ELGA Elgastat Option 4 Series Service manual

ThisOperatorsManualhasbeenpreparedforthe

ELGASTATOPTION4

rangeofwaterpurificationunitsandappliestothefollowingmodels:

ElgastatOption4A

ElgastatOption4B

220/240V50Hz

110/120V60Hz

90/110V60HZ

Themanualcontainsfulldetailsoninstallation,commissioningandoperationoftheunit

purchased.

Ifhowever,youhaveanyqueriespleasecontactyourlocaldistributororElga

ServiceDivisionwhowillbepleasedtodealwithyourenquiry.

LocalDistributorElgaServiceDivision

LaneEnd

HighWycombe

BucksHP143JH

Tel:

(01494)881393

Fax:(01494)881007

TableofContents

1.

HEALTHANDSAFETYNOTES1

2.

PRODUCTDESCRIPTION2

3.ELGASTATOPTION- TECHNICALSPECIFICATIONS4

4.

PROCESSDESCRIPTION6

5.INSTALLATIONINSTRUCTIONS8

5.1.

ServiceConnections8

5.2.Unpacking8

5.3.Installation9

5.4.RemoteLevelControlFacility10.

5.5.Table1 ElgastatOption4 ReverseOsmosisCapacityCalculations13

6.START-UPPROCEDURE14

6.1.

Start-UpProcedureforOption4 units14

7.FITTINGREPLACEMENTCARTRIDGE1:8

7.1.

ReplacingtheLC101Pre-treatmentcartridge...;18

7.2.ReplacementofLC102ReverseOsmosisCartridge....;.;: 20

7.3.ReplacingLC117Dlcartridgepack22

7.4.ReplacingLC105UltravioletLamp.-.

7.5.ReplacingtheLC106PointofUsefilter:

8.CLEANINGPROCEDURE,*,

8.1.

Cleaning/SanitisationProcedure] 25

9.CONSUMABLES, 27

9.1.

Accessories) 27

Opt4 Issue2-05/93

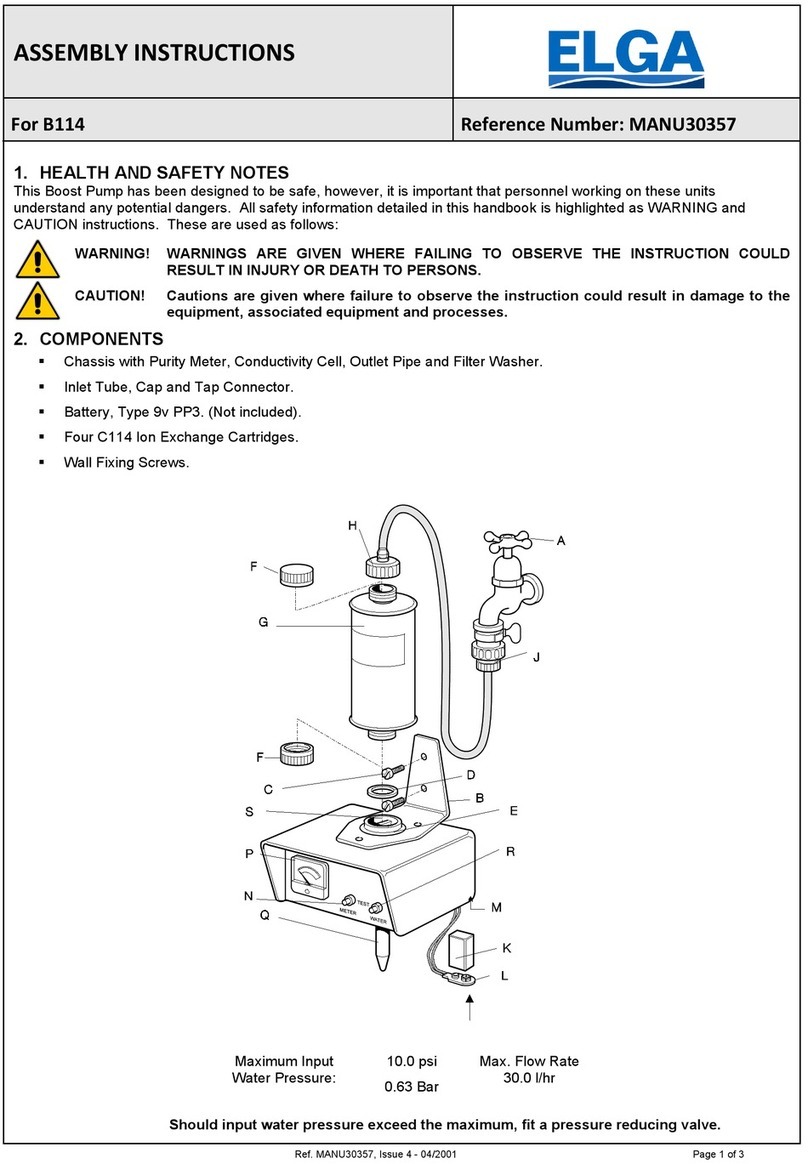

1.HEALTHANDSAFETYNOTES

TheElgastatrangeofproductshavebeendesignedwithsafetyinmind,howeveritisimportant

thatpersonnelworkingontheseunitsarefamiliarwithanypotentialdangers.Themostlikely

sourceofhazardsareasfollows:

1.

Electricity

Thoseproductsrequiringelectricalsuppliesoperateatmainssupplyvoltages.Itis

essentialthattheelectricalsupplyisisolatedbeforeanyworkisstarted.Forroutine

operationssuchaschangingtheDlcartridgepackandPretreatmentcartridgesitis

sufficienttoswitchtheunitoffatthepowerinletmodulelocatedatthetoprearlefthand

side.

Formoredetailedworkoraccesstotheprintedcircuitboardstheunitmustbe

physicallydisconnectedfromthemainssupplybyremovalofthemainsfeed

plug.

2.

Pressure

Mainsfeedwaterpressureortheinternalrecirculationpumpareusedtopumpthewater

throughthevariousstagesofpurification.Thispressurecouldpresenta dangerifnot

dissipatedpriortochangingcartridgesetc.Itisessentialthatthemainspressureis

isolatedandresidualpressureisallowedtodissipatepriortoremovalofanycartridges.

Switchingofftheelectricitywillisolatethesourceofpressureonthoseunitsrequiring

anelectricalsupply.Onthoseunitwithoutrequirementforelectricitythewaterpressure

shouldbeisolatedfromthemainswatersupply.

3.Ultra-VioletLight

Onsomeunitsshortwavelengthultra-violetlightisusedtodestroymicro-organisms.

Thebluelightvisiblefromthefrontoftheunitisquitesafeastheharmfulcomponentof

theultra-violetisfilteredout.Howevertheunitshouldnevertooperatedwiththefront

coverremovedastheoperatorcouldbeexposedtosorneshortwavelengthUVlight.

4.

Chemicals

Cleaningusingspecialistchemicalsisrecommendedonsomeunits.Safetydatasheets

conformingtoCOSHHregulationswillbesuppliedwithanychemicalsandtheseshould

becloselyfollowed.

Pleaseensurethatyouandanyotherstaffworkingontheseproductsarefamiliarwith

thepotentialdangersandthatthepropersafetyequipmentisavailable.Ifindoubt

contactyoulocaldistributorortheElgaServiceDivision.

5.ControlofSubstancesHazardous(COSHH)

Materialsafetydatasheetscoveringthevariousreplaceablecartridgesareavailable

uponrequestifyoucontactyourlocaldistributorortheElgaServiceDivision.

Opt4 Issue2-05/93

2.

PRODUCTDESCRIPTION

TheElgastatOption

4

waterpurificationunithasbeenspecificallydesigned

to

producepurified

waterequivalent

in

quality

to

waterprepared

by

distillation

but

without

the

highenergycosts

associatedwithdistillation.

Thehighelectricalrunningcostsnecessitated

bythe

phasechangewhichtakesplaceduring

distillation

has

longbeenrecognized

asa

major,

ifnot

sometimeshiddendisadvantage

of

usingthistechnique

forthe

production

of

purifiedwater.Additionallypretreatment

is

often

required

to

protect

the

stillfromscaling.

TheElgastatOption

4

wasdesignedwiththesepoints

in

mindandachievesbetterwaterquality

than

is

availablefromdistillationequipmentwhile

atthe

sametimerequiring

no

energy

requirement

inthe

form

of

heating.

The

latestmembranetechnology

is

employed

to

separate

impuritiesfromwater

andthe

drivingforce

for

thisprocess

isthe

pressureavailable

inthe

mainssupply.

Fig1 showstheexternalfeaturesvisible

tothe

user.Access

tothe

waterpurificationcartridges

isviatheremovablerightandlefthandcovers,and

the

electronicsandultravioletlamphousing

is

viathe

frontcover.

<•

Twoversions

ofthe

ElgastatOption

4

havebeendesignedwithnominalflowrates

of4 or8

litres/hr(similar

to

traditionalstills)

and

these

canbe

bench,shelf

or

wallmountedwith

the

additionalfeaturethat

the

purifiedwater

is

producedunderpressurethus

not

requiring

the

gravitycollectionrequired

by

stills.

Brieflywithin

the

Option

4

unitthere

isan

inletsolenoidvalvewhichcontrols

the

flow

of

mains

feedwater

tothe

Pre-treatmentcartridge

and

either

oneortwo

ReverseOsmosis

(RO)

cartridges.

TheRO

'permeate'(partiallypurifiedwater)thenleaves

the

unit

viathe'

outlet

connector

andis

collected

inthe

storagetank.

TheOption

4

unit

is

designed

tobe

operatedwith

a

treatedwaterstoragetank,

andto

ensure

thequality

ofthe

waterwithin

the

storagetank

is

maintained

atits

highestlevels,

the

water

from

the

tank

is

drawnbackinto

the

Option

4

unit

(byan

inbuiltrecirculationpump),

continuouslyrecirculatedthrough

theDl

cartridgepack

andUV

chamberprior

tobei!

returned

tothe

storagetank

viathe

unit'soutletconnector.

V

Dispensing

ofthe

purifiedwaterfrom

the

Option

4 isviathe

dispense

tap(seefig1)andcan

bedispensed

at

flowrates

upto30l/hr.An

optionalPoint-of-use0.2jumbacterialfilter

canbe

fitted

tothe

dispense

tapfor

addedprotection.ReferSection

7.5and9.0.

Thewaterqualityproduced

bythe

Option

4 is

continuouslymonitored

and

displayed

onthe

faciapanel

ofthe

unit.

Typicallywaterfrom

the

ElgastatOption

4 isofa

higherqualitythanthat

of

bothsingle

and

doublepassdistillation

andin

accordancewithBS3978:1987type

2

"water

for

laboratory-use"

@aflowrateof-30l/hr.,-^St

TheElgastatoption4 representsa costeffectiveimprovementintheproductionofpurified

watercomparedtotraditionaldistillation.

Opt4 Issue2-05/93

Removable

LeftHand

Cover

NamePlate

Control

Panel

PowerInlet

Module

On/OffSwitch

MainsPlug

TurnFastener

Water

Inlet

BluePrismatic

Window(UV)

VIEWLEFTHANDSIDE

Removable

RightHand

Cover

TurnFastener

PlugIn

Level

Controls

Purified

WaterOutlet

Dispense

Tap

PumpFeed

Drain

FIG1 EXTERNALFEATURESOFTHEELGASTATOPTION4

Opt4 Issue

2-05/93

\. ELGASTATOPTION- TECHNICALSPECIFICATIONS

FeedWater

Quality- Source

MaximumFI

MaximumTDS

Fiowcate(Max6.2barfeed)

Temperature

Pressure- MaximumtoRO

Minimum

Maximumtorecifcpump

Minimum

DrainRequirements

MaximumFlowrate(gravityfallwithairbreak)

Dimensions

Height

Width

Depth

Weight

Positioning

Connections

Inlet

Outlet

Drain

Recirculation

ControlSystems

Powerrequirements

Powerconsumption

Fuserating

Statusdisplays

Poweron

Process

Standby

WaterGood

ChangeCartridge

Safetyfeatures

Option4A

Potabletapwater

10

1000ppm

65litres/hour

1-35°C

.2bar(90psi)

.1bar(30psi)

6.2

2,

0.34bar(5psi)

PositivePumpSuction

60litres/hour

395mm

380mm

320mm

11kg

Wallorbenchmounted.

8mm

8mm

8mm

8mm

5/16")

ODPushIn

|5/16")ODPushln

y5/16")ODPushln

(5/16")ODPushIn

220/240v50Hz(Standard)

110/120v60Hz(Standard)

90/110v60Hz(Special)

81.5VA

2A(AllModels)

GreenLED

AmberLED

RedLED

GreenLED

RedLED

AutomaticHigh,

IntermediateandLow

LevelControls.

Option4B

Potabletapwater

10

lOOOppm

70litres/hour

1-35°C

6.2bar(90psi)

2.1bar(30psi)

0.34bar(5psi)

PositivePumpSuction

60litres/hour

395mm

380mm

320mm

12kg

Wallorbenchmounted.

8mm

8mm

8mm

8mm

5/16")

ODPushin

5/16")

ODPushIn

'5/16")ODPushIn

'5/16")ODPushIn

220/240v5OHz(Standarc

110/120v"60Hz(Standarc

90/110v60Hz(Special)

81.5VA

2A(AllModels)

GreenLED:

AmberLED

RedLED

GreenLED

RedLED

AutomaticHighip?%

Intermediateanclj^v%

LevelControls.^ *

Technologies

PurificationmethodPre-treatmentmedia

ReverseOsmosis

Ion/organicremoval

Photo-oxidation

0.2JJ

filtration(optional)

Pre-treatmentmedia

Reverseosmosis

Ion/organicremoval

Photo-oxidation

0.2fj

filtration(optional)

Opt4 Issue

2-05/93

Option4AOption4B

FlowRegime

DisinfectionChamber

Singlepassthrough

pre-treatmentandreverse

osmosis.

Continualrecirculationthrough

DlcartridgepackandpastUV

lamp(inconjunctionwith

a

storagevessel)

Aspecialchamberforeasy

disinfectionofthesystem

is

incorporatedintotheunit.

Singlepassthrough

pre-treatmentandreverse

osmosis.

Continualrecirculationthrough

DlcartridgepackandpastUV

lamp(inconjunctionwith

a

storagevessel)

Aspecialchamberforeasy

disinfectionofthesystem

is

incorporatedintotheunit,

TreatedWater

Dispenserate

Maximumdailyoutput(nominal)

ProductionRate(under standard

conditions)*

Purity

-

Inorganics

Organics

TOC

Bacteria+

Particles

PH

30litres/hour

100litresbasedon24hourday

4litres/hour

>

5

Mn-cm@ 25°C

<

0.001

AU@254nm

<50ppb

<1 CFU/ml

0.2/ifiltration(optional)

effectivelyneutral

30litres/hour

200litresbasedon24hourday

8litres/hour

>

5

MO-cm@ 25°C

<

0.001

AU@254nm

<50ppb

<1 CFU/ml

0.2/;filtration(optional)

effectivelyneutral

CartridgeReplacementFrequencies

Pre-TreatmentCartridge

ReverseOsmosisCartridge

UVLamp

DlCartridgeCapacity

PointofUseFilter

6months

Guaranteed 1year

Typicallife2-3years

12months

80,

000

litres

uS/cmat pH7.0**

>

5

M

D-crn

@25°C

6months

6months

Guaranteed1 year

Typicallife2-3years

12months

80,

000

litres

uS/cmat pH7.0**

>

5

M fi-cm @ 25°C

6months

*Standardconditionsare60psiinletpressure,

0

psioutletpressureat25°Cpotablewatersupplywith

cleanprefilter.(RefertoflowgraphsPage13)

+Subjecttosuitableoperatingprodedures.

**ConductivityofROpermeatefeedtocartridge.

Opt

4

Issue2-05/93

4.PROCESSDESCRIPTION

TheElgastatOption4 processlinksfourpurificationtechnologies- reverseosmosis,

adsorption,deionisationandphotooxidation-andincorporatesaninternalrecirculationpump

tomaintainthequalityofpurifiedwaterproducedbytheunit,seeFig2.

Theunitisdesignedtobeoperatedona potablewatersupply,andproduceseither4 or8

litresperhourofpurifiedwaterofbetterqualitythanwaterproducedbydistillation.A

continuoussupplyofpurifiedwaterisproducedbytheOption4 unitandiscollectedand

storedinatreatedwaterstoragetank.Theinternalrecirculationpumpthendrawsthepurified

waterfromthestoragetankandcontinuallyrecirculatesthecontentsofthetankbackthrough

theOption4 unittomaintainthewateratitshighestquality.Theoperationoftheunitisfully

automatedbyuseoflevelcontrolswitcheswithinthetreatedwaterstoragetank.

ThefaciapaneloftheOption4unitisshowninfigure3 anddisplaysthesystemstatus(water

quality)Power,ProcessandStandbylights.Innormalusewiththewaterandelectrical

suppliesconnectedtotheunitthePOWERlightandsystemstatusindicatorswillbeilluminated.

DepressingthePROCESSbutton(seefig3)willstarttheunit(PROCESSlightwillilluminate)

andwillopentheinletsolenoidvalve.InletwaterrequirementsfortheOption4 ispotable

waterbetween2 to6 bar(30to90psi).Waterwillentertheunitthroughtheinletsolenoid

valvethenpassthroughtheLC101PretreatmentCartridgepriortoenteringthedisinfection

portandtheReverseOsmosis(RO)cartridge,thePretreatmentcartridgewillremove

particulatesandanyfreechlorinewhichispresentinthefeedwater.

Thereverseosmosismodulesplitstheflowintotwostreams,permeate(the.purifiedwater)

andconcentrate(thewatercontainingmostoftheimpurities).Theconcentrateftowisrestricted

toenablea continuousbackpressureonthereverseosmosismoduleand'leavestheunitvia

thedrainconnectionontherighthandsideoftheunit.Thisdrainflowshouldneverberestricted

furtherotherwisescalingontheROmembranewilloccur,itshouldbedirectedtoa convenient

drainagepoint.

Thepermeate(purifiedwater)isthencollectedinthestoragetank.Waterisdrawnbackinto

theOption4 unitbyitsinternalrecirculationpumpandisfurtherpurifiedbypassingthrough

aDlcartridgepack(LC117)whichremovesdissolvedionicandorganicimpuritiesfromthe

permeatewater.Theresistivityofthepurifiedwaterleavingthecartridgepackiscontinuously

monitoredandisdisplayedonthesystemstatussectionofthefaciapanel.Watergood

indicatesthatthewaterbeingproducedbytheunitisabove5MD-cm,ifthechangecartridge

lightilluminates,thisindicatesthatthequalityisbelow5MflcmandthattheDlcartridgepack

requiresreplacing.

Thepurifiedwaterthenpassesthrougha UVlightchamberwhichirradiatesthewaterwith

shortwavelengthUVlighttodestroyanymicro-organismspresent.Thefullytreatedwater

canbedispensedthroughthedispensevalve.Forcriticalapplicationsa 0.2^/mpointMuse

filtermaybefittedtothevalveforfinalprotection.Anywaternotdrawnofffromthedispense

valveisautomaticallyreturnedtothestoragetankforfurtherrecirculationandpurification.

Thetreatedwaterstoragetankmustbefittedwithlevelcontrolswitchestocontrolthema&e

upflowviatheROcartridgesandlowlevelprotectionfortherecirculationpumpSedation5

refers.

Ifallthepurifiedwaterisdrawnfromthestoragetankthelowlevelwillactivateandthestandby

lightonthefaciapanelwillilluminate,thiswillswitchtherecirculationpumpandUV<%The

inletsolenoidvalvewillremainopentorefillthetankandoncethereissufficientwater^nthe.

tanktheProcessbuttoncanbepressedtoclearthestandbyconditionandthenreprfssei

tostarttherecirculationpumpandUV.

ForfulltechnicalspecificationoftheOption4 unitseeSection3.

Opt4 Issue2-05/93

ToDrain

lawWaterInlet

!0-90psi

Pretreatment

Cartridge

Disinfection

Port

PumpFeed

fromTank

FeedtoTank

Outlet

FIG2 PURIFICATIONTECHNOLOGIESWITHINTHEELGASTATOPTION4

ProcessLED

(Amber)PowerOn

LED(Green)

WaterGood

LED(Green)

Change

Cartridge

LED(Red)

\/

SYSTEMSTATUS

WATERGOOD

CHANGECARTRIDGE

POWER

PROCESS

7ISTANDBY

Process

ControlButton

Standby

LED(Red)

FIG3 FACIAPANELLAYOUT

Opt4 Issue

2-05/93

5.INSTALLATIONINSTRUCTIONS

5.1.

ServiceConnections

BeforecommencingtoinstallandoperatetheElgastatOption4 unitpleasereadfullyand

observethefollowingpoints.

Environment

Theunitshouldbeinstalledonaflatlevelsurfacepreferablyina cleandryenvironment.The

unitcanalsobewallmountedagainsta verticalwallcapableofsupportingtheweight(for

thiswerecommendtheuseofthewallmountingkitElgaPartNoLA503).

Electrical

CheckthatyourvoltagesupplyiscompatiblewithyourOption4 unit.ElgastatOption4 units

arebuilttoeither220/240v50Hzor110/120v60Hz(checkidentificationlabelslocatedatthe

backoftheunitandinsidetherighthandsidecover).

Drain

Aflexibleconnectiontoasinkorsuitabledraincapable ofhandlingatleast1

l/min

isrequired.

ThedrainpointshouldbebelowtheleveloftheunitandanyconnectionsdireqJWdrainshould

haveanair-breakdevicefitted.

FeedwaterPressure

Amaximumfeedwaterpressureof6.2bar(90psi)canbeusedtofeedtheElgastatOption4

unit.Higherfeedwaterpressuresmustbereducedusinga pressurereducingvalve,contact

theElgaServiceDivisionoryourlocaldistributor.

Normally,2.1bar(30psi)istheminimumpracticalpressureforoperation,a boostpumpis

availablewherepressuresareinadequate.DetailsoftheElgawaterboostpumpsetare

availablefromyourlocaldistributororElgaServiceDivision.

TheexactoutputflowratefortheunitcanbecalculatedfromthegraphsshowninTable1

whichdetailstreatedwateroutputvstemperatureandfeedwaterpressure.

PumpFeed(Recirculation)

Amaximumwaterpressureof0.34bar(5psi)anda minimumpressurerequireme'fiSipfa

positivepumpsuctionshouldbeusedtofeedtherecirculationpump,thissupplyistatlen

fromthetreatedwaterstoragetank.

FeedwaterQuality(toReverseOsmosiscartridgesonly)

TheElgastatOption4 isdesignedtooperateonpotablewatersuppliesupto1000ppmtotal

dissolvedsolids.Itisimportantthattheunitsareprotectedfromgrossparticulatefouling

whichmaybepresentinthefeedwater.Ifyourlocalwatersupplyhasa historyofvisibility

itwouldbeadvisabletoinstallapretreatmentfilterElgaPartNoLC107toensurepurifief|vatej!

qualityisnotaffectedortheunitdamaged.

5.2.Unpacking

CarefullyunpacktheElgastatOptionUnitandcheckthatyouhavereceivedallofthe

componentsandaccessoriesordered.

Opt4 Issue2-05/93

5.3.Installation

1.

Positiontheunitinitsdesiredoperatinglocation.Iftheunitistobewall-mounted,please

followtheinstructionssuppliedwiththeWallMountingKit(ElgaPartNoLA503).

WhentheElgastatOption4unitisbeinginstalled,adequatewallspaceshouldbeallowed

fortheremovalofsidecovers,replacementofcartridgesandgeneralservicing.

2.

TheOption4 unitisdesignedtooperatewitha storagetank(seefig5)andrequiresa

pumpfeedconnectionfromthestoragetanktotheOptionunit.AnElgadesigned25

litretankisavailableforusewiththeOptionunit(ElgaPartNoLA501)plustankwall

mountingkit(ElgaPartNoLA504).

3.Removetransitplugsfromtheinlet,outlet,pumpfeedanddrainconnectorsfromeither

sideoftheOption4 unit.

Toremovetransitplugspush-ingreycolletandpullouttransit

plug.

SeeFig4.

4.

Connect5/16"(8mm)draintubebypushingtubingfullyintodrainconnector(bottom

righthandsideofunit)andrunthedrainlinetoa sinkorsuitabledrainpoint.DONOT

RESTRICT.

5.Connect5/16"(8mm)purifiedwateroutlettubetotheoutletconnector(toprighthand

sideofunit)andatthisstagebecausethenewunitissuppliedcontainingbacteriostatic

solutionswhichmustberinsedoutpriortouse,theoutlethoseshouldbetemporarily

directedtoa sinkordrain.

6.Connect5/16"(8mm)feedtubetotheinlet(bottomlefthandsideofunit)andconnect

toa potablewatersupply.

Connectiontothepotablewatersupplyshouldbeviaanisolatingvalveonthemains

supplyfittedwitha tubeconnectorcapableoracceptinga 5/16"(8mm)ODnylontube,

ratedfor6 bar(90psipressure).

AninstallationkitisavailablefromElga(PartNoLA506),whichincludesa saddlevalve

withcombinednonreturnvalve.Thisvalveisdesignedtopuncture15mmODcopper

tubing(normaldomesticsupplypipe).Thekitalsoincludes10metersof5/16"(8mm)

ODnylontubingforfitmenttothewaterconnectorsontheOptionunit.

7.Connect5/16"(8mm)pumpfeedtubetothepumpfeedconnector(middleconnector

righthandsideofunit)andconnecttubetobottomtakeoffontank(seeFig5).

8.TheOptionunitissuppliedwitha mainsleadwhichhasa mouldedplugtoIEC.320.C14

standardwhichisdesignedtoplugintothesocketonthetoplefthandsideoftheunit.

Thismainsleadwillrequirea plugfusedat5Afittedtotheotherendofthemainslead

andconnectedtotheelectricalsupply.

TheOptionunitisfusedinternallywith2x2ampfuseswhicharelocatedinthepower

inletmoduleonthetoplefthandsideoftheunit.Theyaresituatedbetweenthemains

switchandsocketandaccessisgainedbysimplyremovingthemainsleadandprising

openthefuseholdercoverwherethefusesarethenclearlyvisible.

9.TheOption4 unitisdesignedtooperateinconjunctionwitha treatedwaterstorage

tank,thereforeitisnecessarytoconnectthelevelcontrolsfromtheOption4 unittothe

storagetank.SeeSection5.4.

Opt4 Issue2-05/93

5.4.RemoteLevelControlFacility

ConnectiontoElgasuppliedTank

1.

TheOption4 unitrequires

high,

intermediateandlowlevelcontrols.Thehighand

intermediatelevelcontrolsautomaticallycontrolthefillingofthestoragetankandthe

lowlevelcontrolprotectstherecirculationpumpfromrunningdry.

2.

TheOptionunitissuppliedcompletewithalevelcontrolDINplugprewiredwith3 meters

of6 corecableandisdesignedtoplugintothesocketatthetoprighthandsideofthe

unit,seeFig1.

3.FortheOption4 unitallsixwiresmustbeconnectedtothestoragetanklevelcontrol

terminalblockasfollows.

Connecta)BlackandRedwirestoHighlevelterminals

b)WhiteandYellowwirestoIntermediateterminals

c)GreenandbluewirestoLowlevelterminals

4.

Havingconnectedwirestotankterminals,plugDINplugintosocketonOptionunit.

5.Theunitisnowinstalledandisreadyforstart-up,seesection6.,•

ConnectiontoNonElgasuppliedTank

TowireupthelevelswitchesontheOptionunit,thefollowingprocedureshotrtdbecarried

out:

1.

Installthehighlevelswitchinthetreated waterstoragetanksothattheswitchis'closed'

whenthetankis

full,

and'open'whentheleveldrops.

2.

Installtheintermediatelevelswitchata heightapproximatelyonethirdofwatervolume

downfromhighlevelmark.Theintermediateswitchshouldbe'open'whenthewater

levelisabovethismark,and'closed'whenthewaterleveldropsbelowthismark.

3.Installthelowlevelswitchapproximately1-2cmabovetheinletto-thepump.Thelow

levelswitchshouldclosewhenthewaterlevelisbelowtheswitch.

4.

TheOption4 unitissuppliedcompletewithlevelcontrolDINplugprewiredwith3 meters

of6 corecableandisdesignedtoplugintothesocketatthetoprighthandsideofthe

unit.Connectthewiresasfollows:

a)BlackandRedwirestoHighlevelswitch

b)WhiteandYellowwirestoIntermediatelevelswitch

c)GreenandBluewirestolowlevelswitch.

5.PluglevelcontrolDINplugintolevelcontrolsocketattoprighthandsideofunit.

;••-<

%

6.Nowchecktheoperationoftheswitchesbymovingtheswitchesbyhandasfollows;

ConnectnonelectricalsupplyandpresstheProcessbutton.Thestoragetankatthis1

stageisempty,thereforethepumpandUVshouldbeoffandtheStandbylight

illuminated.

IfthepumpandUVareenergisedswitchoffunit,andcheckthatlowlevel

switchisinstalledcorrectly,i.e.closedcircuitwhentankisempty.

Tocheckhighandintermediateswitches,pressProcessswitchonunit,theinletSQ^oj

valveshouldbeheardtoclickon,nowliftintermediateswitchthereshouldbeno$||nge

andwhileholdingintermediateswitchupnowliftthehighlevelswitch,thiswillnowlwitch

theinletsolenoidvalveoff.

Nowdropthehighlevelswitch,thereshouldbenochange,nowdropintermediate

switchandthesolenoidshouldnowenergiseandopen.

Opt4 Issue2-05/9310

Connector

Collet(darkgrey)

BlankingTransitPlug

PullPlug

Depress

ColletCleanSquare

CutEnd

Simplypushintubetoattach.

Tubeissecuredinposition.

FIG4 TUBECONNECTORDETAILS

TubeNylon

5/16"ODor8.00mm

Opt4 Issue2-05/9311

OPTION4 UNITSTORAGETANK25L

LevelControls

Inlet

30-90psi

•Q

OPTION4 Outlet

PumpFeed

ToDrain

OHigh

OInt

OLow

FIG5 OPTION4 UNITINSTALLEDWITHSTORAGETANK

Opt4 Issue2-05/93 12

5.5.Table1 ElgastatOption4 ReverseOsmosisCapacityCalculations

T1• TemperatureCorrectionFactors- Feedwater

°c

1

2

3

4

5

6

7

8

9

10

Factor

0.38

0.40

0.43

0.45

0.48

0.51

0.53

0.56

0.58

0.61

°C

11

12

13

14

15

16

17

18

19

20

Factor

0.64

0.66

0.69

0.71

0.74

0.77

0.79

0.81

0.85

0.87.

°C

21

22

23

24

25

26

27

28

29

30

Factor

0.89

0.92

0.94

0.97

1.00

1.03

1.06

1.09

1.13

1.16

STEP1

ObtainthenominalflowrateattheoperatingpressurefromGraph1forOption4AandGraph2 forOption4B.

NominalFlowrate-

L/Hour

STEP2

Multiplythenominalflowratebythetemperaturecorrectionfactor(TCF)fromT1toobtaincorrectedflowrate.

(TCF)x nominalflowrate= CorrectedFlowrate.

GRAPH1 - NOMINALFLOWRATEVsINLETPRESSURE

60T

2.03.04.0

FLOWRATEL/HR5.0

4.0

Temp25°C

PotableWater

Fi<10

6.0

GRAPH2 - NOMINALFLOWRATEVsINLETPRESSURE

Temp25"C

PotableWater

Fi<10

1.02.03.04.05.06.07.0

FLOWRATEL/HR8.010.011.0

Opt4 Issue2-05/9313

6.START-UPPROCEDURE

6.1.

Start-UpProcedureforOption4 units

1.

TheOption4 unitshouldbeinstalledcorrectlyasdescribedinSection5.

2.

Turnonthefeedwatersupplytotheunitandadjusttheinletpressure.TheElgastat

Option4 unitwilloperateonafeedwaterpressurebetween2.1bar(30psi)and6.2bar

(90psi).SeeTable1,Section5 tocalculateexactoutputatmainspressureavailable

on-site.

3.Checkallhoseconnectionsarewater-tightandtherearenoleaks.

4.

TheOption4unitsaresuppliedcontainingbacteriostaticsolutionwhichhastoberinsed

outfromthepipeworkandfittings.ThesolutionisrinsedthroughboththeDRAINand

OUTLETtubes,whichthereforeneedtobedirectedtoa drainorsinkinitially.

5.Removetherighthandcoverfromtheunitbyundoingthe4 quarterturnfastenersand

placecovertooneside.NotetheunitissuppliedwithouttheLC117Dlcartridgepack

fitted,

buthasthecartridgeadaptorconnectedtoa by-passblockasshownin^Fig6.

6.Ensurethecartridgeadaptorisleftconnectedtotheby-passblockuntiltheunit"has

beenrinsedofbacteriestaticsolutions.

7.Turnontheelectricalsupplytotheunitandswitchthemainsswitchatthepowerinlet

moduleontheleft-handsideoftheunittotheONposition.ThegreejiPOWERlamp

(seeFig3)shouldilluminateandthesystemstatusdisplaywillstart?tofunction(asno

Dlcartridgepackisfitted,displaywillindicate"changecartridge":Thisshouldbeignored

atthisstage).

8.Havingcheckedthatthewatersupplyhasbeenturnedon,andthelevelcontrolDIN

plugisconnected,pressthePROCESSbutton(theinletsolenoid,willopen)andtheunit

willstart.Atthisstagetheunitwillbereceivinga lowlevelsignal#omthestoragetank,

thiswillbeindicatedbytheredSTANDBYlight(i.e.thepumpanduvwillbeoff)ignore

thisatthisstage.%

9.Leavetheunitrunningfor2hourstodrain.Duringthisperiod,thebacteriostaticsolution

willberinsedfromtheLC102ROcartridges.

10.

After2 hours,pressthePROCESSbuttontostoptheunit.Theoutlettubingcannow

beconnectedtothetreatedwatertank.

11.

Pressthe^PROCESSbuttonagaintorestarttheunitandallowtheunittooperatefora

further2-%b£$rs.Duringthisperiodthestoragetankwillbefillingwithpurifiedwater,

NOTE:

trlifclSTANDBYlightwillbeilluminated.

12.

After2-3hours,pressthePROCESSbuttont§stoptheunitandthenopentheunit's

outlettap.Placea 5 litrecontainerunderneaththetapandthenpressthePROCESS

buttonagain.ThepumpandUVwillnowoperateandtheamberprocesslightwill

illuminate.Closetheoutlettapwhen5 litresisdispensedfromtheunit.

NOTE:

IfthepumpandUVdonotoperate,andtheSTANDBYlightisstillillumined,

allowtheunittofillforafurther1 hourthenrepeatStep12.(Timesmayvaryif

theunitisnotbeingusedwithanElgasupplied25litretank.)

13.

PressthePROCESSbuttontostoptheunit.

14.

TheunithasnowbeenfullyrinsedandtheLC117Dlcartridgepackcannowbefitted

asfollows.

Opt4 Issue2-05/9314

15.

UnpackthenewLC117cartridgeandremovetheyellowplugsfromtheinletandoutlet

portsatthetopofthepack.

16.

Fitthecartridgepackintotheunitbyaligningthetopandbottomofthecartridgepack

withtheguides,seeFig6,andslideintounit.Pushthecartridgepackfullybackinto

theunit.Thecartridgewillbelocatedproperlywhenitispositionedontheflatportion

ofthebottomcartridgeguide.

17.

Thecartridgeadaptorcannowberemovedfromtheby-passblockbyundoingthe

securingscrewinananti-clockwisedirection.Thesecuringscrewiscaptivewithinthe

adaptorandasitisunscrewedthecartridgeadaptorwillbereleasedfromtheby-pass

block.SeeFig6.Chefcktoensurecartridgeadaptorhas0 ringsfittedtothemale

spigots.

18.

Fitthecartridgeadaptorjustremoved,intothecartridgepack'sinletandoutletports

andsecureinplacebytighteningthesecuringscrewina clockwisedirectionuntil

hand-tight.SeeFig7.

19.

TheLC117cartridgepackshouldnowbeinstalledasperFig7,andtheOption4 isnow

readyforuse.

20.

PressthePROCESSbutton.Theinletsolenoidwillnowopenandwaterwillpassthrough

theunitandstarttofillthestoragetankiftheredSTANDBYlightisilluminated.Allow

theunittofillthetankfor15minutesandthenpressthePROCESSbuttontoswitchthe

unitoff.'

21.

NowpressthePROCESSbuttonagain(thisclearsthestandbysignal),andprovided

thereissufficientwaterinthestoragetanktherecirculationpumpandUVwilloperate,

theamberPROCESSlightwillbeilluminatedtoshowtheunitisintheprocessmode.

TheunitisnowdrawingwaterfromthestoragetankandrecirculatingitthroughtheDl

cartridgepackandUVchamberandthenreturningitbacktothetankviatheunit'soutlet

connection.Thesystemstatuslightshouldchangefromredtogreentoindicatethat

thewaterproducedbytheunitisbetterthan5MD-cm.

22.

Theunitwillnowrunautomaticallyandfillthestoragetank,once

full,

theinletsolenoid

closesandtherecirculationpumpcontinuestorun,enablingpurifiedwatertobedrawn

fromthedispensetap.

23.

EnsuretherearenoleaksbetweenthecartridgeadaptorandLC117Dlcartridgepack

(ie,

thesecuringscrewhasbeentightenedcorrectly)andthenrefittherighthandside

cover.Theunitisnowreadyfordailyuse.

24.

Anoptionalpointofusebacterialfilterisavailableforfitmenttothedispensetap(Elga

PartNoLC106)

Dpt4 Issue2-05/9315

CartridgeAdaptor

By-PassBlock

TopCartridge

Guide

SecuringScrew

BottomCartridge

Guide

FIG6OPTION4 UNITWITHOUTCARTRIDGEPACKFITTED

Opt4 Issue2-05/9316

CartridgeAdaptor

SecuringScrew

TopCartridge

Guide

BottomCartridge

Guide

LC117

CartridgePack

FIG7 OPTION4 WITHLC117CARTRIDGEPACKFITTED

Opt4 Issue2-05/9317

This manual suits for next models

2

Table of contents

Other ELGA Water Filtration System manuals

ELGA

ELGA PURELAB Quest User manual

ELGA

ELGA Purelab flex 4 User manual

ELGA

ELGA PURELAB UHQ II User manual

ELGA

ELGA PURELAB Chorus I User manual

ELGA

ELGA MEDICA EDI - US User manual

ELGA

ELGA PURELAB Prima 7 User manual

ELGA

ELGA PURELAB 7000 - US User manual

ELGA

ELGA PURELAB Chorus 2 User manual

ELGA

ELGA B114 User manual

ELGA

ELGA PURELAB Classic - US User manual