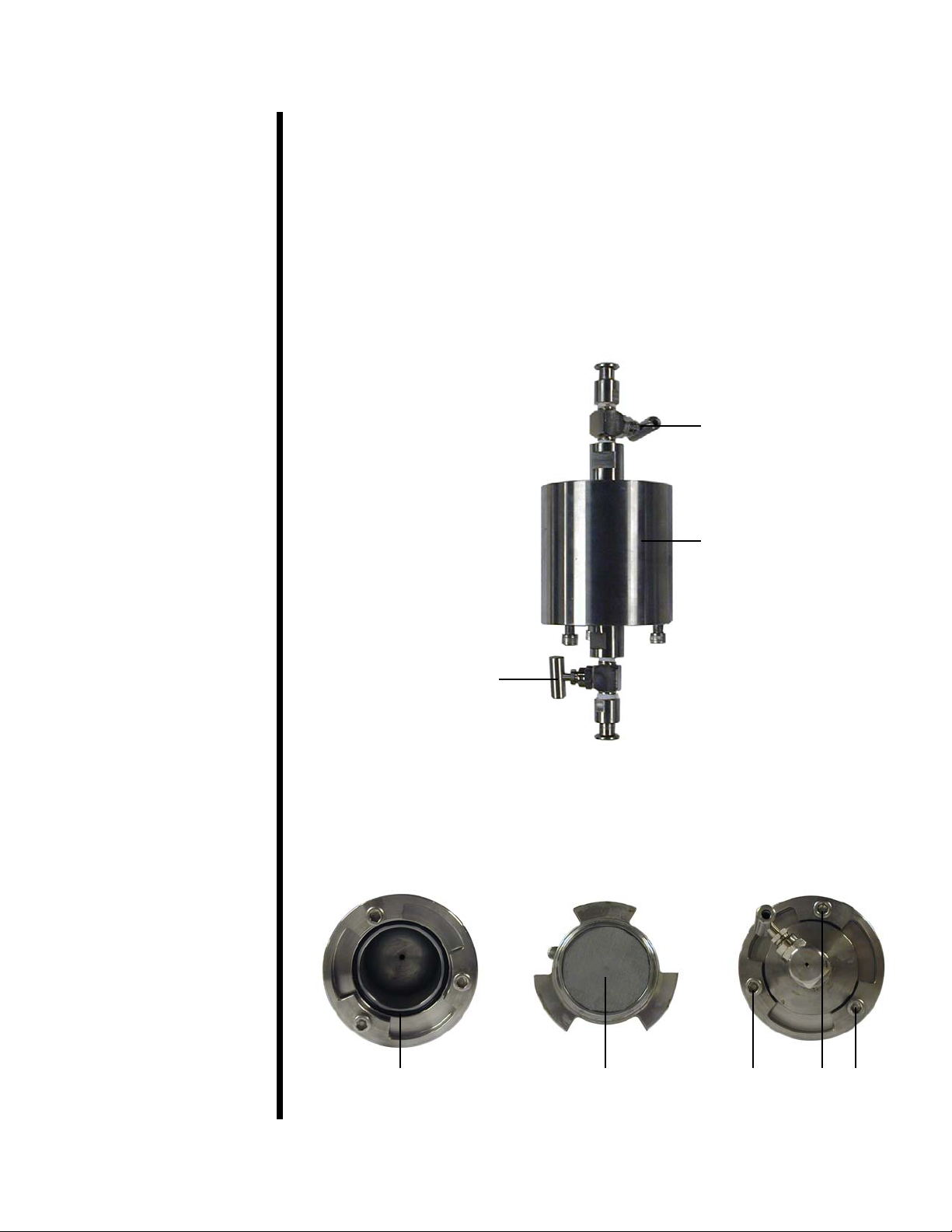

6. If you will be operating above 200°F (93.3°C), place the back pressure

receiver on the bottom valve assembly in the same manner.

7. Remove the CO2cartridge holder from both the top pressuring assem-

bly and the back pressure receiver. Make sure both regulator T-screws

are unscrewed completely and the needle valves are completely

closed. Place a CO2cartridge in each holder and screw the holder onto

the pressuring assemblies until the cartridges puncture. If the red relief

valve on the backpressure receiver is not already pulled out, pull it out

now.

8. Keeping the test cell valves closed, adjust the top and bottom regula-

tors to the recommended back pressure for your test. Open the top

valve one full turn to pressurize the sample. This pressure will mini-

mize boiling while the sample is heating. Maintain this pressure on the

fluid until the desired temperature is stabilized, as indicated by the ther-

mometer. The heating time of the sample should never exceed one

hour.

The upper and lower limits of the test pressure differential are deter-

mined by the test temperature. As this temperature exceeds 212°F

(100°C), the back pressure must be increased in order to prevent

vaporization of the filtrate. The 500 PSI differential pressure must be

maintained, so the top pressure will have to be increased accordingly.

The table below shows the pressures recommended for various test

temperatures.

9. When the fluid sample reaches the desired test temperature, increase

the pressure on the top pressure unit to 500 PSI (3,447.5 kPa) above

the back pressure. Open the bottom valve to initiate filtration and begin

timing.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com 9

Note

Recommended Minimum Back Pressure

Test Temperature Vapor Pressure Minimum Back Pressure

°F °C PSI kPa PSI kPa

212 100 14.7 101 100 690

250 121 30 207 100 690

300 149 67 462 100 690

350 177 135 932 160 1,104

400* 204 247 1,704 275 1,898

450* 232 422 2,912 450 3,105

500* 260 680 4,692 700 4,830

*For tests above 400°F, use Teflon o-rings.