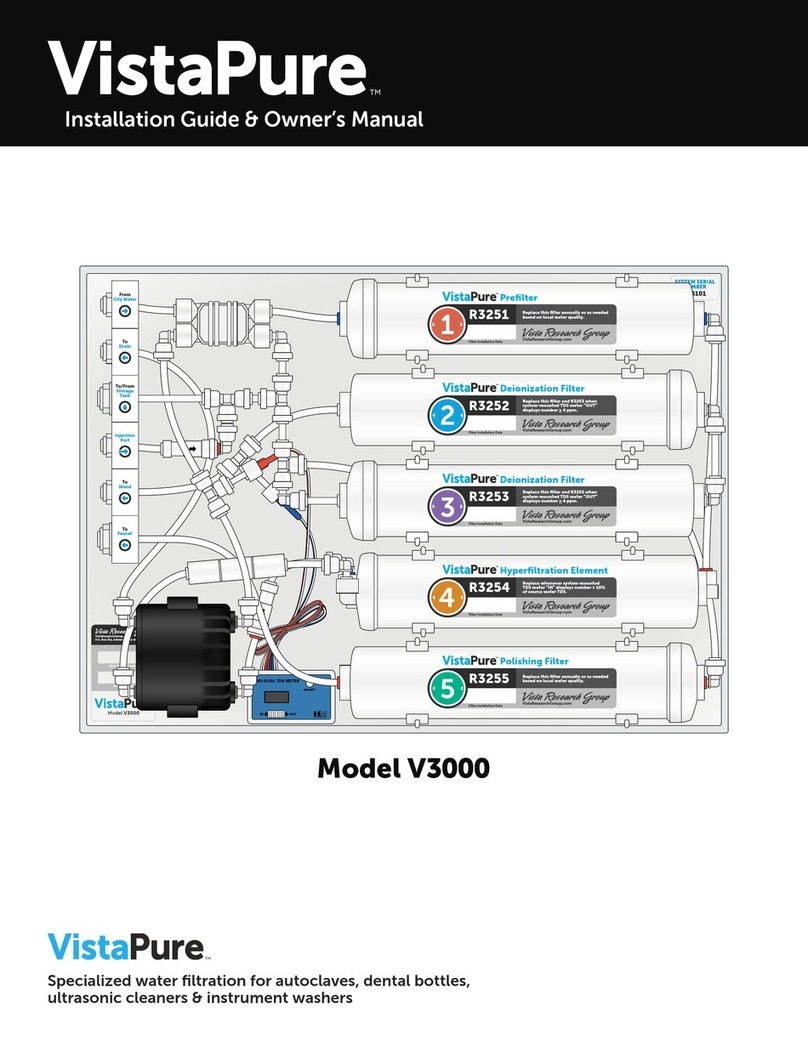

VistaPure V3000 User manual

Installation Guide & Owner’s Manual

Specialized water filtration for autoclaves, dental bottles,

ultrasonic cleaners & instrument washers

Model V3000

From

City Water

To

PreFilter

To

Drain

From

Pump

Injection

Port

To

Tank Line

From

System

To

Autoclave

Wand

From

D/I #2

To

Bottle

Faucet

From

PostFilter

To

Storage

Tank

2Installation Guide & Owner’s Manual

TM

Table of Contents

Introduction ��������������������������������������������������������������������������������������������������������������������������������������������������������������������3

Important Information ��������������������������������������������������������������������������������������������������������������������������������������������������3

Preparation ����������������������������������������������������������������������������������������������������������������������������������������������������������������������4

System Overview ������������������������������������������������������������������������������������������������������������������������������������������������������������5

Installation �����������������������������������������������������������������������������������������������������������������������������������������������������������������������6

Monitoring TDS ������������������������������������������������������������������������������������������������������������������������������������������������������������� 8

Filter Performance Record �������������������������������������������������������������������������������������������������������������������������������������������9

Typical Filter Life & Replacement Thresholds ����������������������������������������������������������������������������������������������������������9

Changing Filter Elements �������������������������������������������������������������������������������������������������������������������������������������������10

VistaPure Wand Installation & Use Instructions �����������������������������������������������������������������������������������������������������10

VistaPure Limited Warranty ���������������������������������������������������������������������������������������������������������������������������������������� 11

VistaPure System Information �����������������������������������������������������������������������������������������������������������������������������������12

Pelton & Crane

Pelton�net

11727 Fruehauf Drive

Charlotte, NC 28273

United States of America

CUSTOMER SERVICE

(800) 659-6560

TECHNICAL SUPPORT

(800) 659-5922

Distribution

SciCan Inc.

SciCan�com

701 Technology Drive

Canonsburg, Pennsylvania 15317

United States of America

PHONE (724) 820-1600

FAX (724) 820-1479

TOLL FREE (800) 572-1211

SciCan Ltd.

SciCan�com

1440 Don Mills Road

Toronto, Ontario M3B 3P9

Canada

PHONE (416) 445-1600

FAX (416) 445-2727

TOLL FREE (800) 870-7777

VistaPure systems are sold through dental and medical dealers throughout North America by:

VistaResearchGroup�com

P�O� Box 321

Ashland, Ohio 44805-0321

United States of America

PHONE (419) 281-3927

FAX (419) 281-7380

VistaPure is a trademark of Vista Research Group, LLC�

3

© 2000-2015 Vista Research Group, LLC. All rights reserved.

VistaPure is designed to produce two grades of high-purity water: distilled-quality water for use in

autoclaves, and non-corrosive, low-TDS water for filling dental bottles, ultrasonic cleaners and for final

rinse cycles in instrument washers� Water used in autoclaves must be virtually free of dissolved solids

in order to protect the heating chamber and to prevent buildup of contaminants that can create hard

deposits and necessitate more frequent cleanings� Water used in self-contained dental bottle systems

should be of a high quality, but not distilled-grade water, which is corrosive to metals used in the

construction of dental units�

The VistaPure system is designed to be built in to sterilization center cabinetry, and can also be installed in

an equipment room� The system provides up to 4�25 gallons of treated water in its pressurized storage tank

(based on city water pressure), and automatically replenishes this supply as water is drawn from storage�

The system does not require electricity—it needs only a potable supply of cold water and a drain� To

maximize the life of the system filtration elements, we recommend that the water supplied to the system

be free of sediment, and softened if the source water is very hard�

Introduction

We recommend that a professional technician or plumber familiar with dental/medical oces perform the

installation since interface with a cold water line and drain is involved� He/she should be familiar with local

plumbing codes and techniques for successful dental/medical equipment installations�

Please keep the Installation Guide & Owner’s Manual handy for future reference and ensure that anyone

responsible for operation and maintenance of the system is familiar with all details contained in this manual�

Please return the Warranty Registration form or register online immediately upon installation�

IMPORTANT INFORMATION

For System Owners

Please read this entire manual before proceeding with installation and operation, and always follow local

plumbing codes�

The VistaPure system can be installed nearly anywhere in the typical dental, medical, lab or hospital setting,

typically near a faucet and sink� The system and tank are designed to fit under a countertop, but can be

installed anywhere there is a quality cold water supply and drain connection� The system board is designed

for horizontal installation� Please keep the system board and water storage tank at the same level�

Please locate the system label on the corner of the mounting board and record the installation date using a

fine-tipped permanent marker or some other writing instrument that will not smear�

IMPORTANT INFORMATION

For System Installers

4Installation Guide & Owner’s Manual

TM

Preparation

Every VistaPure comes in two (2) cartons� Box 1 of 2 contains the system� Box 2 of 2 contains all other

items, including the Installation Guide & Owner’s Manual, warranty registration card, water storage tank,

dispensing wand, faucet, drain fitting, TDS meters, colored tubing and all other accessories� Make sure all

items needed for installation are present and undamaged� If damage is evident, contact the shipping com-

pany or your distributor immediately�

Box 2

S9111

Water Storage Tank

S9155

VistaPure Chrome Faucet

(with Adapter)

S9300

VistaPure Wand

(with clip, wrench, screws)

TU933

10’ Blue Coiled Tubing

S6592

Plastic Line Stieners

S6310P

3/8” x 1/4” Union

S9035

Syringe

S9146

Drain Tee Line Adapter

(with Stem Reducer)

S6588

Cable Tie

S6589

Mounting Cable Tie

S6112P

Swivel Elbow

S6160P

Tank Valve

S9118

Economy TDS Meter

Tubing

White

Red

Black

Natural

Blue

Box 1

VistaPure System

x2

x5

6’

6’

6’

6’

12’

5

© 2000-2015 Vista Research Group, LLC. All rights reserved.

System Overview

Pre & Post Filter Element

R5633

Deionizing Filter Element #2

R5662

Deionizing Filter Element #1

R5662

Hyperfiltration Element

R3080

Pre & Post Filter Element

R5633

H

C

B

I

K

A

A1

A2

A3

A4

A5

A6

To Drain

To Tank

To Wand

To Faucet

From H20 Supply

E

J

F

G

D

System Manifold

A1 From City Water to Prefilter

A2 To Drain from Pump

A3 To Storage Tank from System

A4 Injection Port to Tank Line

A5 To Autoclave Wand from DI #2

A6 To Bottle Faucet from Post Filter

AAutomatic Shut-O Valve

Permeate Pump

Drain Fitting (see page 7)

Water Storage Tank

VistaPure Wand

VistaPure Chrome Faucet

Dual TDS Meter

BSystem Water Shut-O Valve

Storage Tank Shut-O Valve

Injection Port Assembly

Flow Restrictor

Check Valve

I

C

D

E

F

G

H

J

K

6Installation Guide & Owner’s Manual

TM

Installation

If the system is not already mounted in another product (sterilization center, etc�), mount as desired

near a cold water source and 1-1/2” drain�

Position the water storage tank as near to the VistaPure system board as possible, at the same level�

Locate the white elbow tank valve in the accessory pack and attach valve to the top of the storage

tank� Hand-tighten only—never use tools on system valves and fittings! Make sure to open the tank

valve after installing it on the tank—the system will not work if the tank valve is closed� (A valve handle

in the open position is in line with the tubing; when closed, it is 90° to the tubing�)

Provide for a 1/4” connection to the cold water supply� This is usually accomplished using a piercing

saddle valve or compression fitting on the cold water line� Check local codes�

Provide a drain connection using 1-1/2” material with trap as shown on page 7� A 1-1/2” utility Tee

with both 3/8” and 1/4” push-in type fittings are included with each VistaPure� Various optional

configurations are available� See page 7 for details�

Mount the faucet on the sink or countertop deck in the sterilization center, lab or kitchenette as

desired� The faucet & 1/4” push-type faucet connector fitting are included in the accessory kit�

Attach colored tubing to the proper segments on the system manifold and the appliance/device as

shown below and on page 5� When attaching tubing to the push-type fittings, make certain all tubing

cuts are straight and free from burrs� Tubing must be firmly inserted into the fitting (11/16” plunge) to

avoid leaks�

1

2

3

4

5

6

7

• If the system is mounted inside a cabinet, under a sink or on a sliding device, be careful that tubes are

not crushed or crimped� If the system is on a sliding device for easy access, make certain to create a coil

with the tubes that will allow the system to move in and out without causing damage or restriction�

• If the VistaPure system is to be installed remote to the autoclave(s) and/or in a cabinet, fish the solid

blue tubing behind cabinetry to the autoclave center� Join the solid blue tubing and the coiled blue

tubing with the white 1/4” x 3/8” push-type union that is already attached to one end of the coiled

tubing� Make certain to provide a restraint at the straight end of the coiled tubing near the union so that

when pulling out on the autoclave wand and coiled tubing the union connection is not stressed� Extra

lengths of tubing are included with each system� A zip tie with mounting hole is provided with system�

RED From Cold Water Supply NATURAL To and From Tank BLUE STRAIGHT To Autoclave Area

BLACK To Drain WHITE To Faucet BLUE COILED To Autoclave Filler Wand

After all tubing connections have been made, it’s very important to cleanse the system� Place 20-30

mL of clean water into a small paper cup and add about two (2) drops of standard household bleach�

Stir gently with the 35 mL syringe included in the accessory kit, then pull the solution into the syringe�

Remove the safety cap from the injection port on the manifold (see page 5) by holding the collet back

against the cap fitting and pulling it away from the check valve� Inject the mixed solution into the

Injection Port� Then, draw another 20-30 mL of fresh water into the syringe and inject it into the Port

in order to push all the bleach out of the check valve� Replace the safety cap by pushing it firmly onto

the Injection Port tube� Immediately open the Water Supply Inlet Valve (I) on the manifold and water

will begin to flow into the system, filling the tank with treated water and the bleach�

8

7

© 2000-2015 Vista Research Group, LLC. All rights reserved.

Allow the system to run for 20 minutes� Wastewater should be running to the drain Air Gap (D) and

a pulsing / clicking sound should be heard coming from the Permeate Pump (C)� After 20 minutes,

close the Water Supply Inlet Valve (I) on the system manifold, then discharge water from the Faucet

(G) until Tank (E) is empty and water flow stops� The system is now cleansed and ready for use�

9

Open the Water Supply Inlet Valve (I) and allow it to run until the tank is full� This may take over an

hour for the tank to fill completely� However, water can be used anytime after about 30 minutes

since the system produces and stores up to 4�25 gallons of water and can deliver water to both the

Wand and the Faucet even while it’s making new water� The system capacity is about 25 gallons of

production per 8-hour work day�

NOTE:

When starting the system for the first time, black/ gray water will flow from the bottle faucet for 30-60

seconds as the filter is purged�

10

1-1/2”

w/ Trap Drain Line

from VistaPure

7A

Drain Line

from VistaPure

1-1/2”

w/ Trap

7B

Drain Line

from VistaPure 1-1/2”

Pipe

7C

Drain Line from

Instrument Washer

Drain Line

from VistaPure

To Branch

Tailpiece

Countertop

Airgap above

Flood Rim

7D

7A Typical installation of drain Air Gap (S9145) using

existing sink drain system� Order separately�

Typical installation of drain Air Gap (S9145) using

separate riser and trap� Order separately�

Typical installation of drain Tee (S9146) using existing

sink drain system� Included with unit�

Typical installation of dual inlet drain Air Gap system

(S9147) using branch tailpiece� Order separately�

7B

7C

7D

NOTE:

Local codes vary greatly, so be sure to verify the preferred method prior to installation� Every VistaPure has a

pressurized drain discharge and multiple check valves in the system to prevent backflow from drain connections�

8Installation Guide & Owner’s Manual

TM

Total dissolved solids (TDS) is the quantitative measure of virtually all constituents found in a particular

water supply, counted as parts per million (ppm) or milligrams per liter (mg/L)� Water is simply H2O;

basically, everything else found in it would contribute to the TDS� A typical city water supply will have a TDS

reading of 150-350 TDS, although it varies greatly� The federal standard for municipal water systems is a

maximum of 500 ppm TDS� Please do not use VistaPure with private water wells since TDS can be very high

and contain high levels of contamination�

Water for use in autoclaves should be of distilled quality, which is a TDS of 0-5 ppm (some more sensitive

autoclaves require 0-3 ppm)� Water with TDS readings higher than 5 ppm will eventually cause staining,

scale build-up, and more frequent cleaning and/or repair� The worse the water, the more costly the

maintenance and repairs—to the point that some autoclaves won’t even operate if the TDS is high�

The VistaPure system comes equipped with a battery-operated dual TDS meter that enables you to check

the water quality throughout the system� For example, slide the switch on the TDS meter (see Figure 8F) to

“IN�” This reads the level of TDS in the water emerging from the Hyperfiltration module (before it goes into

DI #1)� Slide the switch to “OUT” to display the level of TDS emerging from the Deionization modules (after

DI #2) on its way to the Autoclave Wand� Water should always be running while testing TDS!

A separate, handheld TDS meter is also included, which can be used to determine the level of TDS in the

supply water fed to the system� With these data, one can monitor the complete process as necessary�

Under normal operating conditions, TDS levels might be as follows in this example:

City Water Feed = 200 TDS = X

After Hyperfiltration = 010 TDS = 5% of X

After Deionization = 000 TDS

Remember, this is only an example� However, the reading on the

“IN” should generally be about 5% of the inbound water TDS� The

Deionization (D/I) modules remove the balance remaining to achieve

the 0-3 TDS level desired�

Figure 8E shows the handheld TDS monitor provided with your

system� It can be used to determine the quality of the raw and treated

water� Simply remove remove the protective cap exposing the probe,

push the power button to activate, and immerse the probe into the

water� The LCD display will show the TDS level� After use, shake the

water out of the probe area and wipe the outer portion dry—never

push anything into the probe area� Check the water quality frequently

and change filter elements as required� Both TDS monitors are

powered by a simple button-cell battery, available at most any store�

Monitoring TDS

8E

8F

NOTE:

Replacement batteries for meters should be purchased locally� Both

included TDS meters take two (2) of the following battery: 357A (LR44)

Alkaline Button Cell - 1�5V 110mAh�

9

© 2000-2015 Vista Research Group, LLC. All rights reserved.

Typical Filter Life & Replacement Thresholds

Pre & Post filters (R5633): approximately one year (change at least annually)�

Deionization filters (R5662): 4 months to 3 years, depending on volume of usage and quality of local

water supply� Change BOTH deionization filters whenever the system-mounted TDS meter “OUT” (recorded

in Column D above) displays a number equal to or greater than 4 parts per million (ppm)�

Hyperfiltration filter (R3080): 3-5 years, depending on the volume of usage and quality of local water

supply� Replace the hyperfiltration filter whenever the system-mounted TDS meter “IN” exceeds 10% of the

TDS of the municipal water supply TO the system, as measured with the included, handheld meter (percent

recorded in Column C above)�

Filter Performance Record

Date

“A”

City Water to System

(Use Handheld

TDS Meter)

“B”

After Hyperfiltration

(Use Mounted

Meter “IN”)

“C”

% TDS Remaining

(Divide Column B

by Column A)

“D”

TDS after D/I

(Use Mounted

Meter “OUT”)

Water at

Autoclave Wand

(Use Handheld

TDS Meter)

Water at

Chrome Faucet

(Use Handheld

TDS Meter)

10 Installation Guide & Owner’s Manual

TM

Changing Filter Elements

Warning: never attempt to change any filter element(s) with pressure on the system�

Follow these steps when changing filter elements:

Turn OFF water inlet supply (Figure I on page 5)�

To relieve all pressure from the system, discharge all water from the storage tank by locking open the

handle on the chrome faucet (lift UP on the black handle)

Disconnect the tubing from any filter element(s) to be replaced by pushing in on the collet and

removing the tubing, starting on the side of the filter(s) opposite the system manifold�

Pull the filter(s) out away from the board, one clip at a time, then disconnect the tubing from the other

end of the filter(s)�

Reverse the process to install your replacement filter(s)� Take care to note the proper direction of flow�

Don’t forget to record the installation date on the filer label using a permanent marker and in the table

on the back panel of the instruction manual�

After any filter elements are replaced, perform a system cleansing procedure as outlined in steps #8

and #9 in the installation instructions section of this manual� This cleansing procedure should be

followed at least once per year and anytime a filter element is changed�

1

2

3

4

5

6

Notice: During the initial installation and at least once per year during the tank cleansing process, check

the air precharge pressure in the water storage tank using a digital tire pressure gauge� With the tank empty

and water valve in the OPEN position, remove the cover cap from the air valve and check the precharge air

pressure� The precharge pressure should be set at 7.5 psi for most applications� Add air as needed using a

tire pump or compressor� To lower air pressure if too high, depress the stem in the air valve and re-check�

VistaPure Wand Installation & Use Instructions

Each wand includes an integrated shut-o

valve, a friction clip holder, two 1/2” machine

screws and a hex wrench for the setscrew on the

mushroom push-button� Be sure to leave the hex

wrench with the system after installation�

USE

To use the wand, remove it from the clip holder,

turn the blue valve handle so it’s inline with the

tubing, then press downward on the mushroom

button� Water will flow from the spout�

To store the wand after use, turn the blue handle

so it is 90º to the tubing and press the wand into

the clip holder�

INSTALLATION

Push wand assembly valve onto the end of the

3/8” O�D� coiled tubing� Firmly push and twist

the tubing to make certain it engages into the

O-ring in the valve�

Attach the white 3/8” x 1/4” union adapter on

the opposite end of the coiled tubing to the 1/4”

tubing that runs to the “Autoclave Wand” port

on the VistaPure system manifold�

Attach the small wand holder clip to the desired

location using the two screws provided� The clip

may be oriented in any direction and mounted

in any location�

1

2

3

11

© 2000-2015 Vista Research Group, LLC. All rights reserved.

During the time period and subject to the conditions

hereinafter set forth, Vista Research Group, LLC

(VRG) will repair or replace to the original user any

portion of a VistaPure which proves defective due

to defective materials or workmanship of VRG�

Contact your nearest authorized VRG distributor/

dealer for warranty service� At all times VRG shall have

and possess the sole right and option to determine

whether to repair or replace defective equipment,

parts, or components� Damage due to conditions

beyond the control of VRG is NOT COVERED BY THIS

WARRANTY� (Contact parcel or freight company for

claims on freight damaged in transit)

WARRANTY PERIOD: VRG shall warrant its VistaPure

systems for a period of one (1) year from the date of

installation, or eighteen (18) months from the date of

manufacture, whichever comes first�

LABOR, ETC., COSTS: VRG shall IN NO EVENT be

responsible or liable for the cost of field labor or other

charges incurred by any customer in removing and/

or re-axing any VRG product, part or component

thereof�

THIS WARRANTY WILL NOT APPLY: (a) To defects

or malfunctions resulting from failure to properly

install, operate or maintain the unit in accordance

with printed instructions provided; (b) to failures

resulting from abuse, accident or negligence; (c)

to normal maintenance services and the parts used

in connection with such service; (d) to units which

are not installed in accordance with applicable local

codes, ordinances and good trade practices; (e) if the

unit is moved from its original installation location, or;

(f) if the unit is used for purposes other than for what

it was designed and manufactured�

RETURN OF REPLACED COMPONENTS: Any item to

be replaced under this Warranty must be returned to

Vista Research Group, LLC (VRG) in Ashland, Ohio,

or such other place as VRG may designate, freight

prepaid� Write to the address listed below for a return

authorization and the physical address to which items

should be returned for warranty attention�

PRODUCT IMPROVEMENTS: VRG reserves the right

to change or improve its products or any portions

thereof without being obliged to provide such change

or improvement of units sold and/or shipped prior to

such change or improvement�

WARRANTY EXCLUSIONS: As to any specific VRG

product, after the expiration of the time period of

the warranty applicable thereto as set forth under

the heading “Warranty Period” above, THERE WILL

BE NO WARRANTIES, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE.

Some states do not allow limitations on how long an

implied warranty lasts, so the above limitations may

not apply to you� No warranties or representations at

any time made by any representative of VRG shall vary

or expand the provisions hereof�

LIABILITY LIMITATION: IN NO EVENT SHALL VRG

BE LIABLE OR RESPONSIBLE FOR CONSEQUENTIAL,

INCIDENTAL OR SPECIAL DAMAGES RESULTING

FROM OR RELATED IN ANY MANNER TO ANY VRG

PRODUCT OR PARTS THEREOF.

Some states do not allow the exclusion of limitation

of incidental or consequential damages, so the above

limitation or exclusion may not apply to you�

This Warranty gives you specific legal rights and you

may also have other rights which vary from state to

state�

For your warranty protection (Magnason-Moss

Warranty Act), the warranty card, if provided, should

be completed and returned to VRG within ten (10)

days of installation� Alternatively, register your product

online within ten (10) days of installation at

vrg.support/register� In the absence or other suitable

proof of installation date, the eective date of this

warranty will be based upon the date of manufacture

plus one hundred eighty (180) days�

VistaPure Limited Warranty

VistaResearchGroup�com

P�O� Box 321

Ashland, Ohio 44805-0321

United States of America

PHONE (419) 281-3927

FAX (419) 281-7380

Installation Guide & Owner’s Manual

TM

VistaPure Specialized water filtration for autoclaves,

dental bottles, ultrasonic cleaners & instrument washers

System Model #

System Serial #

Installer Name

Installer Phone

Install Date

Dealer

Dealer Phone

Dealer Address

Notes

VistaPure System Information

Thank you for purchasing the VistaPure system for your practice! The following chart is for necessary

information for future reference� Please fill this out completely and keep this manual in a convenient place

for ready access and reference�

Be sure to use our convenient online warranty registration form at vrg.support/register� If you’d prefer,

you may complete and return the included Warranty Registration sheet� Make a copy of the form for your

records, then mail the original to us�

VistaResearchGroup�com

P�O� Box 321

Ashland, Ohio 44805-0321

United States of America

V3000-IGOM-150922

PHONE (419) 281-3927

FAX (419) 281-7380

Operating Temperature Range 45º - 100º F

Operating Pressure Range 40 - 100 psi

Optimal pH Range 6�5 - 8�5

Max Total Dissolved Solids (TDS) 500

Max pH Range 5�5 - 9�5

Max Influent Hardness 10 gr / 171 ppm

Max Influent Manganese 0�05 ppm

Max Influent Iron 0�1 ppm

Max Influent Hydrogen Sulfide None

Max Influent Chlorine / Chloramine 2 ppm

Max Daily Output (12 hours) 25 Gal (94 L)

Pre/Post Filter Element Service Life 1 Year Max

Pre/Post Filter Replacement Order # R5633

Hyperfiltration Filter Element Service Life 3-5 Years

Hyperfiltration Replacement Order # R3080

Deionization Filter Element Service Life 4-18 Months

Deionization Filter Replacement Order # R5662

System Dimensions (W x H x D) 22” x 16” x 5”

Tank Dimensions (Dia x H) 12�75” x 18”

Approximate Ship Weight (Dry 2 Cartons) 36 lbs

Other manuals for V3000

1

Table of contents

Other VistaPure Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Berbel

Berbel BUR 125 DL installation instructions

Apec Water

Apec Water ULTIMATE RO-PUMP INSTALLATION INSTRUCTION AND OWNER’S MANUAL

Savillex

Savillex DST-1000 Upgrade instructions

Christie

Christie LW400 Replacement Instruction Sheet

Green Turtle

Green Turtle PHIX owner's manual

Pure Company

Pure Company Carbon Filter Water Decanter instructions