Vitec Multimedia RLY-6 User manual

RELAY INTERFACE

INSTRUCTION MANUAL

RLY-6

RLY-6 Relay Interface Instruction Manual

©1997, 2005 Vitec Group Communications, Inc.

All Rights Reserved

Part Number 810310, Rev. A

Vitec Group Communications, Inc.

4065 Hollis Street

Emeryville, CA 94608-3505

U.S.A

Clear-Com is a registered trademark of Vitec Group Communications, Inc.

The Clear-Com Logo is a registered trademark of Vitec Group Communications, Inc.

Eclipse is a registered trademark of Vitec Group Communications, Inc.

RLY-6 RELAY INTERFACE i

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ii-iii

OPERATION 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

INSTALLATION 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

To M a t r ix 2 - 2

To E x t e r n al D e v i c e 2 - 2

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

SPECIFICATIONS 3-1

VITEC GROUP COMMUNICATIONS WARRANTY 4-1

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Exceptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Warranty Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Non-Warranty Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

RLY-6 RELAY INTERFACE

ii

RLY-6 INTERFACE INSTRUCTION MANUAL iii

IMPORTANT SAFETY INSTRUCTIONS

Please read and follow these instructions before operating the RLY-6 general

purpose outputs interface. Keep these instructions for future reference.

(1) WARNING: To reduce the risk of fire or electric shock, do not expose this

apparatus to rain or moisture.

(2) Do not use the apparatus near water.

(3) Clean only with a dry cloth.

(4) Do not block any ventilation openings. Install in accordance with the

manufacturer’s instructions. Install the RLY-6 interface according to the

directions in the installation chapter of this manual.

(5) Do not install near any heat sources such as radiators, heat registers, stoves, or

other apparatus (including amplifiers) that produce heat. Do not place naked

flame sources such as candles on or near the matrix.

(6) Do not defeat the safety purpose of the polarized plug or grounding-type

plug. A polarized plug has two blades with one wider than the other. A

grounding-type plug has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. If the provided plug does

not fit into your outlet, consult an electrician for replacement of the obsolete

outlet.

(7) Protect power leads from being walked on or pinched particularly at plugs, at

convenience receptacles, and at the point where they exit from the apparatus.

Note: A “convenience receptacle” is an extra AC power outlet located on the back

of a piece of equipment, intended to allow you to power other equipment.

(8) Only use attachments/accessories specified by the manufacturer.

(9) Use only with the cart, stand, tripod, bracket, or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use caution when

moving the cart/apparatus combination to avoid injury from tip-over.

(10) Unplug the apparatus during lightning storms or when unused for long

periods of time.

(11) Refer all servicing to qualified service personnel. Servicing is required when

the apparatus has been damaged in any way, such as a power-supply cord or plug

is damaged, liquid has been spilled or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not operate normally, or has

been dropped.

Please familiarize yourself with the safety symbols in Figure 1. When you see

these symbols on an Eclipse matrix system, they warn you of the potential danger

of electric shock if the system is used improperly. They also refer you to

important operating and maintenance instructions in the manual.

Please read and follow these

instructions before operating

the RLY-6 general purpose

outputs interface.

RLY-6 INTERFACE INSTRUCTION MANUAL

iv

Figure 1: Safety Symbols

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

This symbol alerts you to the presence of uninsulated dangerous

voltage within the product's enclosure that might be of sufficient

magnitude to constitute a risk of electric shock. Do not open

the product's case.

This symbol informs you that important operating and main-

tenance instructions are included in the literature accompanying

this product.

RLY-6 RELAY INTERFACE 1-1

OPERATION

INTRODUCTION

This chapter describes how to configure and use the RLY-6 relay interface

module. System operators can use this manual once the Eclipse System has been

correctly installed and the relays have been assigned with the Eclipse

Configuration System.

DESCRIPTION

The RLY-6 provides six independent single-pole, double-throw (SPDT) relays

that are directly controlled by the CPU card in the matrix frame. Like the GPI-6,

this interface connects to the matrix through the separate RJ-45 accessory data

connector on the matrix frame.

The Eclipse system supports up to 10 GPI-6 interfaces, for a total of 60 outputs.

You can use a mix of GPI-6 and RLY-6 interfaces to support up to a total of 60

outputs and/or inputs. For example, five RLY-6 and five GPI-6 modules would

provide 30 relays and 30 inputs for a total of 60 inputs/outputs.

All of the RLY-6 and GPI-6 interfaces in the system are daisy-chained from the

GPI/RLY connection on the matrix. The matrix system will automatically

identify both the type and "address" of every relay output or logic input.

The front panel of the RLY-6 has six green LEDs to indicate the operation of

each of the relays in the module. A seventh yellow LED indicates that the module

is communicating with the CPU card in the frame. There is also a TEST

pushbutton switch for each relay to allow local activation of a relay for test of

hardware connected to the relay contacts.

The RLY-6 interface module provides the following functions:

• Six independent sets of relay contacts which are activated from the matrix.

• DC isolation between relay device(s) and the central matrix.

• An LED indicator for each relay that lights when the relay is active.

Each RLY-6 interface relay contact is a single-throw double-pole pair for use by

the user. They are rated at 1 ampere at 24 volts DC (resistive load). The RLY-6 is

not designed for switching mains AC line voltage. To switch an external device

that runs on the mains AC line voltage, use an external relay that is activated by

the RLY-6.

The RLY-6 interface contains circuitry to ensure that relays are not inadvertently

activated during power-up until commanded by the matrix.

Logical control of the relays in the RLY-6 interface is provided by associating a

relay with any other label in the system using the Eclipse Configuration System

programming software. Activating a TALK or LISTEN label with a relay

The GPI-6 relay interface

module provides six

independent, single-pole,

double-throw (SPDT) relays

that are directly controlled

by the matrix.

General purpose outputs are

also called “relays.”

1

RLY-6 RELAY INTERFACE

1-2

associated to it will also activate that relay. There is a special classification of

labels for relays called Control Labels.

A TEST pushbutton switch is provided for each relay to allow local activation of

the relay for hardware testing purposes.

OPERATION

Once the RLY-6 is installed and configured there are no controls for day-to-day

operation. Operation of each individual relay is indicated by LEDs.

The TEST switches for each relay can be used to operate a given relay to test that

connection.

The yellow LED should be 'on' all of the time indicating that the frame is

communicating with the module.

CONFIGURATION

Control of these relays is accomplished by using the Eclipse Configuration

System programming software. Refer to the Eclipse Configuration System Manual

for more information.

RLY-6 RELAY INTERFACE 2-1

INSTALLATION

INTRODUCTION

This chapter describes the installation of the RLY-6 relay interface module and

wiring to the external devices. The RLY-6 occupies one slot in an interface frame.

Connections are made to the matrix frame via an 8-pin RJ-45 connector, and to

the external devices via two DB-9M connectors. There are no adjustment

controls for the RLY-6.

INSTALLATION

To install the RLY-6 interface module in the IMF-3 or IMF-102 interface frame,

select a slot to install the interface in.

1. Remove the blank plates from the front and rear of the slot in which an

interface module will be installed.

2. Install the interface module in the appropriate slot. Advance the front half the

interface module along the guides in the front part of the slot until it connects

to the midplane connector. Advance the rear half of the interface module

along the guides in the rear part of the slot, until it connects with the

midplane connector.

3. Install the provided screws on the front and rear panels of the interface module

you have just installed, to secure the interface in place in the frame.

The rest of the installation consists of connecting the RLY-6 module to the

control input and to the matrix frame (or to the “daisy-chain” output of another

RLY-6 or GPI-6 interface module).

For more information on installing the RLY-6 interface in an IMF-3 or IMF-102

interface frame, see the Interface Module Frames Instruction Manual.

WIRING

The following sections describe connecting the RLY-6 to the matrix and external

devices.

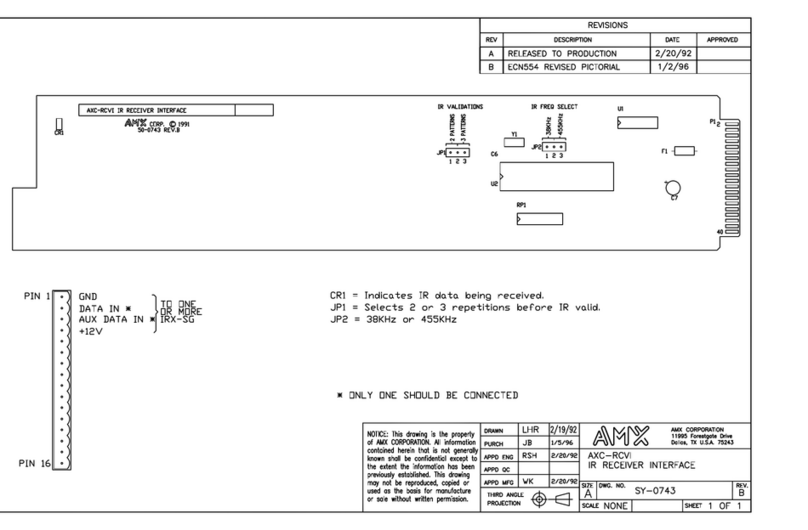

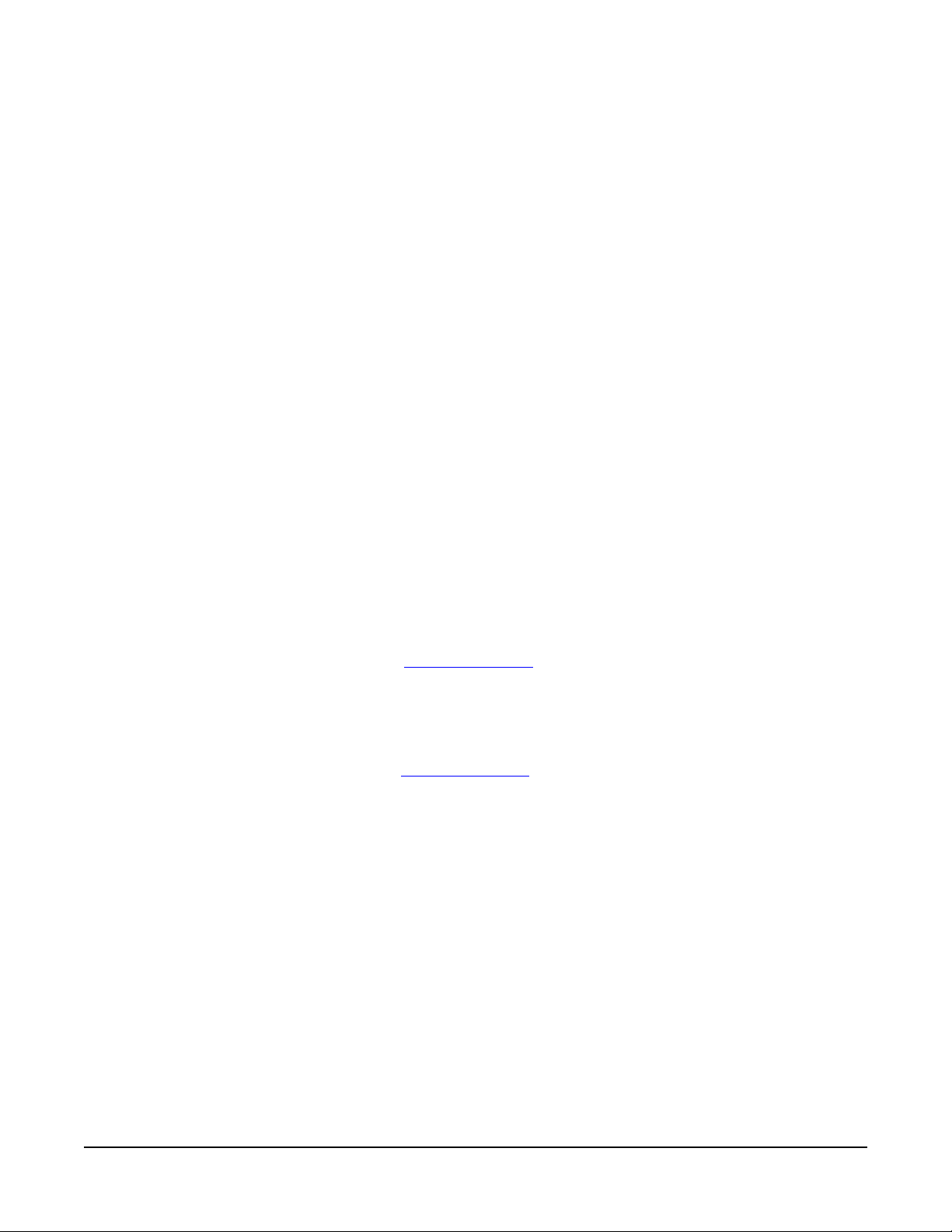

TO MATRIX

To connect the RLY-6 to the matrix, plug one end of a RJ-45 cable (eight wires

with no reversal) into the GPI-RLY INTERFACE connector on the back of the

matrix. Plug the other end into the top RJ-45 (CH. A MATRIX) connector for

the RLY-6.

To connect an additional RLY-6 interface, plug one end of a short RJ-45 cable

into the lower RJ-45 (CH. B MATRIX) for the first RLY-6. Then, plug the other

end into the top RJ-45 (CH. A MATRIX) connector additional RLY-6. (See

Figure 1 on the next page.) Additional RLY-6 interfaces are added in the same

2

RLY-6 RELAY INTERFACE

2-2

way, using "daisy-chain" wiring. If there are multiple RLY-6 modules, the relays

in the first module are numbered 1 to 6; the relays in the second module are

numbered 7 to 12, etc. GPI-6 modules can be mixed in this 'daisy-chained'

scheme. The maximum combined length of all the RJ-45 cables should not

exceed 20 feet (6 meters).

TO EXTERNAL DEVICE

To connect external devices to the RLY-6 interface, use the two DB-9M

connectors on the rear cable assembly panel for the interface. Figure 2 shows the

pin assignment of these connectors as viewed from the frame side of the

connector.

If a DB-9F is plugged into the connector labeled CH. A I/O, relays 1-3 are

available on that connector. The connector labeled CH.A I/O has the contacts

for relays 4-6. In the Figure 2, the labels on the pins apply to either connector.

Example: #1/4 COM refers to the wiper of relay 1 if it is connected to CH. A

and the wiper of relay 4 if it is connected to CH. B.

Figure 1: “Daisy-Chaining” RLY-6 Modules

Ports

Rear View of IMF-3 Frame

GPI/RLY

Interface

Connector

RJ-45 RJ-45 RJ-45 RJ-45 RJ-45

DB-9 DB-9 DB-9 DB-9 DB-9

RJ-45 RJ-45 RJ-45 RJ-45 RJ-45

DB-9 DB-9 DB-9 DB-9 DB-9

Other

Interfaces

GPI-6

#2

RLY-6

#2

R LY- 6

#1

GPI-6

#1

RLY-6 RELAY INTERFACE 2-3

Figure 2: RLY-6 Interface DB-9M Connector Pinout

CONFIGURATION

To associate a relay to a label, use the Eclipse Configuration System (ECS)

programming software, as described in its manual.

1

2

9

8

7

6

5

4

3

#1/4 Normally Open

#2/5 COM

#3/6 Normally Open

#1/4 Normally Closed

#1/4 COM

#2/5 Normally Closed

#2/5 Normally Open

#3/6 Normally Closed

#3/6 COM

RLY-6 RELAY INTERFACE

2-4

RLY-6 RELAY INTERFACE 3-1

SPECIFICATIONS

RelayType 1 Form C

Quantity 6

Contact Max. Volts 24 volts DC

Contact Max. Cur. 1 ampere continuous,

(2 amperes peak at 24 volts DC (resistive load)

DC Isolation 10 mega-ohms

Module Power Supply Requirements

Voltage Required 8 – 10 volts DC

Current Required 150 mA max (25 mA per relay when active)

Connectors

Relay Contacts 2 ea. DB-9M

Matrix Connection 2 ea. RJ-45 each

Indicators and Controls

LED Indicators 6 Green (1 ea. per relay)

1 Yellow (Frame Data)

Pushbutton Switches 6 (1 Test Pushbutton per relay)

Wiring Requirements

Maximum line lengths for connection to Matrix Frame

Matrix Frame to interface frame shall be less than 15 feet ( 5 meters)

Maximum line length between interface frame inputs 6 inches (15 cm)

Operating Environment

Temperature 0 and 70° C (32 -150° F)

Package Dimensions

Height 5 1/16" (129 mm)

Width 1 3/8" (35 mm)

Depth 9 5/32" (233 mm)

Weight .35 LBS (.15 kg)

Notice About Specifications

While Vitec Group Communications makes every attempt to maintain the

accuracy of the information contained in its product manuals, that information

is subject to change without notice. Performance specifications included in this

manual are design-center specifications and are included for customer guidance

and to facilitate system installation. Actual operating performance may vary.

3

RLY-6 RELAY INTERFACE

3-2

VITEC GROUP COMMUNICATIONS WARRANTY 4-1

VITEC GROUP COMMUNICATIONS

WARRANTY

Vitec Group Communications (VGC) guarantees this product to be free of

manufacturing defects in material and workmanship under normal use for a

period of two years from the date of purchase.

TECHNICAL SUPPORT

To ensure complete and timely support to its customers, VGC maintains

Technical Service Centers (TSC) staffed by qualified technical personnel. A

Technical Service Center is staffed to respond to all technical inquiries and to

troubleshoot technical problems regarding all products supplied by VGC. A TSC

is fully available to VGC’s customers during the full course of their warranty period.

Instructions for reaching our Technical Service Centers are given below.

For technical support from Europe, the Middle East, and Africa

Call: +49 40 66 88 40 40 Monday through Friday 09:00 – 17:00 (GMT)

+49 40 66 88 40 41 24hrs, any day (But you must have your PIN number

ready.)

Web site: www.clearcom.com (Click the 24 X 7 User Support symbol on the

Web site.)

For technical support from the Americas and Asia

Call: +1 510 496 6666 or 800 VITEC USA

Web site: www.clearcom.com (Click the 24 X 7 User Support symbol on the

Web site.)

FAX: +1 510 496 6610

EXCEPTIONS

This warranty does not include damage to a product resulting from cause other

than part defect and malfunction. The VGC warranty does not cover any defect,

malfunction, or failure caused beyond the control of VGC, including

unreasonable or negligent operation, abuse, accident, failure to follow

instructions in the manual, defective or improperly associated equipment,

attempts at modification and repair not approved by VGC, and shipping

damage. Products with their serial numbers removed or defaced are not covered

by this warranty.

Clear-Com offers 24/7

customer support.

Return authorization

numbers are required for all

returns.

Both warranty and

non-warranty repairs are

available.

4

VITEC GROUP COMMUNICATIONS WARRANTY 4-2

WARRANTY REPAIRS

While VGC will ensure complete system integrity by providing whatever support

is necessary to resolve any failure covered under the terms of the warranty, the

normal procedure will be to repair or replace any defective Line Replaceable Unit

(LRU) that is returned to VGC during the warranty period.

A Line Replaceable Unit (LRU) is defined as: an assembly that can be safely

removed from the system and readily replaced by plugging in a new unit. In the

case of ancillary items such as power supplies, the entire power supply would be

returned. Whereas, in the case of circuit cards, control panels, etc., only these

assemblies would be returned for repair. All equipment provided by VGC is

covered under the warranty.

This warranty does not include defects arising from installation (when not

performed by VGC), lightning, power outages and fluctuations, air conditioning

failure, improper integration with non-approved components, defects or failures

of customer furnished components resulting in damage to VGC provided

product.

NON-WARRANTY REPAIRS

Equipment that is not under warranty must be sent prepaid to VGC. If

requested, an estimate of repair costs will be issued prior to service. Once repair is

approved and completed, the equipment will be shipped freight collect from the

TSC.

REPLACEMENT UNITS

Should VGC determine, in its reasonable discretion, that any part of a product is

defective due to faulty materials or workmanship, VGC shall at its expense,

repair or replace such part and return the repaired/replacement part to the

customer. The provisions of this warranty shall apply to the repaired/replacement

part for the unexpired portion, if any, of the warranty period.

EMERGENCY ON-SITE ASSISTANCE

VGC can provide emergency on-site technical assistance in support of warranty

activities. The level of support effort required will be decided on a case-by-case

basis. VGC has the qualified technical staff to support any and all emergency site

activities should they occur.

LIABILITY

The foregoing warranty is VGC’s sole and exclusive warranty. There are no other

warranties (including without limitation warranties for consumables and other

supplies), or guarantees, expressed or implied (including, without limitation, any

warranties of merchantability or fitness for a particular purpose), of any nature

whatsoever, whether arising in contract, tort, negligence of any degree, strict

liability or otherwise, with respect to the products or any part thereof delivered

VITEC GROUP COMMUNICATIONS WARRANTY 4-3

hereunder and/or with respect to any non-conformance or defect in any such

product and/or part thereof delivered hereunder and/or with respect to any

non-conformance or defect in any such product and/or part thereof delivered

hereunder, or any other warranties or guarantees, including but not limited to

any liability of VGC for any consequential and/or incidental damages and/or

losses (including loss of use, revenue, and/or profits). In any event, the maximum

extent of VGC’s liability to customer hereunder shall not under any

circumstances exceed the cost of repairing or replacing any part(s) fount to be

defective within the warranty period as aforesaid.

RETURNING EQUIPMENT FOR REPAIR

All equipment returned for repair must be accompanied by:

• Documentation stating the return address, telephone number, date of

purchase, and a description of the problem.

• A repair reference number.

To obtain a repair reference number, contact the appropriate Technical Service

Center at the phone numbers or Web sites listed below. Our representatives will

give you instructions and addresses for returning your equipment. By talking

with our representatives, many problems can be resolved on the phone.

For returns from Europe, the Middle East, and Africa

Call: +49 40 66 88 40 40 Monday through Friday 09:00 – 17:00 (GMT)

+49 40 66 88 40 41 anytime, any day

(But you must have your PIN number ready)

Web site: www.clearcom.com (Click the 24 X 7 User Support symbol on the

Web site.)

For returns from the Americas and Asia

Call: +1 510 496 6666 or 800 VITEC USA

Web site: www.clearcom.com (Click the 24 X 7 User Support symbol on the

Web site.)

Email: [email protected]

FAX: +1 510 496 6610

VITEC GROUP COMMUNICATIONS WARRANTY 4-4

WARRANTY VALIDATION

To validate your warranty, fill in the information below, and mail it to your local

Technical Service Center.

Table of contents

Other Vitec Multimedia Recording Equipment manuals