Vision Engineering SWIFT PRO Series User manual

9Swift PRO Duo

9Swift PRO Cam

9Swift PRO Elite

User Guide

Vision Engineering Ltd has been

certified for the quality management

system ISO 9001:2015.

FM 557119

Est. 1958

www.visioneng.com

Swift PRO series of optical and

video measuring systems

General

Intended use of equipment:

Swift PRO provides high accuracy non-contact

measurement of complex manufactured components

and materials.

Safety

Before using your system for the rst time, please read

the Health & safety section of the user guide.

Ensure that:

Your system and accessories are operated, maintained

and repaired by authorised and trained personnel only.

All operators have read, understood and observe the

user manual, in particular the safety regulations.

Cleaning

Disconnect your system from the electrical source

before cleaning.

Do not use any unsuitable cleaning agents, chemicals

or techniques for cleaning.

Never use chemicals to clean coloured surfaces or

accessories with rubberised parts.

Use a specialist lens cloth to clean optical surfaces.

Servicing

Repairs may only be carried out by Vision Engineering-

trained service personnel. Only original Vision Engineering

spare parts may be used.

Symbols used

Warning!

A potential risk of danger exists. Failure to comply can

cause i) a hazard to personnel; ii) instrument malfunction

and damage. Please consult the operating instructions

provided with the product.

Warning of electrical shock hazard

This symbol indicates the presence of electric shock

hazards. Please consult the operating instructions

provided with the product.

Important information

This symbol indicates important information. Please

carefully follow the instructions or guidelines.

Health & safety

Unauthorised alterations to the instrument

or non-compliant use shall invalidate all

rights to any warranty claims.

Electrical safety

Disconnect your system from the electrical source

before undertaking any maintenance.

Avoid using any form of liquid near the system.

Do not operate your system with wet hands.

Heat safety

A dust cover is supplied with your system. Turn off

your system and ensure it has cooled down before

using the dust cover.

Illumination safety

Do not look directly at the illuminated LED’s. This may

cause damage to the eyesight.

Environmental considerations

Avoid large temperature uctuations, direct sunlight

and vibrations.

Ensure electrical components are at least 10cm from

walls and combustible materials.

Position the system on a rm, rigid and level table.

The equipment should be positioned so that access to

the electrical input connector is always available.

Avoid positioning your system where bright reections

may affect the image.

Operator wellbeing

The advanced ergonomic design and construction

of Vision Engineering products are intended to

deliver superior ergonomic performance, reducing

the exertion of the user to a minimum. Depending

on the duration of uninterrupted work, appropriate

measures should be taken to sustain optimal operator

performance. This could include: Optimal arrangement

of workplace; Variation in task activity; Training of

personnel on workplace ergonomics and general

health and safety principles.

It is important to set-up and optimise your working

environment correctly in order to obtain maximum benet

from the advanced ergonomic design of your system. For

more information visit: www.visioneng.com/ergonomics

Compliance statements

Vision Engineering and its products conforms to the

requirements of the EC Directives on Waste Electrical and

Electronic Equipment (WEEE) and Restriction of Hazardous

Substances (RoHS).

All Vision Engineering products conform to the CE mark,

demonstrating that each product meets the requirements

of the applicable EC directives. Where applicable, other

characteristics of the CE directive are implied such as

essential health and safety requirements from all the

directives that applies to its product, including low

voltage directive and the EMC directive.

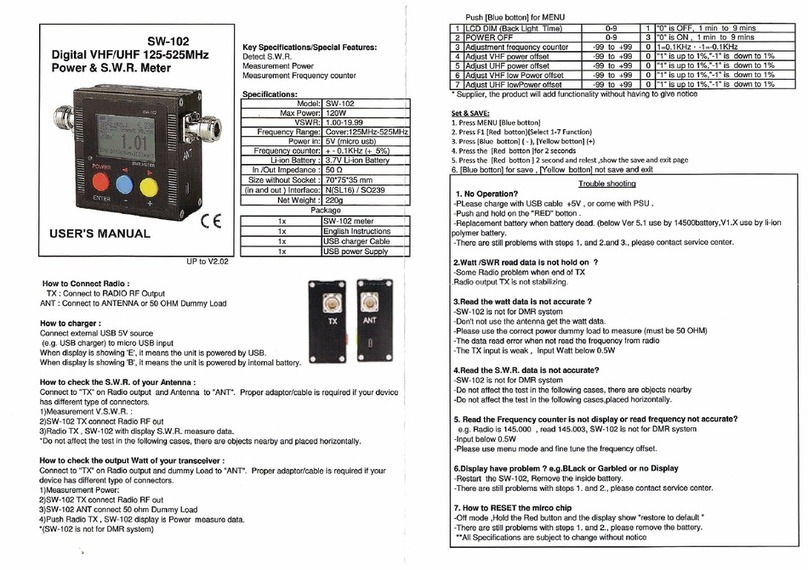

UNPACKING

1 2 3

Copyright

Copyright © 2017 Vision Engineering Ltd., The Freeman

Building, Galileo Drive, Send, Woking, Surrey GU23 7ER,

UK All Rights Reserved.

Mantis® (1532468), Lynx® (3672061) and Dynascope®

(915579) are registered trademarks of Vision Engineering

Ltd. The use of our trademarks is strictly controlled and

monitored and any unauthorised use is forbidden.

Copyright in this document is owned by Vision

Engineering Ltd. Any person is hereby authorised to

view, copy, print and distribute this document subject to

the following conditions:

The document may be used for informational purposes

only

The document may be used for non-commercial

purposes only

Any copy of this document or portion thereof must

include this copyright notice

Revision 1.0, published June 2017 by:

Vision Engineering Ltd.

The Freeman Building, Galileo Drive, Send,

Woking, Surrey, GU23 7ER, UK

www.visioneng.com

Disclaimer

This document is provided “as is” without any warranty

of any kind, either express or implied, statutory or

otherwise; without limiting the foregoing, the warranties

of satisfactory quality, tness for a particular purpose or

non-infringement are expressly excluded and under no

circumstances will Vision Engineering Ltd. be liable for

direct or indirect loss or damage of any kind, including

loss of prot, revenue, goodwill or anticipated savings.

All such warranties are hereby excluded to the fullest

extent permitted by law.

We have compiled the texts and illustrations as accurately

as possible. However, Vision Engineering Ltd. will not be

responsible for the accuracy of the information contained

in this document, which is used at your own risk and

should not be relied upon. The information included in

this manual may be changed without prior notice.

Contents

System equipment

Stand & objectives 1

Swift PRO Cam 1

Stage 1

Head 2

QC 3000 2

Controller 2

Assembly

Removing the transit protection 3

Attaching the lens mount 3

Objective lens attachment 3

Attaching the LED ringlight 4

Attaching the episcopic illuminator (EPI) 4

Connecting the EPI 4

Stage assembly (150mm x 100mm & 200mm x 100mm) 5

PC system connection 6

QC 3000 connection 6

Stage alignment (video systems only) 7

Securing the stage (150mm x 100mm & 200mm x 100mm) 7

Head attachment 8

Fitting the stage glass 8

Stage glass levelling 9

Anti-glare shield attachment 9

Operation & setup

Main system controls 10

Getting the most from your system 11

Routine maintenance 11

Environmental considerations 11

Substage illumination LED replacement (all models) 12

Graticule tting & adjustment 12

Retrotting the Z axis module 13

Optional riser block 13

Episcopic LED replacement 13

Page

Technical specications

Measuring Stage 14

Measuring Range 14

Height adjustment 14

Encoder Resolution 14

Video Camera 14

Optics (Swift PRO Duo and Elite) 14

Illumination 14

PSU fuse ratings 14

Dimensions 14

Swift PRO Duo and Elite 14

Swift PRO Cam 14

Service & calibration record

Serial numbers 15

Service information 15

Warranty

System equipment

www.visioneng.com/support

1

System equipment

Stand & objectives

Stand

Lens mount

Lens options

Illuminator options

Toolkit

Anti-glare shield

Z Axis upgrade kit

(optional)

Swift PRO Cam

Stage

150mm x 100mm manual stage

OR

200mm x 100mm manual stage

System equipment

www.visioneng.com/support

2

Head

QC 3000

Controller

PC

Monitor

Keyboard and mouse

Assembly

www.visioneng.com/support

3

Assembly

Removing the transit protection

`Remove the two securing screws uand then remove the

transit plate v.

Keep the transit protection for future transport of

your system.

It is highly recommended that you ret the transit

protection whenever you transport your system.

Attaching the lens mount

`Insert the lens mount uup into the focus assembly v

and secure it with the securing grub screw w.

Objective lens attachment

`With the lens mount uin place (see above).

`Place the objective lens vup into the lens mount and

screw it into position.

u

v

v

u

w

v

u

Assembly

www.visioneng.com/support

4

Attaching the LED ringlight

`Locate the LED ringlight uinto position over the lens

mount vand tighten the securing screws w.

For connection details, see page 6.

Attaching the episcopic illuminator (EPI)

`Locate the cone uover the EPI vand secure it with

the grub screw w.

`Locate the EPI into the focus assembly xand secure it

with the grub screw y.

Connecting the EPI

`Insert the appropriate end of the connection lead u

into the EPI connector vand then connect the other

end of the lead wto the connector xon the underside

of the focus assembly y.

u

w

v

y

u

v

w

x

w

x

v

u

y

Assembly

www.visioneng.com/support

5

Stage assembly (150mm x 100mm & 200mm x 100mm)

`Use the stand’s levelling foot uto ensure the base is stable.

`Place the stage on the stand ensuring the retractable foot

(position B4 in diagram vbelow) is fully retracted.

`Check the stand stage mount feet wand the underside of

the stage xare clean and free

of any debris.

`Loosely t the stage bolts yin

position B1, B2 and B3 (also

in diagram v) to a light (nger

tight) tension.

If this is a video system,

do not tighten the stage bolts

as the stage will need to be

aligned (see page 7).

For systems with an optical head

only (no video camera), tighten the

stage bolts in the sequence shown in v

to a torque of 2.8Nm.

`Remove all red transit clamps from the stage.

y

yy

w

u

x

Column

Stage Assembly

B4

B3B1

B2

v

Assembly

www.visioneng.com/support

6

PC system connection

All connectors must be engaged fully and secured.

WARNING: To comply with safety regulations, easy access to the mains socket must be maintained.

QC 3000 connection

All connectors must be engaged fully and secured.

WARNING: To comply with safety regulations, easy access to the mains socket must be maintained.

Y Axis

Z Axis (if fitted)

From camera USB to controller

USB to controller

X Axis Mains in

Stand

Ringlight illumination

Sub-stage, EPI accessory, head power illumination, and AUX connector

From camera USB

Sub-stage, EPI accessory, head power illumination

Ringlight illumination

Mains in

Mains in

X22

X21

X32

Stand

Z Axis

Y Axis

X Axis

Assembly

www.visioneng.com/support

7

u

v

v w

w

w

Stage alignment (video systems only)

`Turn on the system.

`Switch on the PC and follow on screen instructions for crossing reference marks.

`Using the Focus control u, focus on the three horizontal lines in the

centre of the alignment plate attached to the stage.

`Rotate the stage by hand until the horizontal lines are

parallel to the horizontal crosshair on the PC’s screen.

`Use the X axis control vto check reference lines remain

parallel with the crosshair.

Before the alignment plate can be removed the

relevant stage securing procedure should be carried

out.

Securing the stage (150mm x 100mm & 200mm x 100mm)

With the stage assembled (see page 5) and aligned (see above),

secure the stage as follows:

`Being careful not to move the stage,

loosen the oating stage foot

securing screw u.

`Insert and screw in the last stage

bolt v and tighten until nger tight.

`Use the Allen key supplied to progressively

tighten all four screws through the

appropriate holes vand win the alignment

plate in the numbered sequence (shown in the

diagram x below) to a torque of 2.8Nm.

(this is approximately equivalent to bolt touch

down plus 1/8th turn).

`Lightly tighten the oating stage foot securing screw.

u

v

Column

Stage Assembly

B4

B3B1

B2

x

Assembly

www.visioneng.com/support

8

Head attachment

`Lower the head uinto position on the focus assembly

v.

`Insert the head connector winto the head socket x.

`Turn the system on using the mains switch.

`Use the X and Y stage controls yto centre the

alignment

plate zin the viewing screen.

`Turn the head to align the head crosshair with the

alignment plate (see inset {).

`Tighten the securing screw |.

`Remove the alignment plate.

If you need to remove the stage for

any reason, re-attach the alignment

plate and ensure the horizontal

lines are parallel to the horizontal

crosshair before removing the stage.

Fitting the stage glass

`Fit the stage glass u into its recess, taking care to

locate its bevelled edges vagainst the location springs

and on to the supports w.

x

y

{

w

v

|

z

y

u

v

w

ww

w

u

Assembly

www.visioneng.com/support

9

Stage glass levelling

`Use the X axis uand Y axis vcontrols to bring the rear right-

hand corner of the stage glass (xed corner) winto view.

`Use the focus control to bring the glass surface into sharp

focus.

`Use the axis controls to bring the front right-hand corner

into view. Use the relevant adjustable glass support to

bring the surface of the glass into sharp focus.

`Repeat for the remaining 2 corners.

`Repeat the above steps if necessary until all 4 corners are

in focus.

Anti-glare shield attachment

`Slide the anti-glare shield uinto the mounting bracket v.

`Using the screws wand washers x provided, secure into

position with the Allen key (also provided).

`Remove the protective lm from the shield.

w

u

v

wx

v

u

Operation & setup

www.visioneng.com/support

10

Operation & setup

Main system controls

Y axis control

X axis control

Coarse focus control

Fine focus control

On/off switch

Substage light dimmer

Episcopic light dimmer

Ringlight dimmer

Iris control

All desktop control systems congured by Vision

Engineering for this product are set with the

following password:

Vision

Operation & setup

www.visioneng.com/support

11

Getting the most from your system

Routine maintenance

The outside of the instrument should be wiped down

with a damp cloth to remove dirt and dust.

The instrument and accessories should be checked for

loose or damaged components.

When not in use, protect your system with the dust

cover.

Always disassemble the system prior to moving.

Environmental considerations

This equipment is designed for indoor use in the

following conditions:

Up to 2000m altitude

Between 5° and 40°C ambient temperature (10° to

35° recommended limits)

Power supply; 100-120V/ 220-240V, 50/60Hz with

voltage uctuations up to 10% of the nominal voltage

Transient over voltages typically present on the Mains

supply

Maximum relative humidity of 80% for temperatures up

to 31°C decreasing linearly to 50% relative humidity at

40°C.

This system is an accurate, industrial gauging instrument.

To achieve the optimum accuracy and repeatability, the

following considerations should be taken into account:

Position the system on a rm, rigid and level table.

Avoid locating the instrument near to a source of

vibration.

Do not place the instrument close to a radiator or

similar heat source.

Do not place the instrument close to a cold temperature

source such as an air conditioning unit.

Do not position the instrument in direct sunlight, or

where bright reections will affect the image.

The equipment should be positioned so that access

to the mains input connector is always available

If the system you purchased is a Video

product and you purchased your own PC,

Vision Engineering recommend the use of a

powered USB hub for the camera signal.

Operation & setup

www.visioneng.com/support

12

Substage illumination LED

replacement (all models)

`Disconnect the system’s power supply.

`Remove the head, stage and illuminators, carefully

place the unit on its side and remove the 4 LED

cover plate securing screws u.

`Remove the LED cover plate v.

`Remove the LED securing screws wand remove it

from the stand

`Disconnect its ying lead from the connector x.

To install a new LED, reverse of the removal

procedure.

Graticule tting & adjustment

`Undo the securing clip uat the base of the front

cover and lift the cover off.

`Place the graticules v(2 off) into position and

secure them with the lock nuts and grubscrews w

(2 per graticule) and the retaining bolts x.

`To focus and centralize each graticule, loosen the

appropriate retaining knob and move the graticule

up or down to focus. Re-tighten the retaining knob.

`To adjust the graticules, place a known 90º gauge

(slip gauge or crossline) on the stage and focus the

image. Close one eye and locate the crossline on

the corner of the gauge by unlocking and adjusting

the grubscrews. Once the image is located, lock the

grubscrews with the locking nuts.

`Repeat the procedure using the other eye. Make the

adjustment so that the graticules overlay each other.

Note: If the image is uncomfortable to the eyes,

repeat the above procedure.

u

u

w

v

x

u

u

u

v

w

x

Operation & setup

www.visioneng.com/support

13

Retrotting the Z axis module

This procedure should only be carried out by

authorised service personnel.

Please contact your local Vision Engineering

branch for assistance

Optional riser block

This procedure should only be carried out by

authorised service personnel.

Please contact your local Vision Engineering

branch for assistance

Episcopic LED replacement

`Remove the episcopic assembly ufrom the Hawk

and carefully place it on a workbench as shown.

`Pull its power lead vclear of the socket.

`Loosen the 2 securing screws wand pull the LED

assembly xclear of the illuminator.

`The replacement procedure is the reversal of the

above.

u

v

w

v

u

w

x

Technical specications

www.visioneng.com/support

14

Technical specications

Measuring Stage

Precision measuring stage, with factory-set Non-Linear

Error Correction (NLEC) calibration as standard.

(X,Y) Stage accuracy: 5+(6.5L/1000)µm

(Z) Z-axis accuracy 10 µm using controlled conditions

with 200x magnication*

Measuring Range

(X,Y) 200mm x 100mm (10kg maximum load)

(Z) 98mm*

Height adjustment

100mm of height adjustment

Encoder Resolution

X = 1µm Y = 1µm Z = 0.5µm*

Video Camera

High resolution colour CCD video camera

Optics (Swift PRO Duo and Elite)

Patented twin pupil monoscopic, innity corrected

optical system, with pre-centred crossline graticule to

both eyes.

Option of custom designed graticule, pre-centred to

one eye

Magnication Options (System Total)

Quick change magnication options - 10x, 20x, 50x,

100x, 200x

Illumination

Cool, corrected colour temperature LED surface

illumination.

Iris-controlled LED substage illumination.

PSU fuse ratings

T2.5A H (2.5A slow blow (HBC) ceramic 5x20mm fuse)

*3-axis variant only

Dimensions

Swift PRO Duo and Elite

A = 680mm max.

B = 430mm (150mm x 100mm)

515mm (200mm x 100mm)

C = 480mm

Swift PRO Cam

A = 450mm

B = 430mm (150mm x 100mm)

515mm (200mm x 100mm)

C = 480mm

A

C

B

A

C

B

This manual suits for next models

3

Table of contents

Other Vision Engineering Measuring Instrument manuals