Vital Systems OCTO24 User manual

Octo24 –pn8732

Ethernet PLC / Remote-I/O

User Guide

(Document Revision 3)

(Updated: May 14, 2020)

© 2017 Vital System Inc

Buford, GA USA

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 1 | P a g e

Contents

Overview ..................................................................................................................................................... 3

Operating Specifications ......................................................................................................................... 3

2. Hardware and Wiring.............................................................................................................................. 4

Digital I/O - M12-A Connectors............................................................................................................... 4

Ethernet - M12-D (FEMALE) Connector –Auto MDIX Capable............................................................... 5

PWR - M12-A (MALE) Connector ............................................................................................................ 5

I/O POWER - M12-A (MALE) Connector.................................................................................................. 5

Selecting Power for I/O ........................................................................................................................... 6

Powering Both CPU & Outputs from PWR Plug (MIX)......................................................................... 6

Powering CPU & Outputs Separately Using the PWR & I/O Power Plug (ISO).................................... 6

3. Device Configuration............................................................................................................................... 7

Network Settings..................................................................................................................................... 8

IP Address ............................................................................................................................................ 8

Subnet Mask ........................................................................................................................................ 9

Gateway............................................................................................................................................... 9

Conveyor Settings.................................................................................................................................... 9

Host ID ................................................................................................................................................. 9

Upstream ............................................................................................................................................. 9

Downstream ...................................................................................................................................... 10

Divert Right........................................................................................................................................ 10

Divert Left .......................................................................................................................................... 10

Merge................................................................................................................................................. 10

Miscellaneous Settings.......................................................................................................................... 10

Remote I/O ........................................................................................................................................ 10

CB:14.................................................................................................................................................. 10

CW:15 ................................................................................................................................................ 11

4. Operating Modes .................................................................................................................................. 12

Remote I/O Controller Mode................................................................................................................ 12

Programmable Logic Controller Mode.................................................................................................. 12

Control More than 8 In & 8 Out using one ladder program ................................................................. 12

CPU LED Blink Patterns.......................................................................................................................... 13

5. Network Communication Protocols...................................................................................................... 14

Ethernet/IP Protocol ............................................................................................................................. 14

Input/Produce Message Format (T O).......................................................................................... 16

Output/Consume Message Format (O T) ...................................................................................... 17

Explicit Requests................................................................................................................................ 18

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 2 | P a g e

Modbus / TCP Protocol ......................................................................................................................... 19

S3G-Master/Slave Protocol................................................................................................................... 20

Profinet RT............................................................................................................................................. 21

Import XML Device Profile................................................................................................................. 21

Profinet Ethernet Configuration........................................................................................................ 22

Real Time Settings ............................................................................................................................. 23

I/O Data ............................................................................................................................................. 23

SICK Scanner Protocol ........................................................................................................................... 24

Scanner Configuration....................................................................................................................... 24

Barcode Operation in Superlogic....................................................................................................... 25

6. Programming and Configuring OCTO24 Devices .................................................................................. 27

SuperLogic Pro....................................................................................................................................... 27

Deploy3G............................................................................................................................................... 28

7. Control Words....................................................................................................................................... 29

8. Control Bit File....................................................................................................................................... 31

9. Network Topology Examples ................................................................................................................ 32

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 3 | P a g e

Overview

The OCTO24 Smart Ethernet Programmable Controller provides networked 24volts Digital I/O for MDR

Powered Roller Conveyor systems using the G20 ZPA cards, as well as general purpose Fast

Local/Remote Machine I/O. These Devices are fully programmable for any type of control application,

and can act as a programmable master device, or a slaved Remote I/O device. The modules

communicate over Ethernet to master or peer devices using Ethernet/IP, Profinet RT, Modbus TCP and

S3G-Master Slave protocols. For MDR conveyors, interlocking messaging bits e.g., upstream,

downstream, merge, divert, etc are handled by the firmware for simplified Ladder Logic Programming.

Operating Specifications

CPU Input Power

18 –26V DC. Typical 24V, 150 mA

Digital Output Voltage

18 –26V DC

Digital I/O Circuit Type

PNP (Sourcing)

Digital Output Max Current

500 mA per Output, 2A Max per Unit

Digital Inputs Voltage

18 –26V

Network

Ethernet 100Mb/s

Ethernet Switch

2 Ports, Auto-MDIX

IP Rating

IP67

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 4 | P a g e

2. Hardware and Wiring

Label

Connector

Description

1

M12-A Male

Digital Input 1, Output 1

2

M12-A Female

Digital Input 2, Output 2

3

M12-A Male

Digital Input 3, Output 3

4

M12-A Female

Digital Input 4, Output 4

5

M12-A Male

Digital Input 5, Output 5

6

M12-A Female

Digital Input 6, Output 6

7

M12-A Male

Digital Input 7, Output 7

8

M12-A Female

Digital Input 8, Output 8

NET 1

M12-D Female

Ethernet Port1

NET 2

M12-D Female

Ethernet Port2

I/O POWER

M12-A Male

Digital Outputs power Plug.

PWR

M12-A Male

CPU and optional Digital Outputs power Plug.

Digital I/O - M12-A Connectors

MALE connector used for I/O 1, 3, 5,

and 7

Pin

Description

Pin1

Output (+)

Pin2

Output (-)

Pin3

Input (+)

Pin4

Input (-)

FEMALE connector used for I/O 2, 4, 6,

and 8

Pin

Description

Pin1

Input (+)

Pin2

Input (-)

Pin3

Output (+)

Pin4

Output (-)

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 5 | P a g e

Ethernet - M12-D (FEMALE) Connector –Auto MDIX Capable

Pin

Description

Pin1

Tx (+)| Rx(+)

Pin2

Rx (+)| Tx(+)

Pin3

Tx (-)| Rx(-)

Pin4

Rx (-)| Tx(-)

PWR - M12-A (MALE) Connector

Pin

Description

Pin1

Power +24V

Pin2

NC

Pin3

GND 0v

Pin4

NC

I/O POWER - M12-A (MALE) Connector

Pin

Description

Pin1

I/O Power +24V

Pin2

NC

Pin3

I/O GND 0v

Pin4

NC

IMPORTANT: When Supplying power to the controller using separate CPU

and I/O plugs, make sure both power supplies –ve terminals are earth

grounded. Without common negative, the unit may sustain excessive

damage.

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 6 | P a g e

Selecting Power for I/O

To select the power source for the unit, open the cover and locate the jumper header with the labels

ISO and MIX. The default setting is configured as MIX, causing both the unit & I/O to be powered from

the PWR plug.

Powering Both CPU & Outputs from PWR Plug (MIX)

Install the two jumpers in the ISO position as shown below. Remove any plugs connected to the I/O

POWER connector.

Powering CPU & Outputs Separately Using the PWR & I/O Power Plug (ISO)

Install the two jumpers in the ISO position as shown below. Use both PWR and I/O POWER plugs to

power the unit. Make sure both power supplies share the same Earth Ground on the

negative terminal.

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 7 | P a g e

3. Device Configuration

The OCTO24 device configuration window can be accessed from either the SuperLogicPro, or Deploy3G

application.

Accessing the device configuration from SuperLogic Pro

Accessing the device configuration from Deploy3G

The Device Configuration Window

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 8 | P a g e

Network Settings

IP Address

The Device IP address is configured partly by the rotary switches and partly within the device

configuration window. The first three bytes of the IP address are configured from the Device

Configuration window, while the last byte is configured using the rotary switches. The default IP

address is set to 192.168.0.1.

The rotary switches configure the last byte (Device ID) of the IP Address (e.g. 0 –99 for decimal rotary

switches, and 0 –255 for hexadecimal rotary switches).

For decimal rotary switches, the hundreds digit of the last byte can be set by simply inputting the

desired value, clicking OK, then rebooting the device (e.g. 47, 147, 247).

NOTE: Hexadecimal rotary switches are only available on some OCTO24 models.

NOTE: IP addresses use unsigned byte minimum and maximum values (0 –255). A value of 255

indicates a broadcast value, and should not be used.

NOTE: For semantics, the first 3 bytes of the Device IP Address will be referred to as the “Device

Network”, while the last byte will be referred to as the “Device ID”.

NOTE: The Device ID can only be set to a value of 1 –250. Any

values beyond this range will result in the device entering an error

state due to an invalid IP Address.

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 9 | P a g e

Subnet Mask

The subnet mask of the OCTO24 device which assists in packet routing and is typically used by network

routers and switches. This is typically set to a value of 255.255.255.0 for most standard network

setups.

Gateway

The default Gateway IP address for the device network which usually indicates the IP address for the

network router/switch that routes packets on the Local Area Network. This value is usually obtained by

taking the first three bytes of the Device IP Address, and setting the last byte to 1. (Example: if the

OCTO24 device is set to an IP address of 192.168.0.20, then the Gateway should be set to 192.168.0.1)

Conveyor Settings

These settings are used in OCTO24 device networks to accomplish

specialized tasks/behaviors such as those required in conveyor

sections.

Host ID

The last byte of the Control PC IP address. This is used by the OCTO24 device as the destination IP

address for forwarding received barcode messages via Ethernet/IP. The default value is “NONE”, which

means that the OCTO24 device will not forward any received messages to a host, and will write the

barcode to CW:61 –80.

Upstream

The device ID of the upstream OCTO24 card. The default value is “-ONE”, which means the current

device ID minus 1. CB:18 is updated by the upstream card to signal that a package is available. CB:12 is

used to signal the upstream device that the card is ready and the upstream can send a new package.

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 10 | P a g e

Downstream

The device ID of the downstream OCTO24. The default value is “+ONE”, which means the current

device ID plus 1. CB:19 is updated by the downstream card to signal that it is ready to receive packages.

CB:11 is used to signal the downstream device that a package is currently in waiting to be sent

downstream.

Divert Right

The device ID of the right divert OCTO24. The default value is “NONE”, which means that no right

divert path is present. CB:6 is updated by the right divert card to signal that it is ready to receive

packages. CB:5 is used to signal the right divert device that a package is currently in waiting to be

diverted right.

Divert Left

The device ID of the left divert OCTO24. The default value is “NONE”, which means that no left divert

path is present. CB:4 is updated by the left divert card to signal that it is ready to receive packages.

CB:3 is used to signal the right divert device that a package is currently in waiting to be diverted left.

Merge

The device ID of the OCTO24 controlling an auxiliary merge line. The default value is “NONE”, which

means that no merge line is present. CB:1 is updated by the merge line card to signal that a package is

currently in waiting on the merge line. CB:2 is used to signal the merge line device that a package can

be received and merged on the main line.

Miscellaneous Settings

Remote I/O

This setting controls the main operation mode of the OCTO24 device. Enabling this setting will set the

device to Remote I/O mode, while disabling it will set the device into PLC mode. See the Operating

Modes section for more information.

CB:14

This setting controls the default value of CB:14. See CB:14 under the Control Bits section for more

information.

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 12 | P a g e

4. Operating Modes

The OCTO24 device has two main operating modes:

Remote I/O Device

Programmable Logic Controller

Remote I/O Controller Mode

Using the SuperLogic configuration window, if the Remote I/O check box is ON, the device allows an

external master to control the I/O directly over Ethernet. The controller does not execute any user

downloaded ladder logic program. Any of the supported Ethernet communication protocols can be

used for I/O manipulation. This is the factory default mode.

The CPU Led blinks in the following two patterns:

When a Master Is ONline: One second On/Off cycle with 2% duty cycle. (very short blips)

When Master Is OFFline: One second On/Off cycle with 50% duty cycle

Programmable Logic Controller Mode

If the Remote I/O check box is OFF, the device executes the downloaded user ladder logic program to

control the I/O. In this mode, any Master device can still connect to the device, but the outputs will

remain in the Ladder Logic program control. The master can write to Control Word file which the

device can pick up and take appropriate actions as defined by the user ladder logic program.

In this mode, the CPU Led blinks in the following patterns:

Ladder Logic Run Mode: Heart-beat blink mode (blip-blip, blip-blip, blip-blip…)

Ladder Logic Stopped: One second On/Off cycle with 50% duty cycle.

Control More than 8 In & 8 Out using one ladder program

The ladder logic program controls the local I/O as well as access and control the I/O on remote OCTO24

devices. The remote I/O points appears as local I/O and are accessed the same way as the local I/O,

e.g. IN:8, IN:50, OUT:72, etc. Up to eight remote OCTO24 cards can be controlled from a single master

OCTO24 device, providing a total of 72 inputs and 72 outputs. See section S3G-Master/Slave Protocol

for more information to configure the card for expanded I/O

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 13 | P a g e

CPU LED Blink Patterns

The CPU LED will display the following blink patterns depending on the current device operation status.

Blink Pattern

Description

Heart Beat (1 blip)

Device is set to Remote I/O mode, and a master is currently

controlling the device.

Fast Blink (3 blinks/sec)

Device is set to Remote I/O mode, but is not currently being

controlled by a master.

Slow Blink (1/sec)

Programming Mode. Device is not set as remote I/O but is not

currently running a ladder program.

Heart Beat (2 blips)

Ladder Logic Run Mode. Device is currently running a ladder

program.

Rapid blink (5 blinks/sec)

for 1.5 seconds, then OFF

for 1.5 seconds.

Duplicate IP address detected on the network. Resolve the

duplicate IP issue by changing the IP address of the device. A power

cycle is required for a new IP address to take effect.

Rapid Blink (5 blinks/sec)

Rotary switch is set to zero.

Irregular Rapid Blink

Bootloader Mode. Scan for the device in Deploy3G and reprogram

the firmware.

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 14 | P a g e

5. Network Communication Protocols

Ethernet/IP Protocol

Configuration Parameters

Device Type

Generic

Name

Any user defined name

Data Format

SINT (byte)

IP Addr

Device IP Address

Octo24 Master

112, Size Min=1, Max=28 Bytes (T O) (Input/Produce Data)

Master Octo24

111, Size Min=8, Max=24 Bytes (O T) (Output/Consume Data)

Config

113, Size 0

Size define how many bytes are configured as inputs to the PLC and outputs from the PLC. The

numbers are from PLC's (or Master's) perspective, not the Octo's.

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 16 | P a g e

Input/Produce Message Format (T

O)

Data to Ethernet/IP Master is read from Control Words 1 through 4, and 49 thru 55, which are 16bit

integers. If the card is not controlling Slave devices, these control word 49 thru 55 can be used for user

defined data.

BYTE

Function/Value

0

Input States, 8 bits

1

Status Bits

Bit 0 –I/O power ON

Bit 1 –Remote I/O Enabled

Bit 2 –Ladder Run mode

Bit 3 –Ladder Error

2

Output States, 8 bits

3

CW:14, Slave Cards online bits (bit0 –slave1, bit1 –slave2, bit2 –slave3, etc.)

4 –5

CW:1, Contents of Control Word 1

6 –7

CW:2, Contents of Control Word 2

8 –9

CW:3, Contents of Control Word 3

10 -- 11

CW:4, Contents of Control Word 4

12 -- 13

CW:49, Digital I/O data for Slave1. (Inputs = bits 0 –7; Outputs = bits 8 –15)

14 -- 15

CW:50, Digital I/O data for Slave2. (Inputs = bits 0 –7; Outputs = bits 8 –15)

16 -- 17

CW:51, Digital I/O data for Slave3. (Inputs = bits 0 –7; Outputs = bits 8 –15)

18 -- 19

CW:52, Digital I/O data for Slave4. (Inputs = bits 0 –7; Outputs = bits 8 –15)

20 -- 21

CW:53, Digital I/O data for Slave5. (Inputs = bits 0 –7; Outputs = bits 8 –15)

22 -- 23

CW:54, Digital I/O data for Slave6. (Inputs = bits 0 –7; Outputs = bits 8 –15)

24 -- 25

CW:55, Digital I/O data for Slave7. (Inputs = bits 0 –7; Outputs = bits 8 –15)

26 -- 27

CW:56, Digital I/O data for Slave8. (Inputs = bits 0 –7; Outputs = bits 8 –15)

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 17 | P a g e

Output/Consume Message Format (O

T)

If the OCTO24 device is configured with Remote I/O operation, Byte0 is mapped to outputs for direct

master PLC control. If remote I/O mode is off, data from master PLC is written to control words CW:9,

CW:10, CW:81-88.

BYTE

Function/Value

0 –1

Control Word 9 (or byte 0 directly to Digital Outputs in Remote I/O mode)

2 –3

Control Word 10

4 –5

Control Word 81

6 –7

Control Word 82

8 –9

Control Word 83

10 –11

Control Word 84

12 –13

Control Word 85

14 –15

Control Word 86

16 –17

Control Word 87

18 –19

Control Word 88

The amount of data written to Octo card is always 4 less. You should always configure 4 more

in the

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 18 | P a g e

Explicit Requests

Explicit requests can be sent to the OCTO24 device using Ethernet/IP which is useful for barcode

scanners. The following message parameters must be used for sending these requests.

Setting

Value

Request Type

Read/Write Tag Message

Operation

Write

Type

SINT (8-bit)

The request data contents will be written to CW:61 –80, which allows 40 bytes of data to be stored for

each request. CB:10 will be activated whenever an explicit request is received and data is written to

the control words. If CB:10 is active while a new explicit request is received, CB:15 will be activated to

signal a buffer overrun condition. See the Control Words, and Control Bits section for more information

Octo24 User’s Guide

www.vitalsystem.com

Ver. 8732doc rev3 © Copyright 2020 Vital System 19 | P a g e

Modbus / TCP Protocol

Modus/TCP protocol can read the entire Control Words file CW: 1…54 via Modbus Holding Registers.

Writes (or Output-Holding) are only allowed to Registers 9, 10, 23 and 24.

Modbus Slave address is ignored.

Reading Modbus Holding Register 1 through 54 will read Control Words 1 thru 54 in the card.

Writing to Modbus Holding Register 9 and 10 will write to Control Words 9 and 10 in the card. Can be

used for any general purpose.

The following special condition applies to Register 23 and 24:

Read Holding Reg 23 = Read 8 Inputs (bits 0…7) and new barcode bit (bit 15)

Read Holding Reg 24 = Read 8 Outputs (bits 0…7) and I/O Power State (bit 15)

Write Holding Reg 23 = Write to CW:23

Write Holding Reg 24 = Write to CW:24, or Write to output pins if Remote I/O Checkbox is on.

This manual suits for next models

1

Table of contents

Other Vital Systems Controllers manuals

Popular Controllers manuals by other brands

Technische Alternative

Technische Alternative UVR16x2 manual

Honeywell

Honeywell FR124 installation instructions

Sentera Controls

Sentera Controls EVSS1 Series Mounting and operating instructions

Resol

Resol DeltaSol CS Plus manual

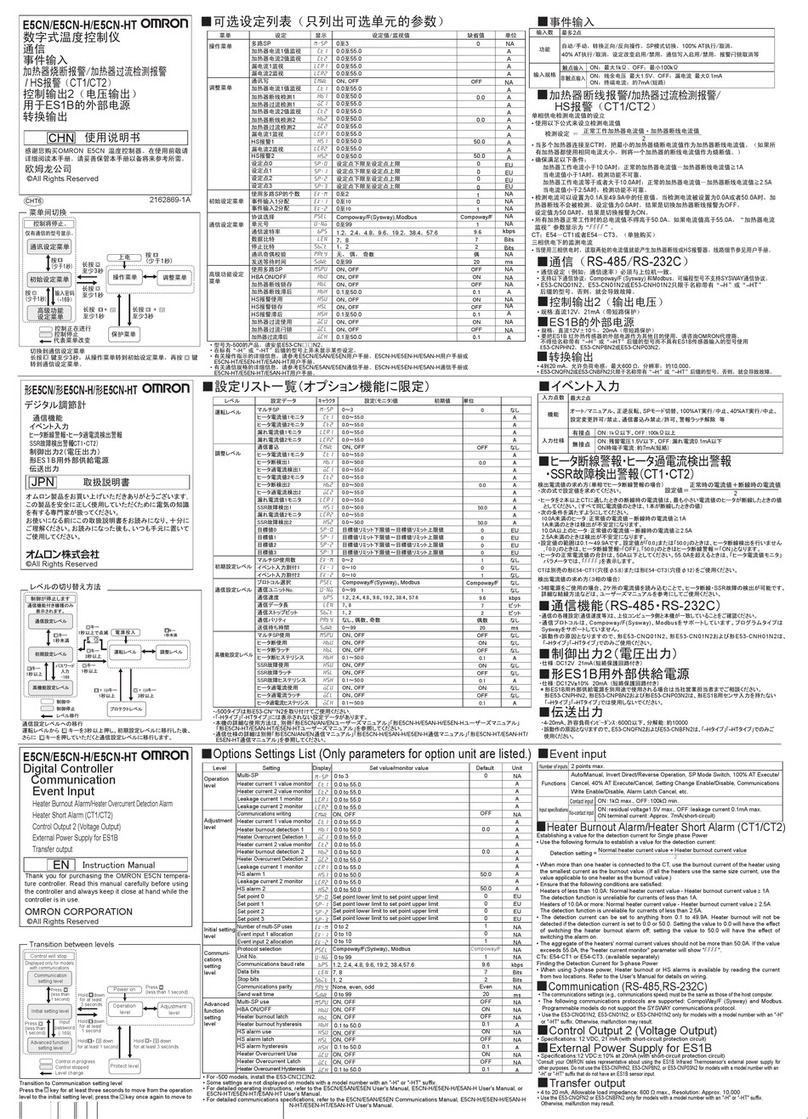

Omron

Omron CP1E INTRODUCTION Introduction manual

Tormach

Tormach ECM1V1.5 installation guide