Vitotherm VCU220 User manual

Instruction

manual

CO2set

CO2dosing unit &

control panel

EN (English) original instructions

Original instructions

The original manual is written in UK English. All other

language versions are translations of the original manual.

Copyright

All rights reserved © Vitotherm BV.

No part of this publication may be reproduced and/or

published by print, photoprint, microfilm or any other means

without the written consent of Vitotherm BV.

Disclaimer of liability

The manufacturer cannot be held responsible for personal

injury, damage to the COset or property damage caused

by incorrect use, foreseeable misuse or failure to follow the

instructions in this manual. This also applies to unauthorised

modifications of the COset and the use of non-approved

spare parts, tools or accessories.

The manufacturer reserves the right to modify this manual

without notification beforehand.

Customer service

Our customer service department is available hours a day to

provide any required technical information and support.

Please have the type plate information of the COset available

when you contact our customer service department (see §..).

+ ()

Warranty

The equipment supplied by Vitotherm has a one-year warranty

covering materials from date of commissioning against defective

parts, limited to the delivery of parts only. Warranty is only

valid when the installation has been realised in accordance with

our instructions and commissioning is executed by a Vitotherm

engineer or by Vitotherm authorised personnel.

During the period of the warranty any failures to Vitotherm

equipment will be repaired within - days. Our local service

expert for future regular maintenance will be at our daily rate.

CO set | Instruction manual rev-_May

1.Introduction 2

1.1.About this document 2

1.2.Symbols and labels 2

1.3.Used terms and definitions 3

1.4.Conformity 3

2.Safety 4

2.1.Introduction 4

2.2.Intended use 4

2.3.Reasonably foreseeable misuse 5

2.4.Qualification of personnel 5

2.5.Protective measures 6

2.6.Residual risks 7

2.7.Warning labels 8

2.8.Safety precautions 8

3.Design and function 9

3.1.System overview 9

3.2.CO2dosing unit 10

3.3.Control panel 11

3.4.Frequency drive 12

3.5.Optional components 13

3.6.Type plate 14

3.7.Technical data 15

3.8.Configurations 15

4.Installation 16

4.1.Checking the delivery 16

4.2.Preparing the elevation structure 16

4.3.Mounting the CO2dosing unit 17

4.4.Connecting the CO2dosing unit 19

4.5.Electrical connections 24

Table of Contents

5.Commissioning 25

6.Operation 26

6.1.Control panel 26

6.2.Switching the CO2set on or o 26

6.3.Performing a system reset 26

7.Troubleshooting 27

8.Maintenance 28

8.1.Pre-emptive parts replacement schedule 28

8.2.Annual Periodic Maintenance 28

9.Transport and storage 30

9.1.Transport 30

9.2.Storage 30

10.Decommissioning and disposal 31

10.1.Decommissioning 31

10.2.Dismantling the CO2dosing unit 31

10.3.Disposal 32

Appendices 33

A CO2dosing unit orientations 33

B Technical data 34

C Declaration of conformity 35

CO set | Instruction manual rev-_May

.Introduction

..About this document

This manual contains instructions and safety information for operation, installation, commissioning and maintenance of the

Vitotherm COset.

This manual is intended for:

• the owner of the COset

• the worker that operates the COset

• the qualified technician that performs the installation of the COset

• the engineer that is authorized by Vitotherm to perform (re)commissioning, adjustments, troubleshooting,maintenance

and repairs of the COset.

..Symbols and labels

...Safety warnings

This manual contains safety warnings that may result in injury when ignored. Each safety warning is indicated with a signal

word. The signal word corresponds with the level of risk of the described hazardous situation:

Signal word Level of risk If not avoided

6DANGER! High Will result in death or serious injury

6WARNING! Medium Could result in death or serious injury

6CAUTION! Low Could result in moderate or minor injury

Safety warnings given at the start of a section apply to the entire section.

Format example of a safety warning:

6WARNING! Contact with live parts can cause electric shocks, burns or even death.

fOnly perform work on electrical equipment if you are an authorised electrician.

fBefore you start working on electrical equipment: Switch o and lock out the power supply

isolator and verify that no voltage is present.

CO set | Instruction manual rev-_May

...Notices

Messages that are not hazard-related are indicated with the signal word NOTICE. These messages do not have a safety alert

symbol.

Format example of a message that is not hazard-related:

NOTICE Operating the engine at an oil level below the minimum limit value can damage the engine.

fRegularly check the oil level and refill when necessary.

...Other symbols

This symbol identifies a reference to an external document, such as an OEM manual.

..Used terms and definitions

Term Definition

COset The combination of the CO dosing unit and control panel.

COdosing unit The pre-assembled collection of components that transports the flue gases from the boiler to a

greenhouse.

Greenhouse distribution

system The network that transports COgas to one or more greenhouses.

Boiler The heating appliance to which the COdosing unit is connected. A water boiler is the most

common type of heating appliance and will be used as the main example in this document.

Boiler house The building in which the COset and boiler are installed.

OEM manual User manual of the original equipment manufacturer.

..Conformity

Vitotherm COsets carry the CE and EAC marks as a proof of compliance to the following directives:

. MD --EG

. EMC --EU

. LVD --EU

See Appendix D for the full declaration of conformity.

CO set | Instruction manual rev-_May

.Safety

..Introduction

Observe the instructions in this manual before you start working with the COset. If you fail to follow the instructions from

this manual you can put persons, surroundings, the environment and the COset at risk. Store this manual in an accessible

place near the COset for future reference.

fAlways comply with the information, such as labels and the type plate, attached directly to the CO2set and keep the

information in a legible condition.

fAlways comply with applicable local laws and regulations.

A Vitotherm COset is used in combination with a Vitotherm Automatic forced draught burner system.

Refer to the instruction manual of the burner system for more information.

The COset is equipped with several safety components that ensure safe interaction with the machine.

..Intended use

The Vitotherm COset is intended to be used in the following ways:

• As an electrically powered fan to collect the flue gases from a boiler system.

• To mix the collected flue gases with clean air to create COgas with the desired temperature.

• To deliver the dosed flue gases to the distribution system of a greenhouse.

• OPTIONAL – To mix the collected flue gases with clean air to regulate the under pressure in the connected COcollector.

The Vitotherm COset is intended to be used under the following conditions:

• The COset must only be installed, operated, commissioned and maintained according to the instructions in this

manual.

• The COset must only be used for an application in compliance with the requirements in the order confirmation.

• The COset must only be used under ambient conditions in compliance with the requirements in the order confirmation.

• The COset must only be used in compliance with applicable local laws and regulations.

Safe use of the COset is only guaranteed if it is used as intended.

CO set | Instruction manual rev-_May

..Reasonably foreseeable misuse

The following is considered foreseeable misuse:

• Use of the COset that deviates from the intended use as described in the previous section.

• Failure to comply with the instructions in this manual.

• Failure to eliminate faults, malfunctions or defects of the COset that impose safety risks.

• Failure to carry out the inspections and maintenance operations as described in this manual.

• Unauthorized removal or modification of parts or safety components of the COset.

• Use of spare parts or accessories that have not been approved by the manufacturer.

• Operation in a closed-o or poorly ventilated room.

..Qualification of personnel

Only authorised personnel is allowed to operate and clean the COset. They must possess the following qualifications:

• are legal of age

• are familiar with and abide by the safety instructions and sections of this manual related to operating the COset

• are familiar with and abide by the applicable local, national and international laws and regulations

• are ocially trained and certified by Vitotherm B.V.

• have received adequate training to operate and clean the COset

• have obtained authorisation to access the COset.

Only authorised technicians are allowed to perform installation and maintenance of the COset. They must possess the

following qualifications:

• are legal of age

• are familiar and abide by the safety instructions and sections of this manual related to installation and maintenance of

the COset

• are familiar with and abide by the applicable local, national and international laws and regulations

• are able to recognize the possible dangers of the COset and take the necessary measures to protect persons and

property

• have received adequate training in the safe maintenance of the COset

• have obtained authorisation to access the COset.

..Protective measures

...Personal protective equipment (PPE)

Personnel that operates the COset must equip themselves

with the following:

Technicians that install or perform maintenance on the CO

set must equip themselves with the following:

Wear foot protection Wear foot protection

Wear eye protection Wear eye protection

Wear ear protection (above dB) Wear protective gloves

Wear head protection (during lifting

work)

...Organizational measures

The owner is responsible for carrying out the necessary organizational measures to ensure safe use. Amongst other measures

this is achieved by, but not limited to:

• Training and authorising personnel. Vitotherm is responsible for distributing passwords to authorised personnel only.

• Performing hazard assessments of the complete system that incorporates the COset and informing personnel of the

possible dangers and protective measures.

• Performing good housekeeping in the facility that houses the COset.

• Running a preventive maintenance program.

CO set | Instruction manual rev-_May

..Residual risks

Despite the safe design and construction of the COset and the prescribed protective measures, the COset poses residual

risks. This manual provides safety messages to indicate these risks. The formatting and appearance of safety messages that

are dedicated to a particular section or sentence are explained in chapter . Overall safety messages are grouped in the

following sections.

...Electricity

6WARNING! Contact with live parts can cause electric shocks, burns or even death.

fOnly perform work on electrical equipment if you are an authorised electrician.

fPerform the work on electrical equipment in accordance with the local safety standards.

fDo not make changes to the CO2set if you are not qualified to do so.

fBefore you start working on electrical equipment: Switch o and lock out the power supply

isolator and verify that no voltage is present.

fUse fuses that correspond with the installed power of the CO2set.

fRegularly check the electrical wiring for loose connections and damage and repair them

without delay.

...Mechanical

6WARNING! The COset contains moving, pressurized and sharp parts that can crush, cut or hit.

fDo not operate the CO2set with covers or guards removed.

fDo not operate the CO2set with missing pipework or components.

fNever touch the air damper box during operation.

fBe aware of sharp edges.

...Transport and storage

6WARNING! The COdosing unit may drop or topple when transported incorrectly.

fUse suitable hoisting equipment.

fMake sure no personnel is below or near the object when lifting or hoisting.

6CAUTION! The frame of the COset is made of steel and is sensitive to corrosion damage.

fAlways store the CO2set in a dry, indoor location.

fDo not unpack the CO2set from the optional transport crate until you are ready to install it.

CO set | Instruction manual rev-_May

..Warning labels

Always comply with warning labels and information signs on the COset. The warning labels and information signs must be

kept legible and must be replaced if necessary. For this purpose, contact the manufacturer.

Symbol Description Location

Do not insert your hands or limbs into the

air inlet of the COdosing unit. Next to the air inlet of the COdosing unit.

..Safety precautions

A COset is equipped with several safety components that help prevent hazardous situations.

For more information about the integration of the safety components into the system, please refer to

the electrical wiring diagram.

...Maximum temperature safety switch

The maximum temperature safety switch shuts down the COset if the flue gas temperature exceeds the set limit of oC.

...Air inlet grid

A protective grid is mounted on the air inlet of the COdosing unit. The grid prevents hands or limbs from entering the air

inlet. Additionally, the grid prevents foreign objects or small animals from entering the air inlet and damaging the -way

valve inside.

CO set | Instruction manual rev-_May

.Design and function

The Vitotherm COset is designed to dose the flue gases from a boiler and transport the gas to a greenhouse, where it

contributes to a healthy increase of crop growth.

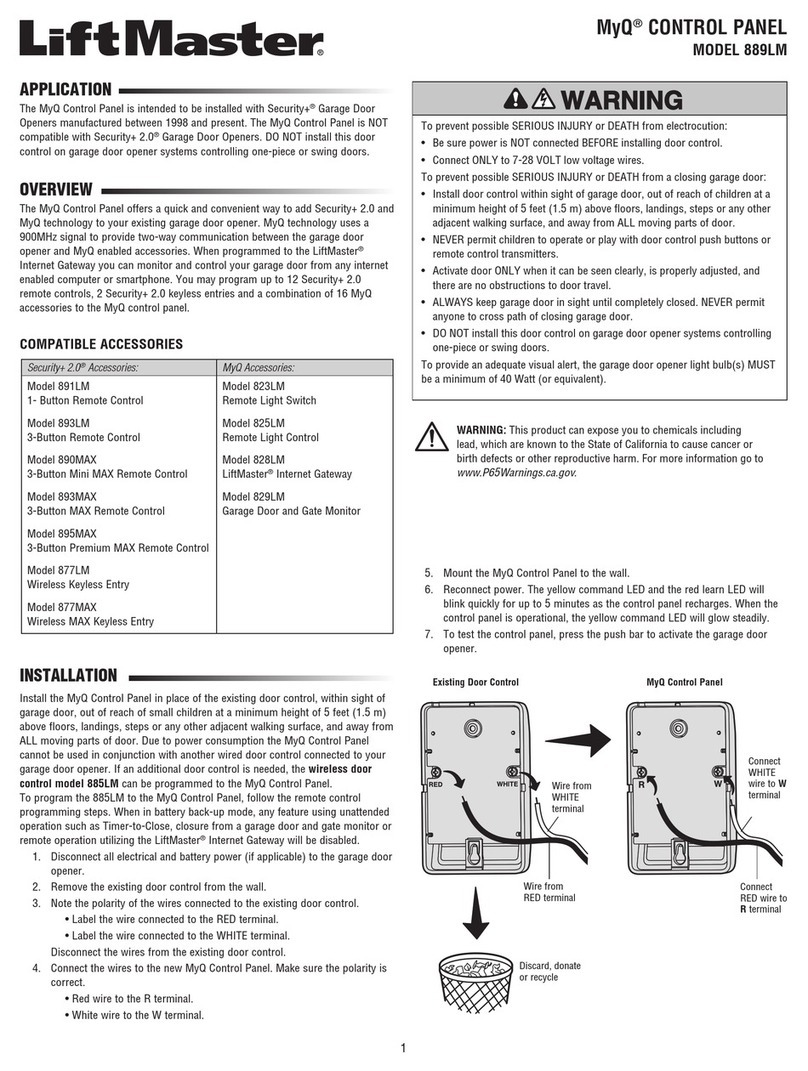

..System overview

The COset consists of the following components:

21 3

4 5 6

1)Boiler

2)Boiler chimney

3)CO2dosing unit

4)Control panel & frequency drive (optional)

5)Vitotherm CO detector (optional)

6)Elevation structure (optional)

The fan of the COset sucks in the flue gases from the boiler chimney as well as clean air from the boiler house. A -way valve

is integrated in the T-piece and modulates the ratio of flue gas and clean air, to control the temperature of the CO gas that is

transported to the greenhouse.

The air mixture is transported to the greenhouse via the air outlet on the fan housing. The fan housing can be mounted in

dierent configurations to better align with the inlet of the greenhouse distribution system (see §..for more information).

CO set | Instruction manual rev-_May

..COdosing unit

2

1

7

8

15

4

5

3

6

17

19

16

14

19

13

18

12

9

10

11

1)Junction box

2)Fan housing

3)Modulating temperature controller

4)Air pressure sensor (LD3) - Transport

monitoring

5)Maximum thermostat

6)Pressure transmitter (only with

optional frequency control)

7)Connection sleeve with hose clamps

(fan outlet)

8)Mounting frame

9)Air inlet & filter grid

10)2-way valve (air inlet)

11)2-way valve transmission arm

12)2-way valve servomotor

13)2-way valve (flue gas inlet)

14)Connection sleeve with hose clamps

(flue gas inlet)

15)Type plate

16)Junction box fan motor

17)Fan motor

18)Hoisting holes

19)Elevation structure connections

NOTICE The exact location of the electronic components may dier based on the configuration of the fan

housing (see §..).

CO set | Instruction manual rev-_May

NOTICE The variation of the COset that is connected to a COcollector has a dierent dosing unit. The

following components are not included in this variation:

fAir inlet

f2-way valve & servomotor

fModulating temperature controlller

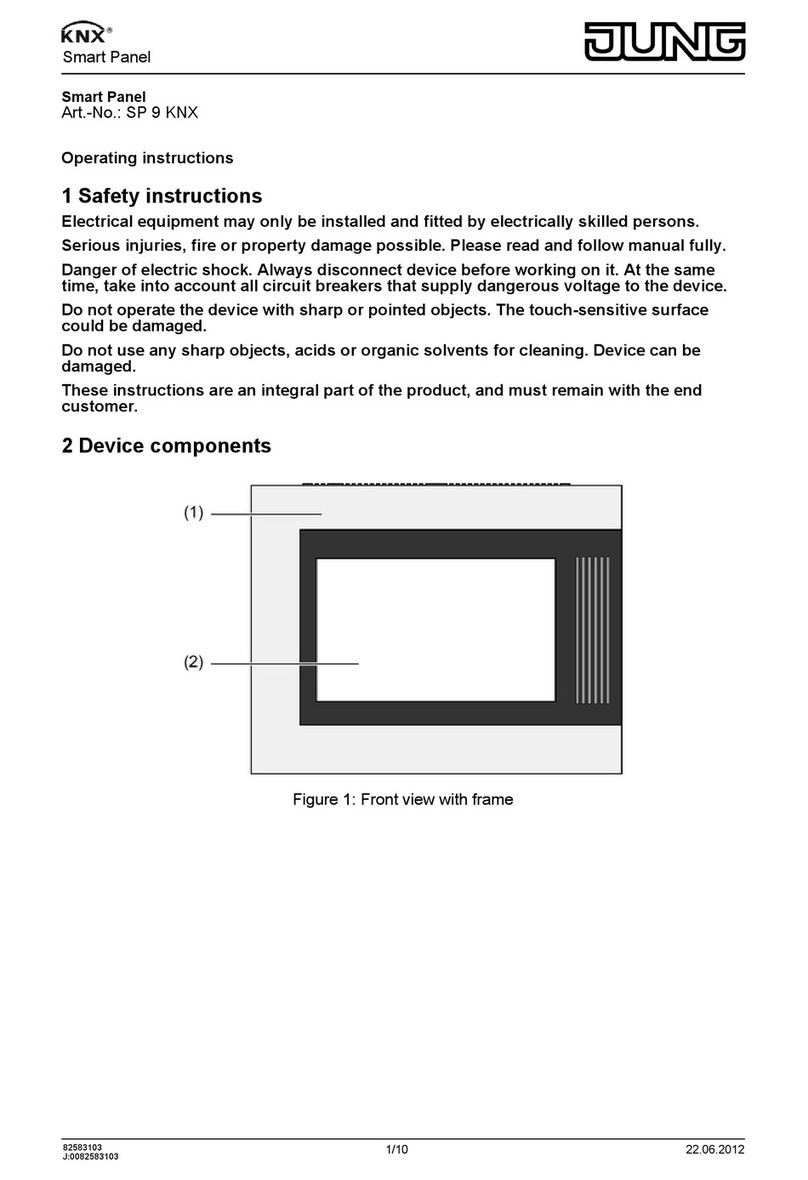

..Control panel

The COset is controlled with a separate control panel. It is recommended to install the control panel at an accessible height,

close to the COset.

2 3 4 51

6 7 8 9

The following switches and lights are available on a standard control panel:

No. Description Function

Max. temperature

failure light

Lights up red when the maximum flue gas temperature is exceeded.

Valve failure (ES) light Lights up red when a valve failure is detected.

Only included together with the frequency control option (see §..).

Fan overload light Lights up red when the load on the fan becomes too high.

Air pressure failure light Lights up red when an air pressure failure is detected

COrequest indication

light

Lights up green when CO dosing is requested.

Keyholes Unlocks the control panel so that it can be opened.

Control

switch

Computer Switches the control to the external computer.

O Switches the control o.

Reset button Resets the COset.

Main power switch Switches the COset on and o.

NOTICE More information about the failures indicated by the lights on the control panel can be found in

chapter .of this manual.

CO set | Instruction manual rev-_May

..Frequency drive

For VCU -

The frequency drive is located next to the control panel and is used to control the fan motor. The frequency drive is operated

via the interface in the top left corner.

The frequency drive comes in two options:

• - V

• - V

Both options are equipped with a pressure sensor ( – mbar).

NOTICE The factory settings of the frequency drive have been set by Vitotherm.

Auto

on Reset

Hand

on

Status Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status 1(0)

1234rpm 10,4A 43,5Hz

Run OK

43,5Hz

On

Alarm

Warn.

Auto

on Reset

Hand

on

Status Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status 1(0)

1234rpm 10,4A 43,5Hz

Run OK

43,5Hz

On

Alarm

Warn.

Auto

on Reset

Hand

on

Status Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status 1(0)

1234rpm 10,4A 43,5Hz

Run OK

43,5Hz

On

Alarm

Warn.

Auto

on Reset

Hand

on

Status Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status 1(0)

1234rpm 10,4A 43,5Hz

Run OK

43,5Hz

On

Alarm

Warn.

1

2

3

4

1)Graphical display with status information

2)Menu buttons and indicator LEDs

3)Navigation buttons and indicator LEDs

4)Operation buttons and indicator LEDs

For more information, please refer to the OEM manual.

CO set | Instruction manual rev-_May

..Optional components

The following options are available for a Vitotherm COset.

...Vitotherm CO detector

type VCD with sampling pump

A Vitotherm CO detector checks the flue gas that is transported from the burner to external applications (e.g. greenhouses)

for carbon monoxide. The CO detector is mounted near the flue gas exhaust.

21

43 5

1)Interface & display

2)Failure feedback light

3)Key lock

4)Control switch

5)Cable connectors

For more information, please refer to the Vitotherm CO detector user manual.

...Seaworthy packaging

If the COset needs to be well protected or

shipped overseas, it can be packed in wooden

crates treated according to ISPM .

...Liquid COcontrol

Built in the control panel

Control system which adds additional COin liquid form to the flue gases, in order to increase the COconcentration of the gas

supplied to the greenhouse.

...Frequency control

A frequency control system can be added to the COset. This system uses a pressure transmitter to maintain a constant gas

pressure inside the dosing unit.

..Type plate

The COset is marked with a type plate in accordance with the applicable legislation requirements.

Vitotherm BV

2641 NE Pijnacker

Overgauwseweg 8

Tel:+31(0)15-3694757

Fax:+31(0)15-3697742

.. A

Hz..

..

V..

Current:

Frequency:

..

Voltage:

Destination country:

Production year:

..Serial nr.:

VCUType:

When servicing the CO2 fan the main switch must be switched off at all times.

Before the CO2 fan is installed and put into operation, the instruction manual must be read.

The electrical part of the CO2 fan is built according tothe EN 60529, the voltage and amperage is as indicated on the nameplate of the fan.

This CO2 fan must be installed according tothe rules in force, and should be used only in a well ventilated area.

1

2

3

4

5

6

7

Lorentzstraat 1

2665 JG Bleiswijk

Tel: 015-369 4757

1. Type

2. Serial number

3. Year of manufacture

4. Country of destination

5. Voltage (V)

6. Frequency (Hz)

7. Current (A)

NOTICE The location of the type plate is indicated in §..

CO set | Instruction manual rev-_May

..Technical data

For EU ( Hz)

This section contains the standard dimensions, materials and performance data of a Vitotherm COset.

For technical data regarding your specific COset, please refer to the type plate (see §..) or the order confirmation. For

performance data in imperial units, please refer to Appendix C of this manual.

Type Fan motor

power

* Motor voltage -way valve

control

Inlet diameter

(suction side)

Outlet

diameter

(pressure side)

Material fan

housing,

T-piece, fan.

kW VAC @ Hz - Ø mm Ø mm -

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

VCU , @ Modulating SS

*Motor voltage may vary per country (, , or V @ Hz).

..Configurations

The fan housing can be mounted in dierent orientations to better align with the inlet of the greenhouse distribution

system. See appendix A for an overview of the dierent orientations.

NOTICE The standard configuration shown in this document is RD (R).

CO set | Instruction manual rev-_May

.Installation

This chapter provides instructions for the basic installation of a COset onto a boiler or other heating appliance. For

information about a custom set-up, please contact Vitotherm.

6CAUTION! The COset may only be installed by qualified personnel. Handling the COset and supporting

components without the required knowledge and experience may damage the COset or cause

hazardous situations during installation and use.

6WARNING! The COset may only be installed in a suciently ventilated boiler house.

NOTICE The COset must always be installed according to national and local laws and regulations.

..Checking the delivery

Required tools:

• Forklift truck with adequate lifting capacity.

To check the delivery:

. Transport the crate(s) to an accessible place near the boiler.

. When delivered in an optional transport crate:

a. Remove the lid of the crate(s).

b. Remove the sides of the crate(s).

c. Remove the lashing straps and packaging materials.

d. Remove any screws that connect parts to the bottom of the crate(s).

. Check if all parts have been delivered according to the agreed scope. If a part is missing, contact Vitotherm immediately.

. Check all delivered parts for damage.

6WARNING! Damaged parts can aect the correct and safe functioning of the COset.

fDo not install damaged parts.

fIf any parts are damaged upon delivery, please contact Vitotherm.

. Check if the delivered COset will fit in the designated area of the room. For the dimensions of the COset, see §...

..Preparing the elevation structure

The COdosing unit can be installed on a supporting elevation structure. The mounting frame of the dosing unit can be

expanded with legs to create this elevation structure.

The COdosing unit can also be installed on the floor. In this scenario, support feet can be attached to the mounting frame.

NOTICE The elevation structure or support feet are not part of the standard delivery and may have to be

created as part of the installation process.

CO set | Instruction manual rev-_May

Connection materials:

• Square steel tubing ( x mm)

• Connection brackets

To prepare the elevation structure:

. Measure the required installation height and determine the required length of the frame legs. Use the dimensions in

§..as a reference.

. Cut four pieces of square steel tubing with the required length.

. Increase the stability of the structure:

a. Weld footpads onto the bottom of the frame legs.

b. Attach crosswise connector pieces between the frame legs.

..Mounting the COdosing unit

Required tools:

• Mobile crane with adequate lifting capacity.

• Suitable hoisting equipment:

• D-shackles

• Round sling

• Elevation structure

• Power drill with steel drill head (Ø mm)

• Ring wrenches or adjustable spanners

6WARNING! The COdosing unit may drop or topple when transported incorrectly.

fUse suitable hoisting equipment.

fMake sure no personnel is below or near the object when lifting or hoisting.

To hoist the COdosing unit:

1)Connect your hoisting equipment to

the hoisting eyes of the fan housing.

2)Carefully lift the dosing unit.

3)Place the elevation structure below

the dosing unit.

CO set | Instruction manual rev-_May

4)Align the mounting frame of the dosing unit

with the elevation structure.

5)Lower the dosing unit onto the elevation

structure.

6)Drill a hole through the bolt hole on the side

of the connection point.

Use a Ø12 mm steel drill.

7 Insert a Ø12 mm metal pin or bolt into the

drilled hole.

8)Tighten the bolts in the connection points to

secure the elevation structure. Use a 16 mm

wrench.

This manual suits for next models

11

Table of contents

Popular Control Panel manuals by other brands

Beckhoff

Beckhoff CP6906-0001-0010 manual

Rosslare

Rosslare HLX-24TH Series user manual

Turbo

Turbo E8T Use and maintenance instructions

Panasonic

Panasonic AK-HRP1005G operating guide

DSC

DSC PowerSeries Neo installation instructions

Whelen Engineering Company

Whelen Engineering Company WeCanX CCTL7 installation guide