Unicam II

Ringlight illuminator

Camera adaptor

M3 USB Interface box

M3 USB interface unit

Note: Please ensure your Windows® operating

system is kept up to date through

Windows® Update.

Note: In applications where the USB

signal/power is weak (i.e. with long leads

and some laptops) we recommend using a

powered hub or repeater cable (available

from your local PC retailer).

QC-5000 PC

QC-5000 PC

Monitor

Keyboard and mouse

Note: Please ensure your Windows®

operating system is kept up to date

through Windows® Update.

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

PACKING CONTENTS

4

2

1

3

1

2

3

ASSEMBLYThe following paragraphs provide instructions on how to assemble the Hawk Measuring System. In most instances

the illustrations are self explanatory; where necessary the illustrations are supported by text.

Removing the transit protection

uUse the red transit handle uand either of the focus control covers v

to lift the stand into the required work position.

uRemove the red transit handle and focus control

covers. Screw the two focus control collars w

(one each side) into position.

uRemove the transit handle by removing the

screws that secure it to the stand.

uLoosen screws xand y. Use the focus

controls zto raise the head platform {

until there is sufficient room to remove the

transit tube |. Unscrew dovetail from

item |as required.

Attaching the stage

uCheck the stand base plate uand the underside of the 200mm x

150mm stage vare clean and free of any debris.

uUsing the red stage transit handles w, lift the stage into position and

secure it using the bolts provided with the stand, not the bolts that

secure the stage into the transit box.

uUse the Allen key supplied to progressively tighten all 4

screws xin the numbered sequence (shown in the

diagram ybelow) to a torque of 2.8Nm. This is

approximately equal to bolt touch down, plus a quarter

of a turn.

uRemove the stage transit handles.

uAdjust the stabilizing foot zto support

the stand base.

uScrew the required condenser lens {

through the stage and into the stand.

Note: Micro condensers should only be used

with micro lenses when viewing a subject at

stage glass level.

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

ASSEMBLY

5

v

x

z

{

|

Micro

Macro

Column

Stage Assembly

Logo

B4

B3B1

B2

w

u

v

w

w

z

x

x

x

x

y

{

u

y

Ringlight attachment

Macro EPI attachment

Note: The same procedure is used to fit either the Macro EPI (illustrated) or the Micro EPI. The Micro

EPI cannot have an Objective Holder or Ringlight fitted.

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ASSEMBLY

6

Securing Screw

Grub Screw

Grub Screw

Securing Screw

3G Ringlight adapter

Macro EPI and ringlight attachment

Micro EPI and lens turret attachment

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

ASSEMBLY

7

Grub Screw

Securing Screw

Grub Screw

Securing Screw

Grub Screw

Grub Screw

Attaching the head only

Mounting camera to rear

uPosition camera attachment between the

viewing head and its arm.

uSecure with the grub screws.

uAttach the adapter to the camera

and tighten 3 x grub screws if not

already fitted.

uLocate camera and adapter to the locking

plate (the locking plate must not be

overtight, but enough to hold).

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ASSEMBLY

8

Head

Connector

Head

Socket

Grub

Screw

Camera

Attachment

Grub

Screws

Locking

Plate

Camera

Adapter

Attaching Unicam II

Attaching the anti-glare shield

CAUTION: The Anti-Glare Shield is made of plastic and

must not be over tightened.

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

ASSEMBLY

9

Unicam

Securing

Screws

Head

Power

Lead

Screws

Inserting the stage glass

Note: The stage glass must be handled with care to avoid any fingerprint marks.

uAlign the glass with it's bevelled edges against the

springs (see table below for spring location and

diagram ufor the correct orientation of

the stage glass).

uCheck that the stage glass is in contact with

all four supports.

uTo level the stage glass, refer to page 18.

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ASSEMBLY

10

Stage size Spring location

150 x 150mm Left & Back

200 x 150mm Left & Front

P

O

u

Cable connection M3-VED (manual systems)

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

ASSEMBLY

11

All connectors must be engaged fully and secured with the screws.

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

recommend using a powered hub or repeater cable (available from your local PC retailer).

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

RINGLIGHT EPI

HEAD

VREF

DISPLAY I/O

X Y Z

MAINS POWER IN

MAINS POWER IN

PC USB

KEY

Mains Power

Lighting/Power

X, Y and Z

PC USB

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

Cable connection M3-CNC (CNC systems)

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ASSEMBLY

12

KEY

Mains Power

USB

Display

Lighting/Power

X, Y and Z

CNC

MAINS POWER IN

All connectors must be engaged fully and secured with the screws.

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

recommend using a powered hub or repeater cable (available from your local PC retailer).

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

Cable connection QC-5000 (manual systems)

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

ASSEMBLY

13

All connectors must be engaged fully and secured with the screws.

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

recommend using a powered hub or repeater cable (available from your local PC retailer).

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

RINGLIGHT EPI

CAMERA

Input

110-240V 50-60Hz

HEAD

Fuse

T1.0AH 240V

T2.0AH 110V

VREF

DISPLAY I/O

SUB-STAGE ILLUMINATION

DISPLAY I/O

Y XZ

PC

(rear)

USB

KEY

Mains Power

USB

Display

Lighting/Power

X, Y and Z

MAINS POWER IN

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

Cable connection QC-5000 (CNC systems)

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ASSEMBLY

14

All connectors must be engaged fully and secured with the screws.

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

recommend using a powered hub or repeater cable (available from your local PC retailer).

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

JJOOYYSSTTIICCKK

VREFVREF

CCNNCC

DISPLAY I/ODISPLAY I/O

Z-AXIS MOTORZ-AXIS MOTORY-AXIS MOTORY-AXIS MOTORX-AXIS MOTORX-AXIS MOTOR

RINGLIGHT EPI

JOYSTICK

TRACKERBALL

CAMERA

DISPLAY I/O

Y XZ

PC

(rear)

USB

CNC

KEY

Mains Power

USB

Display

Lighting/Power

X, Y and Z

CNC

MAINS POWER IN

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

Table of contents

Other Vision Engineering Measuring Instrument manuals