ELGO Electric Z54 Series User manual

Z54 & Z56 Series

Z54-56-000-E_41-99.doc Doku Art. Nr. 799000101

Programmable Position Indicators

Series 54: For use with Encoders

Series 56: For use with MX magnetic scale

2

ESSENTIAL FEATURES 3

MX MAGNETIC SCALE 3

OPERATION 4

USER ADJUSTMENTS 5

Edit Datum and Datum Offset 5

Edit Datum programmed value 5

Setting display to any value 5

Edit datum Offset 6

Edit Datum +/- 1 bit 6

Edit Flexible Multiplier 6

Changing Display Value 7

Counter Configuration 7

Configuration Register 8

Direction of Count 9

Decimal Places 9

Inch / Metric Switching 9

GENERAL TECHNICAL INFORMATION 9

ENCODERS 9

SENSOR - MS17.60.03,0M 10

MAGNETIC TAPE – MB20.50.XX,X 10

TYPE DESIGNATION OF 54/56 SERIES 14

LIABILITY EXCLUSION / GUARANTEE 15

3

Essential Features

The Series 54 / 56 programmable position indicators are available with either a 5 digit 13mm high LCD

display, a 5 digit 14mm red LED display, or 6 digit 10mm red LED display. The indicators incorporate

the following features :

- Input of required datum value by means of the front buttons

- Robust foil covered buttons and compact plastic enclosure

- Can be operated from the batteries or from external power supply

- Memory on power down

- Designed to operate from encoder or magnetic scale feedback

- Setting of multiplication factor for display

- Incremental and absolute measurement

- Programming of features using front buttons

- 5 or 6 Digit display with +/- symbol, LED or LCD.

- Inch/metric selection.

- Display extinguished after 10 sec to save battery.

- Datum offset available.

- External inputs.

The Range available is as follows :-

Series 54 single axis indicator available in LED or LCD display formats. Suitable for encoder

feedback.

Series 56 single axis indicator available in LED or LCD display formats. Suitable for MX

magnetic scale feedback.

MX Magnetic Scale

The MX Scale is a non-contact magnetic linear measuring device used extensively with the ELGO

simple positioning and display product range. The MX scale usually consists of three components :-

MB20.50.xx,xm - Magnetic tape, available to lengths of 25m.

MS17.60.03,0m - Sensing head incorporating feedback cable.

MC - Signal translator which generates a quadrature feedback signal identical

to an encoder.

In the case of the above indicators, the MC has been incorporated (where appropriate) into the

indicators. The addition of this extra circuit board accounts for the additional cost of the MX scale option

and the reason why, due to physical restrictions, the 56 series requires an external NG20 power supply.

4

Operation

These indicators may be fully controlled from four simple push buttons:-

Function select

Must be pressed with another button to select required function.

Pressed on its own, returns from selected function to operation, and stores edited value to

RAM.

Twin Datum

When pressed on its own, adds the Datum Offset to the actual position. Press again to

subtract.

Certain machines, such as panel saws with turnover stops, require two datums with a fixed

offset that can be readily toggled.

Incremental / Absolute operation

When pressed on its own, switches between absolute and incremental operation.

In many applications dimensions are given on drawings, which are relative dimensions. Most

position indicators display only the absolute position and it is necessary to calculate the new

absolute position

e.g. 1928.7 + 325.9 = 2254.6

This is laborious and can lead to errors.

This can be avoided by the use of this range of indicators. The operator can select

= "Incremental". This sets the display to zero. Operator can now move 325.9 and re-

select

= "Absolute" ( the display now reads 2254.6 )

F

F

5

Setting Datum

F

When pressed together, immediately sets the pre-programmed datum position to the display.

This is only possible if the configuration register is set to ( XXXX0 )

(See user adjustments, for random setting of Datum).

Display Extinguish - 56 series (for battery life saving)

The counter and/or display may be extinguished in a number of ways.

The method required must be chosen in the config register.

User Adjustments

Edit Datum and Datum Offset

It is only possible for the operator to edit the Datum and Datum Offset, if the editing feature is unlocked

in the configuration register. ( XXX0X )

NB The Datum and Offset values incorporate any decimal places set in the configuration ( See later )

Edit Datum programmed value

Press both buttons for three seconds, allows the editing of the datum value. Range

( 00000 to + 99999)

Setting display to any value

Instead of having a fixed datum, the display can be set to any value desired and count from there. This

is made possible by setting the Config register to XXX01.

Press both buttons for three seconds, any value may now be set in the normal way.

F

F

6

Edit datum Offset

Press both buttons for three seconds, allows the editing of the Datum Offset . Range ( 00000 to +

99999 )

Edit Datum +/- 1 bit

The indicator provides the facility for the operator to make small adjustments to the actual value of

display to take care of minor machine variations. This is only possible when the configuration register is

set to ( XXXX2 ) NB: Setting of datum as above is not possible, when this feature is selected.

Press both buttons for three seconds, any value may now be set in the normal way.

subtracts one bit/press,

adds one bit/press, to the displayed value.

Edit Flexible Multiplier

It is only possible to edit the Flexible Multiplier if the editing feature is unlocked in the configuration

register. ( XX0XX )

for three seconds, allows the editing of the flexible multiplier

Range X 0.0001 to X 9.9999 (Decimal point is automatically displayed)

Press the above button on completion of any edit, to store value to RAM and return to

operating mode.

F

F

F

F

7

Changing Display Value

Display manipulation of both the User Adjustment and Configuration is done using the following

method, once the desired function to edit has been accessed.

to select the digit to be changed ( this flashes )

to increment the digit between 0 and 9.

stores the value to the internal RAM and returns the indicator to operating mode.

Counter Configuration

F

Press buttons for three seconds, the Configuration mode is entered.

Conf will be displayed. The configuration file determines the operation of the indicator.

F

Digit scroll left to right

Digit scroll

1 to 9

Where present, the 6th LHS digit should

be set to zero. This digit is only used for

a +/- symbol.

N.B.

8

Configuration Register

Pressing the above buttonfor three seconds gives access to the configuration 5 digit register.

F

0 -

1 -

2 - Edit datum + or - 1 bit.

Datum / Datum Offset Edit 0 - Unlocked

1 - locked

Multiplier edit 0 - Unlocked

1 - Locked

Datum offset recalled on power up

0 - No

1 - Yes

0 - Differential counting.

1 - Encoder X 1

2 - Encoder X 2

3 - Encoder X 4

Set datum to stored value

Set as required

X

X

X

X

X

Series 54 / Encoder feedback only

Series 56 / Scale feedback only

Display extinguish

0 - No auto extinguish and no clamp extinguish

1 - Total power off / on with F button.

2 - Total power off after 5 minutes of inactivity.

3 - Extinguish display only, with clamp input

4 - Extinguish display only, after 10 seconds of inactivity

OR

X

Ignore 6th digit

if present

Datum Mode

5 - Extinguish display only, after 30 seconds of inactivity

6 - Extinguish display only, after 1minute of inactivity

7 - Extinguish display only, after 2 minutes of inactivity

*Only available in 3v version

.Only with LED display

.

*

*

*

*

*

*

9

Direction of Count

Press for three seconds gives access to the count direction

to toggle between Up and Down.

Decimal Places

Press for three seconds gives access to the number of decimal places.

to toggle between 1,2 or 3 decimal places.

Inch / Metric Switching

Press for three seconds gives access to either counting in inches or millimetres.

( Inch or nn ).

Press to toggle between these settings

On completion of editing of any section, Press Fto store value to RAM and return to "Config".

Press all four buttons again for three seconds to return indicator to operating mode.

General Technical Information

Indicators

Maximum counting frequency - 10 kHz standard.

- 50 kHz option (specify at order stage)

- Series 56, 50 kHz standard.

Operating temperature - 0 to 50 deg.C

Memory against supply failure - 3 years

Current Consumption of Indicator - LCD : 100mA operating

exluding Encoder : 1mA standby

- LED : 40mA

EE inputs - PNP only.

These provide external contact control of datum and zero reset.

(Must be specified at order stage)

Encoders

Encoder specification - 24 volt PNP or push pull.

10

Sensor - MS17.60.03,0m

15

10

6

1744

3,5

11,2

25

77X

gap max. 2,0 mm

Sensor bold MS 20.60

Maximum speed of travel - 5m/sec

Cable length - 3m standard ( up to 25m available)

Operating temperature - ( -5 ) to ( + 45 ) deg.C

Sealing - IP66

Magnetic Tape – MB20.50.xx,x

Resolution - +/- 0.1mm

Operating temperature - ( -5 ) to ( + 45 ) deg.C

Scale expansion - 0.000016mm / deg.C X m

1,8m

m

CAB

Sensor side

mounting side

11

ST1

1

2

-

+

ST4

BU1

ST3

Pin 1 - L

Pin 2 - N

Pin 3 - E

Pin 1 - 0 Volts

Pin 2 - +24 Volts dc

Pin 3 - Channel A

Pin 4 - Channel B

Pin 5 - Screen

123

ST2 ST1

1234 512 3 456

ST1 - Inputs ST2 - Encoder

ST3 - Power supply ( Only for 110/ 230 Volt ac Versions )

Series 54 (EE Option)

ST1 - 024 version.

Pin 1 - ( - )

Pin 2 - (+ )

Pin 3 - E

Power Supply

ST4 - 003 version

Pin 1 - ( - )

Pin 2 - ( + )

24 volts dc Battery

BU1 - Scale feedback connector

See MX Scale manual.

Series 56

ST3

Series 54 AG (EE Option) ST3 - AC input

Pin 1 - L

Pin 2 - N

Pin 3 - E

ST2 - Encoder

Pin 1 - 0 volts

Pin 2 - +24 volts dc

Pin 3 - Channel A

Pin 4 - Channel B

Pin 5 - Screen

ST3

Series 56 AG

BU1

ST3 - AC input

Pin 1 - L

Pin 2 - N

Pin 3 - E

BU1 - MX magnetic scale

See MX Scale manual

Pin 1 - Screen

Pin 2 - 0 volts

Pin 3 - +24 volts

Pin 4 -

Pin 5 - Datum

Pin 6 - Reset to zero

Offset

dc input for

024 versions

Option EE

Pull up to

24v to activate

or

ST2 ST1

12

34512 3 456

ST1 - Inputs

Pin 1 - Screen

Pin 2 - 0 volts

Pin 3 - +24 volts output

Pin 4 -

Pin 5 - Datum

Pin 6 - Reset to zero

Offset Option EE

Pull up to

24v to activate

Option EE

Pin 4 -

Pin 5 -

Pin 6 -

Offset

+24v output

Datum

12 3 456

Connections

12

Dimensions

Cut Out dimensions Outline Dimensions Side View

92mm

66mm 72

mm

96mm 62mm

68mm

mm

107mm

76

95mm

90mm

M6

60mm

30mm

Panel Mounting Series 54 and 56

AG Enclosure Mounting Series 54 and 56

NG20.0 Power Supply

80mm

45mm

Depth 160mm with

connector

55mm

13

Series Display Power Supply Options

500 100 003 024 110 230 AG EE

54

56

74

76

75

For 56 series indicators to operate on 110/230 v ac, use the

024 version and order a separate NG20.0 power supply.

AG versions always include NG20.0 mounted inside the enclosure.

600

For Version 230 or 110 v operation must be specified at order stage.AG

2 external inputs only available.

14

5X . 500 . 024 . SN000.XXXXXXX

NG20.0

MB 20.50.XX

,

X

MS 17.60.XX

,

X

Type designation of 54/56 series

54 Display with A / B encoder input

56 Display with converter integrated

Number of decade of the readout

500 = 5 digit LED 14mm high

600 = 6 digit LED 10mm high

100 = 6 digit LCD

Supply voltage

024 = 24 V DC

115 = 115VAC (in 54 only)

230 = 230VAC(in 54 only)

Construction

000 = standard

001 = 1st special version

etc

Special Features

EE = External input

AG = Free standing Housing

RS232 = Serial port (in 54 only)

M = high speed counting for MX system (in54 only)

Power supply 100mA 18Vdc din rail mounting version

Accessories 56

Magnetic tape :MB 20.50.25,0

Incremental Magnetic tape

Pole distance 5,0 mm

Length of tape

Magnetic SensorMS 17.60.xx,x

Incremental Magnetic Sensor 0,1mm

Length of sensor cable

15

Liability exclusion / Guarantee

We have checked the contents of this instruction manual carefully, to the best of our knowledge and

belief for conformity with the described hardware and software. Nevertheless errors, mistakes or

deviations can not be excluded, therefore we do not guarantee complete conformity. Necessary

corrections will be included in the subsequent editions. We appreciate your ideas and improvement

suggestions very much. Reprint, duplication and translation, even in extracts, are only allowed with a

written authorization by the company ELGO Electric GmbH. We constantly strive for improving our

products, therefore we keep all rights reserved for any technical modifications without any notice.

ELGO Electric does not assume any liability for possible errors or mistakes.

The guarantee period is one calendar year from the date of delivery and includes the delivered unit

with all components. ELGO Electric GmbH will at its option replace or repair without charge defects at

the unit or the included parts, verifiable caused by faulty manufacturing and/or material in spite of

proper handling and compliance to the instruction manual.

Damages verifiably not caused by ELGO Electric GmbH and due to improper handling are excluded

from any guarantee e.g. by applying faulty voltage, diffusion of liquid into the interior of the engine,

using force, scratching

This manual suits for next models

3

Table of contents

Other ELGO Electric Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

In-situ

In-situ Aqua TROLL 600 Operator's manual

Arun Microelectronics LTD

Arun Microelectronics LTD PVU3 User instructions

VPInstruments

VPInstruments VPFlowScope user manual

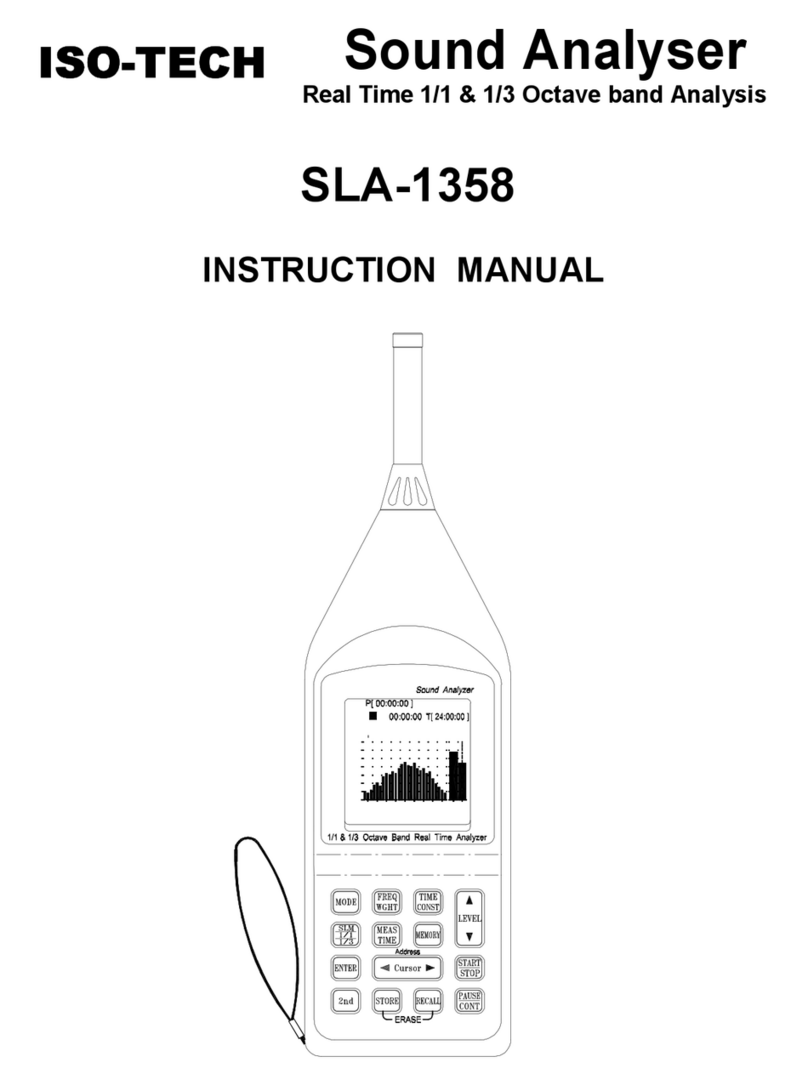

Isotech

Isotech SLA-1358 instruction manual

holthausen elektronik

holthausen elektronik ESW-Mini hol550 user manual

CANchecked

CANchecked MFD15 quick start guide