SiAECOSYS VOTOL EM Troubleshooting guide

SiAECOSYS V2

1

VOTOL EM Controller Program Manual

Non-profession do not operate!

SiAECOSYS V2

2

This manual was explained in detail for the IV generation EM series controller, which update download illustrates

and parameter adjustment.

Before using the software, please read this manual. In order to facilitate the operation, please keep this manual.

In order to make the software of maximum utility, please make sure the end user to use this manual.

Please be sure to read the manual carefully before starting the operation.

Disclaimer:

For the Ⅳgeneration of EM series controller program updates and parameter adjustment can only be

done by professional and technical personnel.

If without the written permission of our company for the ⅣVOTOL generation EM series, the

application update to download and parameter of the controller adjustment is not allowed.

Non-profession do not operate this software.

In the above event, our company will no longer be responsible for accident happens by controller.

SiAECOSYS V2

3

1. Software installation (only support win 7/10)

1.1 USB Driver Installation

(1) Download the “USB-to-serial-win 10-20150814” file, decompressing file.

(2) choose the suitable driver with your computer for installation.

win7,win8, win 10 are available.

1.11. Decompress the operation first

2. Unzip the YH-340 USB package and select CH341SER.EXE to install it.

Follow the steps above to install

(3) After installation, please connect the USB cable with controller and computer.

If it’s unable to connect, pls Check below steps

Right click“my computer” in the desktop

SiAECOSYS V2

4

then click “device manager”

choose “port(COM & LPT)”

choose the COM with“!”, click “search automatically for updated driver software

SiAECOSYS V2

5

Close the software when you finish

After running, please run the software directly: EM_V3 series debugging program;

If the port has”自2012 已停产,请联系供货商(Pls contact supplier if it is stop production since 2012)”

Methods and steps:

First step: Install driver PL2303_Prolific_DriverInstaller_v110

Second step: Right click to update the driver and select Browse Computer to find the driver software.

SiAECOSYS V2

6

Third step: Click to select from the list of drivers for your computer;

Fourth and finally, select version 3.3.10.140 (2009-11-19), click Next, close the window when finished;

SiAECOSYS V2

7

Close the window when finished.

Please run “Em_V3 Series debugging program” directly after completion.

SiAECOSYS V2

8

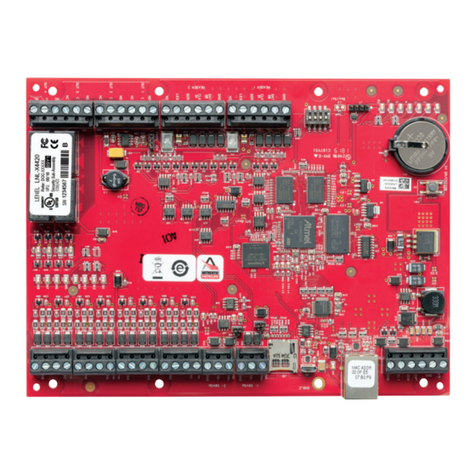

2. Controller connection

2.1 Connect controller

Controller host computer simple wiring diagram

Description: controller B+ connects battery B+ controller B-connects battery B-, controller electric door locks connect

battery or controller B+;

The USB debug line is connected to the controller debug port;

2.1.1 According to the controller with CAN or without CAN to select the appropriate USB debug line; with CAN controller

need to check the CAN enable, without CAN does not need to check; EM200 controller needs to exchange the debug line

CAN-H and CAN- L , otherwise can’t connect the controller;

SiAECOSYS V2

9

2.1.2 Host computer selection

EM50 EM100 EM150 without CAN choose

EM50 EM100 EM150 with CAN choose

EM200 choose

EM50 EM100 EM150 EM200 model XY-03-P with CAN and without CAN can share a host computer

Specific host model needs to inquire the related sales;

3 Open the computer device manager before connecting to the computer to check whether the USB port is successfully

installed. Select the appropriate host computer to connect the host computer to the serial port when the controller is not

powered. After selecting the corresponding serial port on the device port, click CreateFile.

2.2

SiAECOSYS V2

10

Then power on (connect with e-lock), click connect (in setting 1 page), the nominal voltage should not be 0. If it’s 0, click

connect again.

SiAECOSYS V2

11

3. The setting

1. SETTING PAGE 1

Steps to connect the upper computer:

1. Power on the controller,Connect the electric door lock, connect the serial port to the controller

adapter cable and plug it into the computer

2.Open the upper computer debugging interface, as shown in the figure above. In the setting

interface 1, click to search again. After the com? Appears on the device port, click to open the

serial port. The device status shows that it is connected. Click to connect the controller. The

corresponding number will pop up here and the connection success data will pop up. The

connection is successful.

1.1:Voltage equipment

1.1.1、Battery voltage setting: Corresponding to the ECU voltage, over pressure is not allowed.

1.Undervoltage,overvoltage

selected by default +1V

2.overvoltage selected by

default+2V

Busbar current≤ECU Specification

current value

No change allowed

Usually 0

does not change

0-350, the larger the start

delay, the more obvious

10-250, the greater the

acceleration, the faster

10-200, the larger the looser the inertia is

COM3

Connected

21

1. CAN debugging Switch

2. Chinese/English Switch

SiAECOSYS V2

12

1.1.2、Lead-acid battery over voltage, under voltage, soft under voltage basic value default: due to software

settings defects, the original voltage compensation +1V.

1.1.3、The lithium battery is set according to the actual lithium battery parameter value. Due to software

setting defects, the original voltage compensation +1V. The original lithium battery parameters are

compensated for +1V, and the total compensation is +2V.

1.1.4、Attention

1.1.4.1、Over voltage fault: After open the electric door lock, the vehicle doesn’t move. The Controller over

voltage protection function starts.

1.1.4.2、ECU under voltage fault: due to the lithium battery protection board over voltage device is too high

or the under voltage setting is too low, resulting in lithium battery protection, burning MOS.

1.2:Current device

1.2.1、Bus bar current setting: The current is selected according to the ECU specification model.

VOLTAGE

MODEL

EM-30S

EM-50

EM-50S

EM-100

EM-100S

EM-150

EM-150

S

EM-20

0

EM-30

0

48-60V

33A

45A

50A

85A

120A

150A

200A

400A

72V

33A

45A

50A

85A

100A

120A

180A

200A

400A

84V

30A

45A

80A

120A

96V

40A

70A

100A

180A

350A

1.2.2、Phase current setting: can only be adjusted downwards.

1.2.3、Attention

1.2.3.1、Setting the bus bar current too high, causing the ECU burn MOS.

1.2.3.2、As the phase current value decreases, the corresponding motor stall protection time is shortened.

2. SETTING PAGE 2

SiAECOSYS V2

13

Three speed percentage,

landing maximum speed

setting value is 100%

Adjust motor jitter

1. The motor shakes more and more to the major

2. The motor does not shake to minor adjustment,

take a reasonable value, range 100-1200, 50 each

stage.

SiAECOSYS V2

14

1. NO/YES

2. Adjustable exit time

Maximum speed

of corresponding

motor after

landing

Change not allowed

Percentage of 1 gear current

Percentage of current level 2

The overshoot shall not

exceed 20

1.4000 Corresponding

slope of front acceleration

and line current limiting

value of front phase

2. 8000 Adjust the sound

of the motor. The louder

the motor is, the smaller it

is, the bigger it is, and take

a reasonable value

≥High speed flux weakening

Optional

1. It can be checked. The larger the level is, the

more obvious the starting power is

2. Uncheck for hard start

SiAECOSYS V2

15

2.1:Parameters setting for sports mode(S gear)

2.2.1 、Bus bar current setting: According to the controller type current corresponding to the selection,

absolutely no over current is allowed.

VOLTAGE

MODEL

EM-30

S

EM-50

EM-50S

EM-100

EM-100S

EM-150

EM-150S

EM-200

EM-300

48-60V

35A

50A

55A

100A

----

200A

----

320A

550A

72V

35A

50A

55A

100A

150A

200A

250A

320A

550A

84V

33A

50A

50A

100A

----

180A

----

96V

----

45A

50A

80A

----

130A

----

250A

500A

2.2.2、Sport mode flux weakening value:Flux weakening value for S gear: the parameter value is <3000, and

the vehicle speed is adjusted according to the motor parameters. BOOST weak magnetic value> high speed

weak magnetic value

2.2.3、Auto exit function: tick to jog key / uncheck to long press key, select one from two.

2.2.3.1、Check to make the jog effective. The weak magnetic time enters the exit and can be adjusted.

2.2:Downhill electric brake assist:start by select “HDC Enable”, downhill electric brake assist (slow down

in steep slopes) function. Enable electric brake by enter minimum speed, if less than the speed, the

function will be invalid.

2.2.1、Downhill brake assist function: the speed of entering downhill brake assist function is set according

to the actual road test speed standard according to the motor parameters.

2.2.2、Note: The drum motor is not suitable for use, resulting in loose motor shaft.

2.3 、Flux weakening compensation: only valid when the inner rotor motor type is selected as V-shaped

magnetic steel

Note: The maximum value of 255 is generally filled in 95

2.4、Three gear setting:Confirm the motor base speed value adjustment setting parameter value. The basic

speed is filled in according to the <Appendix EM_V3 Parameter Adjustment Calculation Formula>.

2.4.1、The low, medium, high, and third speed values are valid within 100% of the parameter value, and the

medium, high, and high speed values are exceeded and the 100% parameter value is filled. Exceeded by

weak magnetic file (medium, high, BOST)

2.4.2、In the flux weakening area, the actual parameters of the motor are adjusted, and the vehicle speed is

based on the road test.

2.4.3、Single voltage mode: The high voltage value is invalid.

2.4.4、Attention

2.4.4.1 、Drum motor: 60KM/H motor weak magnetic speed is less than <120%, 80KM/H motor weak

SiAECOSYS V2

16

magnetic speed is less than <125%, 110KM/H motor weak magnetic speed is less than <135%.

2.4.4.2 Inner rotor motor Hall: The built-in Hall weak magnetic speed is less than <135%, and the external

Hall weak magnetic speed is less than 170%.

2.4.4.3、Internal rotor motor magnetic knitting: Built-in flux weakening speed <230%.

2.4.4.4The motor base speed exceeds 100% of the motor speed value and enters the weak value zone

adjustment parameter. BOOST>High speed weak magnetic file.

2.4.4.5 Weak magnetic failure: The flux weakening value exceeds the motor and controller parameter

values, causing the motor to demagnetize and the controller to burn MOS.

2.5、Jog/push selection: choose one

2.6、The three-speed default gear: the electric door lock opens the default several options.

2.7、Soft start setting: The smaller the value, the softer the start.

2.8、Speed limit setting:

2.8.1、Function selection: speed limit, unlimited speed, two choices, default speed limit

2.8.2 、The speed limit speed is calculated based on vehicle parameter requirements. <Appendix EM_V3

parameter adjustment calculation formula>

2.8.3 、The upper limit speed and the solution speed limit are determined according to customer

requirements.

2.8.4 、Speed relation of electric brake setting corresponding to weak magnetic acceleration: the speed

corresponding to the highest landing speed of the motor is set by the auxiliary enable of downhill electric

brake. When the setting value is lower than the rated speed of the motor, weak magnetic acceleration is

not required or optional. When the setting value is higher than the rated speed of the motor, weak

magnetic acceleration is required. Note: due to the loss of motor landing relative to no-load, the setting

value of downhill electric brake enabling is usually ≤(motor basic speed + maximum gear flux weakening

value) speed.

2.8.5 、Judge whether the maximum speed demagnetization value is reasonable. First, check the d-axis

current under the speed setting value of downhill electric brake enable. If the d-axis current value is

multiplied by 1.2 times, it is the setting value of the maximum demagnetization value (the second gear

demagnetization value on the setting page). For example, if the downhill point brake enable value is 800,

the motor turns to 800, and the d-axis current displays 500, then the maximum speed demagnetization

value is 500 ×1.2 = 600

Explanation under d-axis current

SiAECOSYS V2

17

3. The setting page 3

3.1、Motor Setting:

3.1.1、Motor pole pairs:Fill in according to the motor manufacturer parameters.

3.1.2、Hall phase shift angle:Fill in according to the motor manufacturer parameters.

3.1.3、Motor type:Fill in according to the motor manufacturer parameters.

Note: Wheel Hub motor is surface mount

3.1.4、Hall, phase line exchange: exchange the motor forward and reverse.

3.2、The controller to speedometer date output has 2 types: Single-line speedometer and hall speedometer,

it needs to be decided by the vehicle’s speedometer.

3.3、Moving assist and cruising function:Used in two-wheelers

Note: Speed "3KM / H, torque 9 ~ 19N.M

3.4 Cruise function: function selection, the default does not open.

3.5 Dual voltage setting: default single voltage。

Note: The dual voltage function speed parameter value is followed by the motor speed setting. Adjust the

parameters on the setup page 2.

3.6 、Reversing speed limit: The calculation formula is adjusted with reference to the EM_V3 parameter

adjustment calculation formula file.

Note: The speed of the two-wheeler is 5KM/H, and the tricycle is 15KM/H.

1. Pole pair shall be filled in

according to motor parameters

2. Opposite adjustment

3. Phase shift angle adjustment

angle, hub usually - 60

4. The motor type hub table is

pasted, and the center is checked

according to the parameters

Either-or

YES/NO

<3km/h

9-12nm

Default low

Checklist

Parameter

preservation

Click write after parameter change

Import the existing configuration file

Double

voltage

selection

SiAECOSYS V2

18

3.7、Reversing, EBS setting, low brake selection, starting safety switch function。

3.7.1、According to the weight of the vehicle (recommended within 30%)

3.7.2、Two-wheeler 35~60 interval

3.7.3、Two-wheeler 45~75 section

3.7.4、Energy recovery with lithium battery parameter value equipment, the actual road test shall prevail.

BMS protection results in burning MOS. Jianyi rushing discharge branch.

3.8、Low brake enable: brake signal high and low brake, default high brake, check low brake.

3.9、Safety Switch Function valid checked

3.10、Import configuration files: configured files are imported from the computer

3.11、Save configuration file

Standard Edition:BZB/V39

IO / V13 interface of IO version

CAN-CAN/V1

Naming method

SiAECOSYS V2

19

4. Expanded page

4.1 update ECU program.

4.1.1 connect the serial port line and the upper computer and controller successfully.

4.1.2 open the "bin" file, select the bin file and download it. The prompt "CCC The last digit of "d" shows

1. The actual value corresponds to the first inspection result of

controller parameter software.

2. The comparison value corresponds to the parameter software

result of the same batch of controllers. If the two values are the

same, the parameters are the same.

1. Simulate the turning handle and function of the whole vehicle.

2. Click remote control first during operation

Adjust whether the display voltage is consistent with the actual voltage

Adjust whether the display current is consistent with the actual current

Adjust d-axis voltage and q-axis current

Download bin software

Click after configuration parameter import and software download

7953

SiAECOSYS V2

20

"d", indicating that the download is successful. Serial port line is divided into the following models: em-30 ~

em-150 general, em-200, em-300, can

4.2: import configuration

4.2.1: select the INI file, open the file, import the controller parameters, and receive the prompt "import

succeeded"

4.3: change configuration

4.3.1: connecting the controller

4.3.2: change parameters to be modified

4.3.3: controller parameter writing

Be careful:

USB isolation cable is used. It is not a special isolation line that burns ECU serial port line and computer.

ECU is not read completely. Click more than once in setting meeting 1 to connect ECU.

5. The setting page Display

Analog vehicle instrument display

1.Speed: display the actual speed of the

motor

2.Voltage: display the actual output

voltage of power supply and battery

3.Current: display the actual output

current of power supply and battery

4. Fault display: display vehicle fault

5.Gear display: display the current gear of

the vehicle

6.Function display: display the current

functions of the vehicle

7.Controller temperature: display

controller chip temperature

8.External temperature: display motor

temperature

9.Temperature coefficient value: display

controller hardware coefficient

Table of contents

Other SiAECOSYS Controllers manuals

Popular Controllers manuals by other brands

Grieve

Grieve WATLOW F4 Basic operation

Digital Equipment

Digital Equipment Pro-Face GLC2000 Series user manual

GOK

GOK VSR 0126 Assembly and operating manual

DMX4ALL

DMX4ALL ArtNet Player X16+ manual

Viessmann

Viessmann Fillstation medium installation instructions

Danfoss

Danfoss ECL Comfort 110 operating guide